1/ Wheels vs tracks: a short series of threads on relative merits of each, starting with one on comparative design efficiency, in terms of volume.

TLDR: tracks are inherently more compact configurations allowing lower & more efficient profiles for the same internal volume

TLDR: tracks are inherently more compact configurations allowing lower & more efficient profiles for the same internal volume

2/ Quick point of order: these threads are to talk about comparative strengths & weaknesses outside the normal framing of 'which is best in a muddy field' and think about a few other angles that don't always get acknowledgement.

3/ Assumptions – comparisons assume we are comparing equivalent vehicles seeking peer weights, internal volumes, automotive performance etc. As that’s never really the case, the comparisons are more conceptual and generic than reflecting vehicle A vs vehicle B.

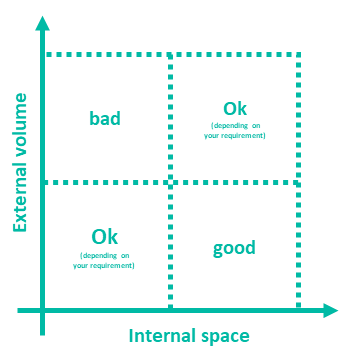

4/ It is hopefully self-evident that the need for the maximum possible internal volume is desirable for an AFV, however this has to be balanced against the need to minimse the external dimensions of the vehicle...

5/ ...to curtail weight, minimise silhouette and stay within maximum practical dimensions (also referred to as critical dimensions - for more on that, see my thread on critical dimensions here:

https://twitter.com/JonHawkes275/status/1262645161298886656?s=20&t=7OkVuH2vcpYtNFu09730-Q)

6/ So, you want to be as efficient as possible in this context. "Packaging efficiency" is a term representing the ratio of usable internal volume of an AFV to the overall vehicle envelope volume, which reflects the efficiency of the space utilisation in the vehicle.

7/ And by this measure, tracked AFV are more space efficient than wheeled AFV. That's the TLDR of the thread really but read on for some examples and pictures. Modern tech has narrowed the gap, but at not insignificant cost and complexity burden.

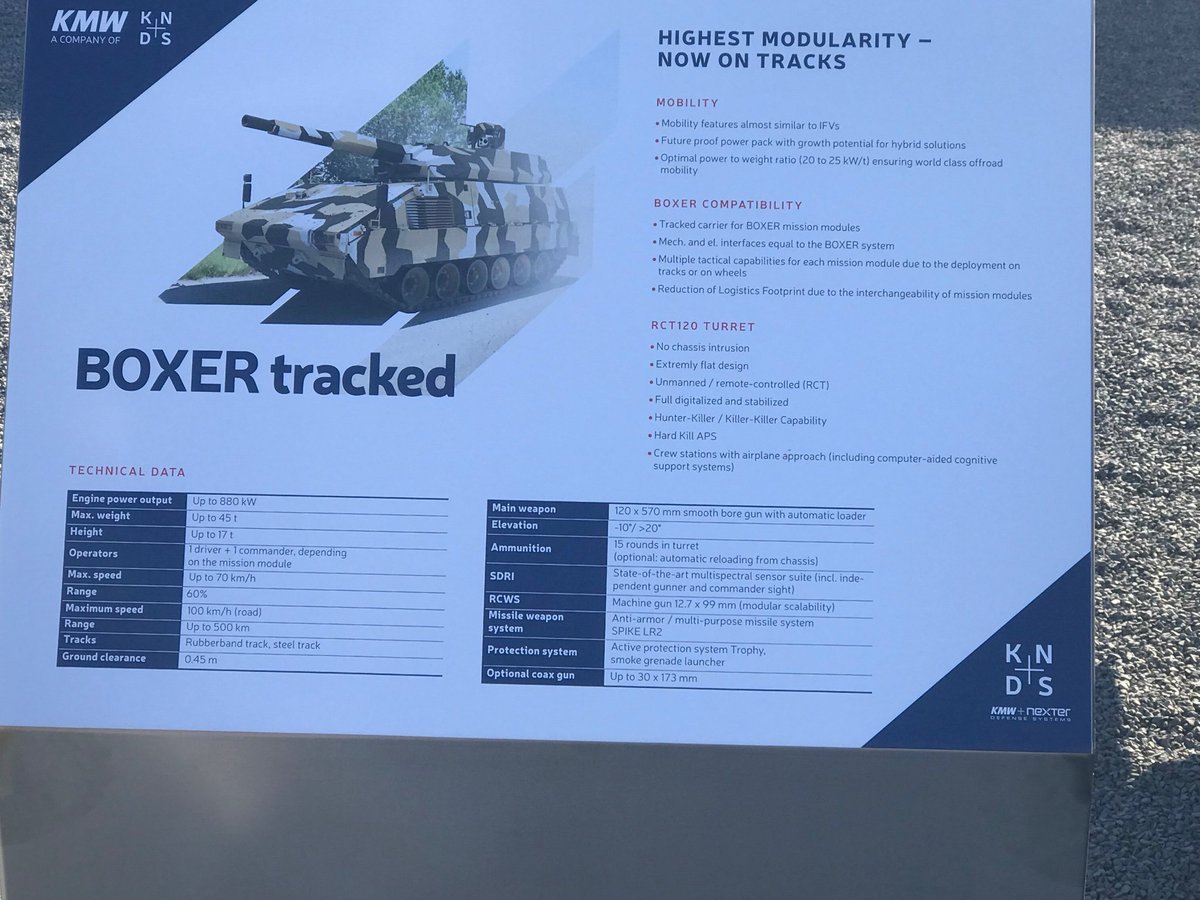

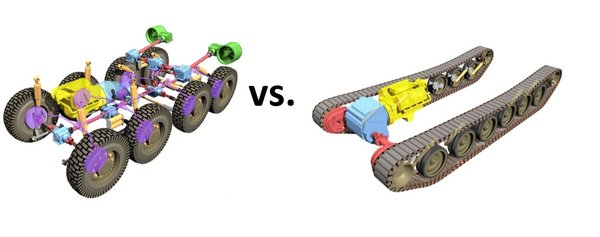

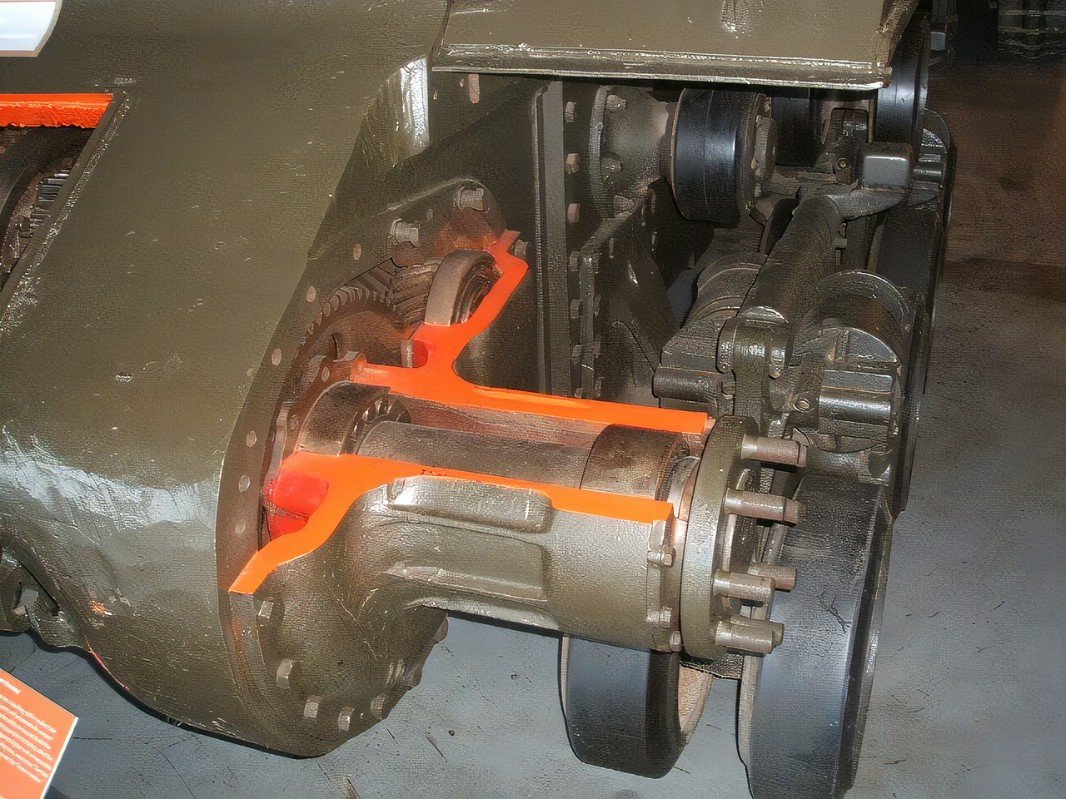

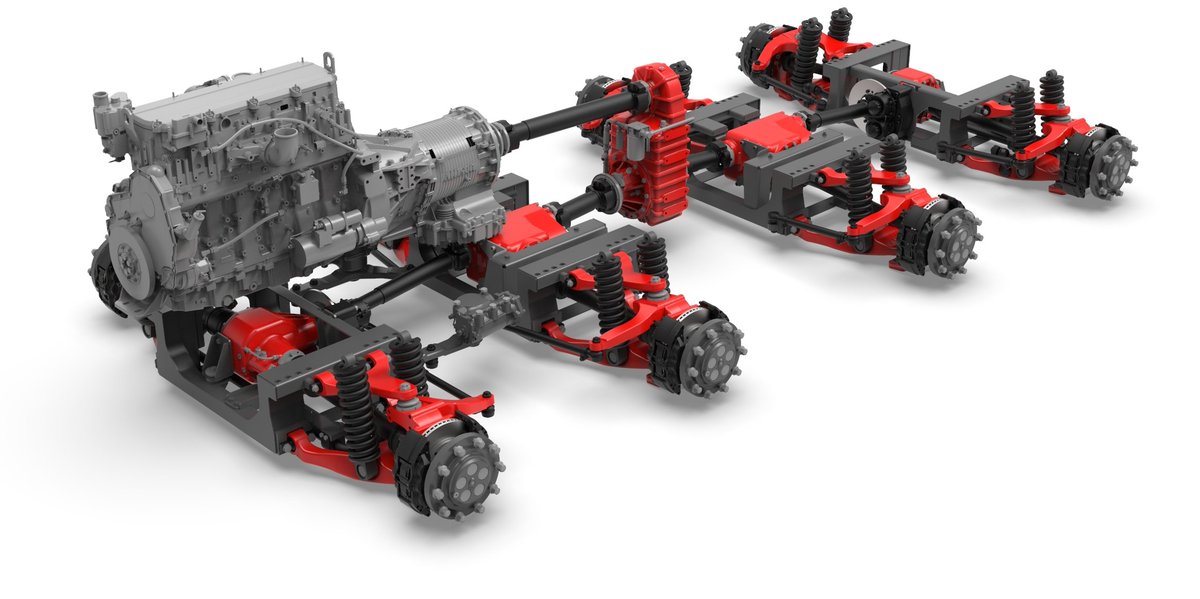

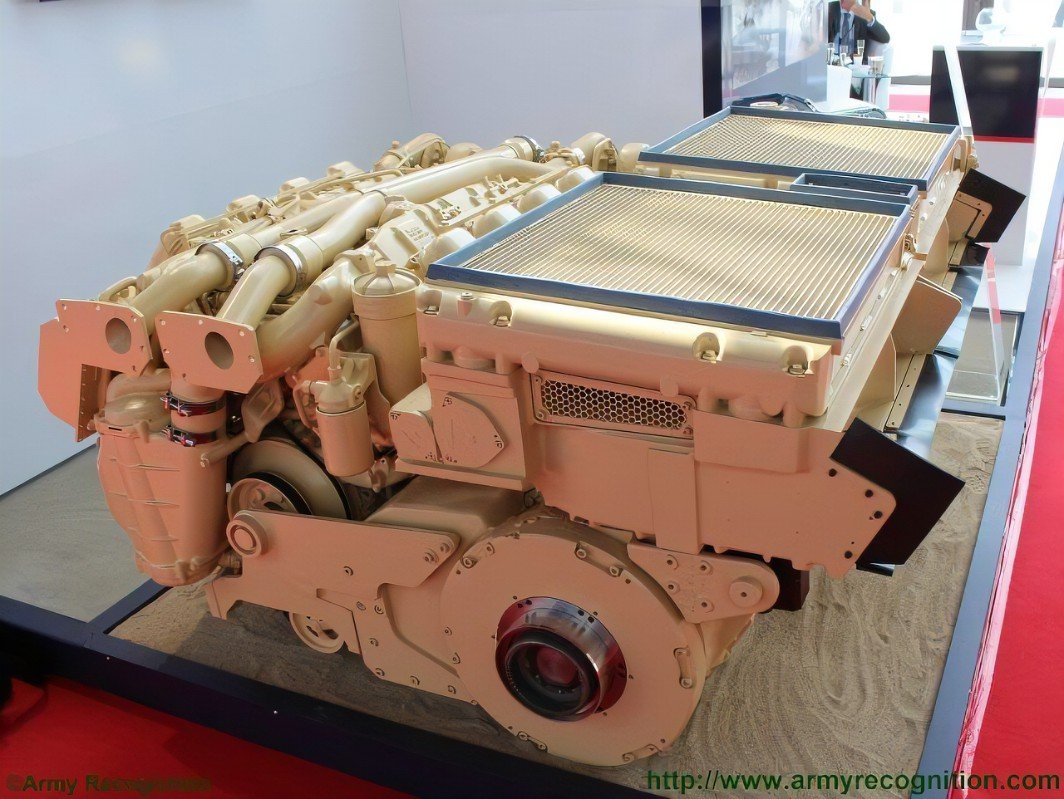

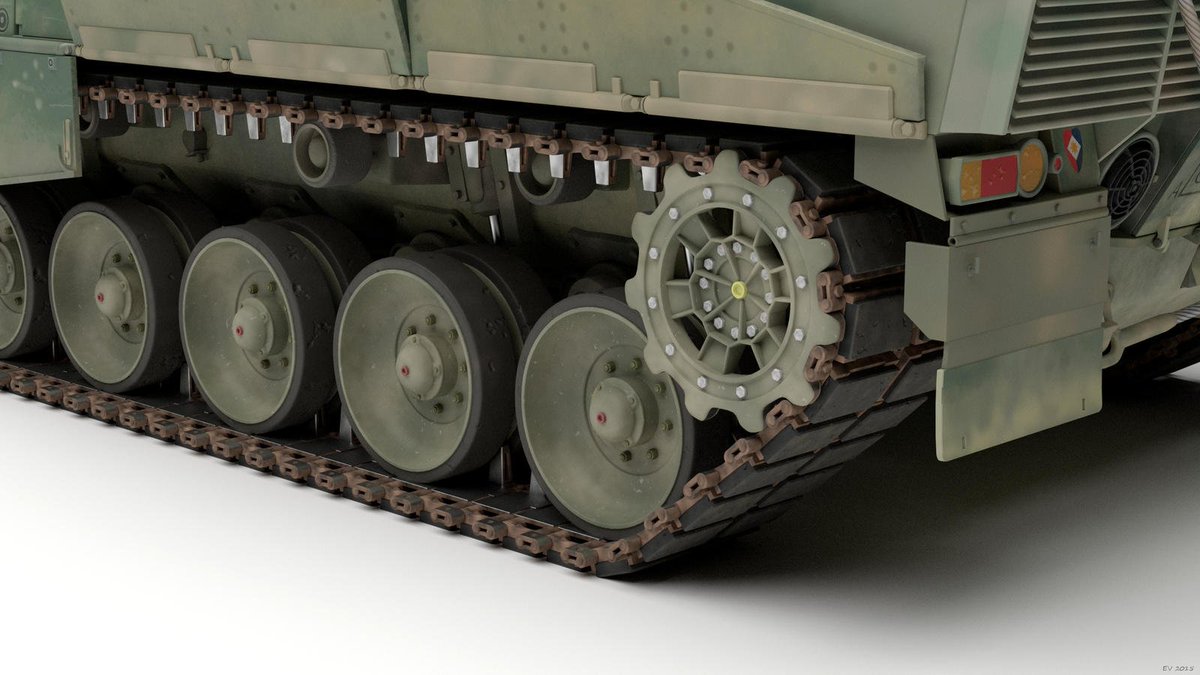

8/ Driveline: Tracked AFV transfer their drive a very short distance from engine to transmission, to final drives, to sprockets. There are no complicated moving shaft joints as the drive is fixed from one component to the next. From a space perspective, its very efficient.

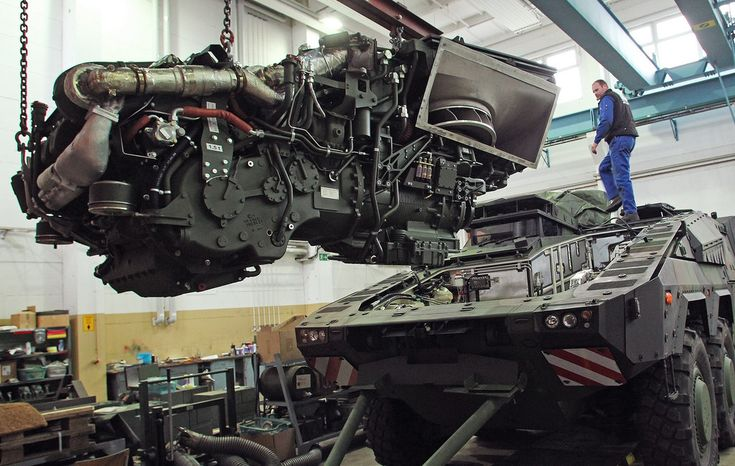

9/ Wheeled AFV have to transmit power to some or all wheels, requiring lots of jointed shafts, cross- & inter-axle differentials and loads of moving parts. That also means you have an axle exposed and able to be damaged...

10/ ...so some vehicles use portal axles to raise them higher, but at the cost of a rather complicated pile of engineering behind every wheel, which has reliability and redundancy risk, and costs a lot more.

11/ Drivetrain volume: Tracked AFV fit almost everything into the pack or closely coupled - transmission, braking, steering - all nice and compact. Only suspension is not tightly integrated, more on that in a minute.

12/ Wheeled AFV, much like a road car, have to place this kit throughout the vehicle. Transmission is usually well integrated with engine, but braking & steering is a whole package attached to all the relevant wheel stations, again at space & complexity cost.

13/ They also have to run the drive through the vehicle to all the wheels. These drive tunnels can be a significant space claim from the available internal volume, especially once you add differentials etc.

14/ Powertrain volume: Tracked AFV generally need more power output than a wheeled AFV for the same performance (speed/acceleration) due to tracks being quite inefficient in terms of rolling resistance. They also need bigger fuel tanks to achieve the same range. This...

15/ ...need for bigger engines and fuel tanks can reduce or even nullify the advantage of the more compact tracked drivetrain, but generally they are at worst peer to one another, due to all the wheeled suspension and steering issues coming up.

16/ Steering: Tracked AFV steer via skid mechanisms (more info in my thread on tracked vehicle steering here:

https://twitter.com/JonHawkes275/status/1314141082763100160?s=20&t=xUoHnkVttcsMim1M2_SEZg) which require no hull intrusion to function.

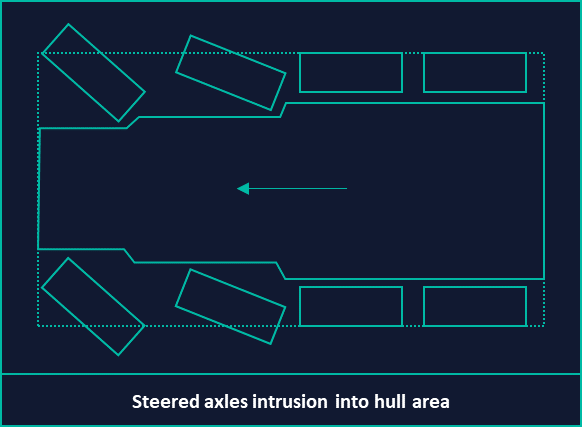

17/ Wheeled AFV generally don't steer all axles, partially because its not needed, but also because it adds a lot of complexity. Wheel articulation angles required for a good turning circle result in a lot of hull intrusion. The bigger the wheel (desireable for...

18/ ...better trafficability in soft terrain) the bigger the intrusion & the worse the impact. Some wheeled AFV have used skid steer to eliminate this issue, but they are rare & have host of new issues that they introduce. France's AMX-10RC is probably the most well known.

19/ Wheel size: Tracked AFV road wheels dont use pneumatic tyres, and are more compact than a wheeled AFV with similar weights, dimensions & mean maximal pressure (MMP). That allows much more suspension travel for the same space, or the same travel in much more compact space

20/ Suspension intrusion: All of these factors add up to a much more compact drivetrain in tracked AFV than wheeled AFV, especially when comparing with driven and steered wheeled axles.

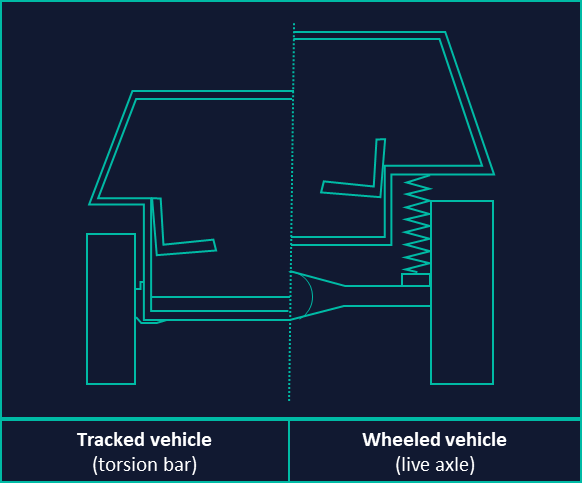

21/ Compare here a tracked AFV (left) with torsion bar suspension with a wheeled AFV with a basic live axle suspension (admittedly basic by modern standards). Same internal volume, vastly different external profiles.

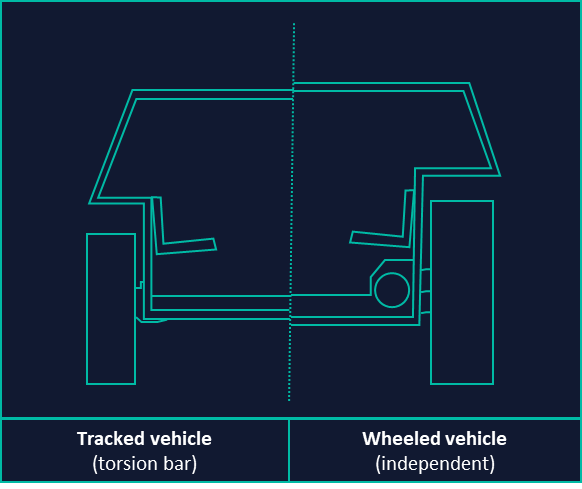

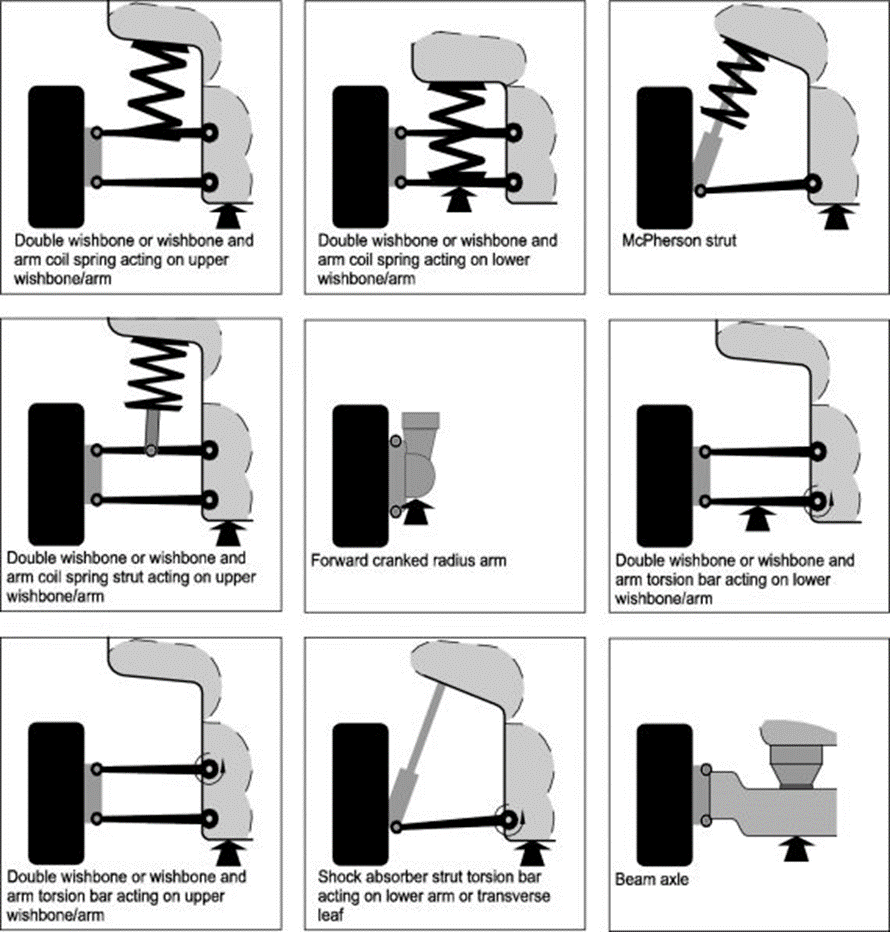

22/ To be a bit fairer, consider the same tracked AFV versus something a bit more modern on the wheeled side with some form of fully independent McPherson or double wishbone suspension. The height has been improved, but at even greater cost to internal volume.

23/ Basically no matter what you do, any wheeled vehicle suspension configuration has a lot of space cost behind the wheel, and in essentially all cases its considerably more than a tracked equivalent.

24/ You could put hydrogas-type suspension on the tracked vehicle to gain more height saving, but at the modest cost of width, so its much of a muchness. In any case, tracks always win this comparison.

25/ And that’s that for a volumetric perspective. Tracks win!

End Note: These will all get gathered up, written a bit more long form, and made into a post over on the blog soon™

End Note: These will all get gathered up, written a bit more long form, and made into a post over on the blog soon™

26/ Next time: obstacle negotiation.

Beyond that: a bit of automotive performance beyond just soft soil; cost and a bit of logistics; survivability considerations; and finally some odds and ends that don’t deserve a whole thread each. /end

Beyond that: a bit of automotive performance beyond just soft soil; cost and a bit of logistics; survivability considerations; and finally some odds and ends that don’t deserve a whole thread each. /end

• • •

Missing some Tweet in this thread? You can try to

force a refresh