On Monday, we presented selected visuals on the Votkinsk, the Roscosmos enterprise producing ballistic missiles for the "Iskander" complex. Today, we will do the Titan-Barrikady that is producing the "Iskander" missile launchers

Let us take an excursion to their factory floor🧵

Let us take an excursion to their factory floor🧵

We will start with this video broadcasted on the regional TV channel AhtubaTV: "Governor Bozhenov met with the workers of the Central Design Bureau "Titan" (2012).

0:14 On this photo of a Titan-Barrikady workshop you can see at least two HAAS machines

mega.nz/file/6nIDkaZJ#…

0:14 On this photo of a Titan-Barrikady workshop you can see at least two HAAS machines

mega.nz/file/6nIDkaZJ#…

It was Russia developing and fielding the Iskander cruise missiles 9M729, that made the US to accuse it of violating the INF treaty (2018) and withdraw from it (2019)

At the same time, the Russian producer of Iskander launchers is operating with the US-made HAAS machines

At the same time, the Russian producer of Iskander launchers is operating with the US-made HAAS machines

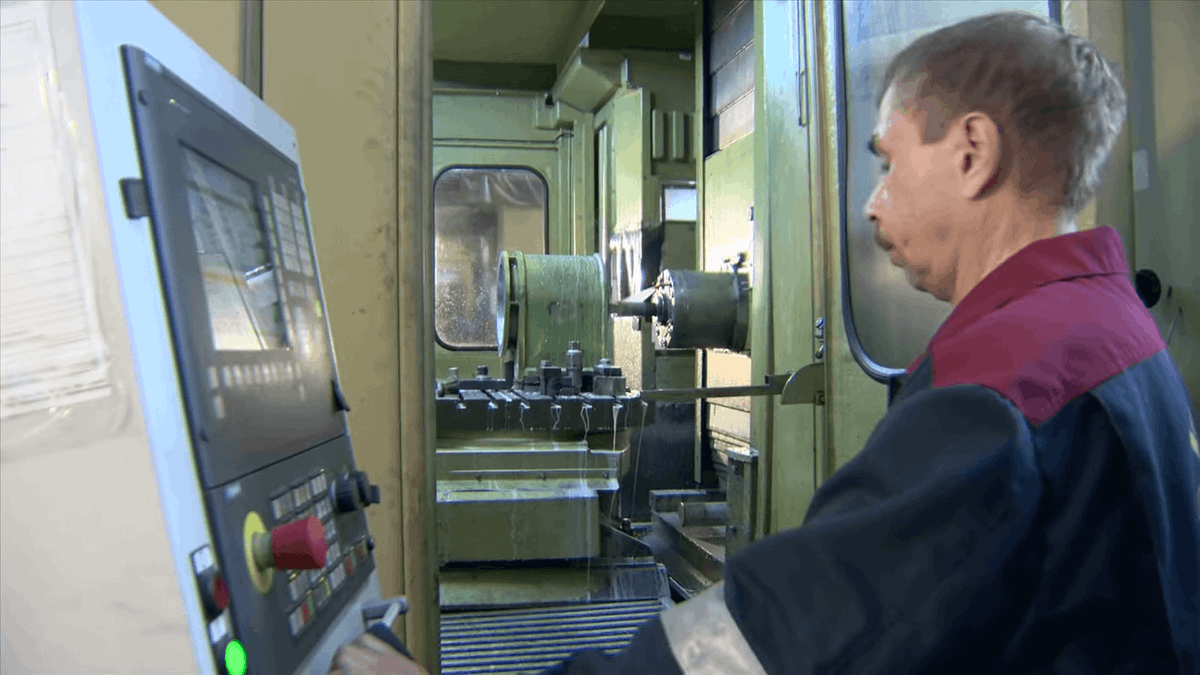

0:26 Sinumerik (Siemens) CNC control panel

Fanuc, Siemens and Heidenhain are thee most widely used CNC controller systems in the Russian military industry by far. The vast majority of all cutting machines, including the Russia-assembled ones, uses one of these three

Fanuc, Siemens and Heidenhain are thee most widely used CNC controller systems in the Russian military industry by far. The vast majority of all cutting machines, including the Russia-assembled ones, uses one of these three

0:56 On the right, you see a HAAS control panel. The American HAAS is one of those relatively less common machine tool producers that is equipping machines with their own CNC controllers

Next video. This is a 37 min-long movie on the TItan-Barrikady (2014)

25:48 This is probably a Soviet-era machine equipped with the modern Sinumerik (Siemens) CNC. Very typical. The old stock is inoperable unless equipped with the modern computer control mega.nz/file/PrZDXbRY#…

25:48 This is probably a Soviet-era machine equipped with the modern Sinumerik (Siemens) CNC. Very typical. The old stock is inoperable unless equipped with the modern computer control mega.nz/file/PrZDXbRY#…

25:51 HAAS again. This major American machine tool producer is the largest North American supplier of the Russian military industry by far

26:05 Fanuc CNC controller

Again, Fanuc, Siemens and Heidenhain are three most common CNC controller systems in the Russian military industry by far

Again, Fanuc, Siemens and Heidenhain are three most common CNC controller systems in the Russian military industry by far

27:05 Two setup operators busy installing machines. They are dressed in the "Baltic Industrial Company" (BPK) uniform. The BPK is a Russian machine tool company focused on distributing, setting up and maintaining imported equipment for the Russian military industry

Sanction it

Sanction it

Next video. It is of a more typical Big Boss Visiting the Plant type "Russian Deputy Defense Minister Yuri Borisov inspected Volgograd companies that execute the state defense orders" (2017)

0:31

On the right HAAS (USA)

On the left Gruppo Shark (Italy) mega.nz/file/3mBmGKSC#…

0:31

On the right HAAS (USA)

On the left Gruppo Shark (Italy) mega.nz/file/3mBmGKSC#…

This headline in a regional media (2022) allows us to take a closer look on the Italian "Shark" machine at the Titan-Barrikady factory floor

volpromex.ru/yekonomika/vol…

volpromex.ru/yekonomika/vol…

0:36 This is an five-axes universal machining center UMILL 1800 EMCO manufactured by the EMCO (Austria)

emco-world.com/en/products/mi…

emco-world.com/en/products/mi…

1:09 Heller H 6000 four-axis machining center produced by the Heller (Germany) heller.biz/en/machines-an…

1:23 Heidenhain CNC controller

As we have already pointed out, Fanuc, Siemens and Heidenhain are three most common CNC controller types in the Russian military industry. For the PLC controllers, Siemens is the most common producer by the wide margin

As we have already pointed out, Fanuc, Siemens and Heidenhain are three most common CNC controller types in the Russian military industry. For the PLC controllers, Siemens is the most common producer by the wide margin

Next video. "Titan-Barrikady. Research Department" (2018)

6:04 EMCO (Austria). This may be an MMV 2000 model

mega.nz/file/buYEWKpB#…

6:04 EMCO (Austria). This may be an MMV 2000 model

mega.nz/file/buYEWKpB#…

6:09 Foreground: Techni Waterjet (Australia) waterjet cutting machine

Background: Two EMCO (Austria) cutting machines

Background: Two EMCO (Austria) cutting machines

7:27

Foreground: EMCO (Austria) machines

Background: Most probably, Traub (Germany) produced "INDEX G250" machining center

Foreground: EMCO (Austria) machines

Background: Most probably, Traub (Germany) produced "INDEX G250" machining center

Next video. “Volgograd defense workers know what the Russian army will be armed with by 2020"

2:29

Foreground EMCO (Austria). It is probably a screw-cutting EMCOMAT E 300 series machine

Background: “LOCH Prazisions-Bohrtechnik” (Germany), unidentified mega.nz/file/a6pVGDya#…

2:29

Foreground EMCO (Austria). It is probably a screw-cutting EMCOMAT E 300 series machine

Background: “LOCH Prazisions-Bohrtechnik” (Germany), unidentified mega.nz/file/a6pVGDya#…

Next video, now of anniversary type. "For the 105th anniversary of Federal Research and Production Center “Titan-Barrikady”

1:45 EMCO-produced Universal CNC turning center MAXXTURN 95 equipped with the SINUMERIK 840D sl mega.nz/file/z3wiCCjD#…

1:45 EMCO-produced Universal CNC turning center MAXXTURN 95 equipped with the SINUMERIK 840D sl mega.nz/file/z3wiCCjD#…

The end. The rest of our visuals on Titan-Barrikady either show the same equipment from the different angles or require too long commentary

• • •

Missing some Tweet in this thread? You can try to

force a refresh