Do water filters actually do anything? We CT scanned several popular water filters before and after use to see what they’re able to keep out of your body. Here’s what we found… 🧵

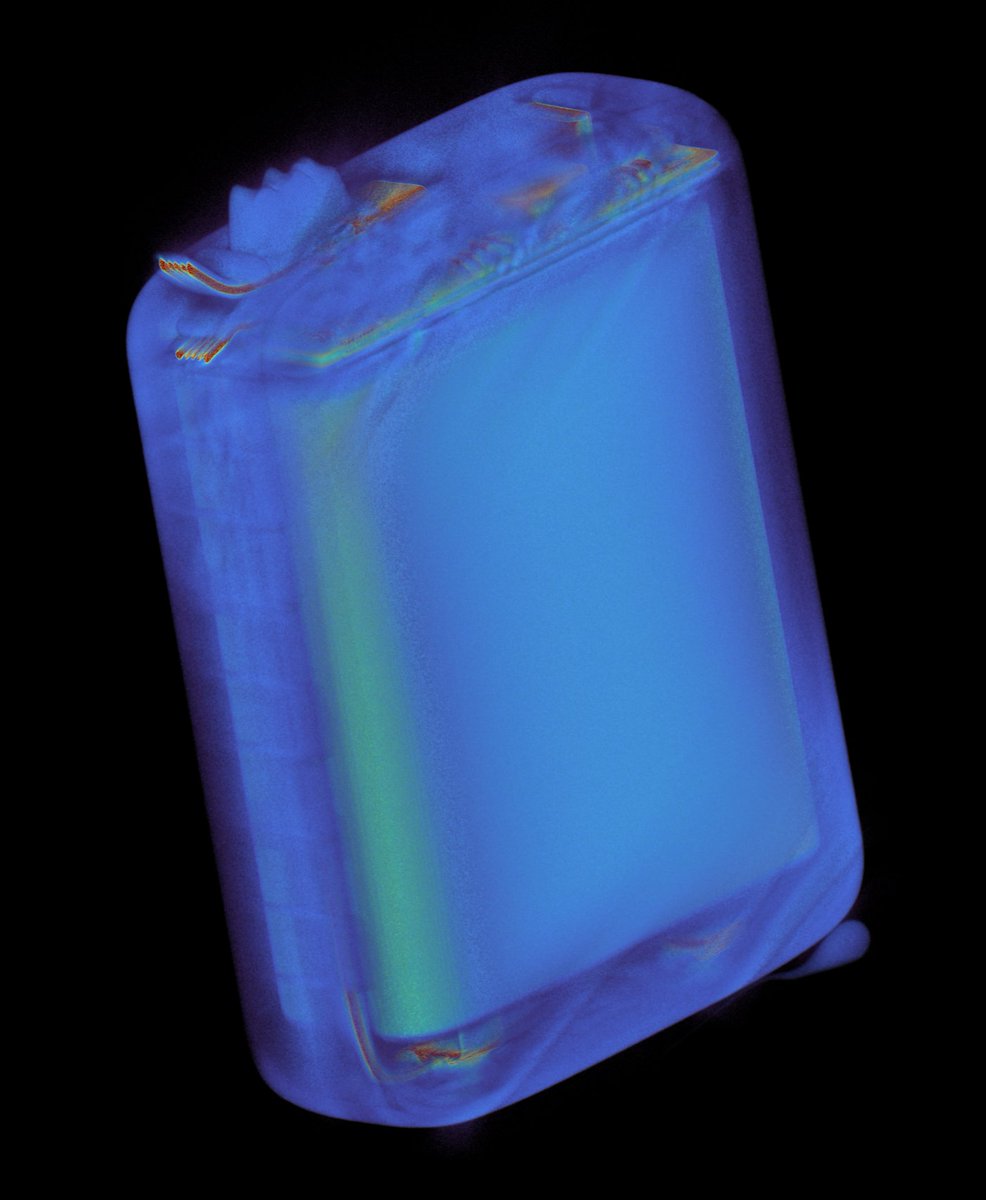

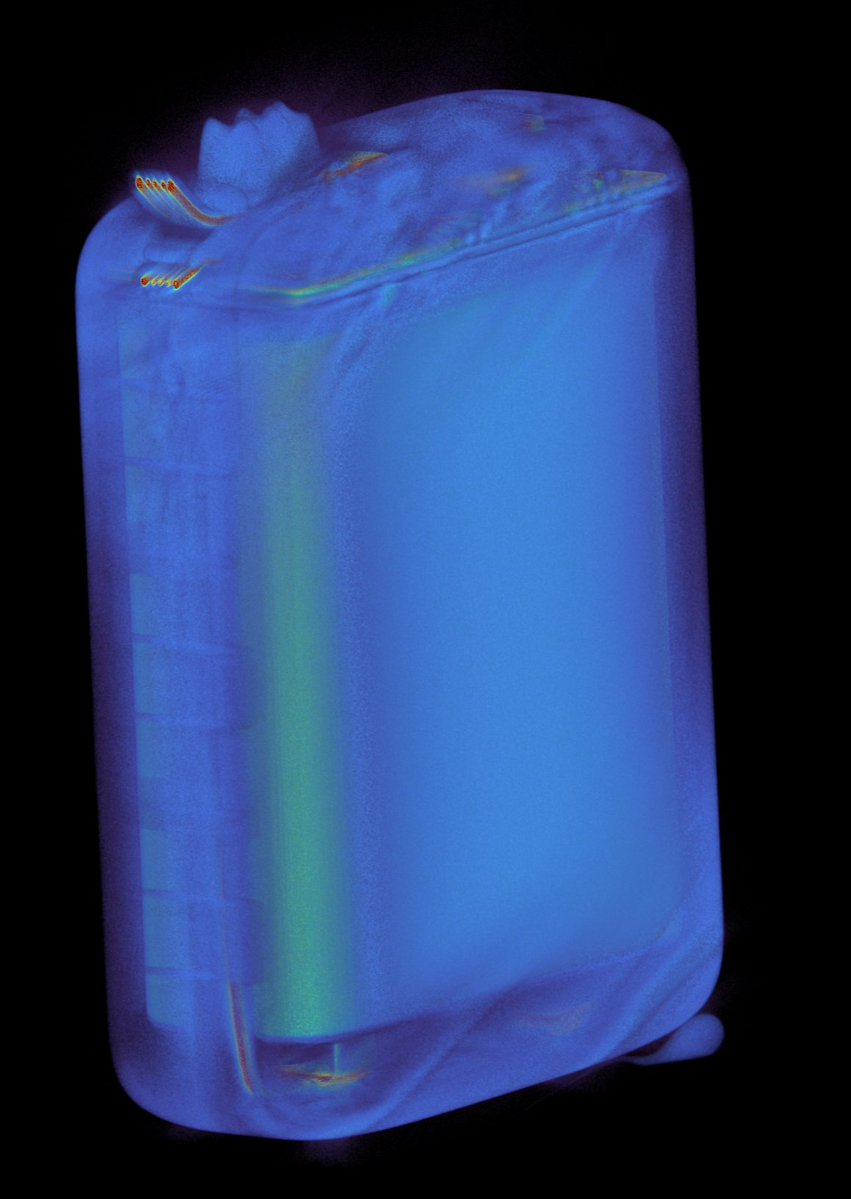

These are before-and-after @lumafield scans of a Brita water filter; it’s filled with a blend of activated carbon and ion-exchange resin and claims to trap chlorine, sediment, and heavy metals like lead. The filter medium swells with use, and it also gets denser. How do we know?

Industrial CT scans capture both geometry and relative density. We start by taking hundreds of X-ray images from different angles, then reconstruct them into a 3D model that can be sectioned and analyzed. A dark area in a 2D X-ray image could be either thicker material or denser material; by rotating the object we’re scanning, we can separate geometry from density. In this @lumafield CT scan, density is visualized as a blue-red color map.

@lumafield As the filter medium inside this Brita cartridge is used, it swells and cracks. Clearly-defined flow channels are visible, suggesting water is following the same path through the filter media each time.

@lumafield Here we’ve used @lumafield’s automated inclusion analysis tool to identify areas that are particularly dense. The densest impurities, highlighted as purple and red specks, have been getting strained out toward the top of the filter medium.

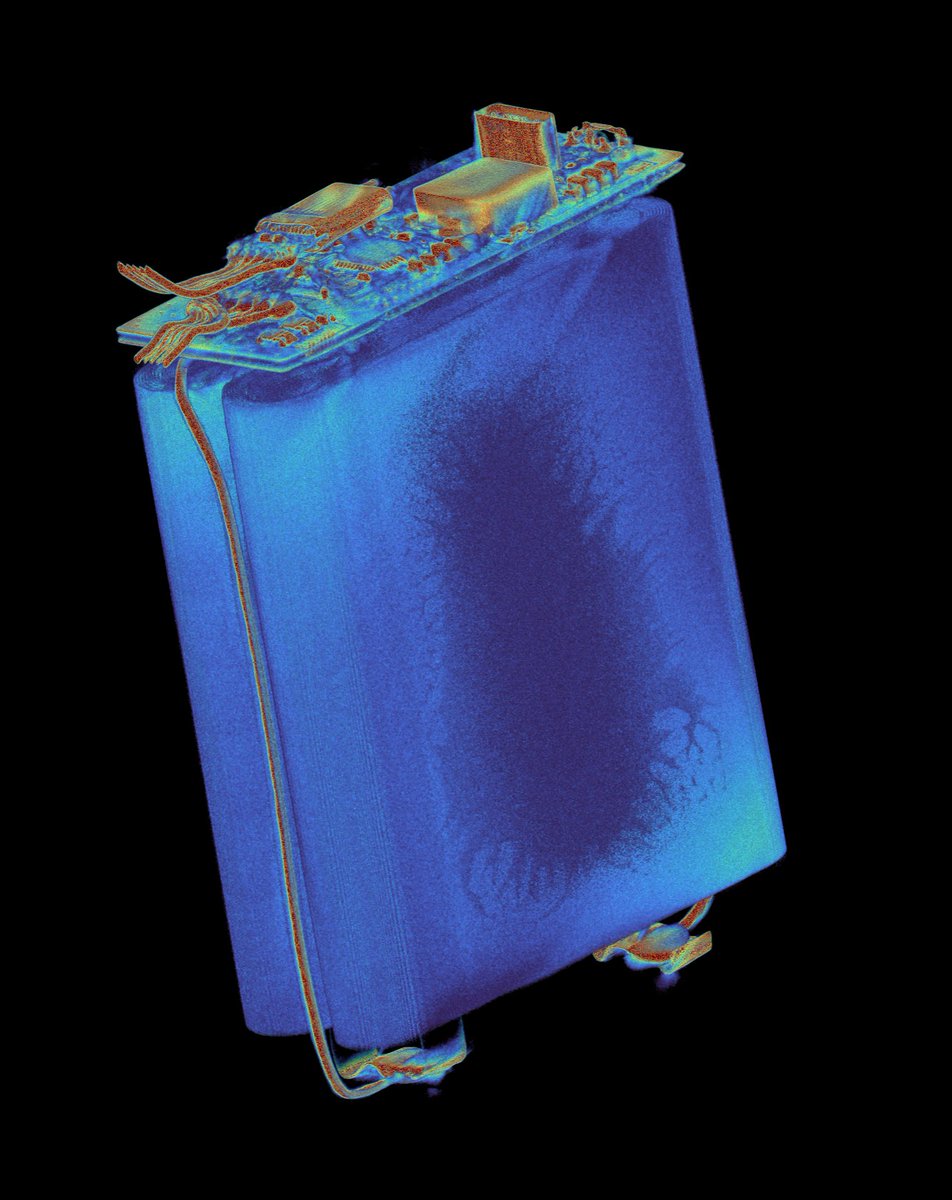

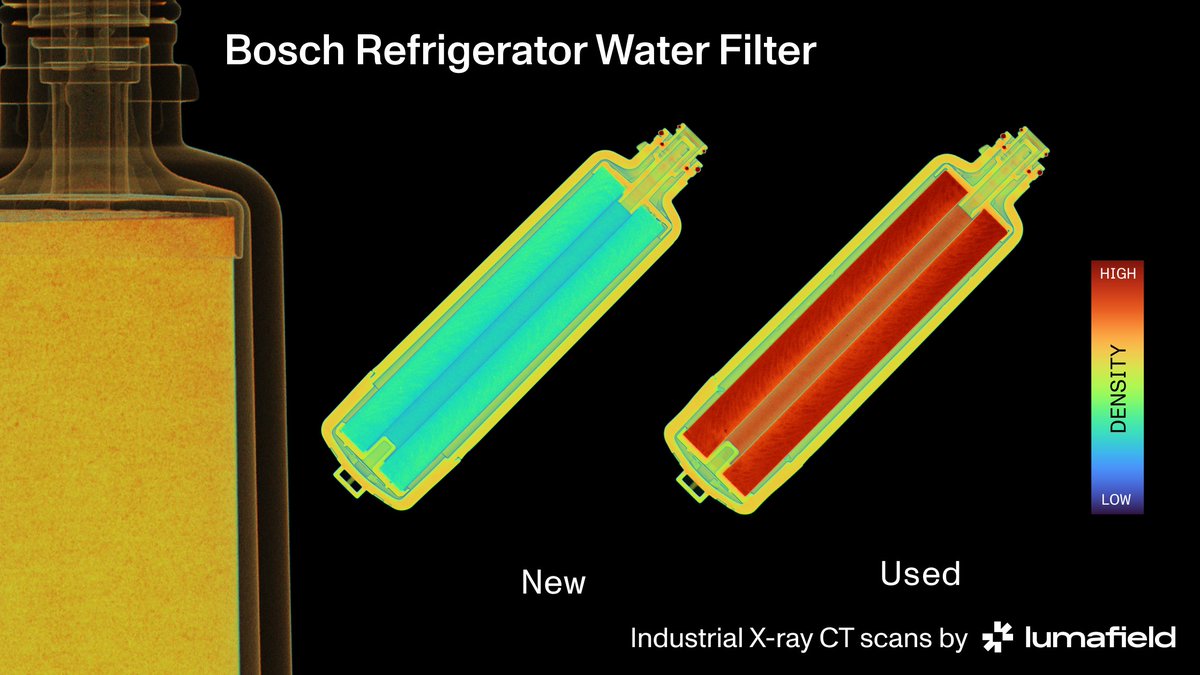

@lumafield Here’s a CT scan of an activated charcoal water filter from a Bosch refrigerator. The manufacturer recommends changing it every 6 months, but this was in my fridge for more than two years 😱

@lumafield @BoschGlobal @BoschHomeUS The water’s flow pattern is clearly visible thanks to deposits in the filter medium. Water flows in along the outer edges of the cartridge, then through the medium to the center channel before heading to the refrigerator’s ice maker.

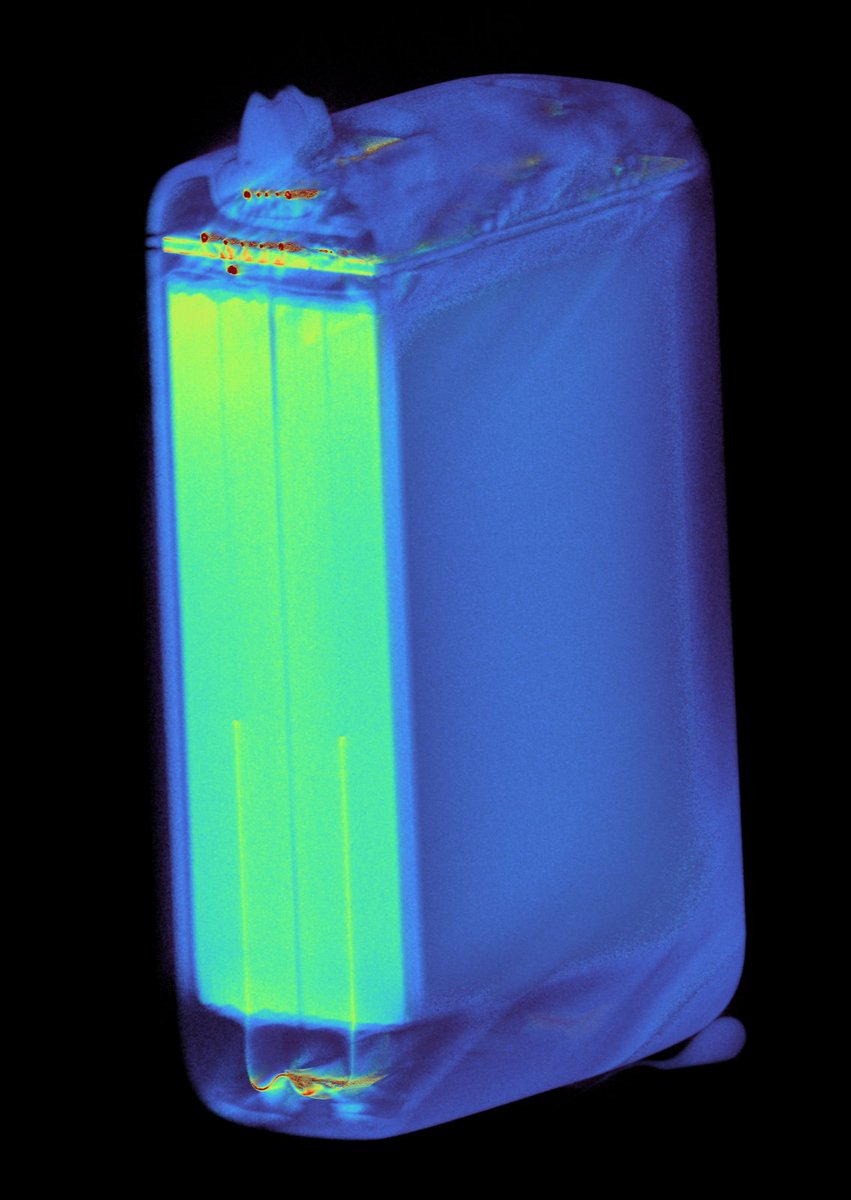

@lumafield @BoschGlobal @BoschHomeUS Reverse osmosis water filters use a semi-permeable membrane made of tightly-wound layers of synthetic material. They’re used in both small residential applications as well as giant industrial water treatment operations.

@lumafield @BoschGlobal @BoschHomeUS We scanned a new reverse osmosis filter, ran it for two months in a hard-water environment, and scanned it again. Scaling deposits of minerals are clearly visible in the used-filter CT scan. As they accumulate, they restrict flow through the filter and reduce efficiency.

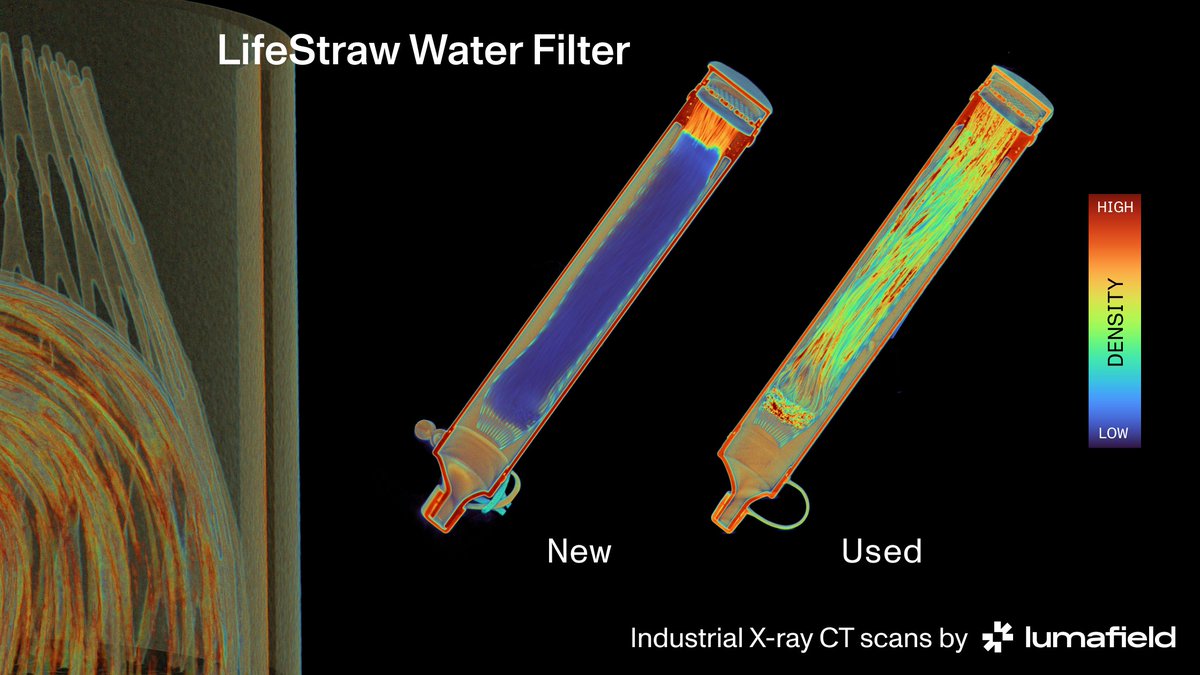

@lumafield @BoschGlobal @BoschHomeUS LifeStraw is a portable, personal water filter that uses hollow fiber membranes with microscopic pores that can block bacteria, parasites, and microplastics. With use, the membrane gradually accumulates contaminants starting at the inlet.

@lumafield @BoschGlobal @BoschHomeUS @lifestraw Takeaways: water filters do actually capture impurities, and you should replace them periodically; as they become loaded, they get less efficient and in some cases less effective.

@lumafield @BoschGlobal @BoschHomeUS @lifestraw Check out for more details on these filters. @lumafield has tons of cool scans to explore!lumafield.com/article/whats-…

@lumafield @BoschGlobal @BoschHomeUS @lifestraw And if you want to learn more about how industrial CT works and how it’s used, check out this intro video.

• • •

Missing some Tweet in this thread? You can try to

force a refresh