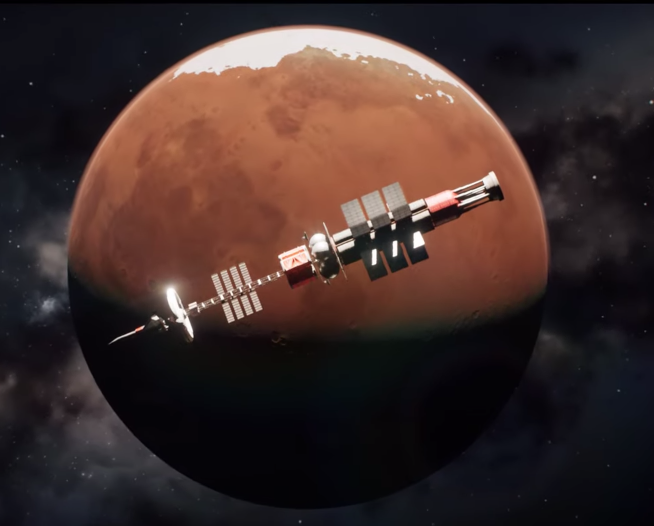

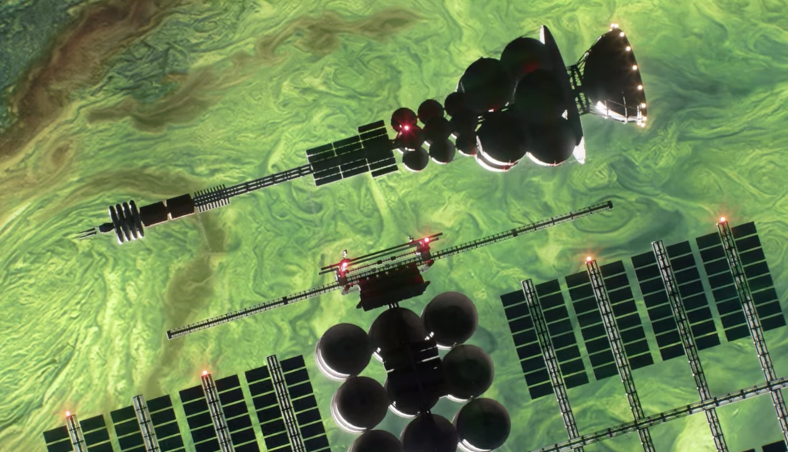

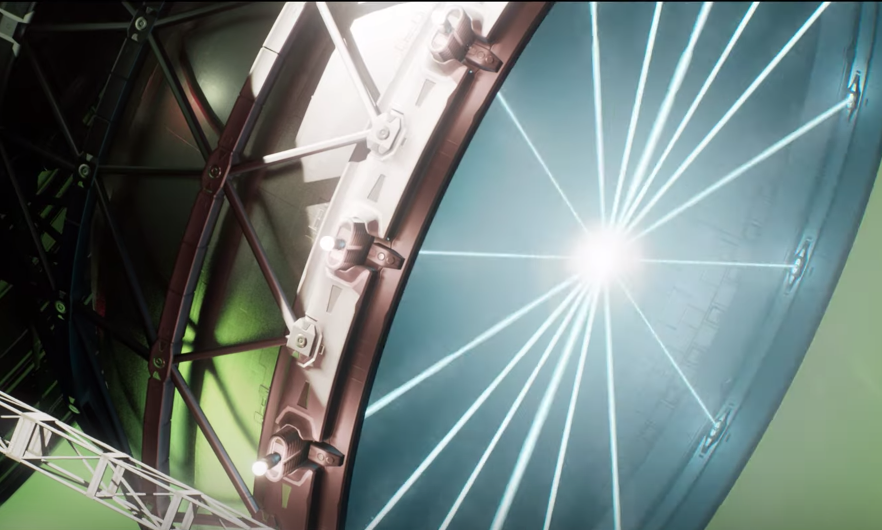

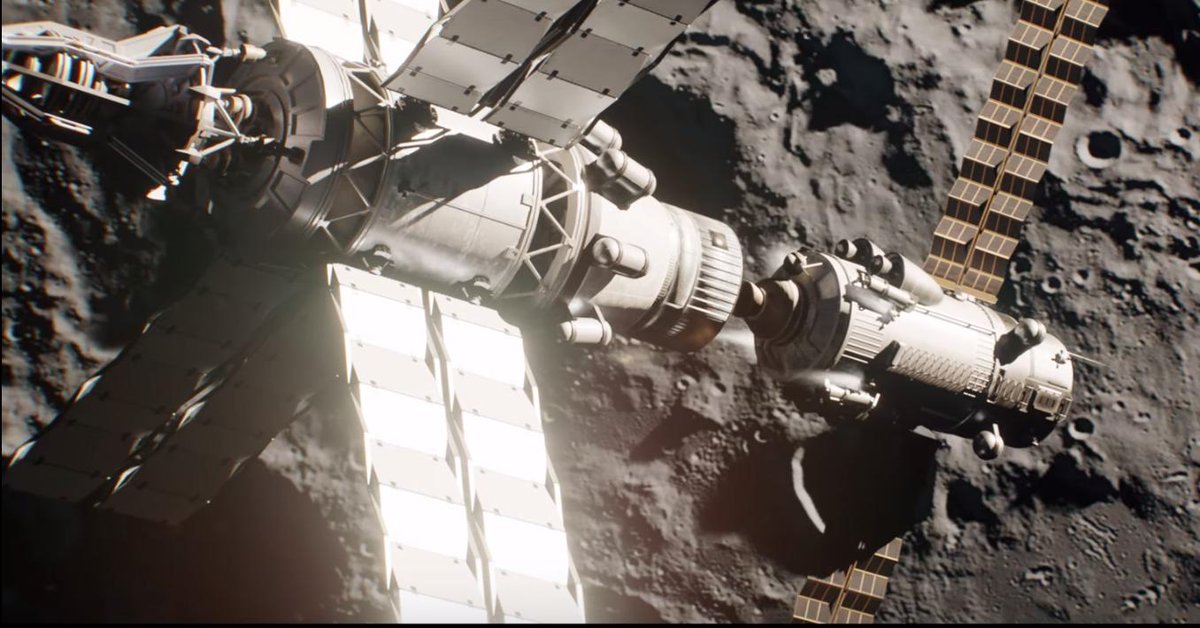

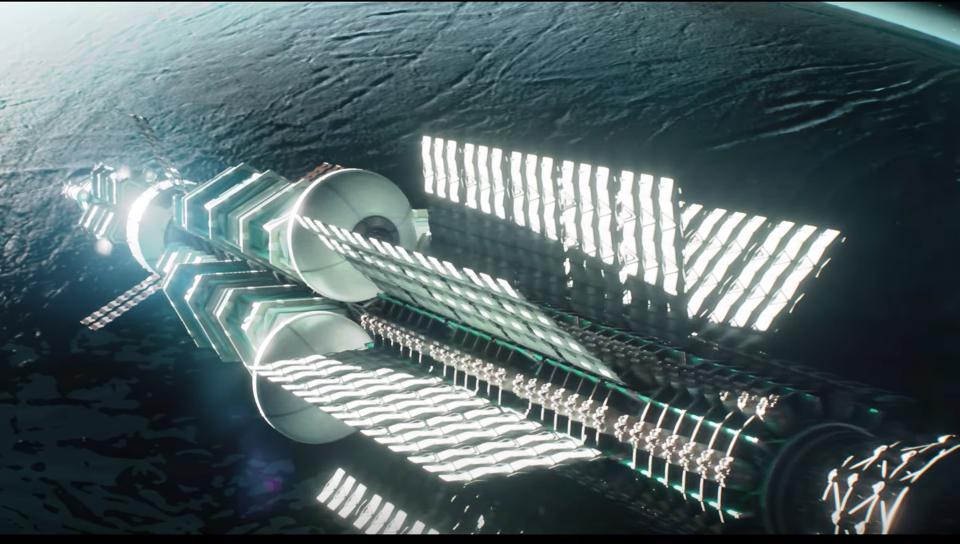

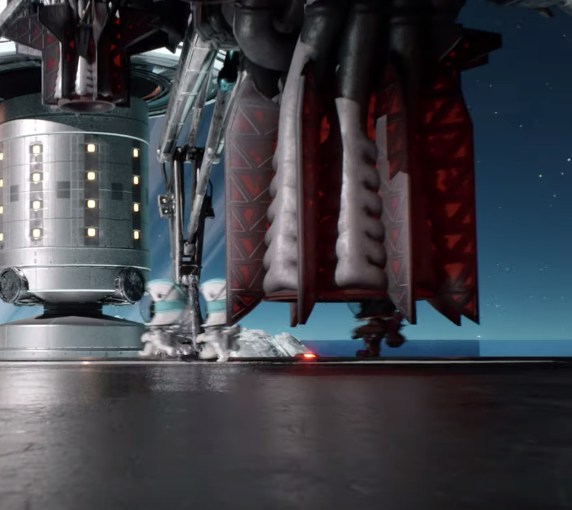

And most importantly - lots of radiators for thermal management. I'm sure @nyrath can recognise the lineage of some of these

• • •

Missing some Tweet in this thread? You can try to

force a refresh