#OffsiteInsights: Beechwood Case Study

Our next case study project, still under construction, hasn't been seen much publicity yet 🚧👷♂️

With dozens of homes already occupied, we believe Beechwood in #Basildon represents a number of significant trends in #ModularHousing 🏗️

Our next case study project, still under construction, hasn't been seen much publicity yet 🚧👷♂️

With dozens of homes already occupied, we believe Beechwood in #Basildon represents a number of significant trends in #ModularHousing 🏗️

@NUlivinghomes is the highly ambitious in-house developer for @SwanHousing. With a regeneration-led approach, the London and South-East focused developer set up a large modular housing factory in Basildon back in 2017.

It must have been successful, as it's since been followed up by a second major facility that opened last year: swan.org.uk/news/2020/swan…

Given the high cost of land relative to the Midlands/North, setting up in the south east is a rare, though not unique, decision.

This is reflected in our data on volumetric modular factories, with pin size indicating facility size:

This is reflected in our data on volumetric modular factories, with pin size indicating facility size:

The current prevailing strategy seems to be: set up factories where land is cheap (Midlands/North) and build/sell where land costs are high (London + South East).

Other big facilities nearby include @BerkeleyGroupUK and #BritishOffsite.

Other big facilities nearby include @BerkeleyGroupUK and #BritishOffsite.

In another significant decision, Swan's modules are made from timber, specifically #CrossLaminatedTimber 🪵

While this is a very popular construction for modular projects in the USA, the UK's Category 1 manufacturers have a clear preference for Light Gauge Steel Frame.

While this is a very popular construction for modular projects in the USA, the UK's Category 1 manufacturers have a clear preference for Light Gauge Steel Frame.

This is, at least, in part due to the regulatory confusion that followed the Grenfell tower fire:

dezeen.com/2021/10/13/uk-…

dezeen.com/2021/10/13/uk-…

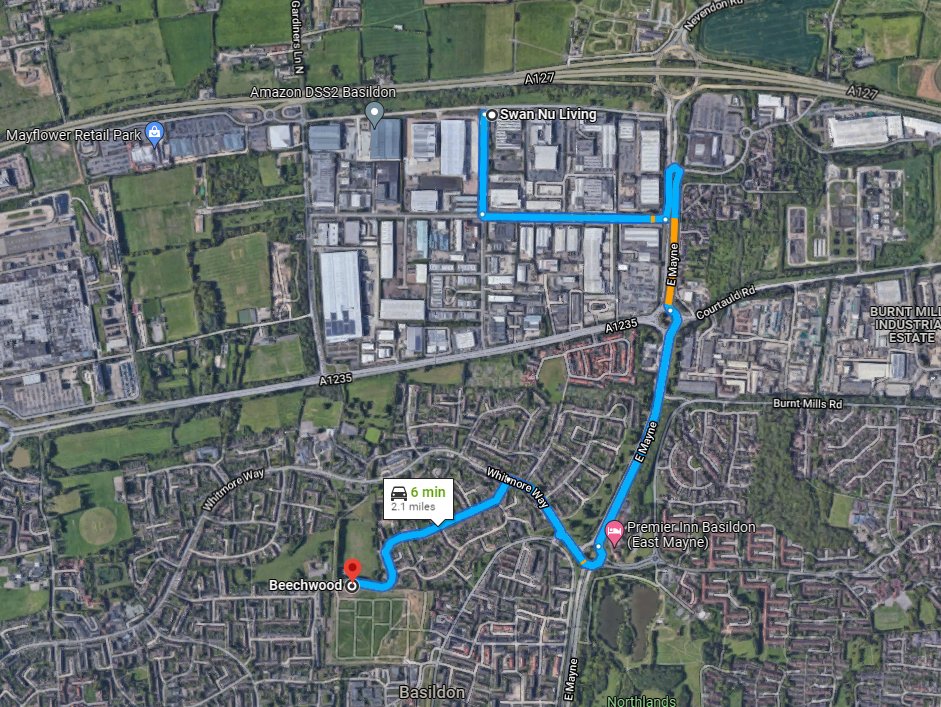

However, @NUlivinghomes couldn't have picked a more perfect location for their first major project. With over 250 homes to deliver in #Beechwood, their factory is less than 1 mile away from the construction site!

But Beechwood is not only a significant CLT modular scheme - each home is fully customisable via a web-based configurator from @Creatomus.

configurator.creatomus.com/project/beechw…

configurator.creatomus.com/project/beechw…

Customers are able to select a plot, adjust the building's form, facade, roofing and internal materials via a design wizard.

If you've ever configured a car, the process will feel familiar. This very much seems like a glimpse into the future of #PropertyDevelopment 😮

If you've ever configured a car, the process will feel familiar. This very much seems like a glimpse into the future of #PropertyDevelopment 😮

The architects behind this job are @PTEarchitects and their website has a great page with a detailed summary of the project's approach: pollardthomasedwards.co.uk/projects/index…

And would you check out those rooflines! Who said modular construction always has to be boxy?

When it comes to making dynamic facades, the sector has something of a reputation to overcome. The silhouettes at Beechwood are dynamic, modern and fun.

When it comes to making dynamic facades, the sector has something of a reputation to overcome. The silhouettes at Beechwood are dynamic, modern and fun.

There you go, #Beechwood has it all! It's modular CLT, it's technology-driven, it's configurable and it's fun 🥳

That wraps us up for February, be sure to follow @kopeai for more #OffsiteInsights in March

That wraps us up for February, be sure to follow @kopeai for more #OffsiteInsights in March

• • •

Missing some Tweet in this thread? You can try to

force a refresh