i've been thinking about how to blow up power MOSFETs. it turns out that there are several interesting ways to make a MOSFET fail... 🧵

but where to start? why not the MOSFET datasheet? (follow along here vishay.com/docs/91018/sih… if you like)

one easy way to blow up a MOSFET is to exceed the absolute maximum ratings. they really are absolute!

first up is the drain to source voltage. this is the voltage between the drain and source terminals (duh) which is sort of the business end of the MOSFET. when used as a switch, these are the switch contacts. go above 100V? boom! avalanche failure.

you can also exceed the gate to source voltage. there is a very thin layer of silicon dioxide that insulates the gate from the source, and if you go outside of +/-20V, on this MOSFET, boom! it *shorts out*. usually that causes more stuff to explode on your circuit board.

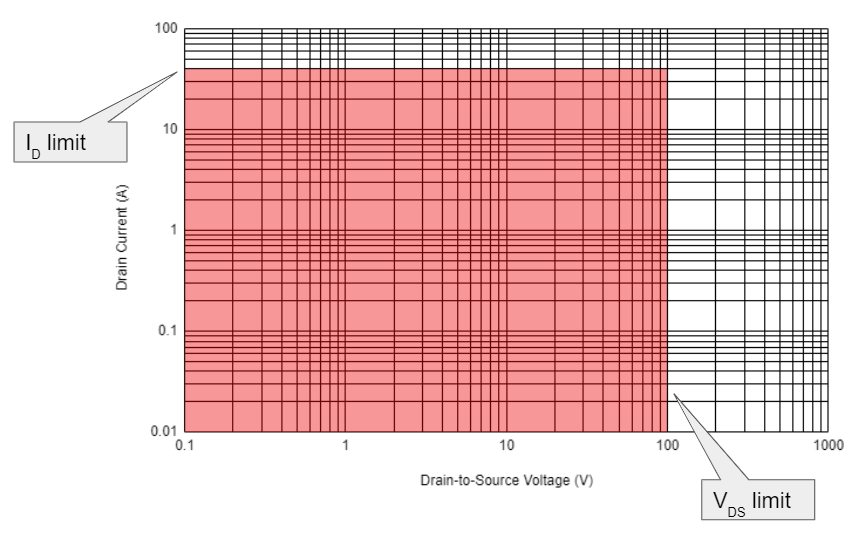

manufacturers have a SOA graph in the datasheet (Safe Operating Area) that describes the conditions that are safe for a MOSFET. let's go through it step by step. here we graph drain current vs drain to source voltage.

yes, there is a maximum current rating! if you go above that...BANG

you have to clip off part of the SOA because of the inherent resistance of the MOSFET (RDSon). it's not physically possible to exceed this limit because of Ohm's law. i could put 1V across the MOSFET but it will never pass more than 3A because of this built-in resistance.

here's where it starts to get interesting. it turns out that the drain current limit is actually a *thermal* limit. and you can only run the full 40A drain current and 100V drain to source voltage for a very, very, very short time. 10us.

what happens is that the MOSFET gets really hot because it can't dissipate the heat all that quickly. once the tiny little silicon die gets above 175C (in this case) then all bets are off! (yeah, it goes bang)

we can figure out how much power that is. at 40A and 100V, we get 40*100 = 4000W or 4 kilowatts!

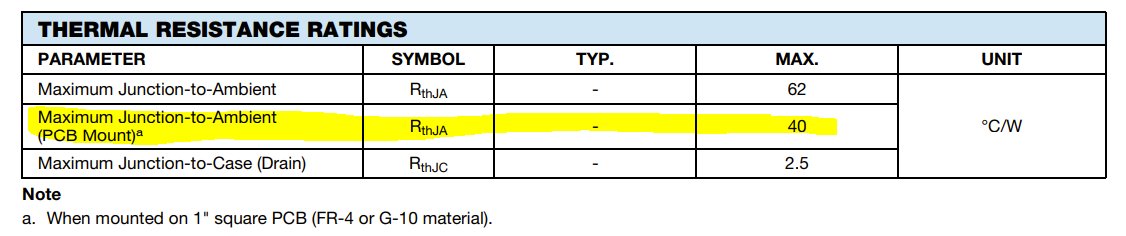

to figure out what that could do to the temperature, we need to look at the thermal section of the datasheet. the thermal impedance is 40C/W, so 40 * 4000 = 160,000C. yeah that's a bit above the maximum rating of the die.

but it's OK for 10 microseconds because the die has *thermal mass* which is the thermal equivalent of a capacitor. so it can store up a bunch of energy and slowly dissipate it over time. the manufacturer doesn't typically tell this number to you directly.

but they do give you a nice graph! for a single 10us pulse, the thermal impedance (equivalent) to the case of the MOSFET is about 0.03C/W. so at 4KW, we get a temperature rise of 120C. with an ambient temp of 25C, that's 145C which is OK!

you must let it cool down again before you hit it with another pulse. that is why there are other lines on the graph for different duty cycles--to account for reduced cooldown time.

by the way, the theta-JA number in the datasheet (thermal impedance from the Junction to Ambient air) is measured using a standard PC board with a 1 square inch sheet of copper acting as the MOSFET's heat sink, something like this.

if you want to blow up your MOSFET, don't give it a heat sink. give it just the tiniest little footprint. and don't put an array of vias underneath the large metal pad--you might end up conducting heat away into a nearby heat sink!

there's a particularly insidious factor i should also mention. the MOSFET on resistance *increases* with temperature!

in fact, it *more than doubles* which can really throw you for a loop in a design. if you want to blow up a MOSFET, definitely don't factor this into your worst case calculations!

one shortcut people like to use is to calculate the I-squared-R losses [(I^2)*R] which tells you the power dissipated as heat for a given drain current and on resistance. if you forget that MOSFETs get hot and use the "typical" value for on resistance...BANG!

incidentally there are some subtle and nasty ways that you can accidentally exceed the ratings of a MOSFET.

☠️inductive load? during switching this generates voltage spikes that can exceed VDS(max).

☠️there is gate-to-drain capacitance, so if your gate driver has too high of an impedance or no protection, a large voltage pulse on the drain can drag the gate along with it, exceeding VGS(max).

☠️don't forget about the parasitic body diode! try forcing current from the source to the drain: power dissipated = 0.7V (the diode drop, approx) x drain current = BANG!

☠️creative folks with access to a cyclotron also enjoy making MOSFETs fail by putting them in the path of a high energy particle beam.

☠️don't forget good-old-fashioned physical violence. it's not that hard, just tighten down the heat sink. keep tightening. more. more! ok there we go

...and i'm sure you folks can come up with some things i forgot about.

for more technical details, here are some useful papers:

Vishay app note on MOSFET current ratings, showing how they are *thermally* derived.

file.elecfans.com/web1/M00/20/F9…

Vishay app note on MOSFET current ratings, showing how they are *thermally* derived.

file.elecfans.com/web1/M00/20/F9…

another good Vishay app note on how avalanche failure actually works.

vishay.com/docs/90160/an1…

vishay.com/docs/90160/an1…

this Vishay app note has a good set of photos showing dead MOSFETs. lots of electron microscopy.

vishay.com/docs/69294/an9…

vishay.com/docs/69294/an9…

a paper discussing modern trench MOSFETs. turns out they're really complicated!

ieeexplore.ieee.org/stamp/stamp.js…

ieeexplore.ieee.org/stamp/stamp.js…

these folks put MOSFETs into various particle beams. sounds crazy but you have to do this to find parts that you can put into satellites and spaceships.

ntrs.nasa.gov/api/citations/…

ntrs.nasa.gov/api/citations/…

ALSO because i know one of you will bring up this tired trope, here's the IBM canister of magic smoke. there. are you happy? 😂

• • •

Missing some Tweet in this thread? You can try to

force a refresh