yes, it's the Florida International University pedestrian bridge collapse. it came down during construction due to critical design flaws. unfortunately several folks lost their lives.

there is a very good illustrated digest that the NTSB created about their investigation of the collapse.

ntsb.gov/investigations…

ntsb.gov/investigations…

typically, a truss looks more like this: it's got two sets of structural members which provide some amount of redundancy. if a single member fails, you close the bridge and repair it, but the bridge will not collapse.

the florida bridge used only a single set of truss members, and was not a redundant design.

a typical truss bridge is built using steel truss members. members can experience forces both in tension (trying to stretch it out) and compression.

however, the florida bridge was built using concrete truss members. you can do this BUT you have to realize that concrete becomes very weak in *tension*, about 10% of its strength in compression!

the usual way around this is a technique called PT (post tensioning). it's a trick where you run some steel tendons through the beam and tighten them down after the concrete has hardened. this puts the beam in compression.

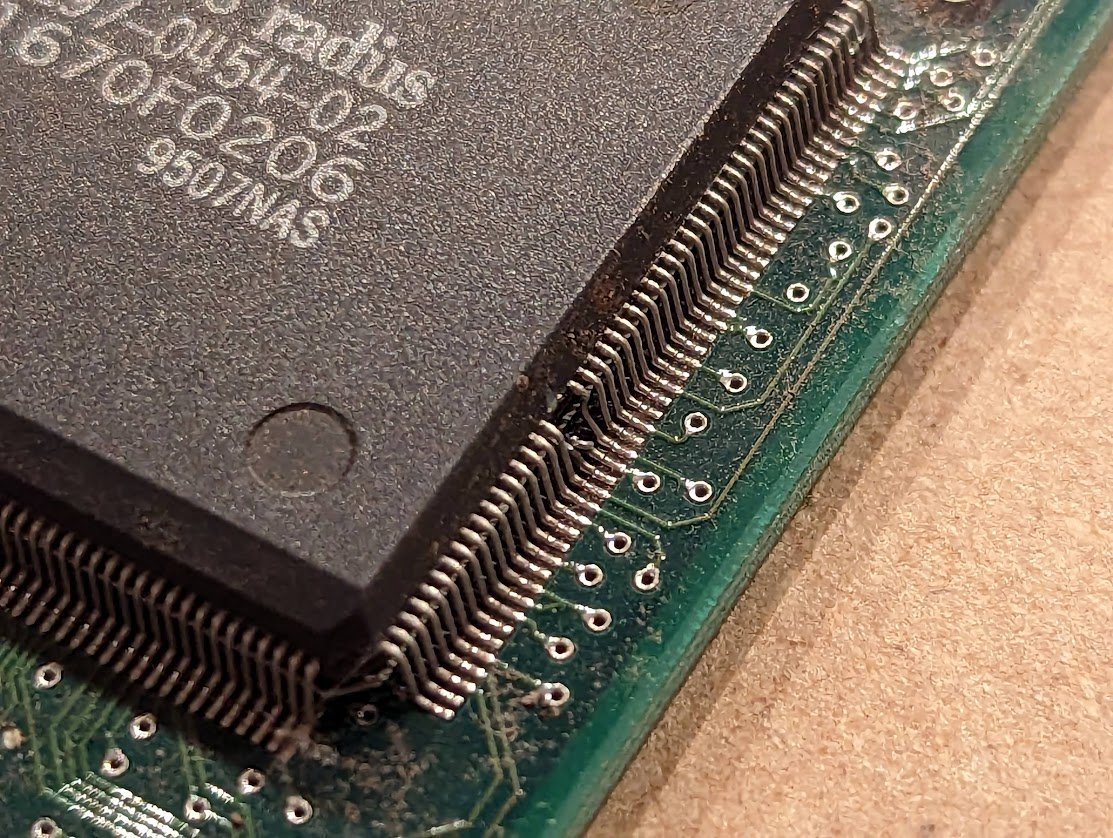

here are the truss members in the florida bridge. the idea is that after post-tensioning, all the members are in compression.

anyway, the concrete was poured at an adjacent lot and the bridge was moved into position over a period of about 8 hours. this was done to minimize the disruption to traffic.

once the bridge was in position and the temporary supports removed, workers noticed some disturbing cracks. these were not small!

concerned, the construction crew contact the engineering firm, who assured them that cracking was expected and that it was nothing to worry about.

the idea was that the tensioning needed adjustment, and that everything would be ok after that.

unfortunately, while the crew was doing that, the truss failed. concrete dust and debris blew out of the end of truss, and the bridge collapsed.

a cold joint is where two separate concrete pours meet. you can't pour this whole thing all at once. you pour once, then allow the concrete to harden, and then you pour again. the line between is the cold joint.

a cold joint is a weak spot. the cracks give us clues as to how truss member 11 failed. this member was *pushing* very hard against truss member 12, and it wanted to slide against the deck, which caused all the shear cracking shown in blue.

but why was there so much force on truss member 11?

back to basics: the bridge weighs 1900 kips, and a kip is 1000 pounds(force). half of that force is exerted at one end, and the other half at the other end. this is pretty simple.

if we assume that truss member 12 has no force, then we can calculate the force in truss member 11 using simple trigonometry. with 950 kips pushing up, the Y component of that truss must push down with 950 kips (according to our buddy Newton)

from that we can calculate the force in shear (along the axis of the deck of the bridge) as whopping 1,520 kips!

that means that 80% of the weight of the bridge was *pushing* along this red arrow, parallel to the deck of the bridge. it's already weak because of the cold joint, and it was just too much for the surrounding concrete to bear.

this sort of problem should have been caught much earlier in the design process. i don't know why the engineering firm missed it. the independent company they hired for peer review also missed it.

so why did the peer review firm miss it? they performed their structural analysis on the completed bridge, not any partially completed stages! with the back span in place, it would have taken the load off of truss member 11.

but bridges don't magically pop into being. they have to be constructed a stage at a time.

you can dream up all sorts of neat things and model them in your CAD program, but ultimately people have to physically build it.

btw the bridge almost looks like a suspension bridge, but it is not. the steel pipes going to the upper pylon are partially decorative but also change the resonant frequency of the bridge, dampening vibrations from pedestrians. that's a lesson that was learned a long time ago

the lesson? in 1831, British soldiers marching in step across the newly-constructed Broughton suspension bridge caused it to collapse when their cadence accidentally coincided with its resonant frequency.

ultimately, i feel bad for the professional engineer who put his stamp on this bridge. apparently he personally viewed those cracks and didn't consider them to be a problem. what a terrible burden to bear.

i've left out a lot of details and simplified things quite a bit. if you want the definitive report, read the very thorough NTSB investigation here. ntsb.gov/investigations…

did you find this thread interesting? i've done a few others like it, such as this thread about a power company's negligence that burned down an entire town.

https://twitter.com/TubeTimeUS/status/1306359385656946688

another time i looked at the 3 major causes behind a horrific car crash involving a Tesla.

https://twitter.com/TubeTimeUS/status/1319739566685782016

the Boeing 787 battery fires were also quite interesting to read about.

https://twitter.com/TubeTimeUS/status/1335020440419356672

i don't have a SoundCloud and i don't take donations (Ko-Fi or otherwise) but please consider making a donation to your local food bank. they're really hurting from the pandemic and can use the extra money.

• • •

Missing some Tweet in this thread? You can try to

force a refresh