i'm really tired of ragebait on how advanced china's industrial base is.

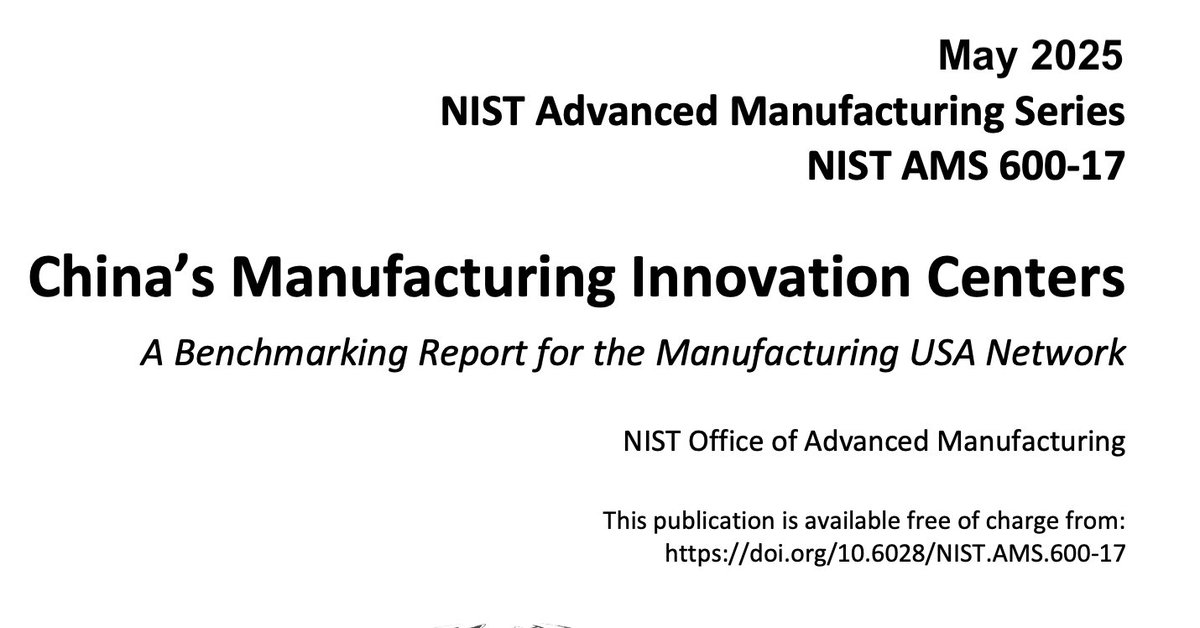

let's dispel this by diving into NIST's MIC report.

note: do not read this if you're a gullible euro VC or western exec who would back down after a factory visit to china. we still need to act NOW.

let's dispel this by diving into NIST's MIC report.

note: do not read this if you're a gullible euro VC or western exec who would back down after a factory visit to china. we still need to act NOW.

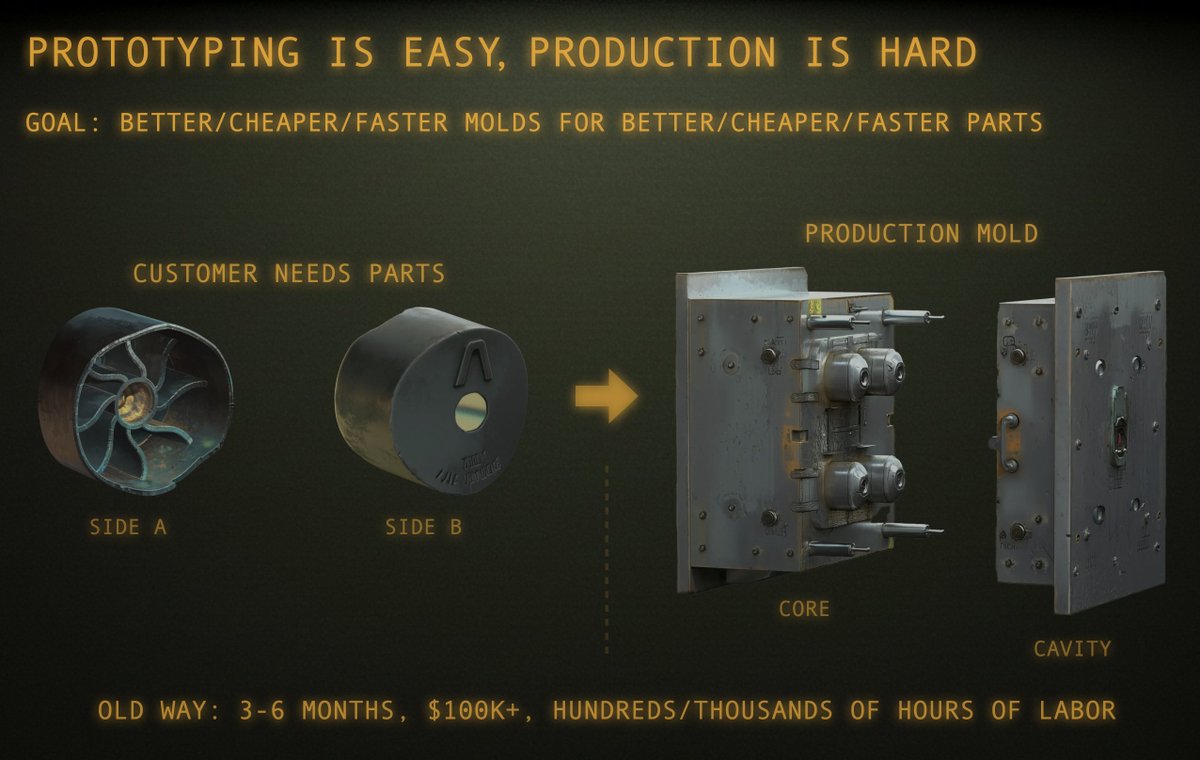

first, let's be clear what "advanced manufacturing" actually means:

it's not what, but HOW you manufacture. machines, software, process optimization, automated quality control. digitization, etc.

you can make a plastic bottle cap in a high-tech way or a low-tech way.

it's not what, but HOW you manufacture. machines, software, process optimization, automated quality control. digitization, etc.

you can make a plastic bottle cap in a high-tech way or a low-tech way.

here's the reality per NIST citing chinese government sources:

only 37% of chinese manufacturers reached BASIC digitization only 4% have leading-edge manufacturing capabilities

they built more factories. they didn't build tons of advanced factories.

only 37% of chinese manufacturers reached BASIC digitization only 4% have leading-edge manufacturing capabilities

they built more factories. they didn't build tons of advanced factories.

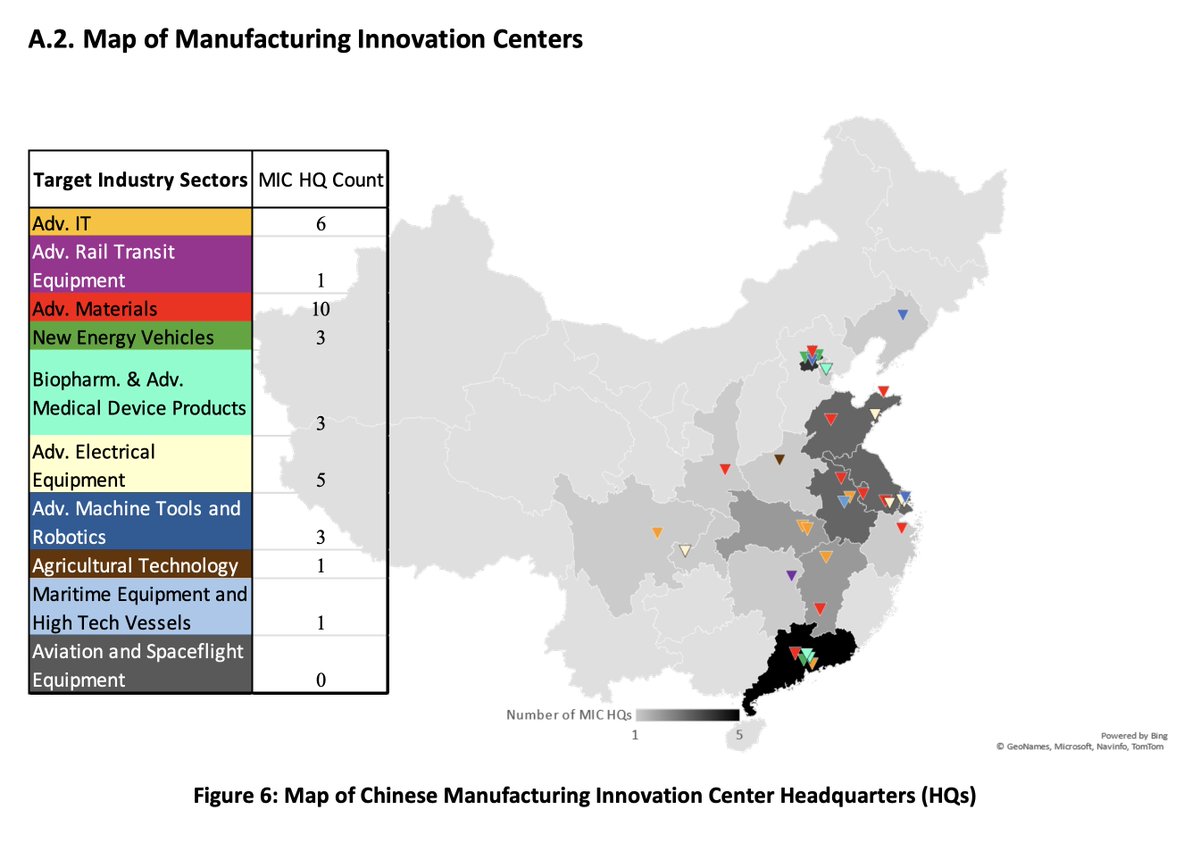

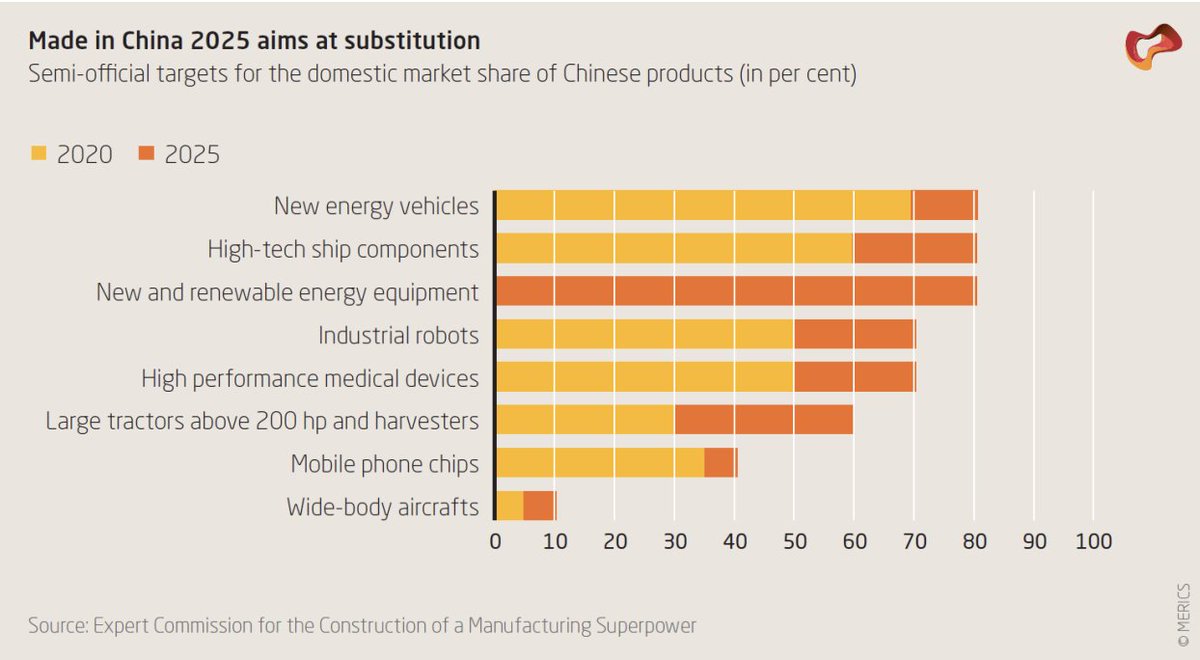

china gets this. made in china (MIC) 2025 had one explicit goal: reach ~80% domestic production in key industries by 2025.

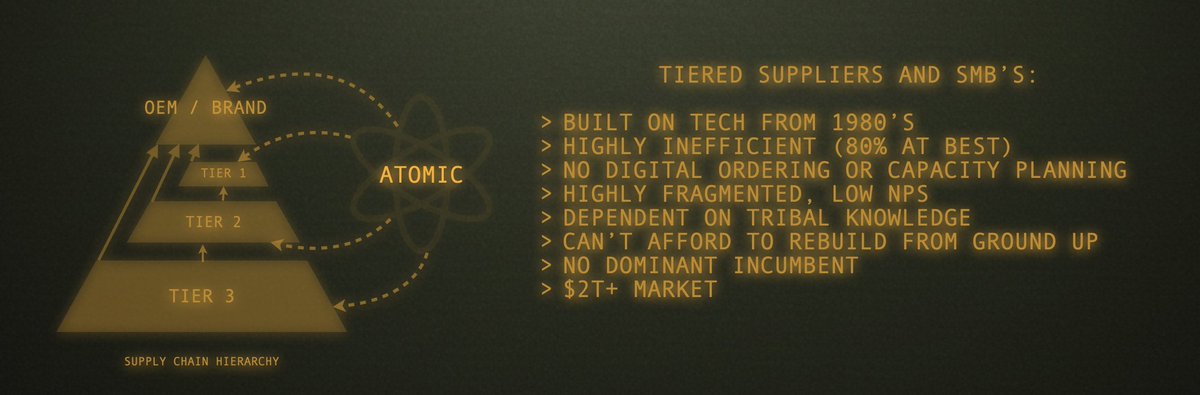

they launched 33 "manufacturing innovation centers" (MICs) - R&D hubs for inventing new production methods - backed by $300B+ in funding.

they launched 33 "manufacturing innovation centers" (MICs) - R&D hubs for inventing new production methods - backed by $300B+ in funding.

new energy vehicles, high-tech ship components, industrial robots, medical devices, mobile phone chips, even wide-body aircraft.

replace every foreign product.

replace every foreign product.

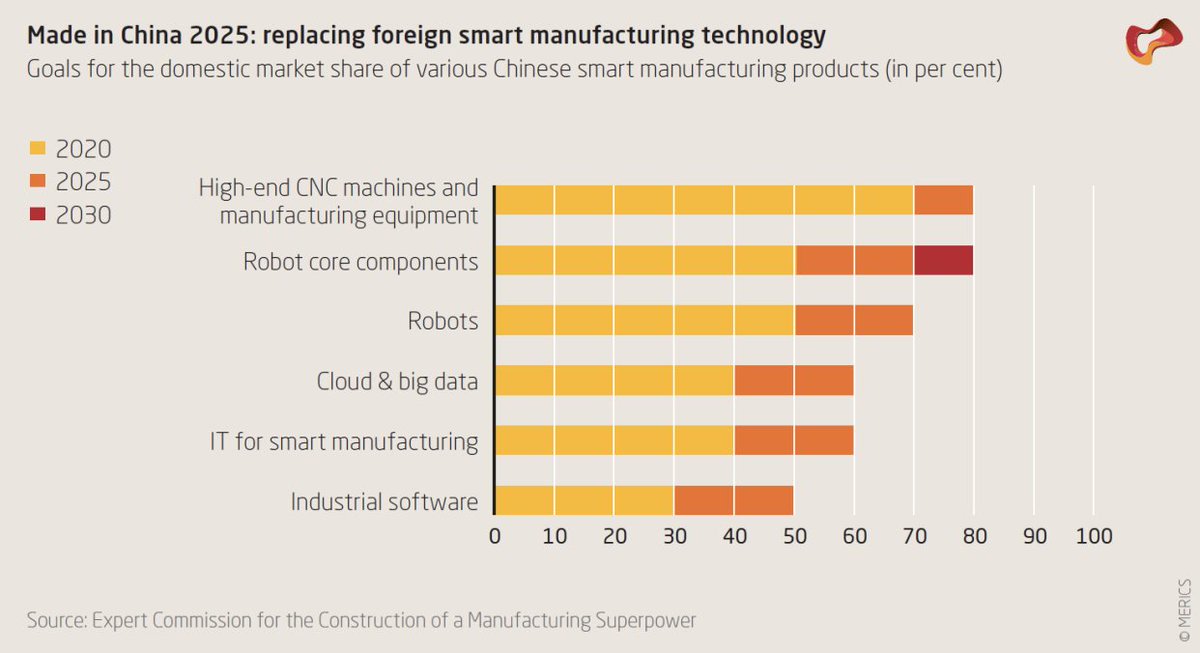

but here's the deeper strategy: don't just replace foreign products. replace the foreign manufacturing technology itself.

the plan targeted 50-70% domestic share in high-end CNC machines, robot core components, industrial software, smart manufacturing IT.

the plan targeted 50-70% domestic share in high-end CNC machines, robot core components, industrial software, smart manufacturing IT.

so what happened after $300B+ and 33 innovation centers over 9 years?

massive "overcapacity" that isn't a bug - it's a weapon.

solar capacity 2-3X global demand. auto factories running at 59%. selling at negative margins.

this isn't failed planning. this is dumping subsidized products to kill foreign competitors and deindustrialize everyone else.

massive "overcapacity" that isn't a bug - it's a weapon.

solar capacity 2-3X global demand. auto factories running at 59%. selling at negative margins.

this isn't failed planning. this is dumping subsidized products to kill foreign competitors and deindustrialize everyone else.

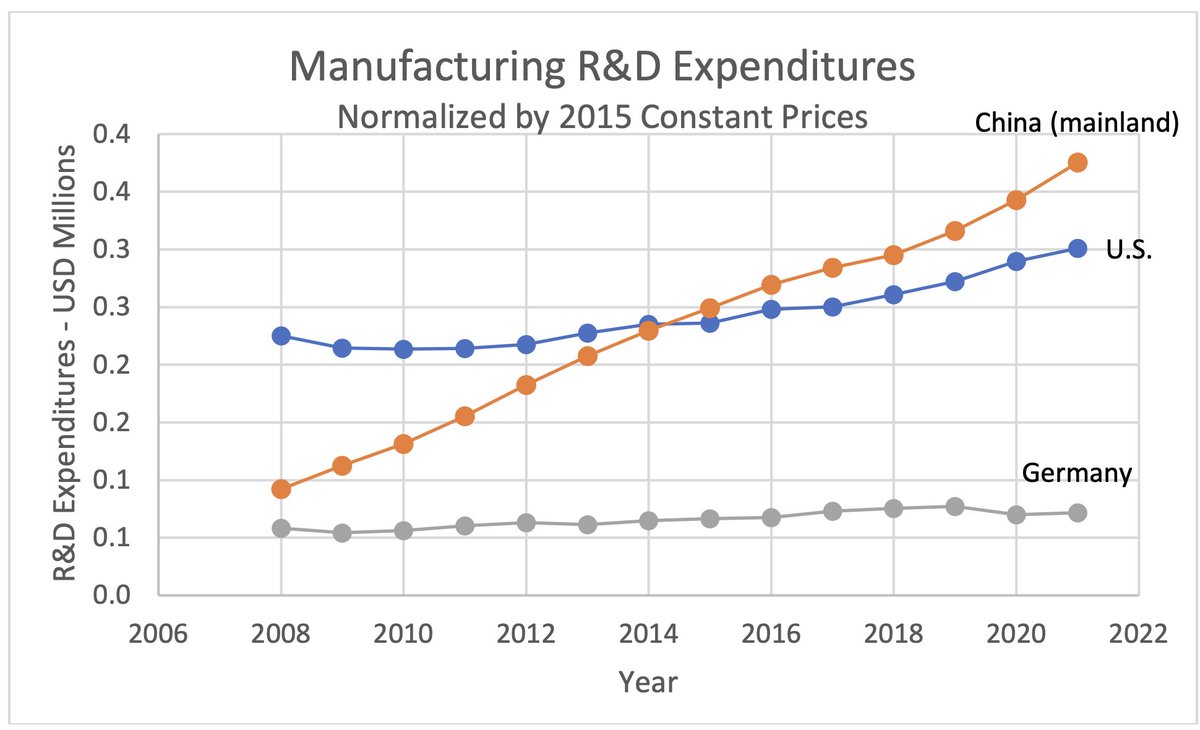

meanwhile, US Manufacturing USA gets $160M annual federal funding for 18 institutes.

germany's fraunhofer gets $374M - investing ~20X more relative to GDP.

we're letting china outspend us on manufacturing process R&D while we still lead in actual innovation.

germany's fraunhofer gets $374M - investing ~20X more relative to GDP.

we're letting china outspend us on manufacturing process R&D while we still lead in actual innovation.

the real story: build so much capacity you can flood global markets.

operate at a loss, state banks cover it. undercut every competitor until their factories close.

then you're the only supplier left.

operate at a loss, state banks cover it. undercut every competitor until their factories close.

then you're the only supplier left.

the "overcapacity" isn't a market failure. it's deliberate economic warfare to ensure no one else can manufacture.

and it's working. look at how much us and eu manufacturing capacity has declined while china's dominates.

and it's working. look at how much us and eu manufacturing capacity has declined while china's dominates.

so what do we do? build. now.

not in 5 years when committees finish studying it. the window to reindustrialize is closing. every quarter we debate, they add more factories. speed is the only counter to scale.

not in 5 years when committees finish studying it. the window to reindustrialize is closing. every quarter we debate, they add more factories. speed is the only counter to scale.

read here: nvlpubs.nist.gov/nistpubs/ams/N…

• • •

Missing some Tweet in this thread? You can try to

force a refresh