Let's talk Geothermal Energy!

We've already discussed gas power, the dying breaths of an ancient past. We've contemplated charming the wind, tapping the arteries of Poseidon and the sorcery of the reactor core.

But can we power our world directly from the Forge Of Hephaestus?

We've already discussed gas power, the dying breaths of an ancient past. We've contemplated charming the wind, tapping the arteries of Poseidon and the sorcery of the reactor core.

But can we power our world directly from the Forge Of Hephaestus?

In this thread we'll go over:

-Where does the heat come from?

-Different types of geothermal cycles & drawbacks.

-The future: Enhanced Geothermal System (EGS).

-If it succeeds, where will it take off first?

-Where does the heat come from?

-Different types of geothermal cycles & drawbacks.

-The future: Enhanced Geothermal System (EGS).

-If it succeeds, where will it take off first?

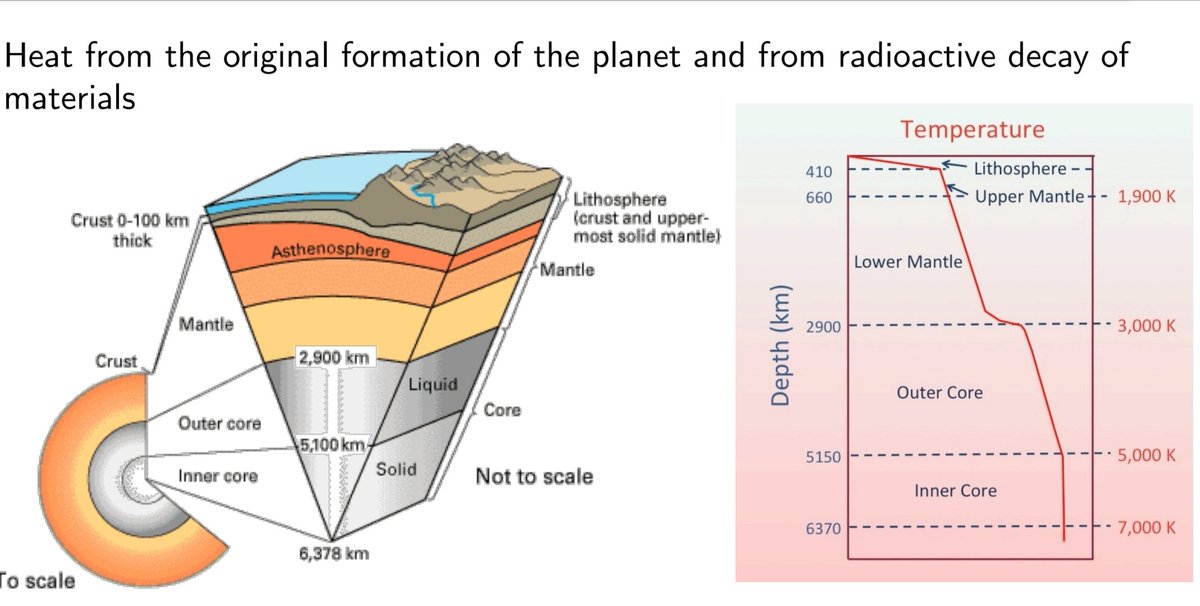

The Forge Of Hephaestus is kept hot by the dying embers of supernovae: Radioactive elements in the Earth's core decay & give off heat. The core is 7000 Celsius, but up here the temperature increases, on average, 30C per km depth.

And sometimes much more...

And sometimes much more...

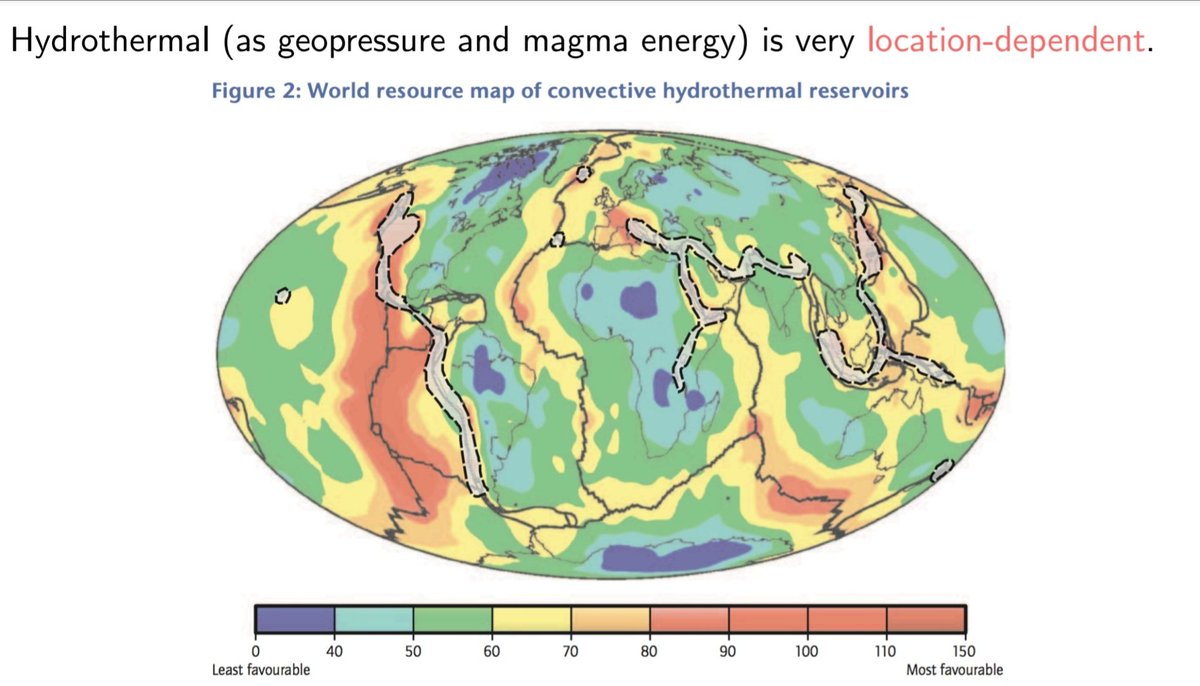

In the heart of the old continents like Africa this gradient can be very low, but there are swathes of the world where it is 50C or even 70C/km. In zones with active volcanism 150C/km is possible!

But what is actually needed? Let's go through five current geothermal cycles.

But what is actually needed? Let's go through five current geothermal cycles.

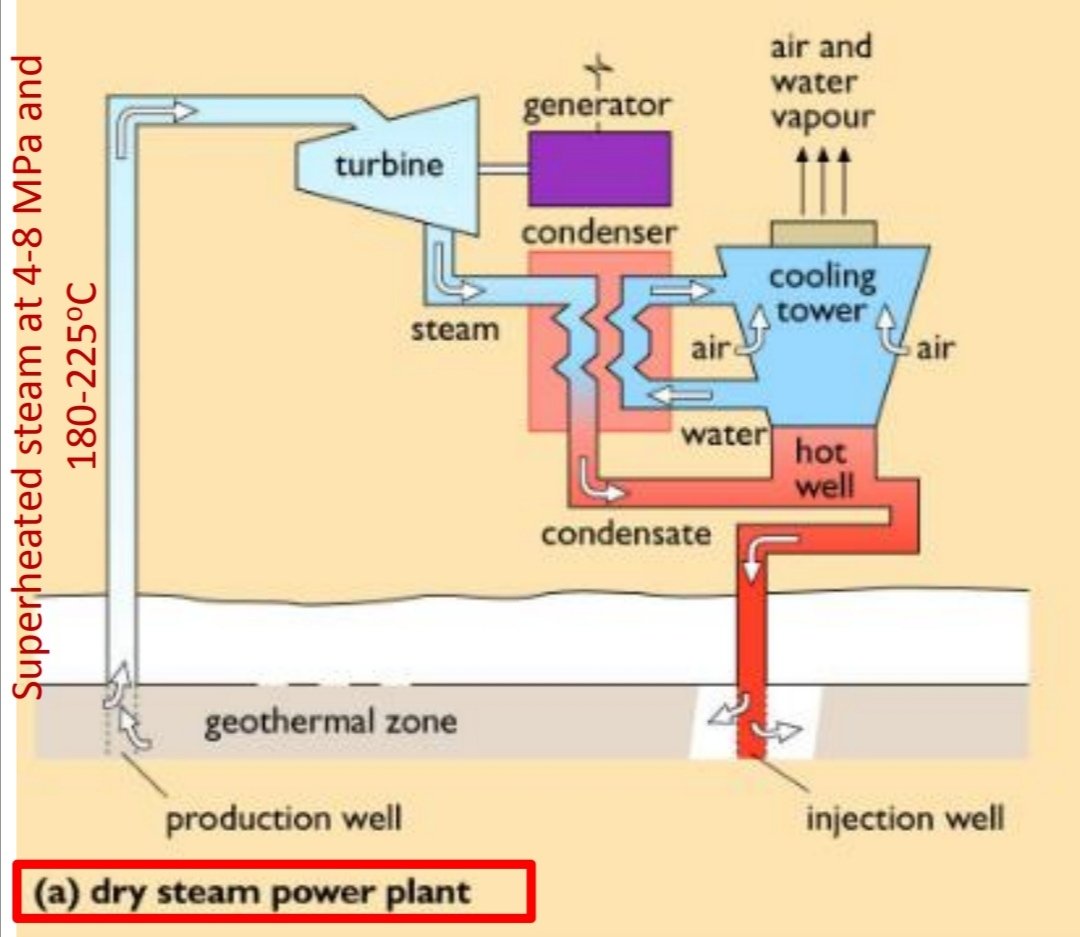

Dry steam cycle.

For very high temperature geothermal resources only: Superheated steam evaporates on it's way to the turbine at 180C-225C and 4-8 MPa, expanding within the turbine system. It is then condensed and re-injected.

Dry steam is 27% of global capacity.

For very high temperature geothermal resources only: Superheated steam evaporates on it's way to the turbine at 180C-225C and 4-8 MPa, expanding within the turbine system. It is then condensed and re-injected.

Dry steam is 27% of global capacity.

An example of dry steam is The Geysers thermal power complex in California, comprising 22 plants slowly built up over a near surface magma field from 1960. It has a generation capacity of 1,517MW, equivalent to 1 or 2 nuclear reactors.

2) Single flash steam power.

When thermal energy isn't quite sufficient for a total steam conversion, a flash chamber is used, with the remaining water recirculated. This is economically useful with a source at 150C or above. 43% of global geothermal capacity is this type.

When thermal energy isn't quite sufficient for a total steam conversion, a flash chamber is used, with the remaining water recirculated. This is economically useful with a source at 150C or above. 43% of global geothermal capacity is this type.

Single flash has a compromise in the flash drum: Higher pressure means higher specific power but a lower steam flow rate.

Chemicals & gases need removing from the fluid.

Some fresh water injection is needed to replenish losses.

The Guanacaste 55MW plant is an example.

Chemicals & gases need removing from the fluid.

Some fresh water injection is needed to replenish losses.

The Guanacaste 55MW plant is an example.

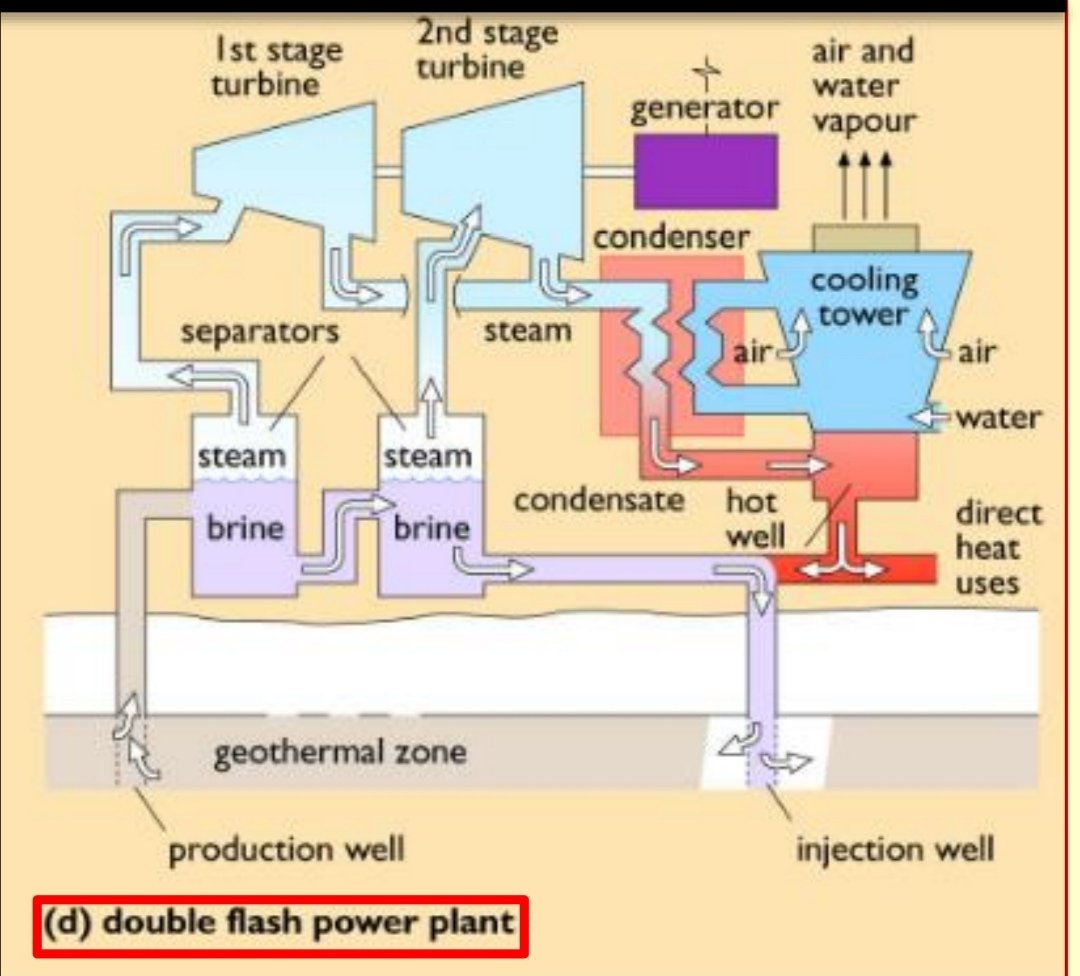

Double flash is a more complex evolution of single flash, allowing higher thermal efficiencies by using a high & low pressure flash and gaining more from a given source. Like the previous methods it can perform cogeneration: Producing a mixture of electricity & process heat.

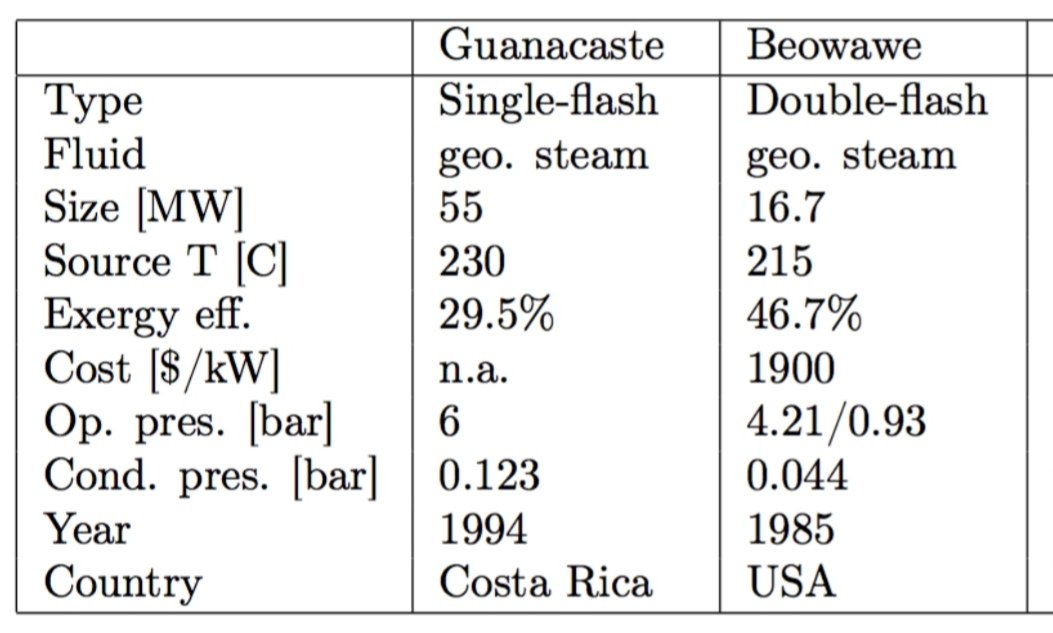

Compare & contrast the efficiencies and operating pressures of the Guanacaste (single flash) and Beowawe (double flash) geothermal plants.

Adding a 2nd cycle: Organic Rankine Cycle (ORC).

If the primary fluid isn't hot enough for a flash, a heat exchanger allows vapour flash in a secondary lower boiling point fluid (e.g Pentane, Butane). Useful for low grade thermal sources, this is a low capacity solution.

If the primary fluid isn't hot enough for a flash, a heat exchanger allows vapour flash in a secondary lower boiling point fluid (e.g Pentane, Butane). Useful for low grade thermal sources, this is a low capacity solution.

Kalina cycle:

Another 2nd-cycle approach, using recovery heat exchangers to allow a wider range of fluids (ORC fluids can be flammable), and higher efficiency.

As with the ORC cycle, this eliminates atmospheric coolant loss and the need for replacement injection water.

Another 2nd-cycle approach, using recovery heat exchangers to allow a wider range of fluids (ORC fluids can be flammable), and higher efficiency.

As with the ORC cycle, this eliminates atmospheric coolant loss and the need for replacement injection water.

The Forge Of Hephaestus is provident indeed, but it is not infinite. Geothermal plants worldwide all face the long term decline of their thermal potential.

This makes sense: If you are draining heat energy, you are disrupting a natural equilibrium and will slowly cool the rock

This makes sense: If you are draining heat energy, you are disrupting a natural equilibrium and will slowly cool the rock

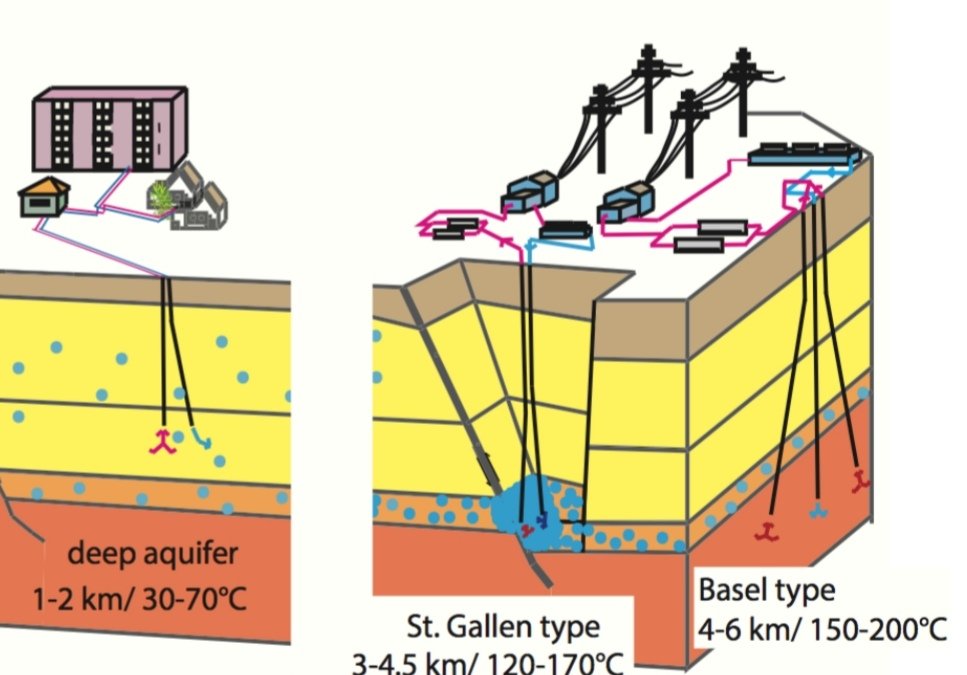

This is made more awkward by the relative scarcity of good geothermal sites using conventional methods, which requires a deep aquifier in porous, permeable hot rock trapped beneath a layer of impermeable rock, with a strong thermal gradient.

This combination of factors is rare enough to make geothermal energy a small niche, but what if we could *create* these environmental factors in hot, impermeable rocks, and so expand geothermal's reach hundreds of times?

This is the Enhanced Geothermal System (EGS).

This is the Enhanced Geothermal System (EGS).

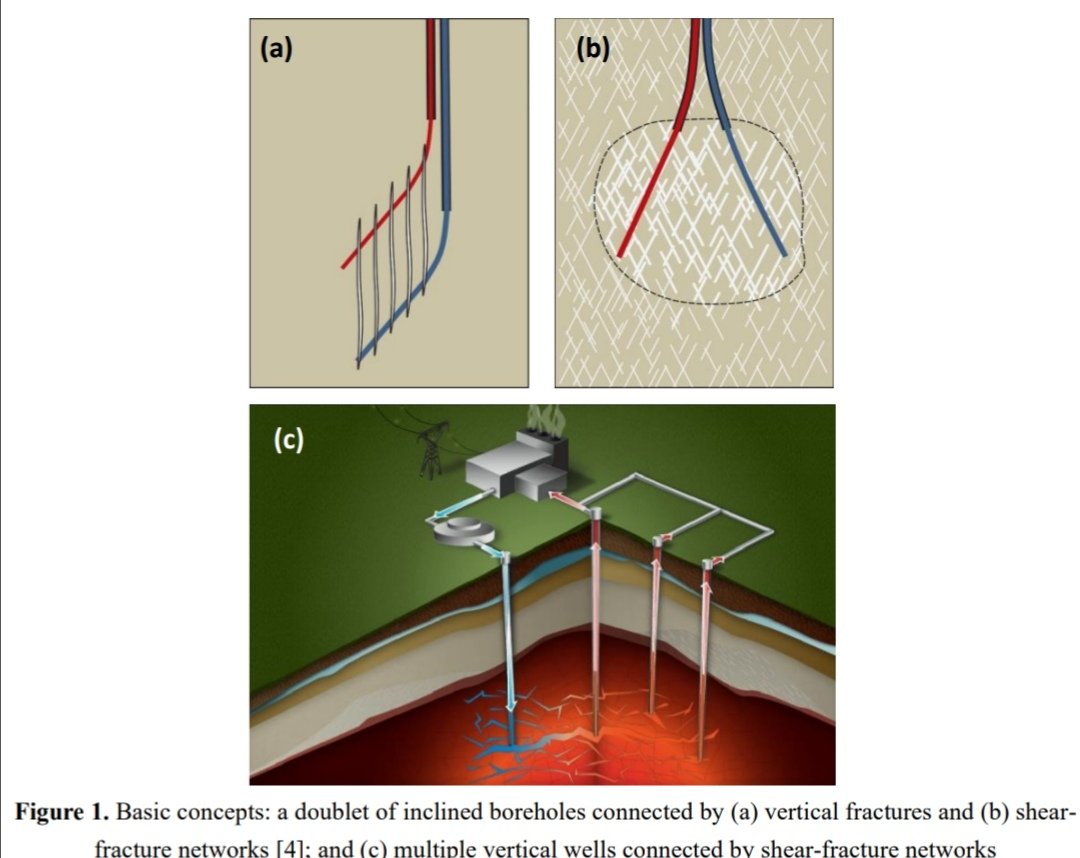

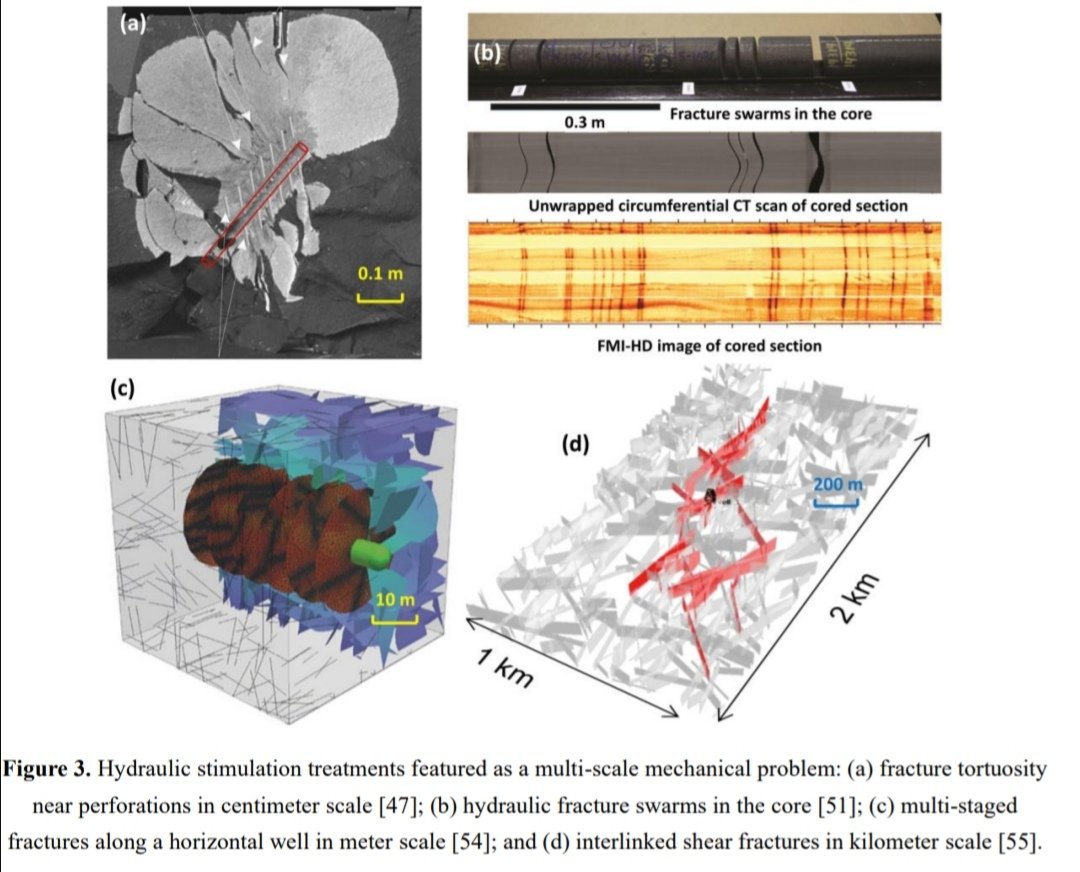

Borrowing from hydraulic fracturing techniques used in oil & gas, EGS bypasses the need for trapped aquifiers and instead targets impermeable hot rocks at a 4km-5km depth to fracture a subterranean reservoir directly. This eliminates the siting bottleneck of geothermal power.

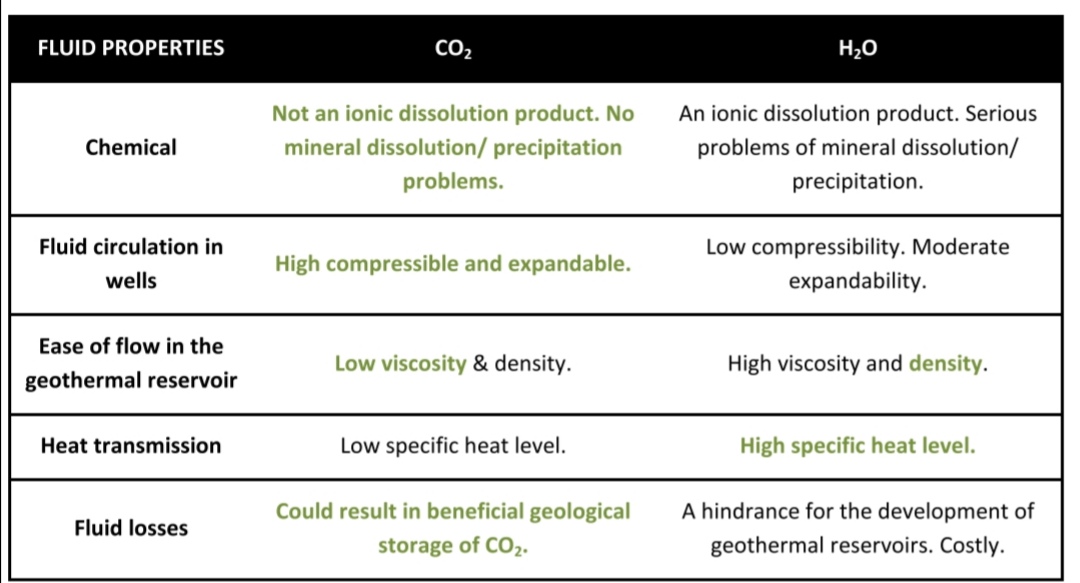

EGS also allows exciting new working fluids: Supercritical CO2 promises superior heat transmission, better flow through a complex fractured reservoir and eliminates the mineralization and corrosion challenge posed by subterranean water.

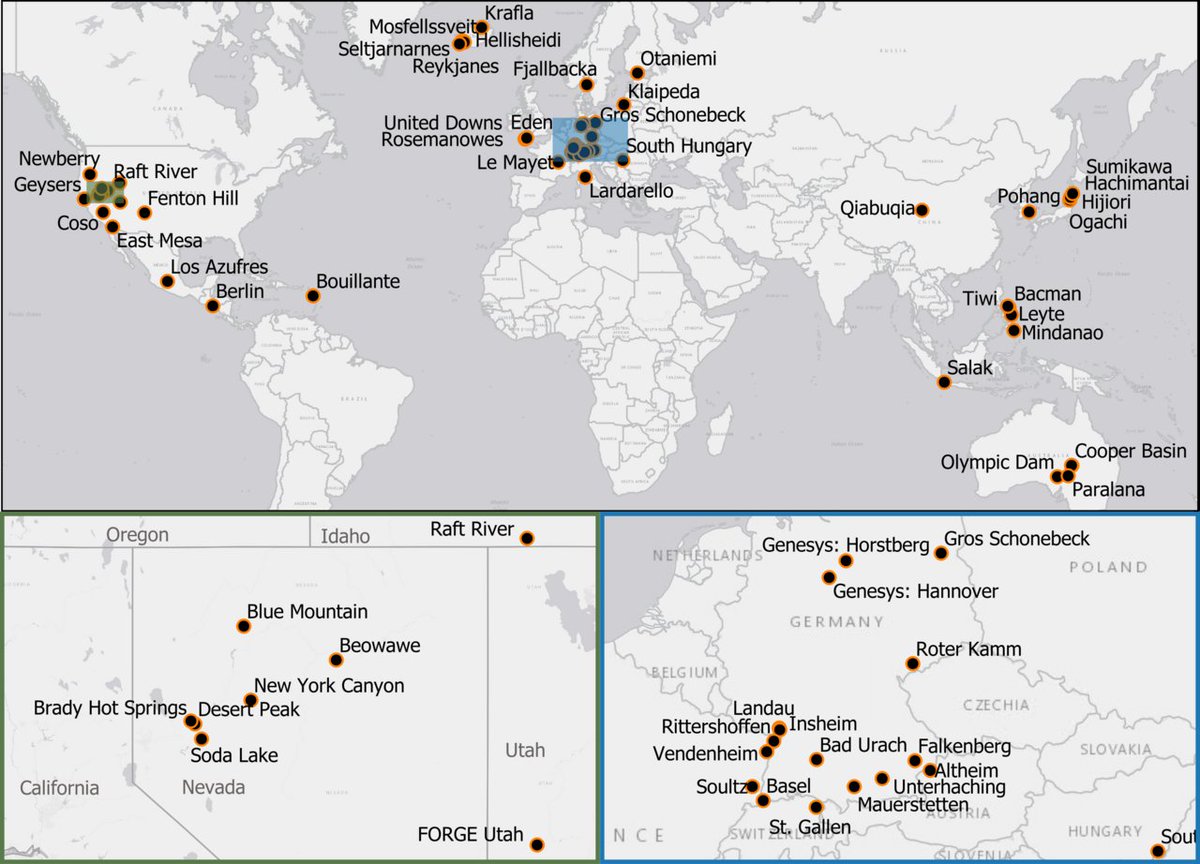

The world's first EGS project was started by the Los Alamos laboratory in the 70s, and the US & Europe investigated the technology with R&D plants for many years.

Recently, the number of EGS demonstration projects has started to take off....

Recently, the number of EGS demonstration projects has started to take off....

It's no surprise: Deep drilling at affordable cost, hydraulic fracturing & well diagnostics came of age in the US fracking boom in the last 2 decades, driving down costs, and this represents most of the capital outlay of an EGS system.

https://twitter.com/Jordan_W_Taylor/status/1755996729822851312?t=ZOjqW1eBjT45BrmaL-1tBQ&s=19

The Department Of Energy has estimated that EGS could have the potential to power 65 million homes in America, at maybe 45 USD/ MWh.

But that's easier said than done: A host of EGS pilot projects have been run, and many were failures.

Why?

But that's easier said than done: A host of EGS pilot projects have been run, and many were failures.

Why?

An EGS project needs to drill multiple wells, then hydraulically fracture a network of cracks that intersect & give an even spread of flow paths in the new reservoir.

Rock often fractures unpredictably along natural lines, short-circuiting or failing to join the network.

Rock often fractures unpredictably along natural lines, short-circuiting or failing to join the network.

There is good news though: Late last year a Google sponsored startup, Fervo Energy, exported EGS energy into the Nevada grid using an ORC cycle plant. High electricity prices, combined with fracking knowledge & the IRA subsidies, could trigger a boom.

If the boom occurs I'm betting on the USA: With abundant hot rock deposits, fracking experience, investment capital and EGS research over the years it is in a prime position.

America birthing yet another energy boom may grate on some people, but it could have company: A rich thermal seam runs straight through Europe as well.

But if we are to charm the gods of the underworld, we will need to stop using Fracking as a dirty word.

But if we are to charm the gods of the underworld, we will need to stop using Fracking as a dirty word.

So here's to yet another possible future, in which a civilization of wonders is powered, unseen & unheard, by the forge of continents.

Articles used are attached, all free downloads. I hope you enjoyed this!

Articles used are attached, all free downloads. I hope you enjoyed this!

• • •

Missing some Tweet in this thread? You can try to

force a refresh