⚙️ Tracked Boxer and the UK

---

Continuing yesterday's thread looking at some options for medium tracked vehicles that can be:

a) introduced "immediately" to the British Army; and

b) How that slots into the British Industry and Army.

Video © @KM_GmbH used without permission.

---

Continuing yesterday's thread looking at some options for medium tracked vehicles that can be:

a) introduced "immediately" to the British Army; and

b) How that slots into the British Industry and Army.

Video © @KM_GmbH used without permission.

⚙️ Unlike M2 Bradley, there are no desert storage depots for the in-development Tracked Boxer.

There are, however, 5 production lines for the wheeled Boxer MRAV and a pooled supply chain run through OCCAR:

2 lines in Germany

1 in the Netherlands

2 in the UK

~1 in Australia also

There are, however, 5 production lines for the wheeled Boxer MRAV and a pooled supply chain run through OCCAR:

2 lines in Germany

1 in the Netherlands

2 in the UK

~1 in Australia also

⚙️ Why the sudden thought experiments surrounding medium tracked vehicles for the UK? Yesterday's thread covers part. But to expand there is still a land war ongoing in Europe, grumblings about budgets and I have a fear of knee-jerk UOR procurements.

https://twitter.com/TotherChris/status/1620375736187224066

⚙️ There are many options. We looked at M2 Bradley yesterday. This thread is about Tracked Boxer.

https://twitter.com/TotherChris/status/1620375743825055744

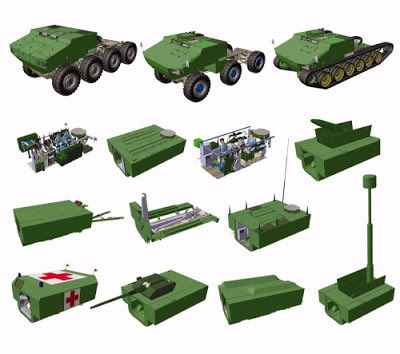

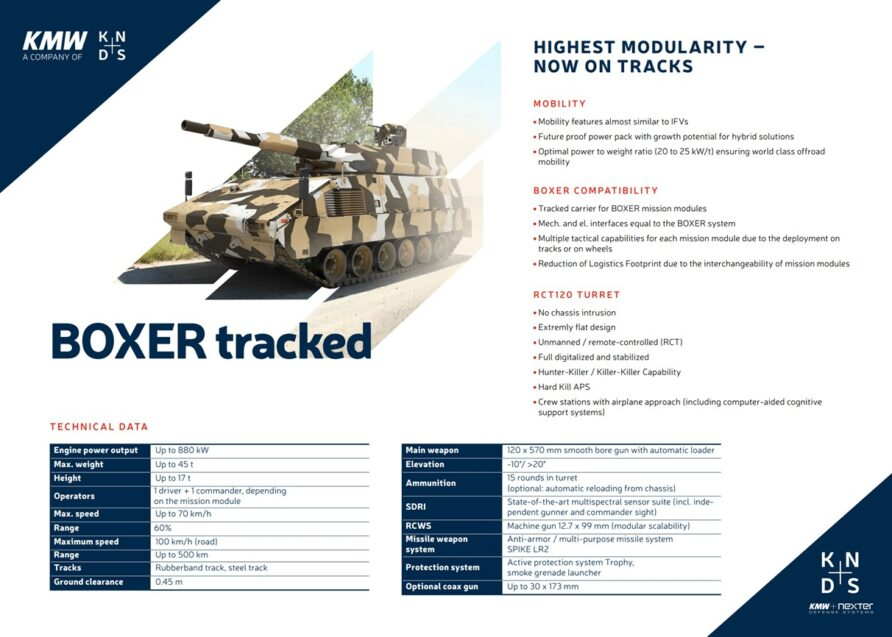

⚙️ Unveiled at Eurosatory 2022 but in development for some time before that, Tracked Boxer displayed two important features to an audience in the know:

➡️ A full recoil 120mm smoothbore uncrewed turret module; and

➡️ A Tracked Drive Module able to accept ANY Boxer Mission Module

➡️ A full recoil 120mm smoothbore uncrewed turret module; and

➡️ A Tracked Drive Module able to accept ANY Boxer Mission Module

⚙️ This is the USP. Any Mission Module developed for a given Role and carried by Boxer MRAV can now also be deployed by Tracked vehicle where the mobility/manoeuvre consideration favours it.

⚙️ This is not a new concept, the Anglo-Swedish SEP was briefly considered after the UK pulled out of MRAV initially also considered this approach but never cracked the implementation before cancellation.

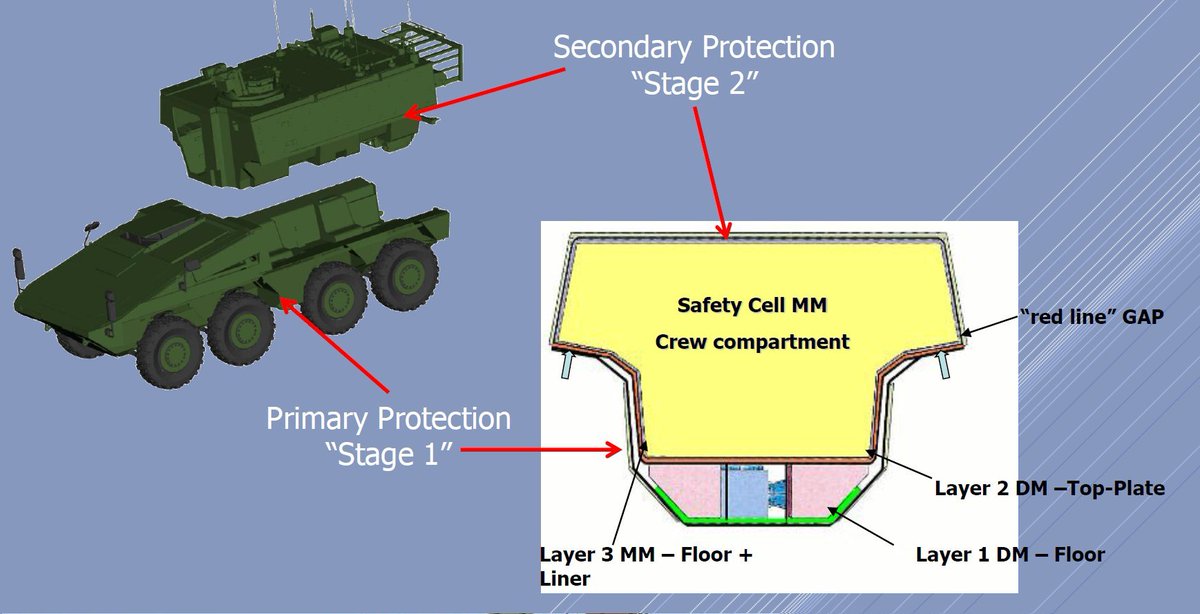

⚙️ Instead this is a specially designed Tracked Drive Module that resolves issues with length vs width ratios. It comes in overall *smaller* than a Lynx or Redback (!).

Note additional width available for armour packs or storage.

Also note 8 dismounts under the 120mm turret...

Note additional width available for armour packs or storage.

Also note 8 dismounts under the 120mm turret...

⚙️ Similar to the Boxer Drive Module, it has also been designed to use the additional layers as protection. Spaced armour and layers built in, before armour packs are added. I was also guilty of misperceiving this as parasitic until very knowledgeable folks explained the system.

⚙️ Industrially, the UK is scaling to manufacture the majority of a Boxer, Drive and Mission Modules, right now. The British Army are also leveraging OCCAR and the other Production Lines to accelerate initial purchases built to an identical, common, spec.

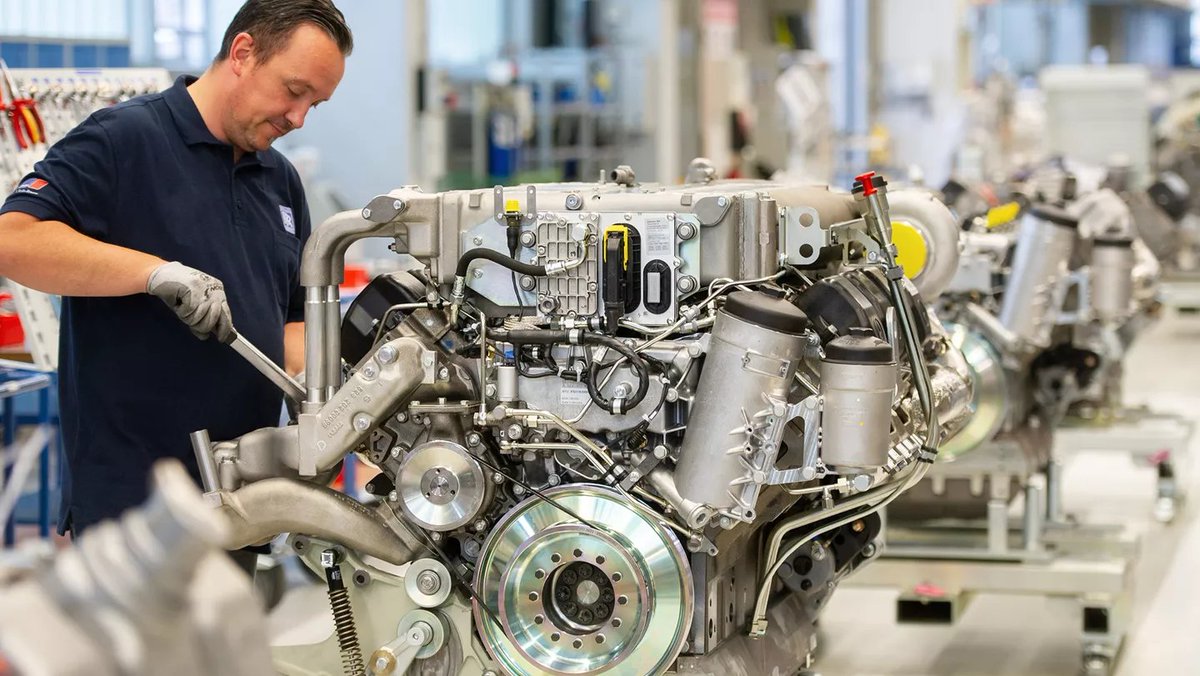

⚙️ Horstman suspension and angled gearboxes with technology transfer from RENK, Rolls-Royce manufacturing Series 199 engines at East Grinstead where they manufacture Series 1600engines for Hitachi trains (made in the North East).

⚙️ Critically, Boxer is the heaviest weight armoured steel hull construction going on in the UK. It is not an easy line to ramp up. Maintaining armoured steel integrity through bending and welding is skilled, represented by certification that takes time and hard work to earn.

⚙️ Into this existing chain of hull welding Tracked Boxer would be dropped. Leveraging controls, electronics, cabling, lights, periscopes from the Boxer MRAV supply chain. Add in Horstman suspension and transmission, Soucy CRT or William Cook tracks...

⚙️ The prototype presented at Eurosatory has an MTU 880 series engine as KMW had one to hand, however a move to a 199 Series, preferably the TE20 if possible, would allow engine swaps with Boxer MRAV. TE21 commonality with Ajax. A Cummins VTA-903 is also possible (see M2 thread).

⚙️ How does the Army acquire Tracked Boxer immediately?

It doesn't.

Boxer MRAV delivery is accelerated instead, along with development of the Mission Modules.

As Tracked Boxer arrives, Mission Modules are moved off, shared or rotated between MRAV or Tracked Drive Modules.

It doesn't.

Boxer MRAV delivery is accelerated instead, along with development of the Mission Modules.

As Tracked Boxer arrives, Mission Modules are moved off, shared or rotated between MRAV or Tracked Drive Modules.

⚙️ The Army stays on target delivering fully fleshed out and supported Mechanised Manoeuvre Units and pivots on these as the backbone until Tracked Boxer is ready. Units gain "Deep Expertise" with the systems. Production Lines mature and carries that skill to the Tracked version.

⚙️ By fully fleshed out, we mean moving beyond the IOC capability of APC's to turreted, fires, recce, SHORAD and beyond.

⚙️ These now-matured or maturing Mission Modules are then moved over from the MRAV Drive Module to the Tracked Drive Module as desired.

⚙️ The beauty of the "accelerating Boxer" approach to delivering a medium tracked vehicle is the low risk and lack of upsetting apple carts. Warrior carries on until EOL, no decision on Ajax needs to be forced. 1,000's of personnel do not have to change direction radically.

⚙️ Measured. Steady. Hold the line.

The backing of 5 production lines and redundant supply chains. No need for a UOR splurge here beyond funding further supply line acceleration and Mission Module procurement.

Leaves the UK with one hell of an IP held, exportable AFV industry.

The backing of 5 production lines and redundant supply chains. No need for a UOR splurge here beyond funding further supply line acceleration and Mission Module procurement.

Leaves the UK with one hell of an IP held, exportable AFV industry.

⚙️ Accelerating Boxer also provides the UK with options surrounding Warrior and Ajax should the Army and MOD choose to exercise them. Takes the pressure off.

Here's my personal preference for the two fleets:

Here's my personal preference for the two fleets:

https://twitter.com/TotherChris/status/1620375823676239873

⚙️ Please read @thinkdefence's piece on what other components of an AFV can be new-built in the UK here, many already supplying the Boxer MRAV programme:

thinkdefence.co.uk/2023/01/lets-b…

thinkdefence.co.uk/2023/01/lets-b…

⚙️ Yesterday's thread on the M2 Bradley can be found here for further reading:

https://twitter.com/TotherChris/status/1620375732768890881

⚙️ Original, higher quality video from the first tweet here:

/FIN

• • •

Missing some Tweet in this thread? You can try to

force a refresh