views

We CT scanned a Stanley Quencher cup to look for the lead that’s supposedly inside. Here’s what we found, and what it says about how these cups are made… 🧵

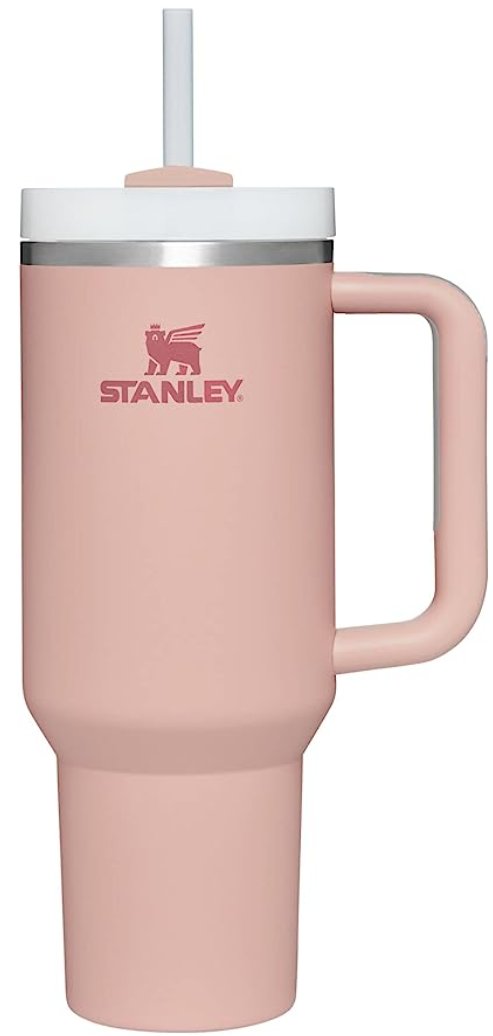

These cups have been a viral sensation, increasing Stanley’s revenue 10X since 2019. But late last year, social media influencers discovered lead in the cups. Stanley confirmed the cups contain lead, but says the lead doesn’t contact the cup’s contents. So what’s going on?

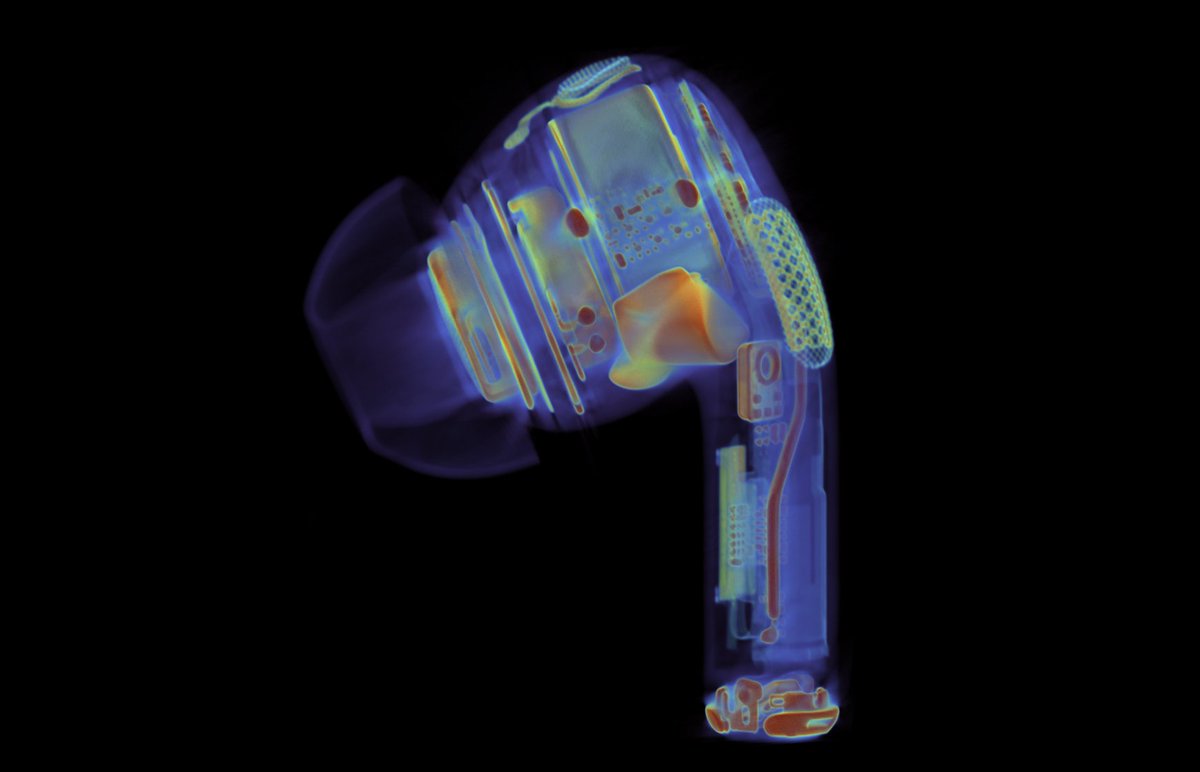

Here’s a @lumafield CT scan of a Stanley Quencher. Using X-ray images taken from different angles, we’ve constructed a 3D model that includes internal and external features. We can crop into the cup to see its cross section.

@lumafield By the way, you can explore our scans yourself right here: . Now on with the teardown…lumafield.com/article/findin…

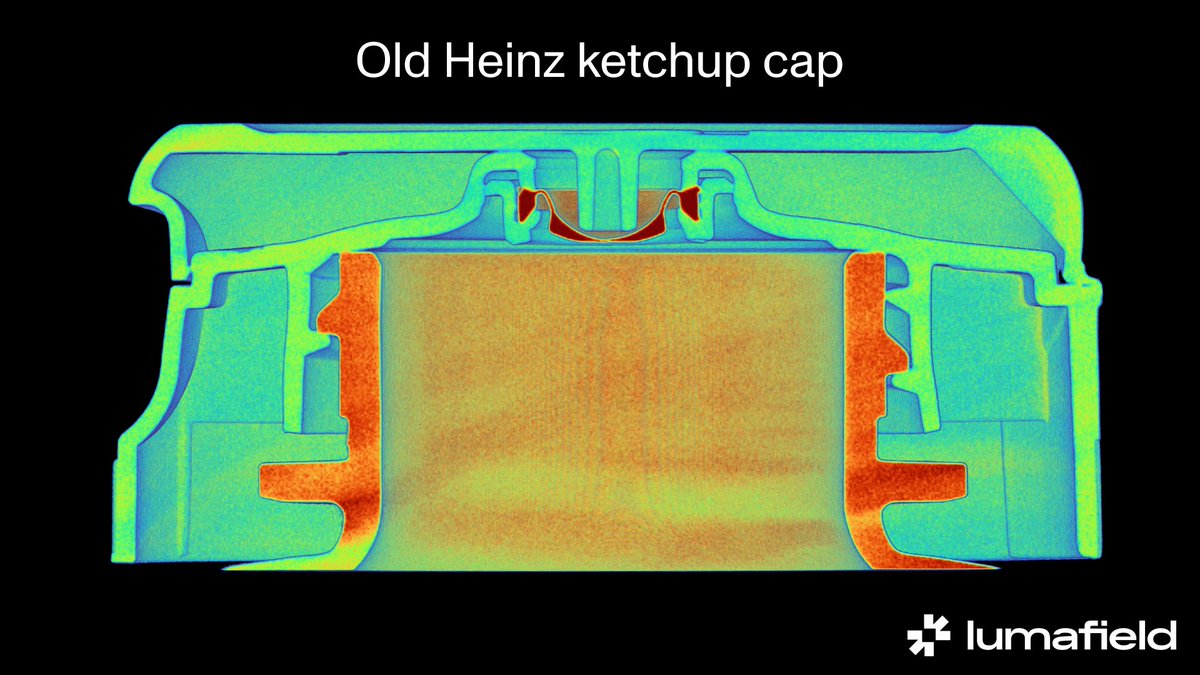

@lumafield Industrial CT scans differentiate materials by density; here less-dense materials, like the cup’s plastic lid and handle, are colored blue. Denser materials are colored orange and red. There’s a very dense material at the bottom of the cup…

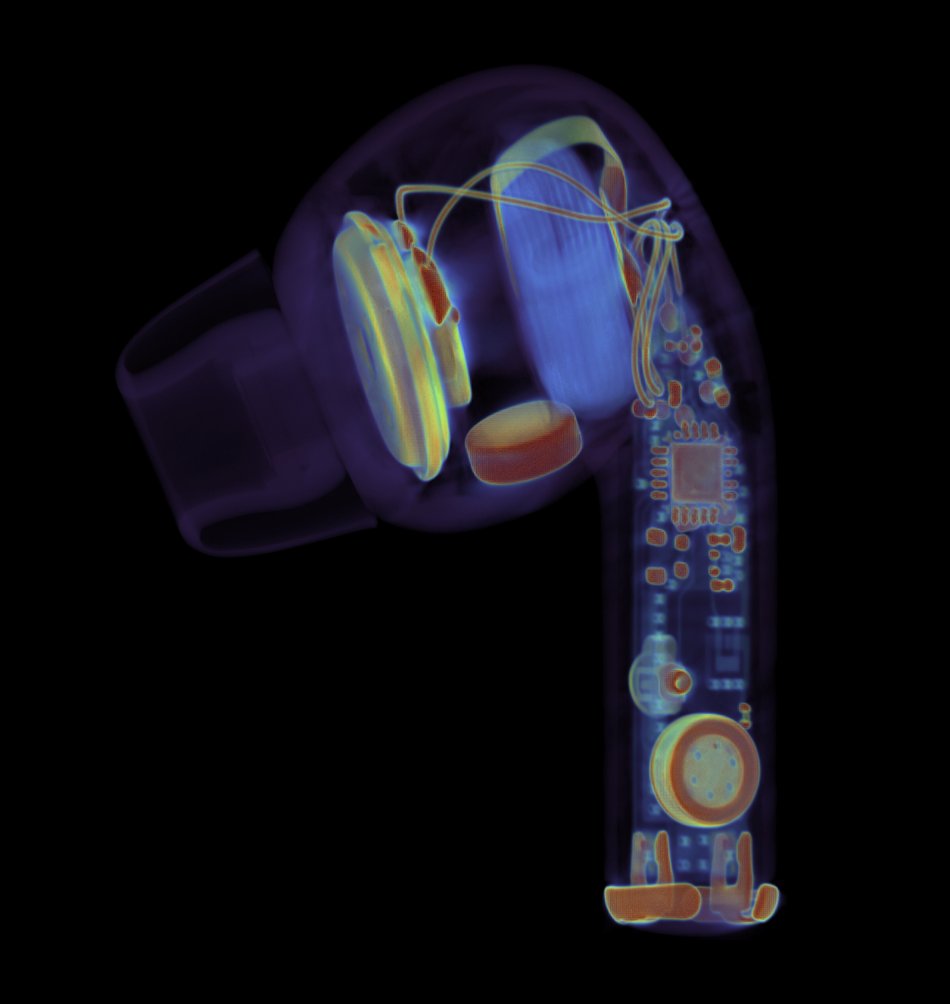

@lumafield Insulated cups like the Quencher have two layers of stainless steel separated by a vacuum that inhibits heat transfer. Sitting just above the bottom of the outer layer is a bright red blob: this is lead solder. Below it is a stainless steel disc. Why is there lead in the cup?

@lumafield These cups are manufactured by fabricating the inner and outer stainless steel layers separately, then welding them together at the top. A hole is left in the bottom of the outer layer, and the cup is placed in a vacuum chamber to extract the air from between the layers.

After the air has been extracted from between the cup’s inner and outer layers, the hole in the bottom of the cup needs to be sealed before the vacuum chamber is opened. The tried-and-true method is to insert a small pellet of lead solder between the cup’s layers during assembly, then heat the cup inside the vacuum chamber until the lead melts and seals the hole.

@lumafield Why not use unleaded solder? Lead is an ideal material from a process control standpoint; it has a low melting point and highly predictable characteristics. Lead solder is still sometimes used in electronics for this reason, even though unleaded solder is widely available.

@lumafield This type of tradeoff is very common in manufacturing: accept an undesirable but high-performance material as part of your process, or invent a new process at higher cost, lower performance, and/or higher defect rate.

@lumafield In any case, our CT cross section shows that the lead is entirely shielded, and its user won’t be exposed to lead at all. If the medallion covering the lead solder is pried off, it might become accessible—but in that case, a replacement cup is covered by Stanley’s warranty.

@lumafield Check out the CT scans of the Stanley Quencher and a more detailed writeup here! lumafield.com/article/findin…

@lumafield And if you’re interested in how industrial CT works and what it’s used for, check out this explainer video:

• • •

Missing some Tweet in this thread? You can try to

force a refresh