1/ Wheels vs tracks: a short series of threads on relative merits of each, continuing with another on the ability to negotiate trenches.

TLDR: tracks are better at trench crossing than wheels, and for wheels the fewer the # axles, the worse it gets.

TLDR: tracks are better at trench crossing than wheels, and for wheels the fewer the # axles, the worse it gets.

2/ Quick point of order: these threads are to talk about comparative strengths & weaknesses outside the normal framing of 'which is best in a muddy field' and think about a few other angles that don't always get acknowledgement.

3/ Final point of clarity – comparisons assume we are comparing equivalent vehicles seeking peer weights, internal volumes, automotive performance etc. As that’s never really the case, the comparisons are more conceptual and generic than reflecting vehicle A vs vehicle B.

4/ So, Trench crossing: In general terms, tracked vehicles have a good capability. For 8x8s its reasonable, problematic with 6x6 and poor with 4x4.

5/ So once more tracks win out, again because that uniform surface of the tracks makes it much easier to overhang and then climb out of the other side of a trench.

6/ The tracks act to contain the road wheels, preventing them dropping into the trench so far as to immobilise the vehicle, and then provide a form of ramp for the vehicle to drive up and out.

7/ These characteristics mean tracked vehicles can actually benefit from crossing at speed rather than slowly, but you need to be very careful the conditions are right before you do!

8/ Secondly, the sprocket/idler being projected ahead of the roadwheels creates an effective lengthening of the running gear, allowing the vehicle to reach a little further.

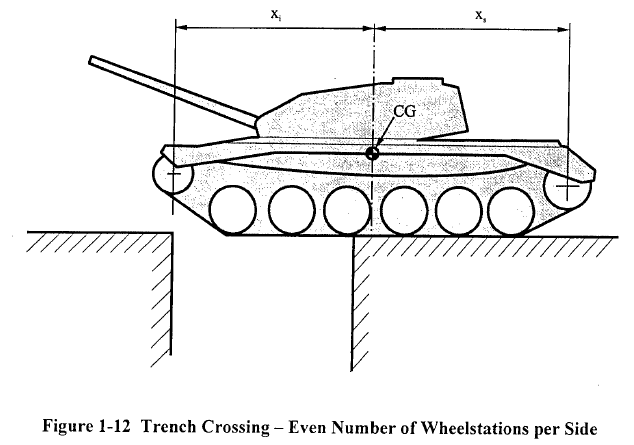

9/ An interesting factor is number of road wheels, or rather whether odd or even. Odd mean CoG ideally needs to be above centre wheelstation, allowing the vehicle to pivot about this point.

10/With even numbers, a central CoG sees the vehicle pitch into the trench as soon as the last frontal wheel ahead of CoG passes over the gap. The further forward the CoG is, the worse this becomes.

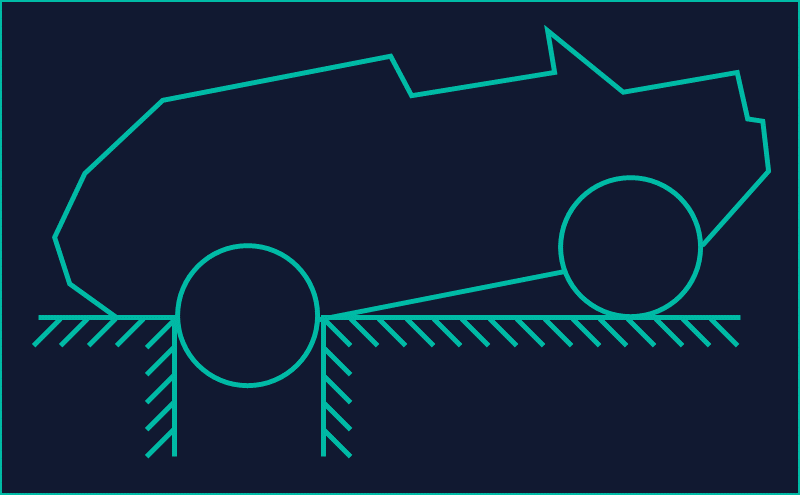

11/ For wheeled AFV again depends on # axles. 4x4s are worst, once front axle drops into the trench youre unlikely to get out, as you are now facing a step climb of >55% tyre diameter with most of the AFVs weight wedging it in place. This...

12/ ...constraint was talked about in the last thread

https://twitter.com/JonHawkes275/status/1606208650221178882?s=20&t=a6Xt11AvAYxNM5TgsJKnPg. Effectively, 2-axle AFV dont have a trench crossing capability.

13/ 3-axle (6x6) is similar, with a (not) fun see-saw effect. If the front wheel drops in, the vehicle will still get stuck. But if the rear wheel drops in as it exits, it may also get stuck. That centre axles needs good suspension travel to avoid this pitfall.

14/ To try and mitigate these problems, wheeled AFV can approach a trench obliquely, preventing the condition where an entire axle drops in at once. This is by no means an assured method, however.

15/ 4-axles (8x8) is much better, with the limitation being a trench where the front 2 axles both fall into the trench, effectively creating the same issue as with a 4x4, just grouping the axles.

16/ ≥5 -axle vehicles are very rare, but again follow the expanding model that is clear – better than the one that came before, but again once tipped into the trench it is likely to be stuck.

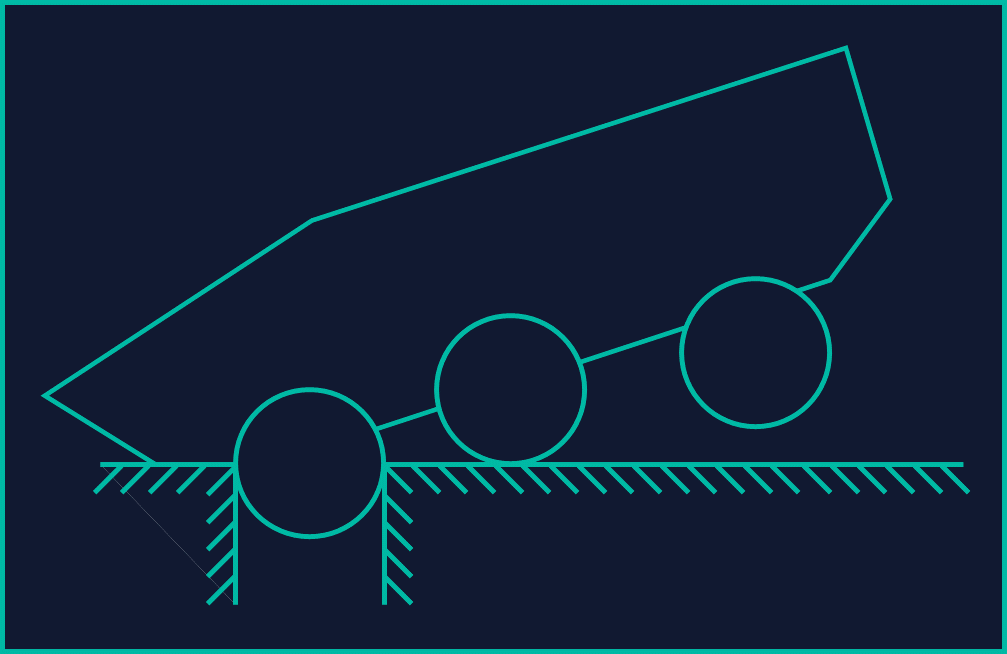

17/ Where tracked AFV want to avoid projections beyond sprocket to make sure tracks contact obstacles, wheeled AFV may benefit from a projected nose.

18/ When toppling into a trench it prevents the wheels falling too far into it and providing sufficient torque, the vehicle can drive its nose up the far side of the trench and then climb out as a low step obstacle.

19/ In any case, the result is that tracked AFV have a much better time of it, thanks in large part to the fact they are laying a quasi-mini bridge (though better to have a real one) to run their wheels over.

20/ Be under no illusions though, tracks are better, but ditches and trenches remain perilous for AFV, and a very effective way of stopping tanks dead. A bridge is always better (@thinkdefence)

20/ And that’s that for trench crossing. Tracks win again!

End Note: These will all get gathered up, written a bit more long form, and made into a post over on the blog soon™.

End Note: These will all get gathered up, written a bit more long form, and made into a post over on the blog soon™.

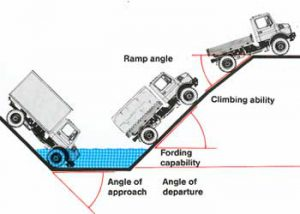

21/ Next time: more obstacles – ground clearance & approach/departure angles.

Beyond that: cost and a bit of logistics; survivability considerations; and finally some odds and ends that don’t deserve a whole thread each.

Beyond that: cost and a bit of logistics; survivability considerations; and finally some odds and ends that don’t deserve a whole thread each.

• • •

Missing some Tweet in this thread? You can try to

force a refresh