A spark in the darkness...

This week Sheffield Forgemasters achieved, in 24 hours, the welding of a nuclear Small Modular Reactor RPV mockup that should have taken up to a year.

How?

Incoming energy revolution: This is the Electron Beam Welding thread!

This week Sheffield Forgemasters achieved, in 24 hours, the welding of a nuclear Small Modular Reactor RPV mockup that should have taken up to a year.

How?

Incoming energy revolution: This is the Electron Beam Welding thread!

What is Electron Beam Welding (EBW)?

EBW is a fusion weld process using a focused electron beam to deliver energy. It features very high depth to width ratios, precise depth control, purity and speed.

Fine. So how is this achieved, and what has this got to do with nuclear?

EBW is a fusion weld process using a focused electron beam to deliver energy. It features very high depth to width ratios, precise depth control, purity and speed.

Fine. So how is this achieved, and what has this got to do with nuclear?

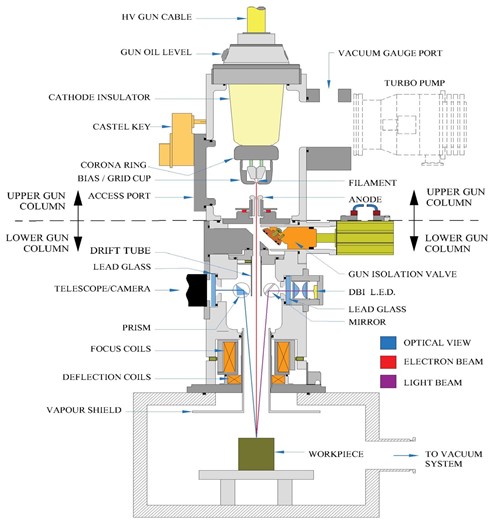

Free electrons can be induced to emit from a sharp electrode carrying a sufficient voltage. You want as many free electrons as possible, meaning as much current per mm as possible, meaning high temperatures. In practice, Tungsten electrodes are often used.

The electrons are then accelerated through a powerful high potential electric field to 0.3-0.7 times the speed of light: A second, even more negatively charged cathode forms a shaped electrical field with an anode.

Voltages across these can go from 30-220kV.

Voltages across these can go from 30-220kV.

With the electron beam now created, it needs to be focused.

Scattering in the beam leaves it's power density too low for welding, so a cylindrical coil focuses the beam to a point. The current passing through this coil can then also control the focal point of the beam.

Scattering in the beam leaves it's power density too low for welding, so a cylindrical coil focuses the beam to a point. The current passing through this coil can then also control the focal point of the beam.

Beam steering.

Sometimes you want to move the workpiece, and other times you want to move the beam itself. For the latter case, four coils, symmetrically placed around the beam, can deflect and steer the beam in the direction needed with ease & speed.

Sometimes you want to move the workpiece, and other times you want to move the beam itself. For the latter case, four coils, symmetrically placed around the beam, can deflect and steer the beam in the direction needed with ease & speed.

OK, so what's this got to do with nuclear energy?

The Reactor Pressure Vessel (RPV) holds the reactor core. Carbon steel with austenitic nickel-chromium steel cladding, it's wall thicknesses are 100s of mm and it can weigh 100s of tons.

Fabricating them is long & arduous.

The Reactor Pressure Vessel (RPV) holds the reactor core. Carbon steel with austenitic nickel-chromium steel cladding, it's wall thicknesses are 100s of mm and it can weigh 100s of tons.

Fabricating them is long & arduous.

Welding & cladding RPVs is extremely time consuming: We'll deal with cladding another time.

Welding is done with a shielded metal arc (TIG) welder, filling a machined chamfer. TIG welds penetrate only a few mm, so many passes are needed at a few mm/s, with regular inspection.

Welding is done with a shielded metal arc (TIG) welder, filling a machined chamfer. TIG welds penetrate only a few mm, so many passes are needed at a few mm/s, with regular inspection.

Depending on the RPV design, there can be many welds. This adds up. Preheating is needed, and shrinkage of a large volume of weld filler creates internal stress that needs relieving through heat treatment.

The many passes create opportunities for voids and discontinuities.

The many passes create opportunities for voids and discontinuities.

EB welding, by contrast, excels at deep single-pass welds with narrow weld pools. It's usually an autogenous weld process, meaning no filler wire is used. This is quick & metallurgically useful, but does require careful preparation of the weld zone.

Up to 200mm in a single pass, minimal shrinkage (though post-weld heat treatment is still advisable), no oxide or nitride contamination, better retained strength, fewer flaws, less NDE required and it's been around for decades.

EB welding sounds great! What's the catch?

EB welding sounds great! What's the catch?

It's a high maintenance process and can be tricky, but the main problem for nuclear is the same thing that contributes to the unparalleled purity of the EB weld...

... It takes place in a vacuum.

... It takes place in a vacuum.

The vacuum, ten times purer than TIG's argon shield gas, is usually generated in a dedicated EB chamber, and doing this for fullsize nuclear fabrications would be impractically expensive.

But Sheffield Forgemasters, with Cambridge Vacuum Engineering, found a new way...

But Sheffield Forgemasters, with Cambridge Vacuum Engineering, found a new way...

The EBflow system uses a travelling vacuum seal to create EB welding conditions locally over the weld zone without needing a vacuum chamber. It's specifically designed for thick section fabrication: Monopiles, pressure vessels...

Small Modular Reactors.

Small Modular Reactors.

The SMR selling point: Series production will lower costs with learner effects, modular production & efficiency-enhancing investment. A bold dream that only works when you can build them quickly.

EB fabrication is a key enabler, especially when nuclear coded welders are scarce.

EB fabrication is a key enabler, especially when nuclear coded welders are scarce.

But while the nuclear primary cycle is the best prize for this technology, it might not be the biggest: A 100m offshore wind turbine monopile needs up to 6000 arc-on hours of TIG welding. Out-of-chamber EB could shave this to a fraction.

This is a multi-sector energy triumph.

This is a multi-sector energy triumph.

As an aside, for a quick explanation of what the nuclear primary cycle is, see this thread. Now back to EB welding...

https://twitter.com/Jordan_W_Taylor/status/1745848069990596690?t=Lk105DUZSRw0vSyM2uCvgw&s=19

The out of chamber EB technology is potentially revolutionary, can be applied to cylindrical and linear welds and is perfectly suited to oversize, thick-section fabrications with high quality demands.

We are witnessing the start of something new and spectacular...

We are witnessing the start of something new and spectacular...

Next comes the ASME code case for nuclear manufacture. This could take years, but the direction is clear.

Sometimes technology proceeds gingerly, in a shuffle.

And other times? A great leap...

I hope you enjoyed this!

Sometimes technology proceeds gingerly, in a shuffle.

And other times? A great leap...

I hope you enjoyed this!

You can follow some of the involved parties on X, of course: Sheffield Forgemasters, Cambridge Vacuum Engineering & the Nuclear AMRC.

@CamVacEng

@NuclearAMRC

@ForgemastersHQ

@CamVacEng

@NuclearAMRC

@ForgemastersHQ

• • •

Missing some Tweet in this thread? You can try to

force a refresh