1/To find out what's important in aerospace gas turbine design it's best to see what the pros are working on. This is a thread on the Rolls-Royce Ultrafan development engine, and the features that make it special.

Basically, a window into the industry's future.

Basically, a window into the industry's future.

2/So you know what's coming, we're going to visit the following, from front to back:

1)Gas turbine basics.

2)Composite fan blades & casing.

3)Bypass ratio.

4)Compressors.

5)Lean burn combustion.

6)The power gearbox (a big deal!)

1)Gas turbine basics.

2)Composite fan blades & casing.

3)Bypass ratio.

4)Compressors.

5)Lean burn combustion.

6)The power gearbox (a big deal!)

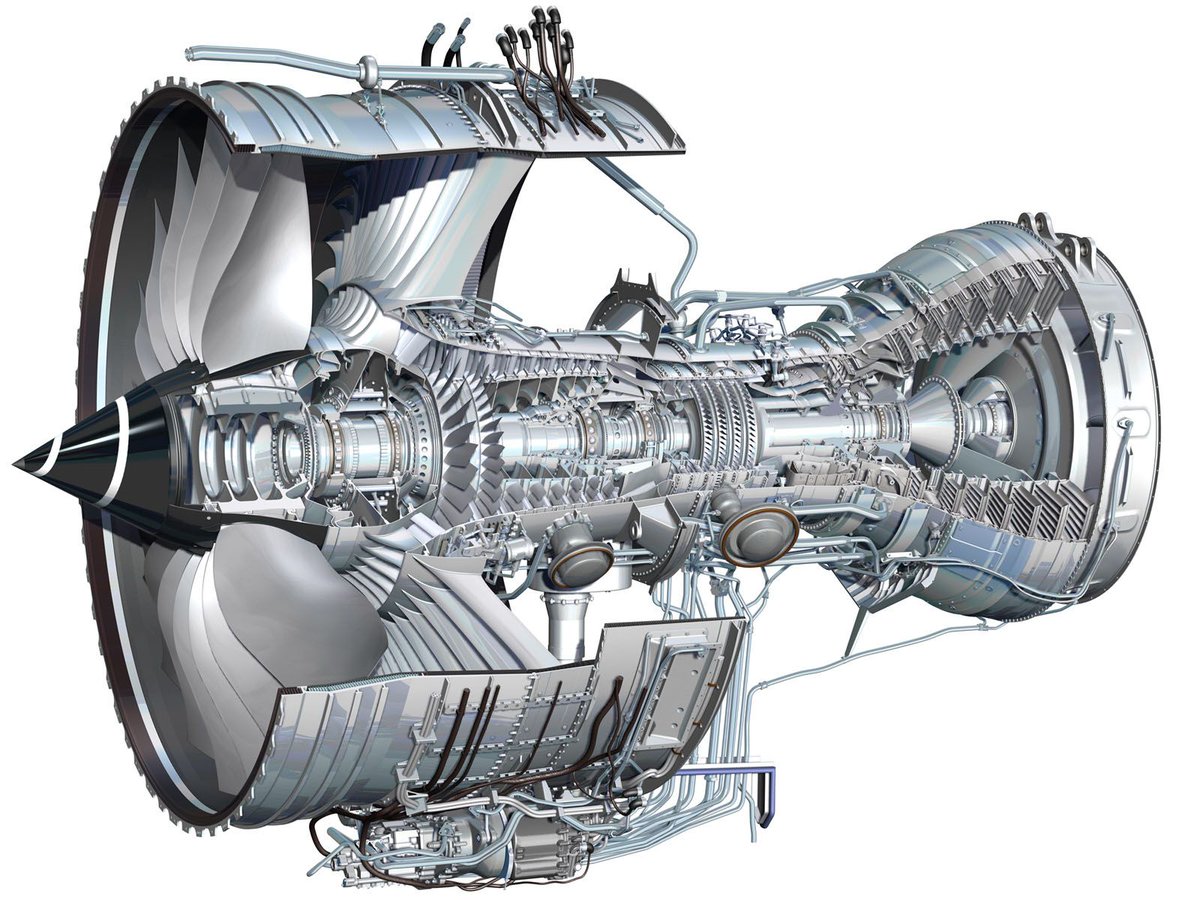

3/Firstly a basic primer.

Turbojets are a Brayton Cycle engine with turbines, hence the 'turbo'. Air is pulled through a compressor, then enters the combustor. A kerosene fuel/ air mix ignites, expands and pushes through the turbine stage, which powers the compressors. A cycle

Turbojets are a Brayton Cycle engine with turbines, hence the 'turbo'. Air is pulled through a compressor, then enters the combustor. A kerosene fuel/ air mix ignites, expands and pushes through the turbine stage, which powers the compressors. A cycle

4/Transmission.

The turbine is typically two stage, and powers two compressor stages. The high pressure turbine powers the high pressure compressor, and the low/ intermediate pressure turbines likewise, through two shafts, one inside the other.

The turbine is typically two stage, and powers two compressor stages. The high pressure turbine powers the high pressure compressor, and the low/ intermediate pressure turbines likewise, through two shafts, one inside the other.

5/Turbofan.

The turbofan adds something new: A bypass stage. A ducted fan, powered by the low pressure turbine, accelerates air around the core but not through it: It's more efficient to push a large volume gently than a small volume roughly. This is almost always useful.

The turbofan adds something new: A bypass stage. A ducted fan, powered by the low pressure turbine, accelerates air around the core but not through it: It's more efficient to push a large volume gently than a small volume roughly. This is almost always useful.

6/3rd shaft.

Uniquely, Rolls-Royce widebody engines employ a 3 shaft configuration, with a 3rd low pressure turbine powering the fan. This is more mechanically complex, and almost bankrupted the company two decades ago, but allows efficient energy management & a modular design

Uniquely, Rolls-Royce widebody engines employ a 3 shaft configuration, with a 3rd low pressure turbine powering the fan. This is more mechanically complex, and almost bankrupted the company two decades ago, but allows efficient energy management & a modular design

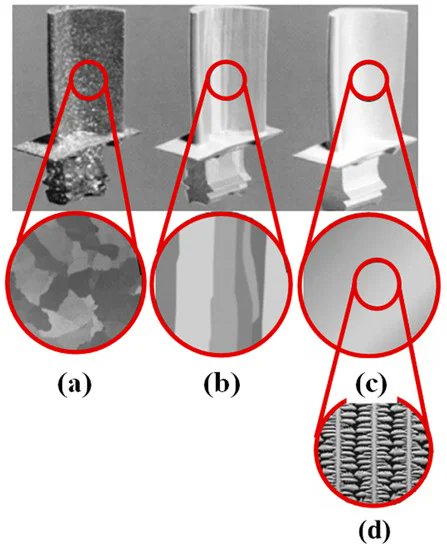

7/The fan: Materials.

RR is late to the game here: GE beat them by a decade to carbon composite fan blades. Not only do they save weight, but they reduce the need for bulky kevlar armour in case of a blade separation (See pic), allowing a composite fan case: Added lightness!

RR is late to the game here: GE beat them by a decade to carbon composite fan blades. Not only do they save weight, but they reduce the need for bulky kevlar armour in case of a blade separation (See pic), allowing a composite fan case: Added lightness!

8/The fan: Legacy titanium.

A shoutout, nonetheless, to the hollow diffusion bonded/ superplastic formed titanium fan blades they replace: High pressure nitrogen blown hollow sparred blades. Inflated like a big titanium balloon. Delightful!

A shoutout, nonetheless, to the hollow diffusion bonded/ superplastic formed titanium fan blades they replace: High pressure nitrogen blown hollow sparred blades. Inflated like a big titanium balloon. Delightful!

9/The fan: Size.

The Ultrafan is aptly named: With a 140" diameter, the fan system is the world's largest. The bypass ratio, or volume of air through the bypass vs the core, is a massive 14:1

For reference, legacy engines have a BPR of 5:1-7:1 and the latest manage 10:1

The Ultrafan is aptly named: With a 140" diameter, the fan system is the world's largest. The bypass ratio, or volume of air through the bypass vs the core, is a massive 14:1

For reference, legacy engines have a BPR of 5:1-7:1 and the latest manage 10:1

10/BPR

High BPR means the efficient fan does more of the work, and requires a lower fan pressure ratio to fly the plane, which makes it more efficient still. This is enhanced further when the engine operating pressure ratio, set by the compressor, is very high. Bringing us to..

High BPR means the efficient fan does more of the work, and requires a lower fan pressure ratio to fly the plane, which makes it more efficient still. This is enhanced further when the engine operating pressure ratio, set by the compressor, is very high. Bringing us to..

11/Compression ratio.

For turbomachinery to work at all, the air must be compressed before the combustor.

Because hot air wastes energy, max thermal efficiency demands that after the combustor we expand as much as possible in the turbine, doing useful work.

For turbomachinery to work at all, the air must be compressed before the combustor.

Because hot air wastes energy, max thermal efficiency demands that after the combustor we expand as much as possible in the turbine, doing useful work.

12/Air hates being compressed. Many stator & rotating stages are needed, because excessive adverse pressure gradients will lead to boundary layer separation, a rotating stall and, potentially, engine surge.

Annoyingly, air also heats as it is compressed, impacting efficiency.

Annoyingly, air also heats as it is compressed, impacting efficiency.

13/But if you can do it with a minimum of losses, your engine benefits.

The direction of progress:

The old workhorse, the Trent 700, had a 38:1 compressor pressure ratio.

The latest T1000, TXWB & T7000 hit 50:1.

The Ultrafan manages an unearthly 70:1! This then enables...

The direction of progress:

The old workhorse, the Trent 700, had a 38:1 compressor pressure ratio.

The latest T1000, TXWB & T7000 hit 50:1.

The Ultrafan manages an unearthly 70:1! This then enables...

14/Lean combustion.

This is a big compromise. Lean burning (a higher than necessary air:Fuel ratio) encourages cleaner burning, however it also lowers average combustion chamber temperature. Gas turbines get more efficient, not less, with increasing turbine inlet temperature.

This is a big compromise. Lean burning (a higher than necessary air:Fuel ratio) encourages cleaner burning, however it also lowers average combustion chamber temperature. Gas turbines get more efficient, not less, with increasing turbine inlet temperature.

15/Lean combustion

However, the adiabatic flame temp of kerosene is 2093C, which is *about* 300-400C higher than the cooled max operating of turbine entry vanes, so there is a narrow band in which lean premixing can help. This band narrows with improved vane cooling & metallurgy

However, the adiabatic flame temp of kerosene is 2093C, which is *about* 300-400C higher than the cooled max operating of turbine entry vanes, so there is a narrow band in which lean premixing can help. This band narrows with improved vane cooling & metallurgy

16/Lean premixing.

In the conventional approach, the fuel is injected directly into the combustion chamber along with about 30% of the incoming air. In lean burn, the premixing occurs with the majority of the air volume before entering the combustor and igniting.

In the conventional approach, the fuel is injected directly into the combustion chamber along with about 30% of the incoming air. In lean burn, the premixing occurs with the majority of the air volume before entering the combustor and igniting.

17/Lean premixing.

Lean fuel/ air premixing is an exacting science which I cannot do justice. It brings risks of vibration, noise, flameouts... Lean premixing is *hard*, but RR demonstrated it in 2018. More complete combustion, reduced CO2 and reduced NOx is the result.

Lean fuel/ air premixing is an exacting science which I cannot do justice. It brings risks of vibration, noise, flameouts... Lean premixing is *hard*, but RR demonstrated it in 2018. More complete combustion, reduced CO2 and reduced NOx is the result.

17/Lean premixing.

Lean fuel/ air premixing is an exacting science which I cannot do justice. It brings risks of vibration, noise, flameouts... Lean premixing is *hard*, but RR demonstrated it in 2018. More complete combustion, reduced CO2 and reduced NOx is the result.

Lean fuel/ air premixing is an exacting science which I cannot do justice. It brings risks of vibration, noise, flameouts... Lean premixing is *hard*, but RR demonstrated it in 2018. More complete combustion, reduced CO2 and reduced NOx is the result.

18/The Power Gearbox.

Finally, the Big Dog. Remember the low pressure turbine stage that drives the fan? Well traditionally that is direct-drive, which presents a problem: The ideal rotation speed of a low pressure turbine stage is nowhere close to that of a large fan stage.

Finally, the Big Dog. Remember the low pressure turbine stage that drives the fan? Well traditionally that is direct-drive, which presents a problem: The ideal rotation speed of a low pressure turbine stage is nowhere close to that of a large fan stage.

19/The ultimate fix: Pratt & Whitney pioneered the geared turbofan in 2008 with the PW1000G, a later variant of which eventually saw service on the A320neo in 2016. Since then the race was on to supersize the technology for the widebody market.

20/The result, the Ultrafan Power Gearbox, is a beast: A planetary gearbox designed to operate at 50MW (or 500 family cars), it's clocked 64MW (87,000 horsepower) in testing. That is legitimately enough to light up a small city.

And it's just for that monster fan stage.

And it's just for that monster fan stage.

21/And that's an incomplete list of gas turbine focal points.

Not mentioned so far: Metallurgical improvements to blades & casings, turbine & compressor bladed discs, electrification vs direct drive, hybrid electrics and hydrogen burning. All of these & more in due course.

Not mentioned so far: Metallurgical improvements to blades & casings, turbine & compressor bladed discs, electrification vs direct drive, hybrid electrics and hydrogen burning. All of these & more in due course.

22/More fun engineering threads:

Turbine blade metallurgy's 'weird trick':

The open-rotor engine:

Turbine blade film cooling:

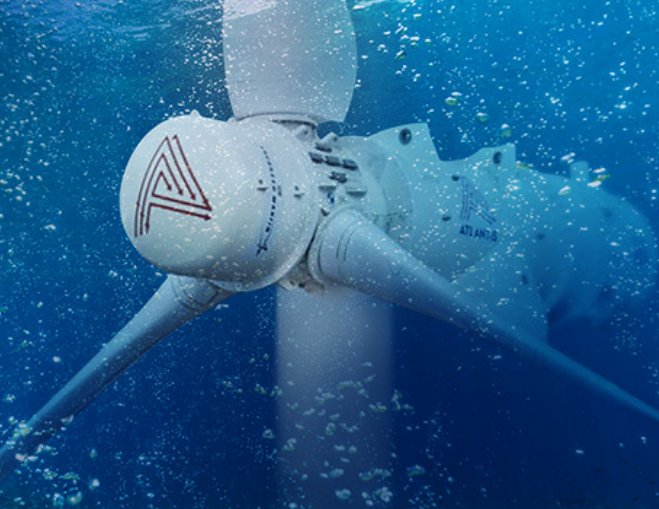

Tidal energy basics:

Turbine blade metallurgy's 'weird trick':

https://twitter.com/Jordan_W_Taylor/status/1602708433081454595?t=ivGOgPTsr3r-BP50MKjbaA&s=19

The open-rotor engine:

https://twitter.com/Jordan_W_Taylor/status/1594005868852514816?t=_qkxlWWwqZmMnERqaAq6wA&s=19

Turbine blade film cooling:

https://twitter.com/Jordan_W_Taylor/status/1596473208487956480?t=74armmuqh1nKB31cYUvkGw&s=19

Tidal energy basics:

https://twitter.com/Jordan_W_Taylor/status/1598247533310279681?t=QnOme_huZWtw5Yd4NGII-A&s=19

• • •

Missing some Tweet in this thread? You can try to

force a refresh