Alright! Everyone has been taking wild guesses about what I consider a simple, yet brilliant design feature on the Yamato class. However, everyone was thinking big!

So what could this mystery thing be? Well, before we get to it, we need to first talk guns and loading them!

1

So what could this mystery thing be? Well, before we get to it, we need to first talk guns and loading them!

1

As battleships evolved, they increasingly made use of larger, more powerful guns.

In turn, these guns required larger turrets to house them. However, other things also increased in size along with the guns, namely the propellants and loading mechanisms.

2

In turn, these guns required larger turrets to house them. However, other things also increased in size along with the guns, namely the propellants and loading mechanisms.

2

As naval guns got larger and the shells they fired got larger, the propellants needed to propel them down the barrel got proportionately larger as well.

Larger guns typically needed multiple bags of propellant. Even divided up, these individual bags could be quite heavy.

3

Larger guns typically needed multiple bags of propellant. Even divided up, these individual bags could be quite heavy.

3

For example, the 46cm (18.1") guns of the Yamato class needed 360kg of propellant, divided up into six 60kg bags.

It was impossible for the gun crew to manhandle this propellant into the chamber. This was why battleships had to make use of complicated loading systems.

4

It was impossible for the gun crew to manhandle this propellant into the chamber. This was why battleships had to make use of complicated loading systems.

4

The problem with the loading system was that they were bulky. Furthermore, it had to be designed to fit inside of a turret of practical size. A balance had to be maintained where the turret was not overly heavy or large, but the guns could be loaded without unnecessary steps.

5

5

Too many unnecessary steps would lead to a reduction in the rate of fire.

Most small guns could use a relatively simple loading cycle. The shell would be rammed into the chamber followed by the propellant.

A two stroke loading system.

6

Most small guns could use a relatively simple loading cycle. The shell would be rammed into the chamber followed by the propellant.

A two stroke loading system.

6

The larger, heavier propellant charges of the largest naval guns could not allow for this in the restricted confines of the turret.

Thus, the largest naval guns had the propellants broken into groups to be rammed into the chamber Usually in two groups of propellants.

7

Thus, the largest naval guns had the propellants broken into groups to be rammed into the chamber Usually in two groups of propellants.

7

This was a three stroke system. The rammer had to ram the shell and two groups of propellant separately.

Some Navies were able to retain a two-stroke system, but it usually required manhandling the propellant onto the ramming tray and slowed the rate of fire.

8

Some Navies were able to retain a two-stroke system, but it usually required manhandling the propellant onto the ramming tray and slowed the rate of fire.

8

The Yamato class, using such giant guns, naturally presented quite a problem.

Japanese designers pondered this (while also being mindful of the problems for the 51cm/20.1" successor weapons) and developed a rather ingenious solution.

9

Japanese designers pondered this (while also being mindful of the problems for the 51cm/20.1" successor weapons) and developed a rather ingenious solution.

9

The loading system could move out of the way to make room for the shells and propellants!

This was accomplished through the use of two ramming systems, one for the shells and one for the propellants.

10

This was accomplished through the use of two ramming systems, one for the shells and one for the propellants.

10

The first ramming system involved a shell ramming tray and shell rammer. These were mounted on a sliding bogie.

The shell would be hoisted into position and then tipped into the shell tray. The bogie slid forward into position to let the shell be rammed into the breech.

11

The shell would be hoisted into position and then tipped into the shell tray. The bogie slid forward into position to let the shell be rammed into the breech.

11

Once the shell was loaded, the entire shell ramming system would be slid backwards on the bogie. This would free up space for the propellants.

The propellants would arrive together, all six secured in a powder cage. The cage would arrive already positioned at the breech.

12

The propellants would arrive together, all six secured in a powder cage. The cage would arrive already positioned at the breech.

12

There, a second rammer would ram all six bags into the chamber. A two stroke loading system with no need for human interference!

Once the rammer retracted, the powder cage would then descend back down the barbette and the breech

would be closed. The gun was ready to fire.

13

Once the rammer retracted, the powder cage would then descend back down the barbette and the breech

would be closed. The gun was ready to fire.

13

Once the guns fired and the breech was opened again, the another shell would be tipped into the tray and the bogie would once again slide forward into position, starting the process all over again!

14

14

This was a beautiful system for a variety of reasons.

It allowed for a simple, two stroke system that removed the human element as much as possible. This sped up the rate of fire and allowed the 46cm guns to remain competitive with smaller weapons.

15

It allowed for a simple, two stroke system that removed the human element as much as possible. This sped up the rate of fire and allowed the 46cm guns to remain competitive with smaller weapons.

15

In addition, the system was remarkably compact.

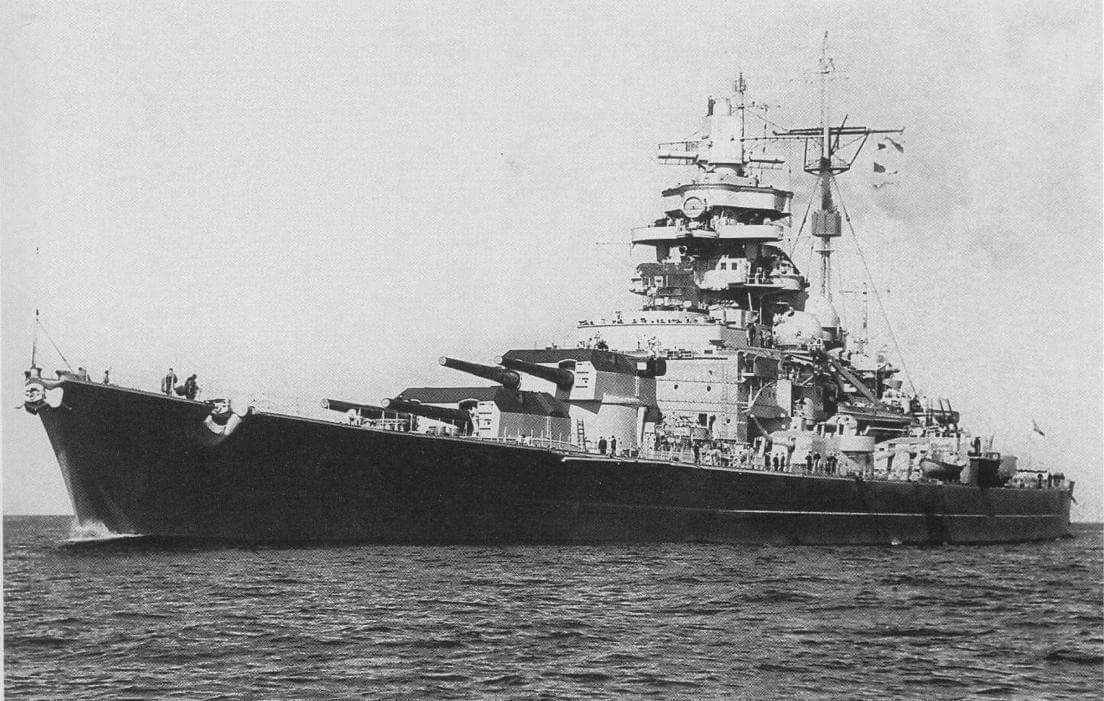

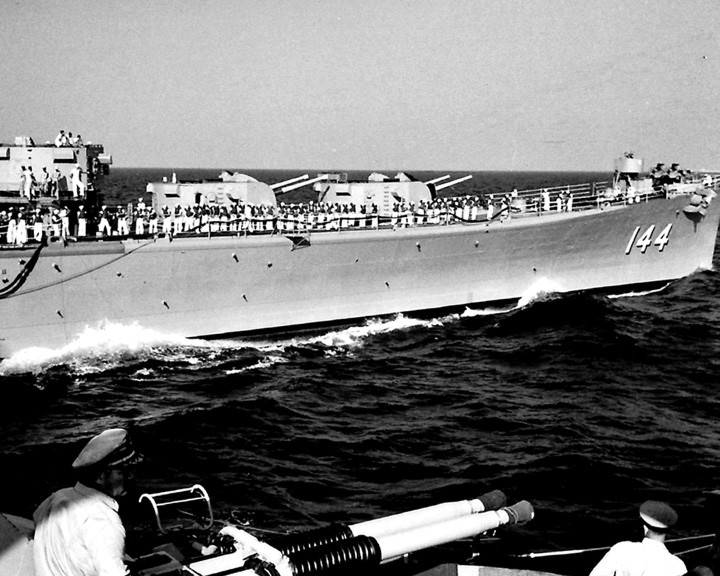

Compare the size of the Yamato turret with the German and British 15" twin turrets. They were not much larger (at least in size) in relation to smaller 15" and 16" triple turrets.

16

Compare the size of the Yamato turret with the German and British 15" twin turrets. They were not much larger (at least in size) in relation to smaller 15" and 16" triple turrets.

16

The downside was that the system was heavy, a fact that contributed to the prodigious weight of the Yamato turrets.

In addition, the system likely made turret protection difficult. Making the turret more flashtight was probably a challenge.

17

In addition, the system likely made turret protection difficult. Making the turret more flashtight was probably a challenge.

17

Overall I would say that Japanese designers achieved quite a remarkable feat.

Despite the large shells and propellant charges, they still retained a respectable rate of fire. This was achieved while still keeping the overall system relatively compact.

18

Despite the large shells and propellant charges, they still retained a respectable rate of fire. This was achieved while still keeping the overall system relatively compact.

18

It's also worth pointing out that the Royal Navy wanted to utilize a similar system for the Lion class. The Mark IV guns were to use a two-stroke loading system, but they still had not figured out how to fit it inside the turret. Gives credit to Japan's shell bogie system!

19

19

Overall, I think this is a perfect example of the considerable thought that Japan put into the Yamato class. In many ways, the Yamato design was more advanced than its contemporaries. Japan built a massive battleship, but not one that was massively unwieldy.

20

20

To see the system in operation, check out this cool video. It might not be perfectly exact due to the destruction of records, but it should be close enough!

@threadreaderapp unroll

• • •

Missing some Tweet in this thread? You can try to

force a refresh