Mineralization, or mineral trapping, has become a catch-all term in carbon removal. However this one term can mean several technologies or processes depending on the method. A general overview 🧵

Mineralization, in the CDR context, is the reaction that moves CO2 from the fluid state (dissolved in water, supercritical, gaseous) into a solid state carbonate.

It can be lumped into one of two, broad, categories:

1. In-situ

2. Ex Situ

It can be lumped into one of two, broad, categories:

1. In-situ

2. Ex Situ

In-situ mineralization occurs in the subsurface, thus "in" situ

This process is currently being done by @CarbFix in Iceland, and by @4401earth in Oman. It can involve injecting CO2 dissolved in water, called a seltzer @lacroixwater, into mafic and ultra mafic geologic formations

This process is currently being done by @CarbFix in Iceland, and by @4401earth in Oman. It can involve injecting CO2 dissolved in water, called a seltzer @lacroixwater, into mafic and ultra mafic geologic formations

These projects use basalts and peridotites respectively, but other mafic/ultra-mafic rocks include: olivine, diabase, gabbro, dunites, serpentites, amongst others

All the rocks have relatively high Mg, Ca, or Fe content and the proportion gives the mafic vs ultra distinction.

All the rocks have relatively high Mg, Ca, or Fe content and the proportion gives the mafic vs ultra distinction.

The Mg, Ca, and/or Fe ions of mafic/ultra-mafic are important because they react with the CO2 to form the solid carbonate.

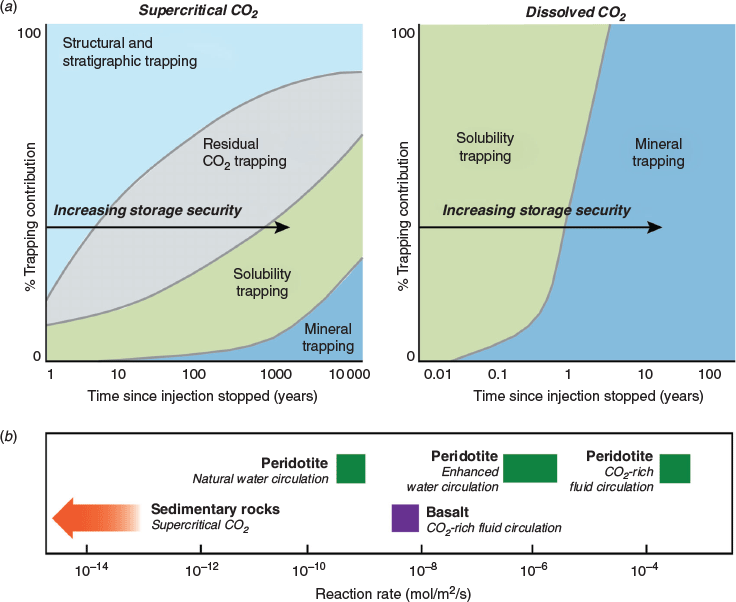

These reactions are faster than sandstone/sedimentary basins, whether they are quartz-based or calcite/dolomite cemented.

These reactions are faster than sandstone/sedimentary basins, whether they are quartz-based or calcite/dolomite cemented.

Some CO2 is mineralized in sedimentary basins. The difference is in time it takes to happen, but it's mineralization all the way down.

In the subsurface, CO2 can also be trapped by a cap rock (structural), in pore space (residual) or in formation fluid (solubility).

In the subsurface, CO2 can also be trapped by a cap rock (structural), in pore space (residual) or in formation fluid (solubility).

Ex-situ mineralization occurs on the surface, thus "ex"

This is can one on mine tailings, alkaline industrial wastes but is sometimes used to described "enhanced weathering", or mineralization in concrete.

This is can one on mine tailings, alkaline industrial wastes but is sometimes used to described "enhanced weathering", or mineralization in concrete.

Mine tailings are generated during

the extraction and production of asbestos, chromite, diamond, nickel, platinum-group metals, and talc.

These tailings react passively with atmospheric CO2 to produce carbonate minerals under natural conditions.

@carbinminerals

the extraction and production of asbestos, chromite, diamond, nickel, platinum-group metals, and talc.

These tailings react passively with atmospheric CO2 to produce carbonate minerals under natural conditions.

@carbinminerals

Alongside mining, many industrial processes also

generate high-surface-area materials that could be potential sources of Mg2+, Fe2+, and Ca2+ cations. Industrial byproducts such as fly ash, cement kiln dust, and iron and steel slag.

generate high-surface-area materials that could be potential sources of Mg2+, Fe2+, and Ca2+ cations. Industrial byproducts such as fly ash, cement kiln dust, and iron and steel slag.

Enhanced weathering is a process that aims to accelerate the natural weathering by spreading finely ground silicate rock, such as basalt, onto surfaces which speeds up chemical reactions between rocks, water, and air. It removes CO2 as carbonate minerals or ocean alkalinity.

Companies doing EW @LithosCarbon, Travertine, Silicate, Eion

Ex-situ is also used to described mineralizing CO2 in concrete like what @CarbonCure, @Carbon_Built or Neustark is doing.

There are benefits and challenges with every method of mineralization. Each method has vastly different availability, monitor/report/verification certainty, cost etc. but each will play a roll in removals and carbon market places going forward.

Regardless of in-situ or ex-situ a CO2 rich fluid is interacting with a mineral to create a stable carbonate. But as always the devil is in the details.

No comment on this thread about the benefits and challenges of each but mineralization is gaining interests and we should be clear the fate of the carbonate product (ex vs in) and the method in which that fate is achieved (technology used).

• • •

Missing some Tweet in this thread? You can try to

force a refresh