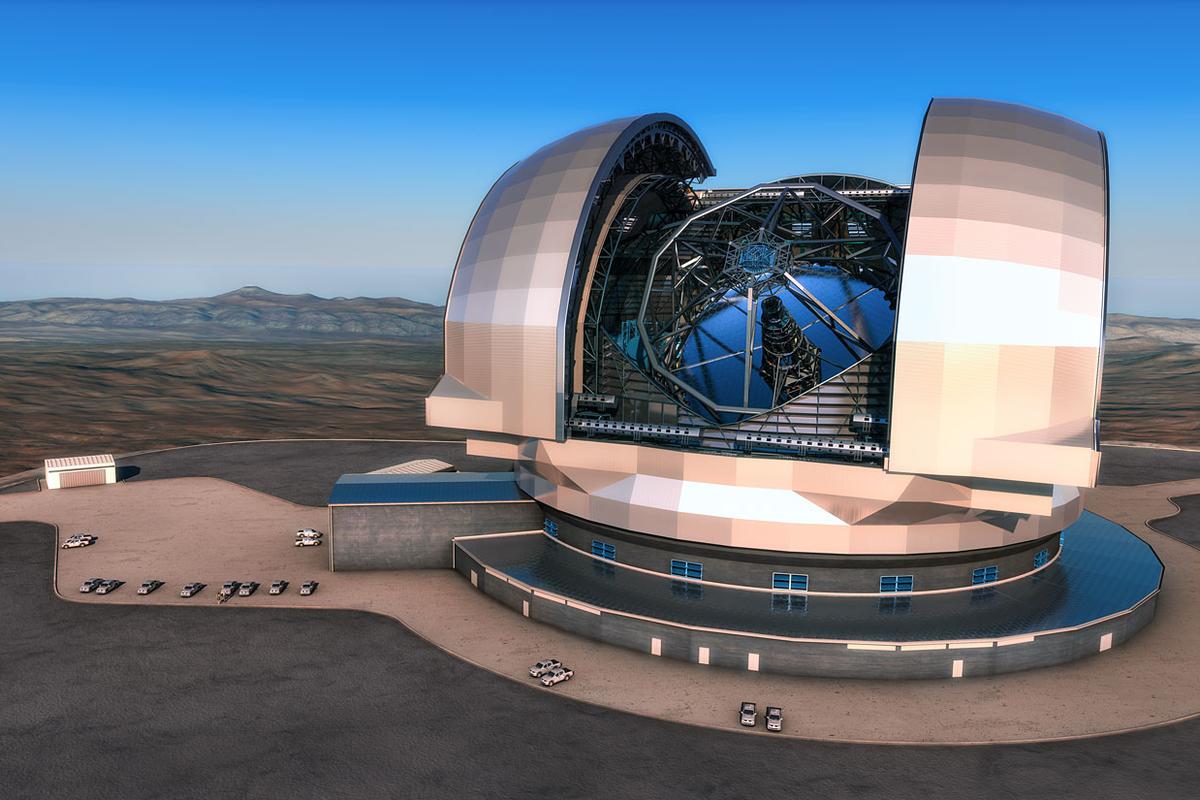

High on a mountain in the Atacama desert, Chile, the European Southern Observatory is building something immense.

It's called the Extremely Large Telescope, and here's a highlight reel of this beast's ultimate capabilities.

It's called the Extremely Large Telescope, and here's a highlight reel of this beast's ultimate capabilities.

With a 39m main mirror it will be, by a long way, the biggest optical & infrared telescope in the world. It will transform study of planets around other stars, distant galaxies, the early universe, dark matter, black holes.

And it's an engineering miracle.

And it's an engineering miracle.

A telescope is limited, among other things, by the light it's main mirror can gather. The ELT will gather 100 million times more light than the human eye.

It will do this with an adaptive array of five mirrors, four of which can adaptively change shape.

It will do this with an adaptive array of five mirrors, four of which can adaptively change shape.

M1:

The 39m primary mirror is made up of 798 interlocking hexagons which are all in active control: To adjust for thermal and wind variation each must be precisely positioned & shaped to within 10s of nanometres, 10,000 times thinner than human hair, across the entire radius!

The 39m primary mirror is made up of 798 interlocking hexagons which are all in active control: To adjust for thermal and wind variation each must be precisely positioned & shaped to within 10s of nanometres, 10,000 times thinner than human hair, across the entire radius!

Each M1 segment is supported at 27 locations, with warping harnesses. Each segment has 3 positioning actuators to control tip & tilt to within 2nm.

In total, M1 has 798 segments, 2500 actuators and 9000 edge sensors.

In total, M1 has 798 segments, 2500 actuators and 9000 edge sensors.

M2 & M3:

In any other telescope, the M2 & M3 mirrors would be huge even as primary mirrors.

After firing, the mirror blanks are cooled & annealed for 3 months for near perfect homogeneity to minimize internal stresses, then heat treated into glass ceramic for 6 months.

In any other telescope, the M2 & M3 mirrors would be huge even as primary mirrors.

After firing, the mirror blanks are cooled & annealed for 3 months for near perfect homogeneity to minimize internal stresses, then heat treated into glass ceramic for 6 months.

The 4.25 metre mirrors have a near zero coefficient of thermal expansion. They are ground, figured & polished to within nanometres accuracy, 20,000 times more precise than the width of a human hair: Figuring and polishing takes 2 years.

M4:

The world's largest deformable mirror: Designed to adjust for vision distortion produced by atmospheric turbulence or facility vibration, it is a thin shell sitting 90 microns away from a silicon carbide reference surface. 5000 actuators adjust it's shape up to 1,000 times/s

The world's largest deformable mirror: Designed to adjust for vision distortion produced by atmospheric turbulence or facility vibration, it is a thin shell sitting 90 microns away from a silicon carbide reference surface. 5000 actuators adjust it's shape up to 1,000 times/s

The M4 shell is measured to the nanometre range 70,000 times a second, and the primary input also includes 8 powerful lasers fired into the upper atmosphere, which are used as references to measure and correct for atmospheric turbulence hundreds of times a second.

Instruments:

The HARMONI 3D spectrograph.

MICADO high resolution near infrared camera.

METIS mid infrared spectrograph.

ANDES multi wavelength high resolution spectrograph.

MOSAIC multi object spectrograph.

The HARMONI 3D spectrograph.

MICADO high resolution near infrared camera.

METIS mid infrared spectrograph.

ANDES multi wavelength high resolution spectrograph.

MOSAIC multi object spectrograph.

The dome itself is built on a film of oil and shock absorbers on the foundations to guard it against seismic interference.

The ELT will be ready for first light around 2028, and is likely to quickly eclipse it's predecessor (the VLT) which is even now the most scientifically productive astromical telescope in the world.

European science & engineering has it's weaknesses, but also undoubted strengths. Projects like the ELT are absolutely one of them.

Follow the European Southern Observatory at @ESO

Follow the European Southern Observatory at @ESO

• • •

Missing some Tweet in this thread? You can try to

force a refresh