Recently, I was going through con-call of Ganesha Ecosphere and read somewhere that there's going to be huge demand for rPET granules in India

Here are some brief details on Recycled PET Industry🧵

Plastic waste has large environmental consequences

Is, Recycling PET= Great Business + Cleaning Environment

(1/n)

Here are some brief details on Recycled PET Industry🧵

Plastic waste has large environmental consequences

Is, Recycling PET= Great Business + Cleaning Environment

(1/n)

PET stands for Polyethylene Terephthalate, which is a type of polyester commonly used in production of plastic bottles, containers, and packaging

Commonly found in:

· Beverage bottles

· Food packaging

· Clothing (fleece, polyester)

· Other Industrial applications

(2/n)

Commonly found in:

· Beverage bottles

· Food packaging

· Clothing (fleece, polyester)

· Other Industrial applications

(2/n)

Recycled PET (rPET) refers to PET that has been collected, sorted, cleaned, and processed for reuse in new products

It helps conserve virgin materials, reduce landfill waste, and create a more sustainable material cycle

Different Types of Products made from Recycled PET

(3/n)

It helps conserve virgin materials, reduce landfill waste, and create a more sustainable material cycle

Different Types of Products made from Recycled PET

(3/n)

The process to recycle PET:

1. Collection

2. Sorting

3. Cleaning

4. Shredding

5. Melting and Reprocessing

6. Manufacturing from pellets

Key raw materials for recycling PET include PET waste (bottles, containers), cleaning agents, and energy for the recycling process

(4/n)

1. Collection

2. Sorting

3. Cleaning

4. Shredding

5. Melting and Reprocessing

6. Manufacturing from pellets

Key raw materials for recycling PET include PET waste (bottles, containers), cleaning agents, and energy for the recycling process

(4/n)

Benefits of Using Recycled Materials Over Virgin Plastic

1. Recycled materials reduce carbon emissions (30%-80%)

2. Life Cycle Assessments confirm environmental benefits of PET bottle recycling into fibers.

3. Recycled PET offers:

# 40-85% less non-renewable energy use

(5/n)

1. Recycled materials reduce carbon emissions (30%-80%)

2. Life Cycle Assessments confirm environmental benefits of PET bottle recycling into fibers.

3. Recycled PET offers:

# 40-85% less non-renewable energy use

(5/n)

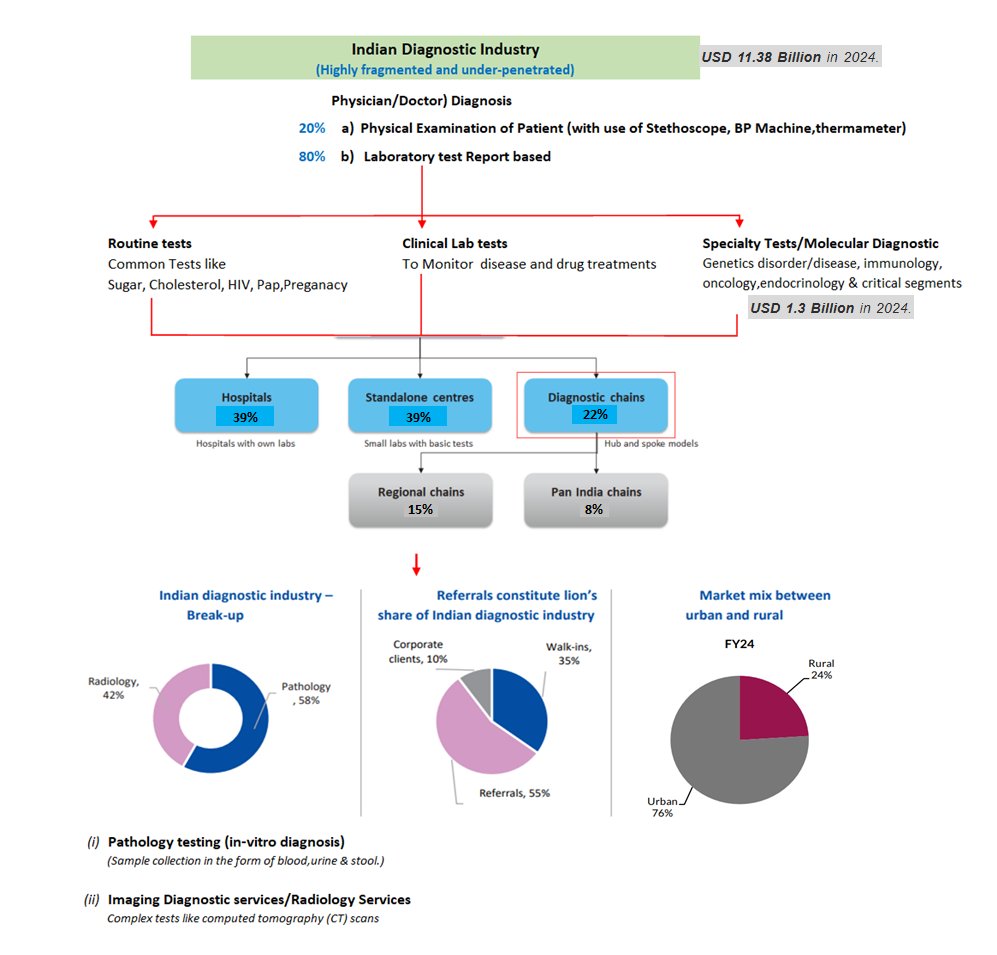

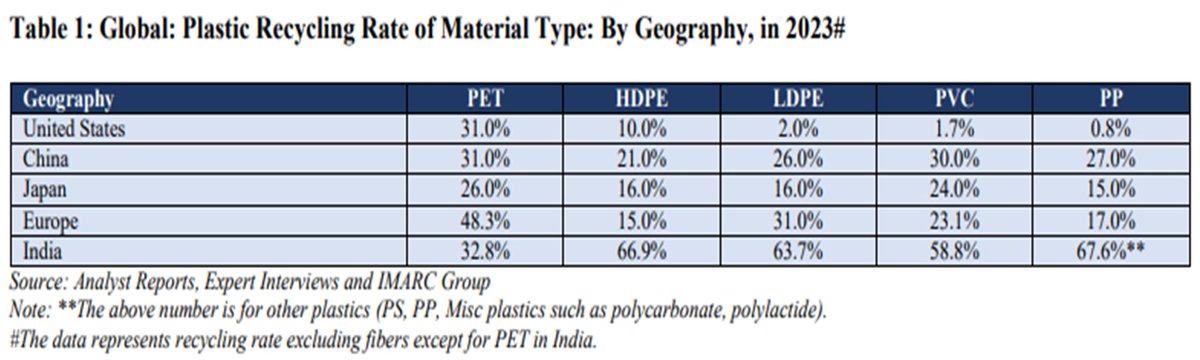

Indian rPET market reached a value of $0.80 Bn in 2023, growing at a CAGR of 19.5% during 2017-2023

(6/n)

(6/n)

Global rPET market size was estimated at $10.8 Bn in 2023 and is expected to grow at a CAGR of 8.5% from 2024-30

Segmental Highest Global Market Share in 2023

o Bottles & containers

o Grade A rPET

o Recycled PET flakes

o The clear rPET segment

o The fiber segment

(7/n)

Segmental Highest Global Market Share in 2023

o Bottles & containers

o Grade A rPET

o Recycled PET flakes

o The clear rPET segment

o The fiber segment

(7/n)

Key Players:

Reliance Industries (India)

Indorama Ventures (Thailand)

Coca-Cola (Global)

PepsiCo (Global)

PolyQuest (Mumbai)

Lotte Chemicals (Chennai)

Remondis (Germany)

Plastipak Holdings, Inc.

Ganesha Ecosphere (Kanpur)

Challenges & Opportunities👇

(8/n)

Reliance Industries (India)

Indorama Ventures (Thailand)

Coca-Cola (Global)

PepsiCo (Global)

PolyQuest (Mumbai)

Lotte Chemicals (Chennai)

Remondis (Germany)

Plastipak Holdings, Inc.

Ganesha Ecosphere (Kanpur)

Challenges & Opportunities👇

(8/n)

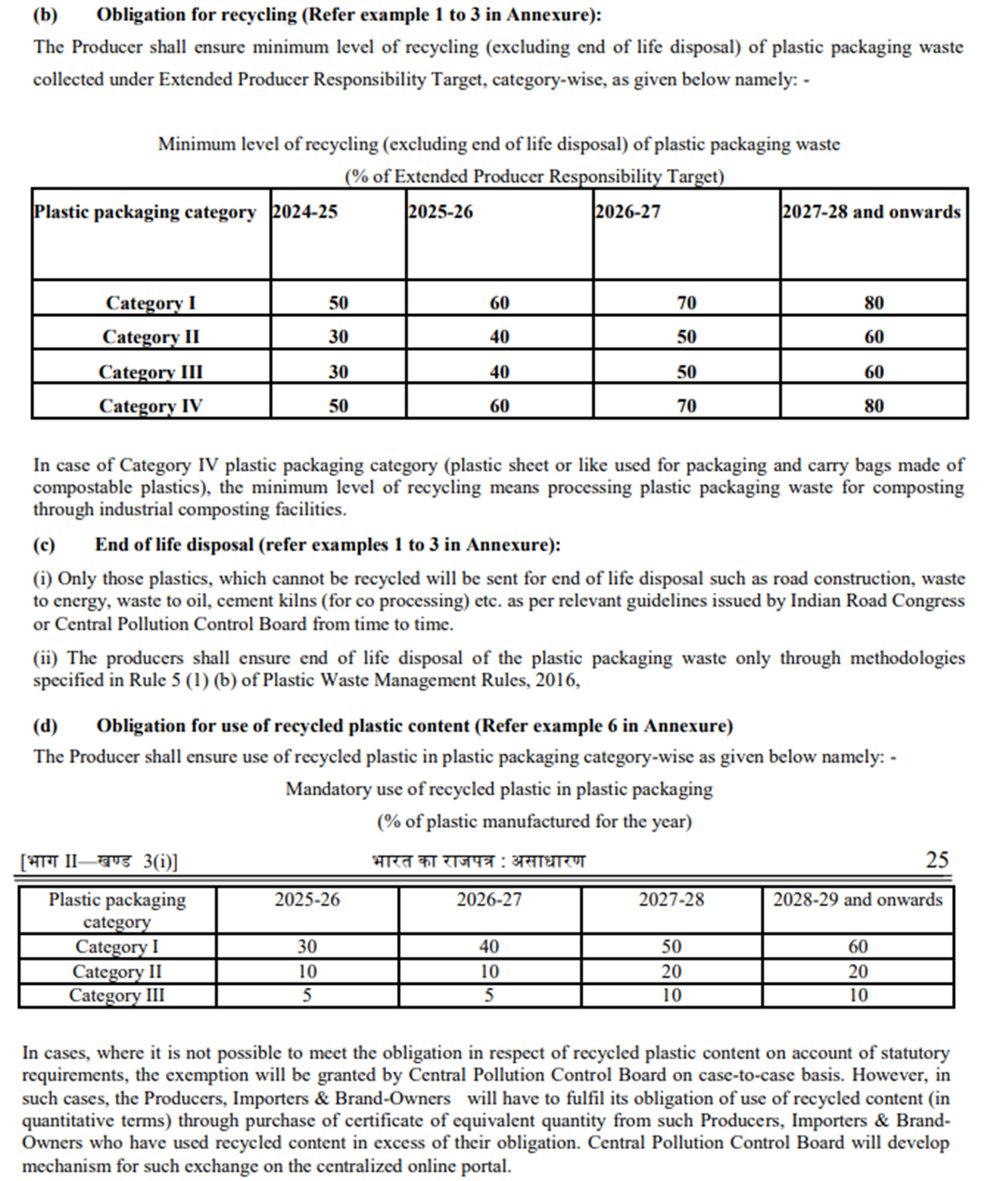

Latest Govt of India Rules

# The Plastic Waste Management Rules, 2016: It mandate minimum use of recycled plastic content in certain products

# Extended Producer Responsibility (EPR): It holds manufacturers responsible for the end-of-life management of their products

(9/n)

# The Plastic Waste Management Rules, 2016: It mandate minimum use of recycled plastic content in certain products

# Extended Producer Responsibility (EPR): It holds manufacturers responsible for the end-of-life management of their products

(9/n)

Global Customers of rPET Products and Recent Developments in rPET Industry:

o Adidas America, Allbirds, Everlane, Patagonia & Nike

o In 2023, US-based bottled water brand Chlorophyll Water announced the launch of new bottles made using 100% recycled PET(rPET)

(10/n)

o Adidas America, Allbirds, Everlane, Patagonia & Nike

o In 2023, US-based bottled water brand Chlorophyll Water announced the launch of new bottles made using 100% recycled PET(rPET)

(10/n)

Sources referred:

maximizemarketresearch.com/market-report/…

petnology.com/online/news-de…

grandviewresearch.com/industry-analy…

jprecycling.net/plastic/proces…

intcoplastic.com/en/pet-bottle-…

cpcb.nic.in/uploads/plasti…

bseindia.com/corporates/dow…

maximizemarketresearch.com/market-report/…

petnology.com/online/news-de…

grandviewresearch.com/industry-analy…

jprecycling.net/plastic/proces…

intcoplastic.com/en/pet-bottle-…

cpcb.nic.in/uploads/plasti…

bseindia.com/corporates/dow…

@UnrollHelper

• • •

Missing some Tweet in this thread? You can try to

force a refresh