The 1937 Gardendale Project was a trial of rammed earth as a technique used in mass produced affordable homes in Alabama, USA. In terms of cost they were comparable to other building methods of the era but the money was spent on people (labor) rather than factories (material).

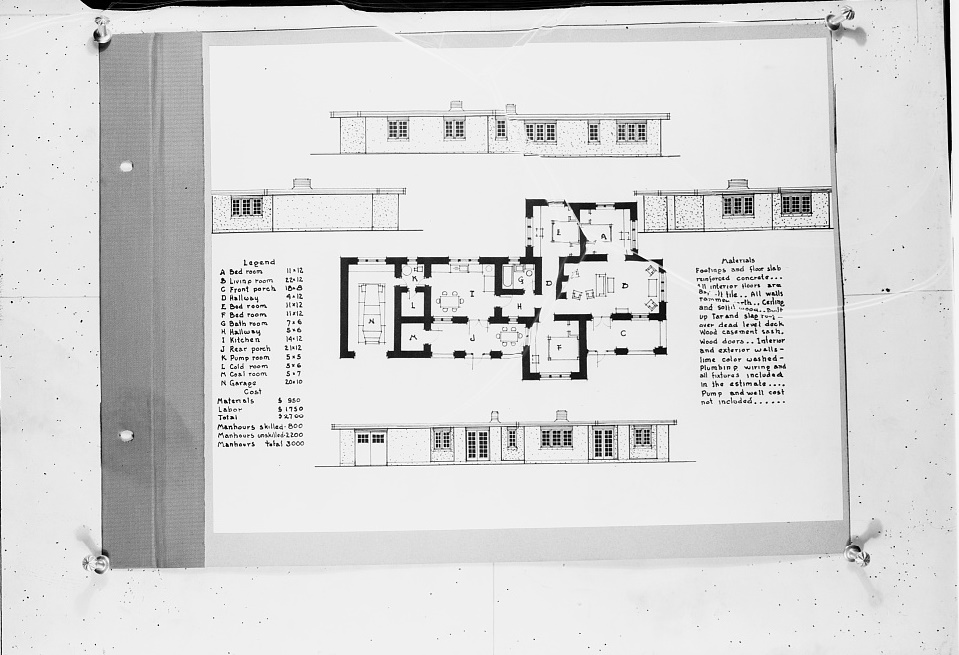

The seven original structures, designed by architect Thomas Hibben, worked perfectly and still stand in near perfect conditions, apart from the flat leaky roofs (modernism) and the concrete foundations (because of course).

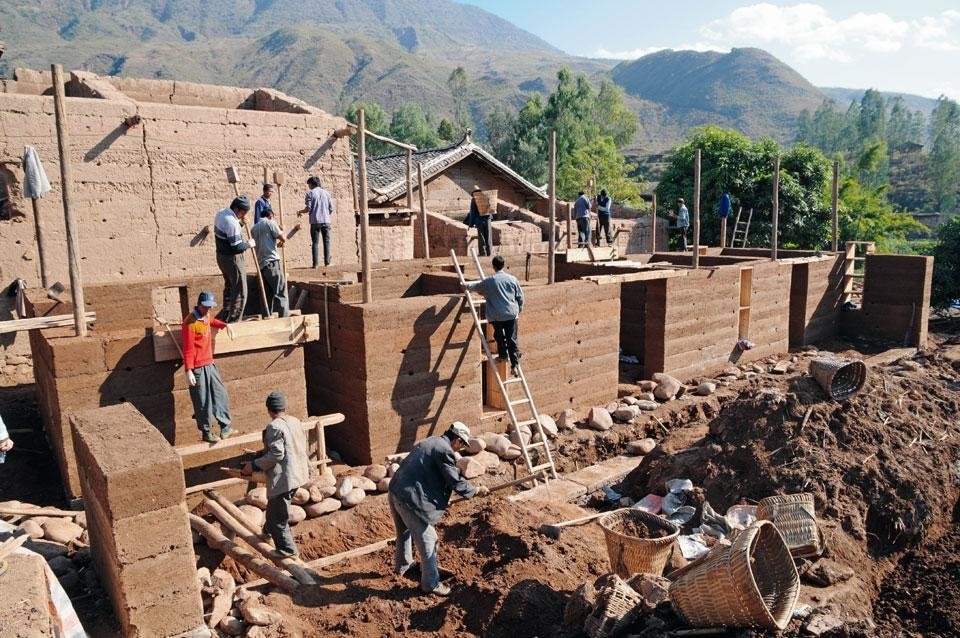

A common complaint against rammed earth is that it is slow. But Hibben's crew of 14 men, all amateurs, learned quickly and proved that they could be built with speed: the last house in the project took them five days to complete.

Another common complaint was the rammed earth houses were ugly. Many people passed on them, despite the worldwide fame the project received (even Nehru came for a visit). So some houses were made to look more traditional within the same time frame and budget. Moving in day!

Apart from the forms used in shaping the walls, the tools involved were handmade from local materials, and could be made by the individual worker to fit his own needs and physical strength. All ingredients for the house except the French doors, came from the plot itself.

Rammed earth is the way forward for people in low income communities to build their own homes on their own land in dense urban villages without welfare, charity, or usury, on abandoned land or from converted parking, in small plots of 400-1200ft²: to build equity and stability.

Form neighborhood work teams, pick designs from pre-selected pattern books and let the user/owners create their own homes, leaving space for small backyards, plazas, wells, towers, corner stores, etc. With rammed earth you can even build tall (Lyon) or distinguished (Kanazawa).

• • •

Missing some Tweet in this thread? You can try to

force a refresh