This is a thread on ground transportation proving and testing infrastructure that exists across India. This includes civil and defence facilities available across India.

Starting with Maruti Suzuki’s test track in Rohtak. Quite a big and diverse Proving ground

Starting with Maruti Suzuki’s test track in Rohtak. Quite a big and diverse Proving ground

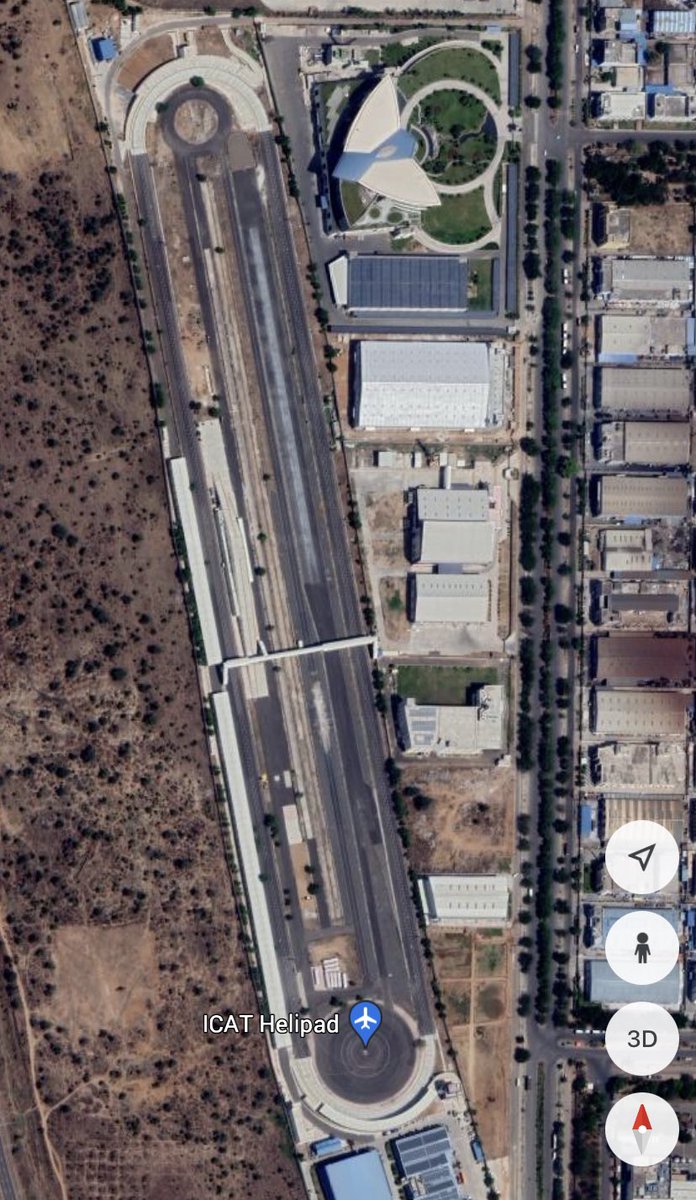

Moving South to the National Capital Region we have the government ICAT’s test facility and homologation centre that carries some regulation and R&D work on the part of govt. This facility is located in Gurgaon.

As we move down to Jaipur outskirts Hero Motors has a sprawling Two wheeler proving ground right by their R&D centre. Quite diverse set of test facilities within that proving ground.

As we move to Pithampur, Indore we have the NATRAX the largest vehicle proving ground in India. This was recently expanded by the government. This has off-road vehicle testing capabilities too. This is where SAE Baja o petitions happen.

Then we come to VRDE, Ahmednagar as part of DRDO. This is where DRDO’s armoured vehicles and trucks are developed and tested.

Then we come to the automotive hub of Pune. Let’s start with Bajaj’s 2-wheeler testing facility in outskirts of Pune.

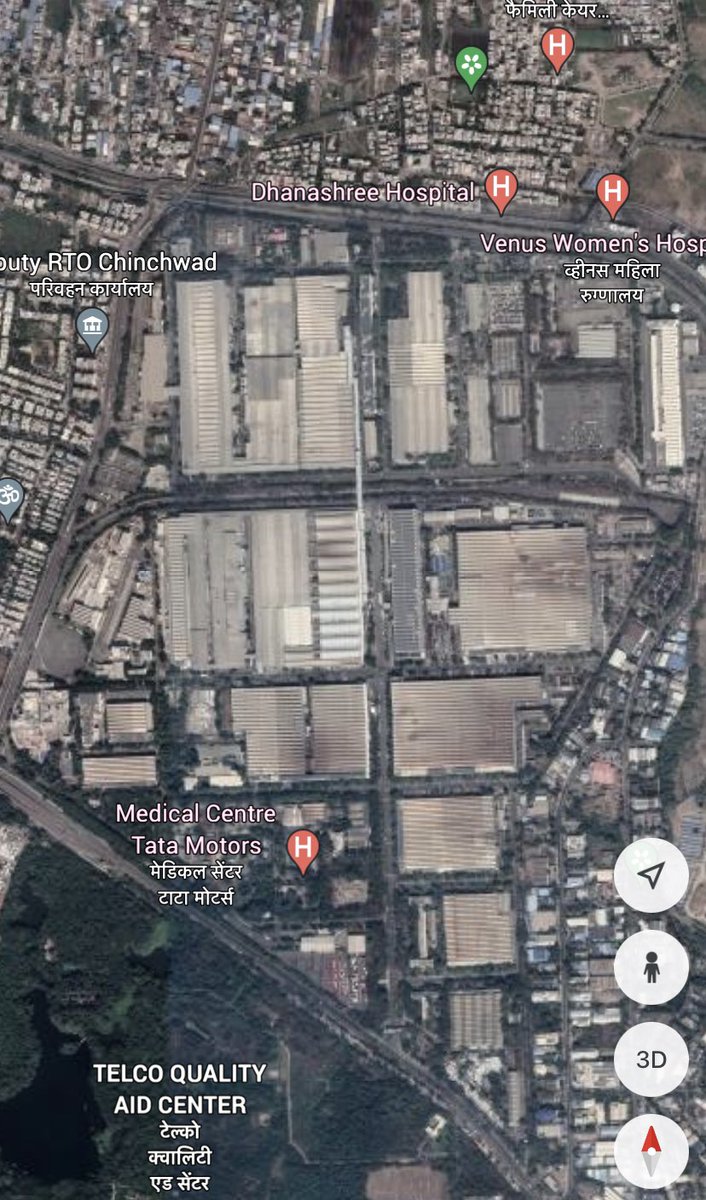

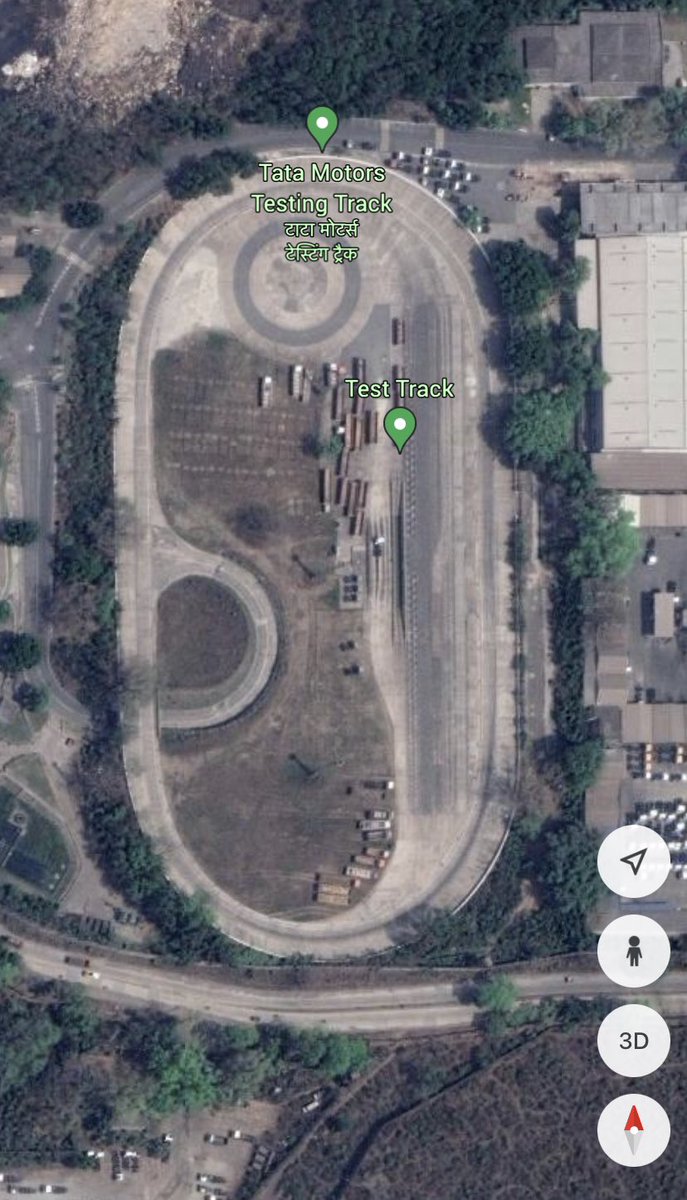

Tata Motors has two proving grounds. One on site(first two pics) in Tata Motors plant in Pune. And secondarily they have a truck proving ground in Jamshedpur(3rd pic).

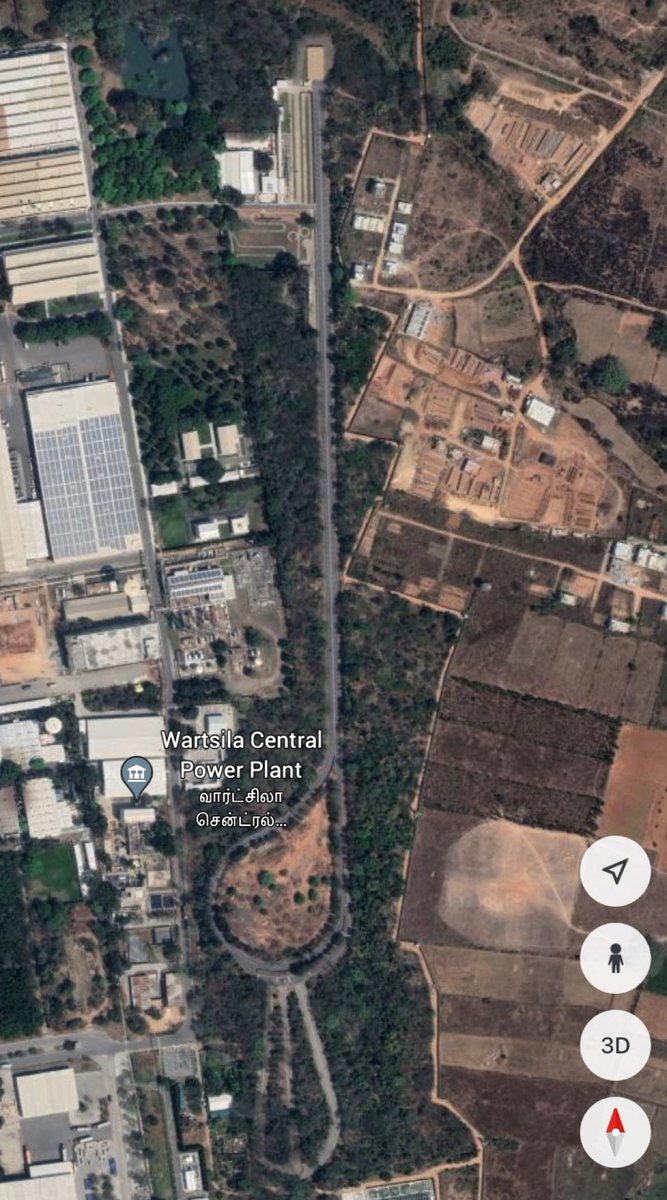

Then we come to South India. TVS’s two wheeler proving ground is located in Hosur next to its R&D centre.

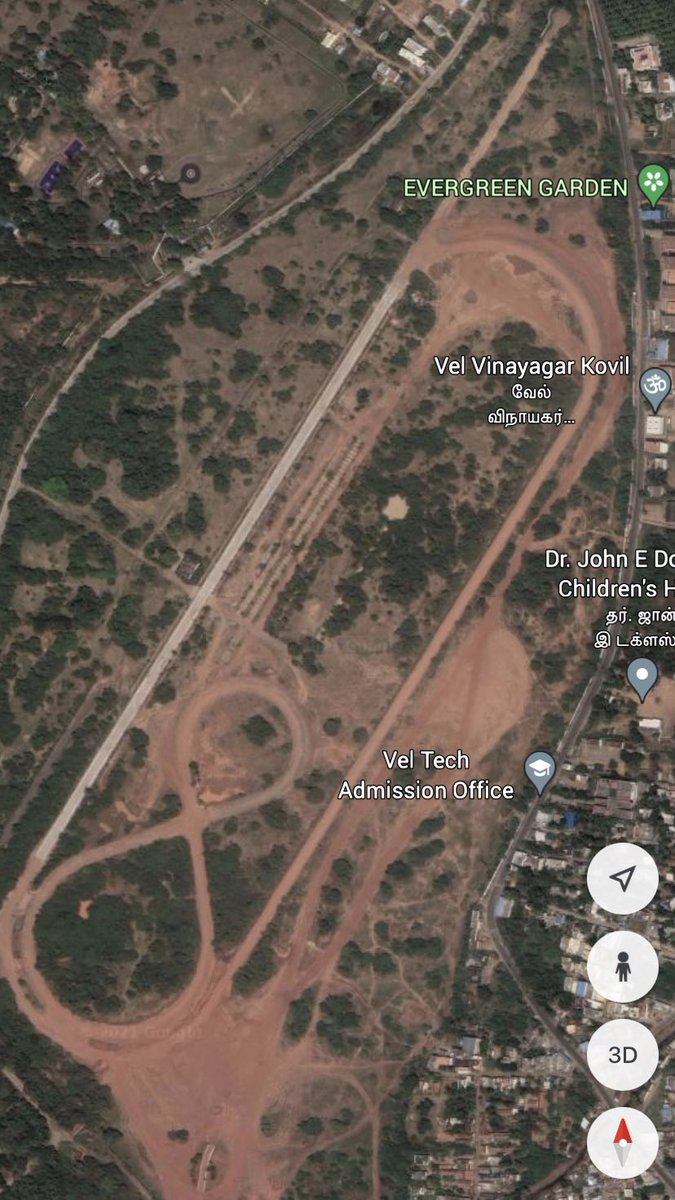

And now we reach the automotive capital of India, Chennai 😀😀. Let’s start with Ashok Leyland’s proving grounds next to its product development Center in Vellivoyal Chavadi. One of the oldest testing grounds in India.

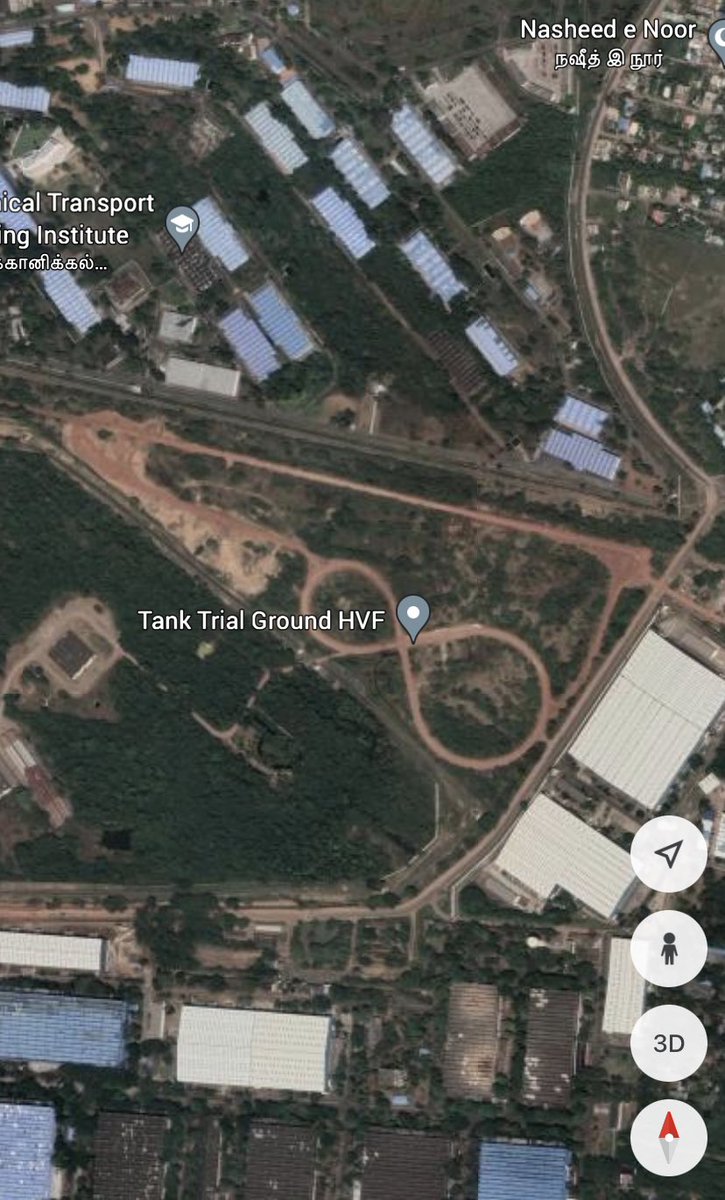

Now we reach CVRDE and HVF and it’s proving grounds. One of the few Army Tank development and Test facilities in the world. Located in AVADI, Chennai. Anecdote: Tanks take civilian roads to travel from HVF to the test facility. Tank only lanes on public roads. 😀😀

Then we have the only tier-1 proving test facility in India. Wabco(now ZF) has its test facility in Chennai to test its braking and ECU products for cars and trucks.

This now near defunct Ford plant in Maraimalai Nagar, Chennai had its own test facility within the plant. Hopefully Tata Motors will take over this and have a better test facility than what it has in Pune.

Next we have Daimler’s factory attached trucks and buses test facility in Oragadam, Chennai. This is more for the finished products out of factory that have been homologated for Indian conditions. New product testing might be less.

Next is the Indian govt owned Global Automotive Research Centre which is across the road from the Daimler plant. A wide range of Electric Vehicle nee product testing happens here for the Bangalore based EV startups. Mahindra and Renault Nissan too occasionally use this facility.

And finally comes Mahindra’s mega SUV proving ground in Cheyyar, 70 km from Chennai. Mahindra has its R&D centre 20 km away at Mahindra Research Valley which has its small test grounds. But the big one inaugurated recently is for developing SUVs of the future.

Please let me know if I’ve missed any. There are Ofcourse other proving grounds as part of facTories like with Yamaha, Royal Enfield, Honda Cars, Toyota, Hyundai, Volkswagen, Mercedes Benz etc. Those are more like final testing than for product development testing.

Oh yes I also forgot to add Vehicle Factory Jabalpur’s test facilities. Owned by Vehicles PSU of Ordinance Factories Corporation. A test facility that’s full of solar plant.

Thanks to @SlyandSulk. Adding another TVS testing track inside TVS training Centre. Looks like an offroad one.

Another tier-1 supplier's own product development and testing facility. Thanks. @StoreOn10 Brakes India's test facility at Polambakkam 100 km from Chennai.

Looks like This is the new TVS product development proving grounds. This is near Denkanikottai, south of Hosur. I would presume TVS funded EV Ultraviolette too used this for their product testing. Thanks @RDinakar.

• • •

Missing some Tweet in this thread? You can try to

force a refresh