The strange story of the Demon UAV and fluidic thrust vectoring.

Or: How to fly a plane with no control surfaces at all...

Or: How to fly a plane with no control surfaces at all...

Many years ago in the University of Manchester I came across a project called FLAVIIR. I wasn't personally involved, but I was interested: It's primary focus was fluidic flight control: Flight control with no flaps and no mechanical thrust vectoring.

Simple. Stealthy. Elegant.

Simple. Stealthy. Elegant.

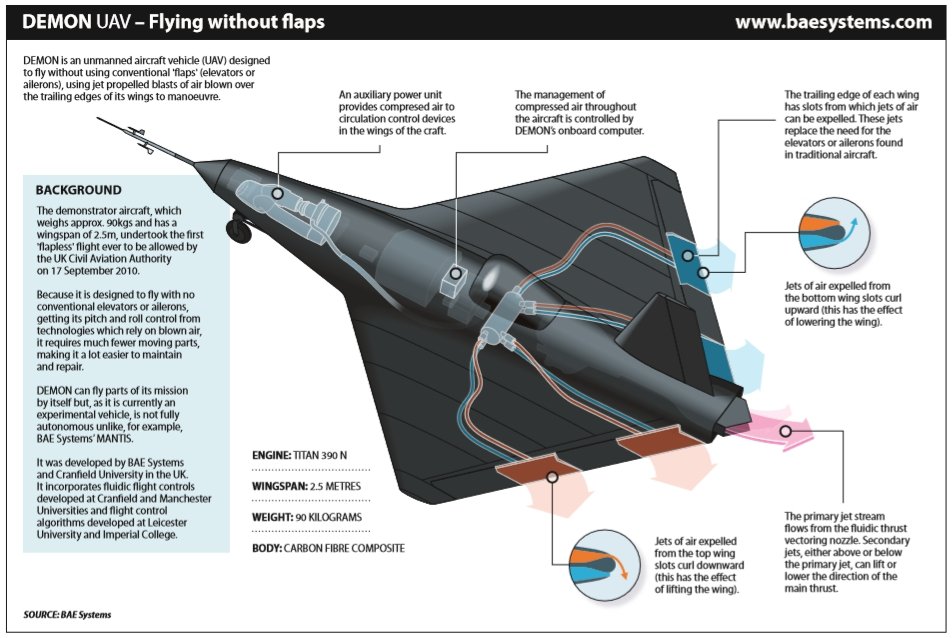

The FLAVIIR project was a 6 year project between BAE Systems, Cranfield University and my alma mater, Manchester University. It featured a grab bag of blue sky technologies that would be developed into a flight ready UAV.

The most notable were fluidic flapless flight controls.

The most notable were fluidic flapless flight controls.

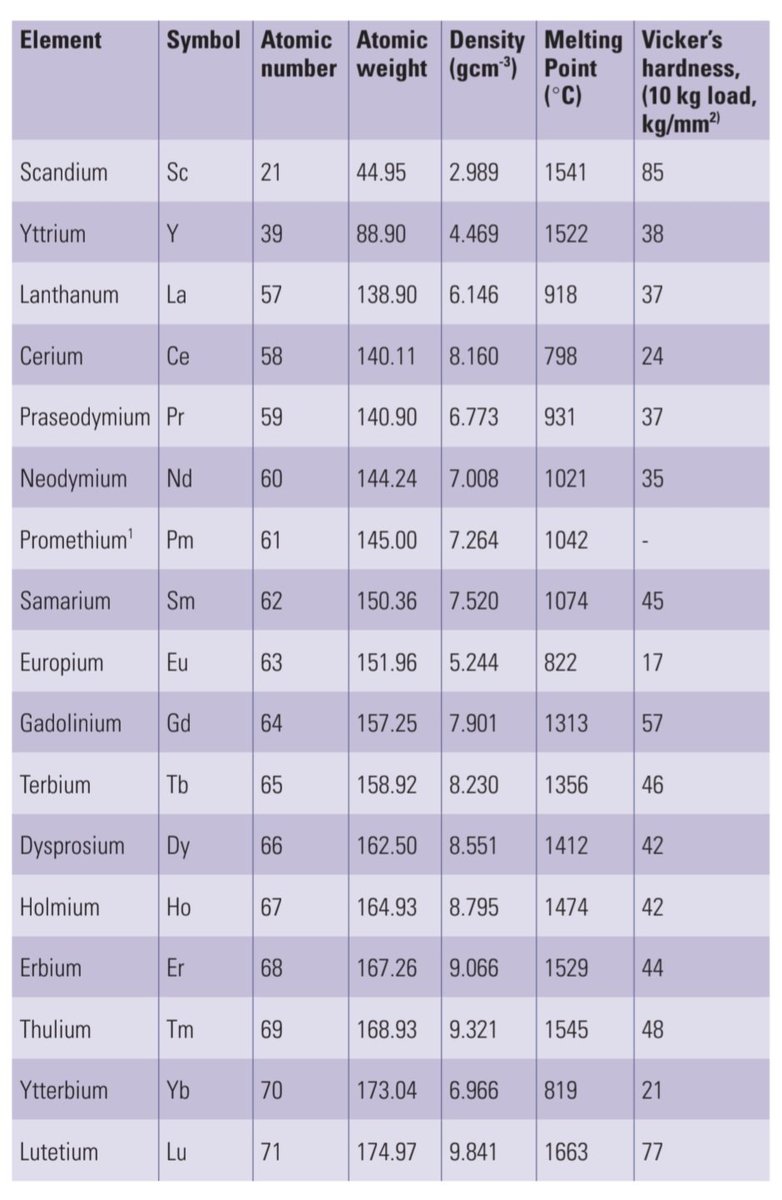

The fluidic controls were twofold: Coanda effect blown flaps to replace mechanically actuated flaps and ailerons in roll, and fluidic thrust vectoring to replace elevators/ mechanical thrust vectoring in pitch, and rudders in yaw.

So why fluidic thrust vectoring? Why not a conventional mechanical system?

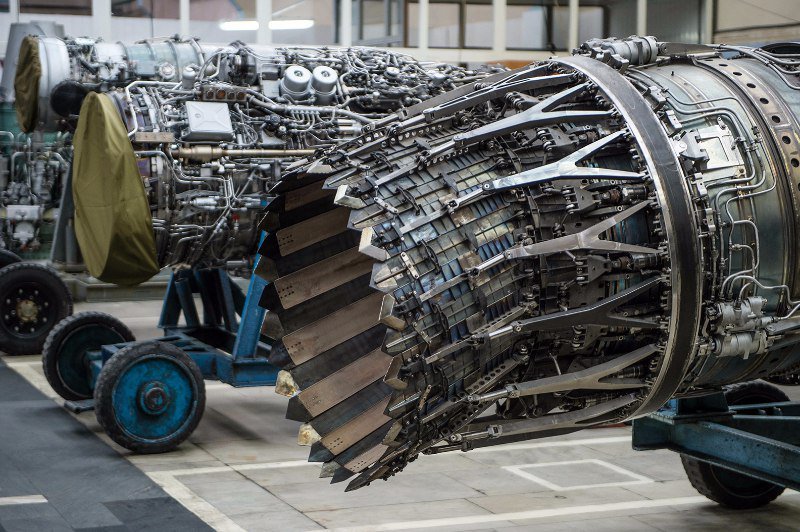

Mechanical thrust vector systems are complex, heavy (to 20%-30% of engine weight), have expensive high temp components and a short life. They can also be quite inefficient, with up to 10% thrust loss.

Mechanical thrust vector systems are complex, heavy (to 20%-30% of engine weight), have expensive high temp components and a short life. They can also be quite inefficient, with up to 10% thrust loss.

What is fluidic thrust vectoring?

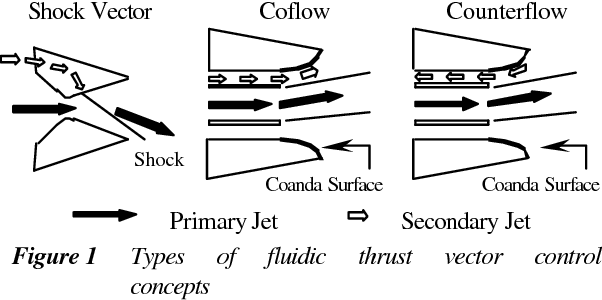

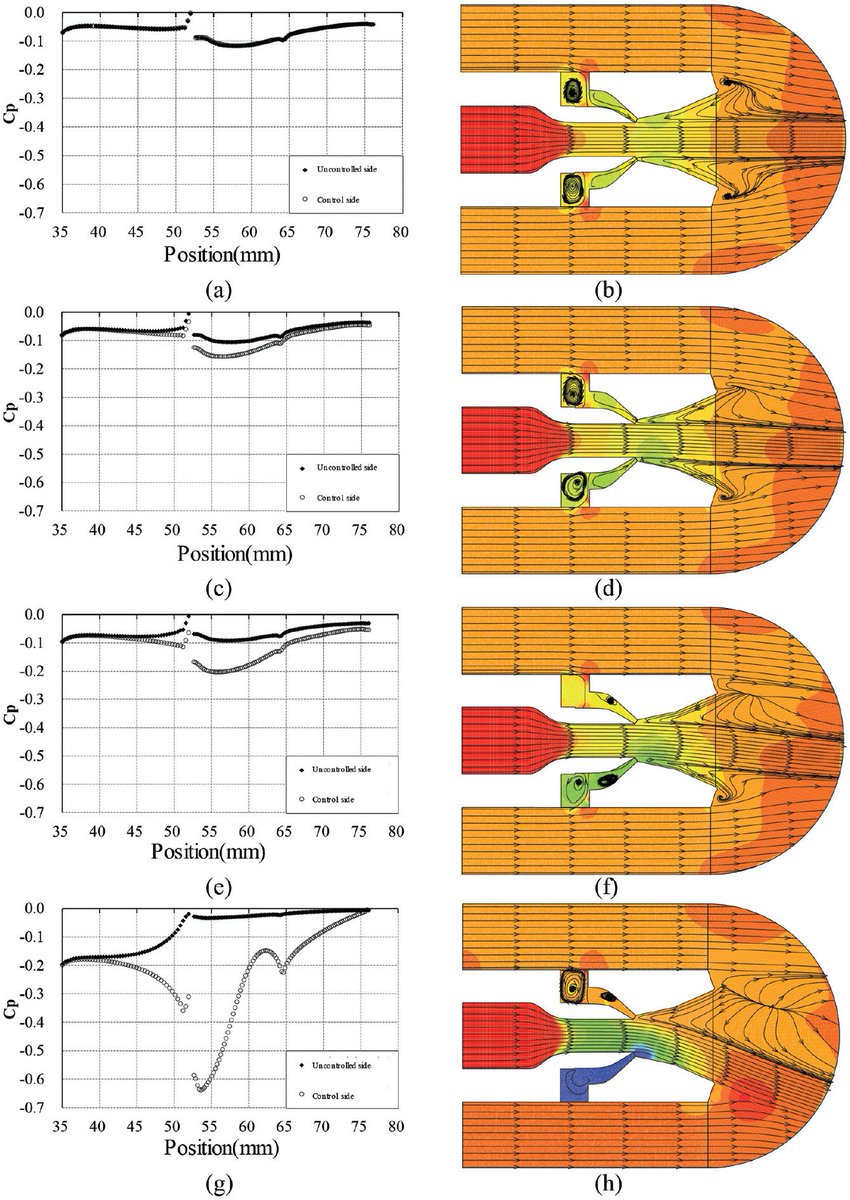

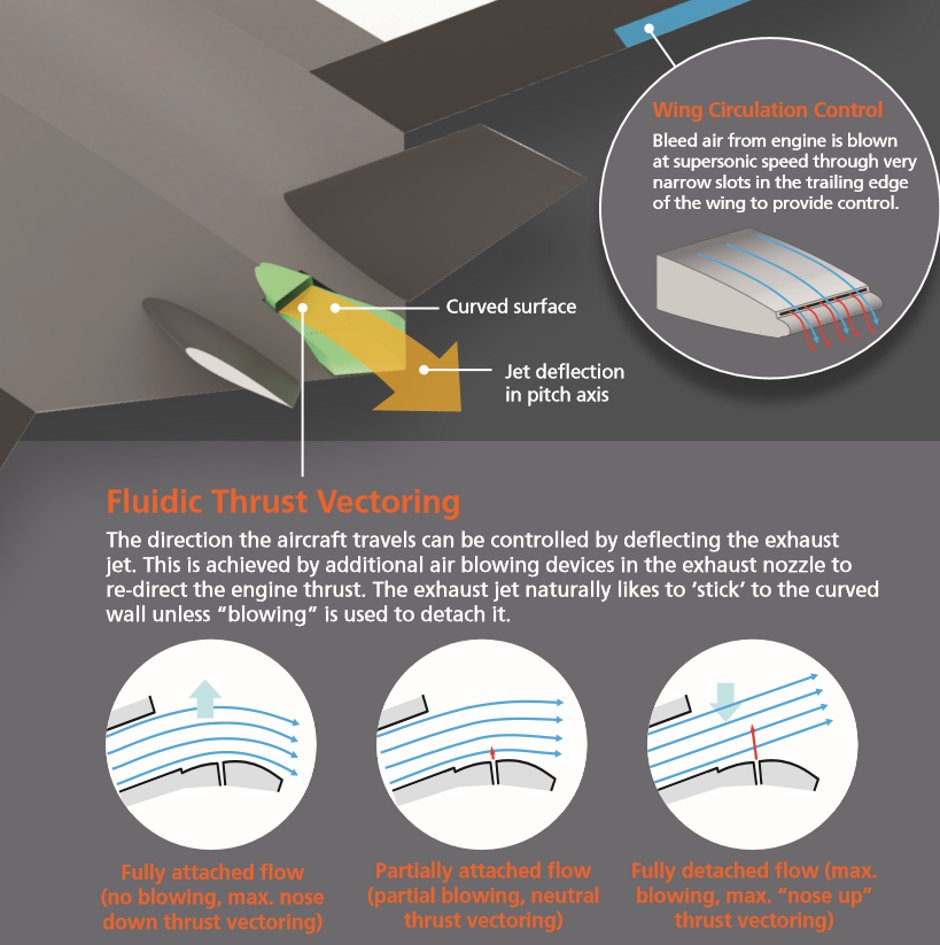

By injecting mixing flow adjacent to a jet exhaust plume, the direction of the exhaust can be induced to change without mechanical intervention. There are many ways to do this: Co-flow injection, shock impingement and counter flow injection.

By injecting mixing flow adjacent to a jet exhaust plume, the direction of the exhaust can be induced to change without mechanical intervention. There are many ways to do this: Co-flow injection, shock impingement and counter flow injection.

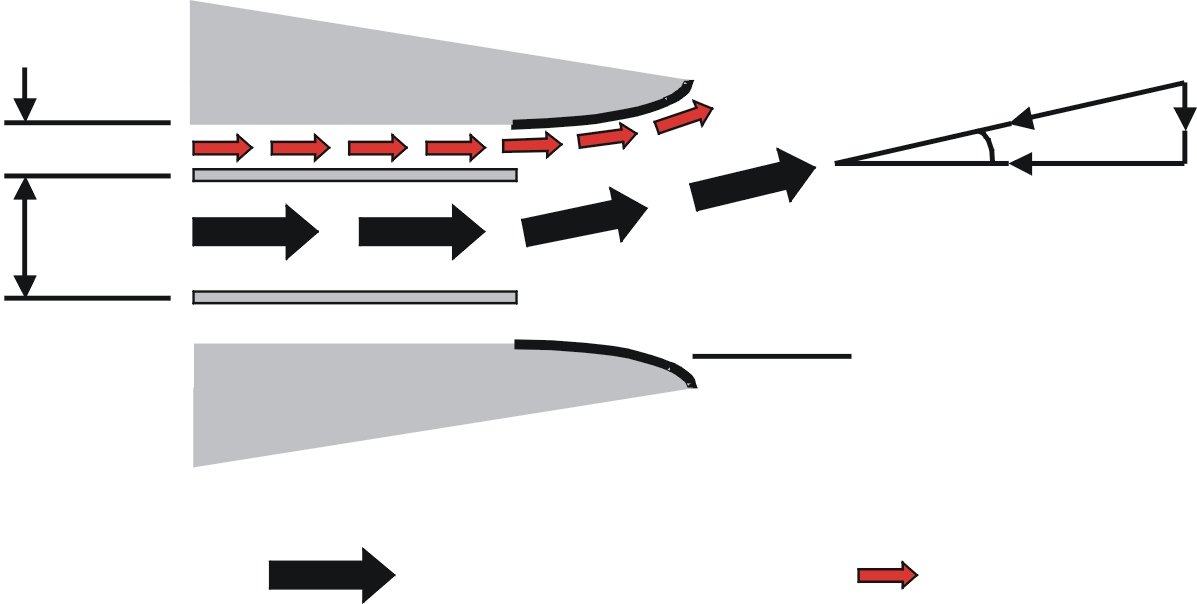

Efficiency of operation is high: Co flow injection can produce sizeable control inputs with as little as 1% of injected flow.

There has even been a study on passive fluidic thrust vectoring, entraining aircraft boundary layer air without active injection: More efficient still.

There has even been a study on passive fluidic thrust vectoring, entraining aircraft boundary layer air without active injection: More efficient still.

But FLAVIIR used Co flow injection.

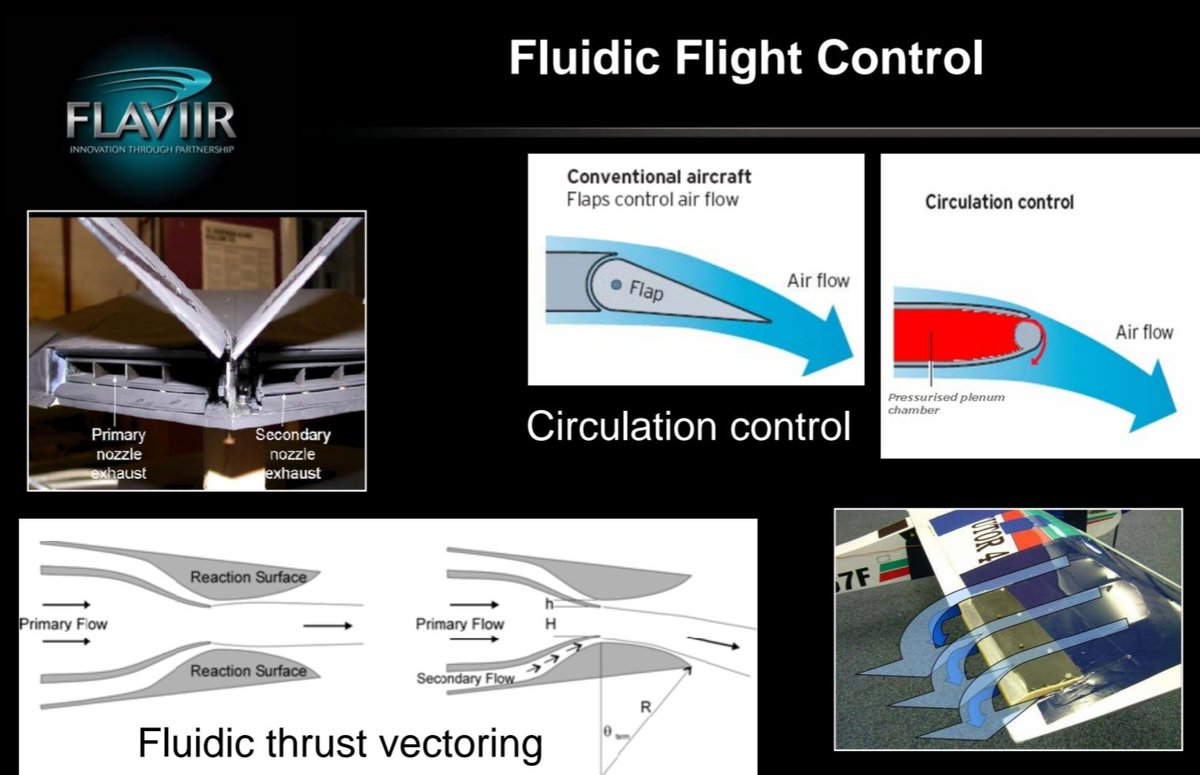

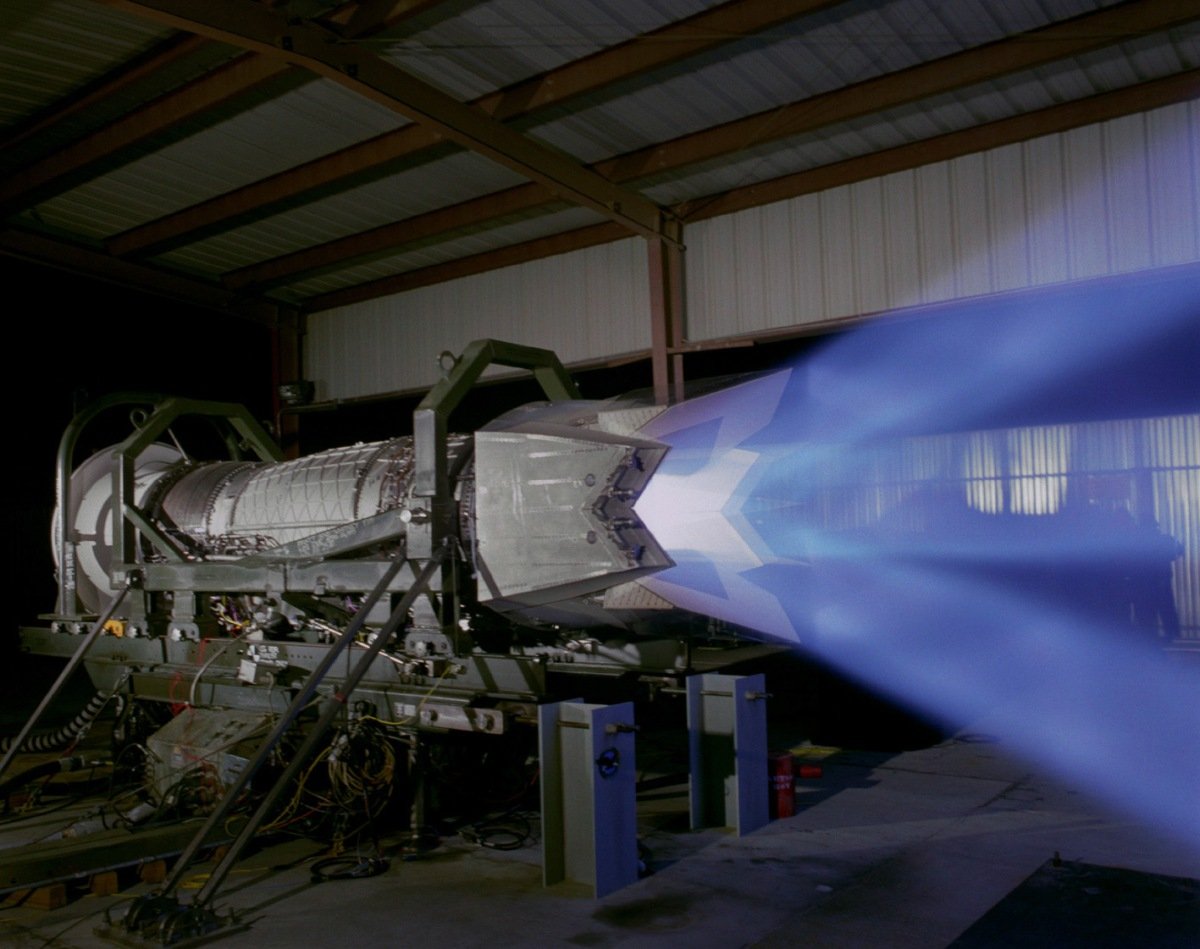

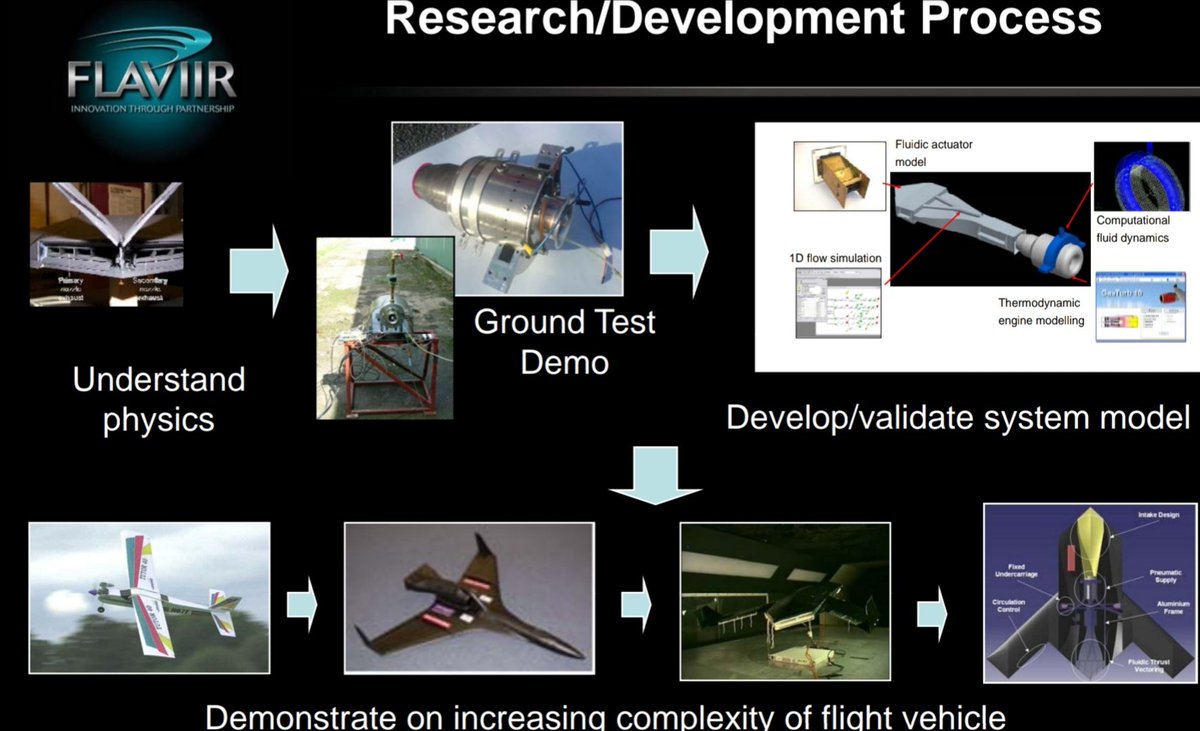

New technologies were trialled and matured into increasingly integrated and sophisticated platforms, starting with small electric motor craft & wind tunnel testing, and building to turbojet scale prototypes.

New technologies were trialled and matured into increasingly integrated and sophisticated platforms, starting with small electric motor craft & wind tunnel testing, and building to turbojet scale prototypes.

The goal: An integrated demonstrator UAV bringing together all the advanced concepts under development.

The Demon.

The Demon.

Demon flew in 2009 & 2010, and was the first aircraft to fly without the use of flaps or geometry shape changes.

So what has happened since then?

via @YouTube

So what has happened since then?

via @YouTube

BAE Systems is a massive defence contractor, so you'd expect something to come of this, but there was radio silence until 2019, when the Magma UAV flew: A development of the technologies pioneered in the Demon, with efficient supersonic nozzle fluidic vectoring.

Here's a Magma video: Flaps are only used for takeoff and landing.

What's to follow this? Who knows. The technology is promising, particularly for high reliability stealthy drones or high altitude applications. Keep your eyes open.

What's to follow this? Who knows. The technology is promising, particularly for high reliability stealthy drones or high altitude applications. Keep your eyes open.

• • •

Missing some Tweet in this thread? You can try to

force a refresh