Our friends @Se_Railway have been contacted by passengers who regularly ride on the line from #Margate to #Faversham via #Whitstable as to why their trains are running at a reduced speed in some places on the route.

They should be fixed soon but in the meantime, here's why... /1

They should be fixed soon but in the meantime, here's why... /1

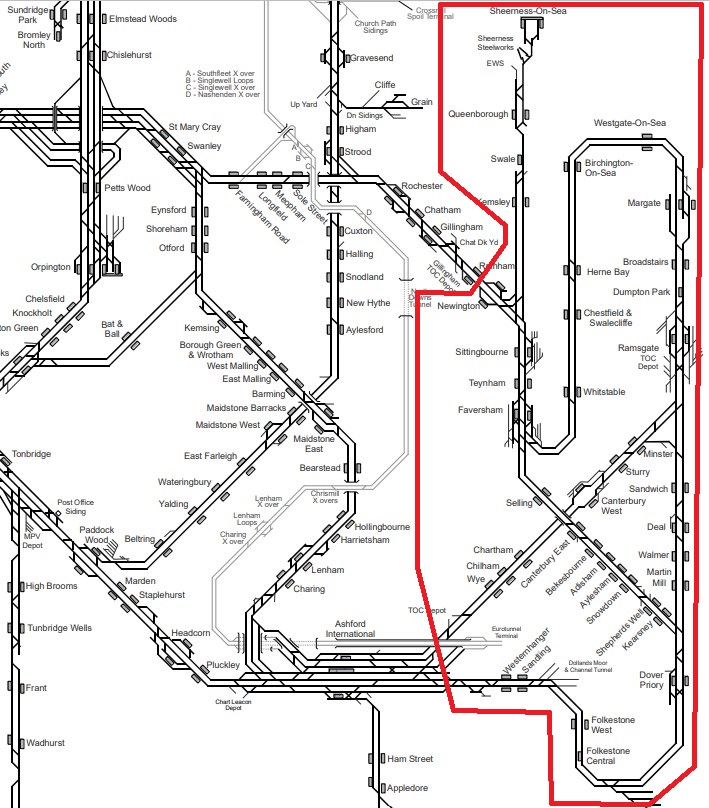

@Se_Railway The route from Margate takes passengers from the chalky Isle of Thanet down to sea level near Birchington and then across a part of Kent that features a great deal of London Clay (a sort of yellowy gooey soil). /2

@Se_Railway The line across the marshes at Birchington (see below) is built up on an embankment built of that clay, as it was the only material the Victorian engineers had to hand when the line was constructed in 1863. /3

Since then, we've learned that clay is a terrible material to build railways out of as when it dries out in hot summers, it shrinks rapidly, especially when nearby trees are soaking up whatever moisture is left.

This is a lump from Whitstable this summer. /4

This is a lump from Whitstable this summer. /4

This summer was the hottest and driest in recorded history, so the clay shrank out from underneath the railway, notably on that section from Birchington, but also around Seasalter, near Whitstable. /5

Locals will also remember how huge cracks opened up in fields and parks around the area as the clay shrank and it doesn't take much to imagine what that would do underneath a railway (or indeed the Thanet Way, as happened). /6

The net result was track quality degraded rapidly and we had to put speed restrictions in place in the worst-affected areas - including a massive 4-mile stretch on that Birchington marshes area, and around Whitstable too. /7

Essentially, the track was left like corrugated cardboard and we had to slow trains from 85 down to 50 so passengers weren't bounced around.

Since the summer we've been working hard to get those speed restrictions "off" and we are nearly there, with just two miles left. /8

Since the summer we've been working hard to get those speed restrictions "off" and we are nearly there, with just two miles left. /8

How do we do that? We use one these - a tamper.

It acts like shaking the duvet - picking the track up and smoothing it out.

Tamper CGI networkrail.co.uk/running-the-ra… /9

It acts like shaking the duvet - picking the track up and smoothing it out.

Tamper CGI networkrail.co.uk/running-the-ra… /9

The reason it has taken so long is simply trying to get access to enough tampers and crews to get the job done, when swathes of the Southern region, which runs from Weymouth to Whitstable, are built on clay and have similar issues. /10

In fact, a 4-mile stretch of the West of England line near Salisbury suffered the same problem and we had to rewrite the timetable as a result. It has just returned to normal now, and the Faversham line isn't far off too. /11

Here's a short film we made with our resident nerds Chris and Colum, focussing on the West of England line but equally as relevant to Birchington and the line there. /12

The reason the Kent line didn't get a timetable rewrite was that it's double track and although there were (and are) delays, they could be managed.

The West of England line is largely single track and late trains caused mayhem as delays propagated and made the timetable fail. /13

The West of England line is largely single track and late trains caused mayhem as delays propagated and made the timetable fail. /13

We hope that explains why your trains have been slower and we promise they will be at full speed again soon.

If you're wondering what can be done to protect the many miles of railway built of clay... /14

If you're wondering what can be done to protect the many miles of railway built of clay... /14

... we reckon we have around 600 sections of clay embankment in the South, which would cost between £15-£20bn to dig up and replace.

So the best thing we can do is monitor them carefully, and make sure we remove water-hungry tree species from the lineside. /15

So the best thing we can do is monitor them carefully, and make sure we remove water-hungry tree species from the lineside. /15

The key thing to remember is we can't tamp track on soil that is still moving - otherwise it will go off spec almost immediately.

Hence, doing the work in November when it was cold and wet at last.

More on our railway and climate change here:

networkrail.co.uk/sustainability…

Hence, doing the work in November when it was cold and wet at last.

More on our railway and climate change here:

networkrail.co.uk/sustainability…

• • •

Missing some Tweet in this thread? You can try to

force a refresh