A PRIMER FOR BATTERY DAY

This is a lengthy thread

- so get some popcorn and settle down to a relaxing read

- the punch lines are many all the way through to the end

This is not an attempt to predict all of Battery Day

- it is just a primer on one aspect - SIZE

@elonmusk

This is a lengthy thread

- so get some popcorn and settle down to a relaxing read

- the punch lines are many all the way through to the end

This is not an attempt to predict all of Battery Day

- it is just a primer on one aspect - SIZE

@elonmusk

Let us assume that this is in fact a Roadrunner cell

What is its size ?

- some say it is 54 mm diameter x 99 mm length or “5499”

For illustration purposes I am going to assume that it is 55 mm diameter x 90 mm length or “5590”

Length is both a critical factor and constraint

What is its size ?

- some say it is 54 mm diameter x 99 mm length or “5499”

For illustration purposes I am going to assume that it is 55 mm diameter x 90 mm length or “5590”

Length is both a critical factor and constraint

The constraint that I am applying here is the height limitation of the existing Model 3 and Y Battery Packs

- which I am assuming to have an overall height of 105 mm and a module height of 90 mm

- which I am assuming to have an overall height of 105 mm and a module height of 90 mm

With a physical size of 5590 I estimate each cell to weigh around 0.618 kg or 1.36 lb

That’s a serious piece of Bologna Sausage

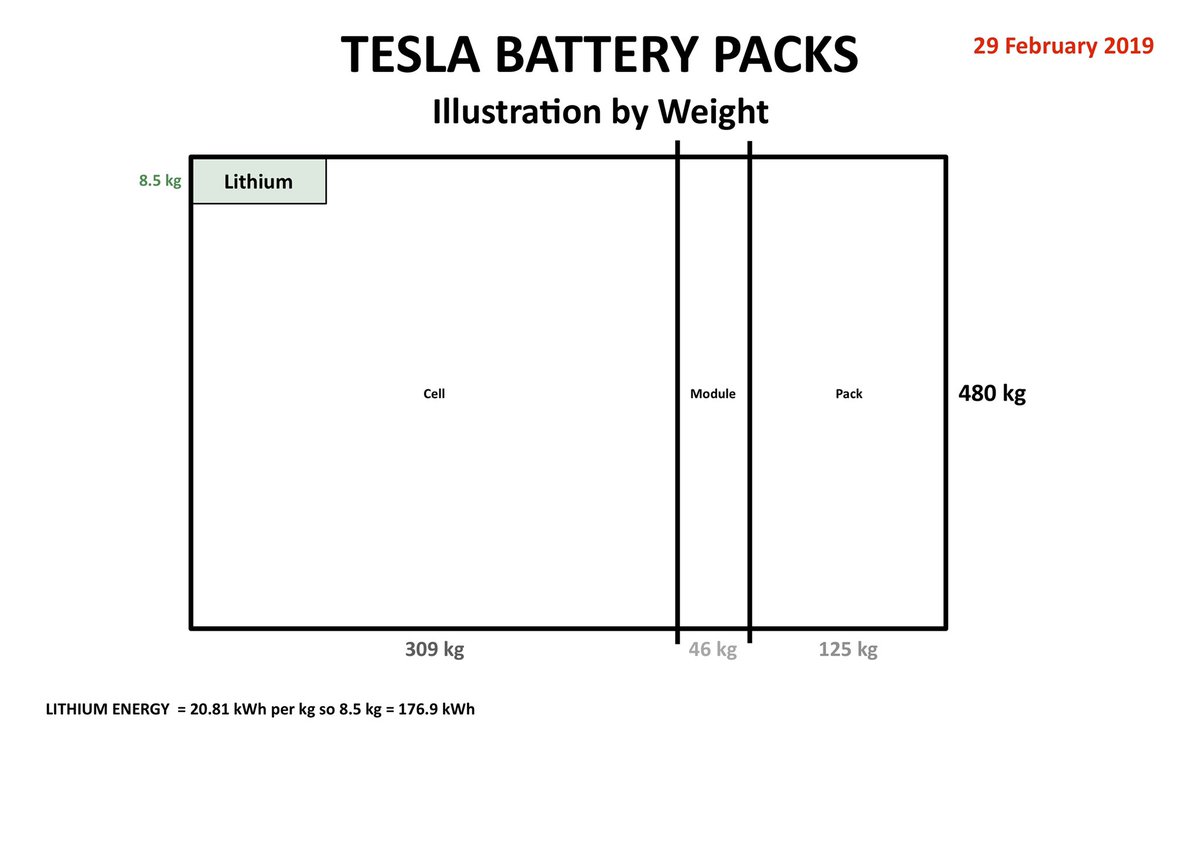

Staying with a total cell weight of 309 kg that translates to 500 cells in a pack instead of 4,416 cells

That’s a serious piece of Bologna Sausage

Staying with a total cell weight of 309 kg that translates to 500 cells in a pack instead of 4,416 cells

Just using “illustrative” numbers and not trying for precision but just directional importance :

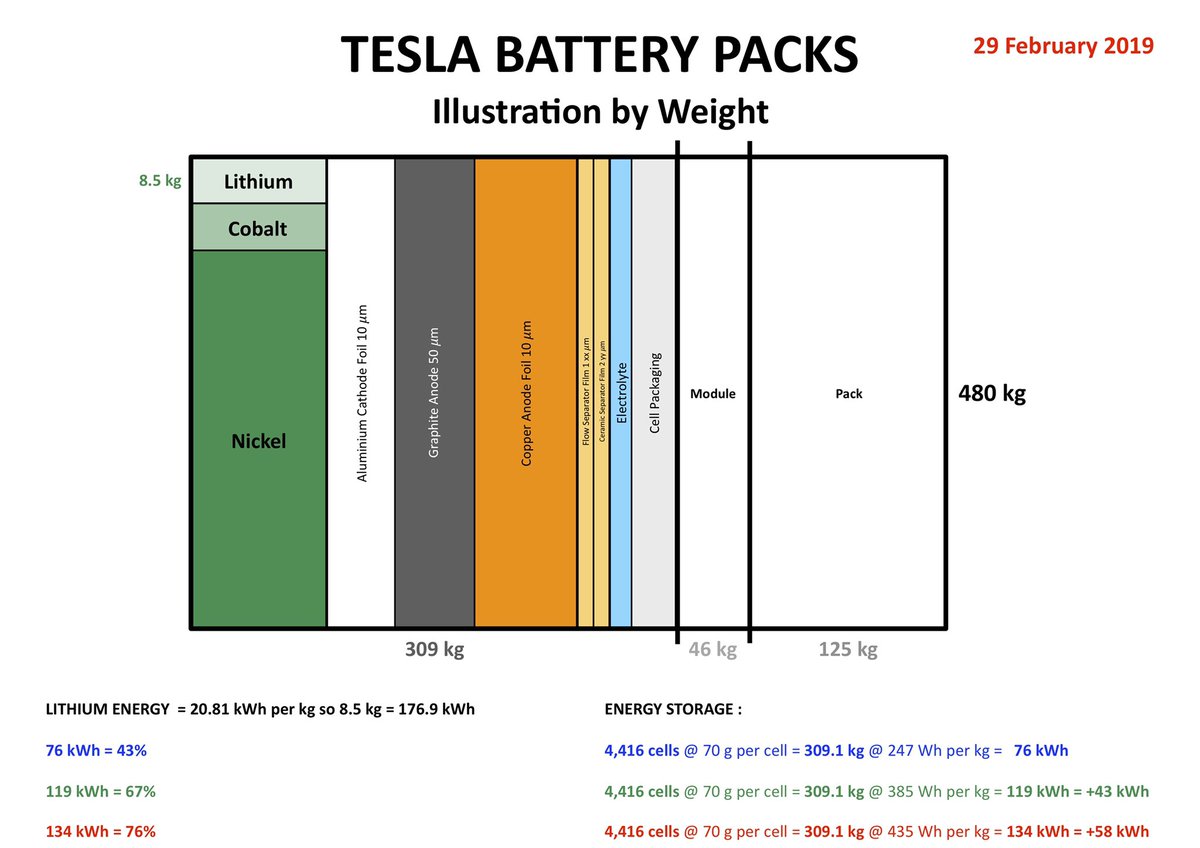

2170 profile : 4,416 cells at 70 g each = 309 kg

5590 profile : 500 cells at 618 g each = 309 kg

2170 profile : 4,416 cells at 70 g each = 309 kg

5590 profile : 500 cells at 618 g each = 309 kg

Fewer cells should result in less inactive packaging materials and less electrical connecting materials with more of the weight being given to the active materials

So even without chemistry changes we can expect a bump in total energy stored

Perhaps from 76 kWh to say 80~85 kWh

So even without chemistry changes we can expect a bump in total energy stored

Perhaps from 76 kWh to say 80~85 kWh

Now remember that we have stretched the height to 90 mm versus 70 mm

90 mm / 70 mm = +28.6%

This means more of the physical volume goes into the length rather than into the area

So the horizontal footprint is smaller because more of the volume of the battery is in the length

90 mm / 70 mm = +28.6%

This means more of the physical volume goes into the length rather than into the area

So the horizontal footprint is smaller because more of the volume of the battery is in the length

HORIZONTAL FOOTPRINT :

4,416 cells = 66.453 cells squared x 21 mm diameter = a square of 1,395.5 mm in each direction if cells were packed tight with all touching

500 cells = 22.361 cells squared x 55 mm in diameter = a square of 1,229.8 mm in each direction

4,416 cells = 66.453 cells squared x 21 mm diameter = a square of 1,395.5 mm in each direction if cells were packed tight with all touching

500 cells = 22.361 cells squared x 55 mm in diameter = a square of 1,229.8 mm in each direction

CAVEAT

Note that this calculation is just a quick approximation that does not try to take into account hexagonal packing density nor actual separation and spacing between the cells

Note that this calculation is just a quick approximation that does not try to take into account hexagonal packing density nor actual separation and spacing between the cells

This effective horizontal square is reduced by 165.70 mm in each direction

So the horizontal dimensions of the battery pack can be a lot smaller

Or you can add more cells into the same horizontal area

+28.8% without considering the actual gaps between the cells

So the horizontal dimensions of the battery pack can be a lot smaller

Or you can add more cells into the same horizontal area

+28.8% without considering the actual gaps between the cells

MORE SPACE

This frees up horizontal space for more cells

This can allow larger amounts of stored energy to be carried in the same horizontal space

Maybe it could allow more use of lower energy LFP cells which are also cheaper

It opens up new tradeoffs for existing vehicles

This frees up horizontal space for more cells

This can allow larger amounts of stored energy to be carried in the same horizontal space

Maybe it could allow more use of lower energy LFP cells which are also cheaper

It opens up new tradeoffs for existing vehicles

SMALLER CARS

The denser packing is also positive for smaller cars

- because a physically smaller battery pack on the horizontal plane still allows for the same energy content

So the shorter narrower cheaper vehicles start to get some favor

The denser packing is also positive for smaller cars

- because a physically smaller battery pack on the horizontal plane still allows for the same energy content

So the shorter narrower cheaper vehicles start to get some favor

PRODUCTION :

There are expectations for Battery Day to reveal many little changes that can have the potential for making simpler shorter production

But let’s just look at ONE variable here

Current Panasonic lines are said to have a nominal output rate of 400,000 cells per day

There are expectations for Battery Day to reveal many little changes that can have the potential for making simpler shorter production

But let’s just look at ONE variable here

Current Panasonic lines are said to have a nominal output rate of 400,000 cells per day

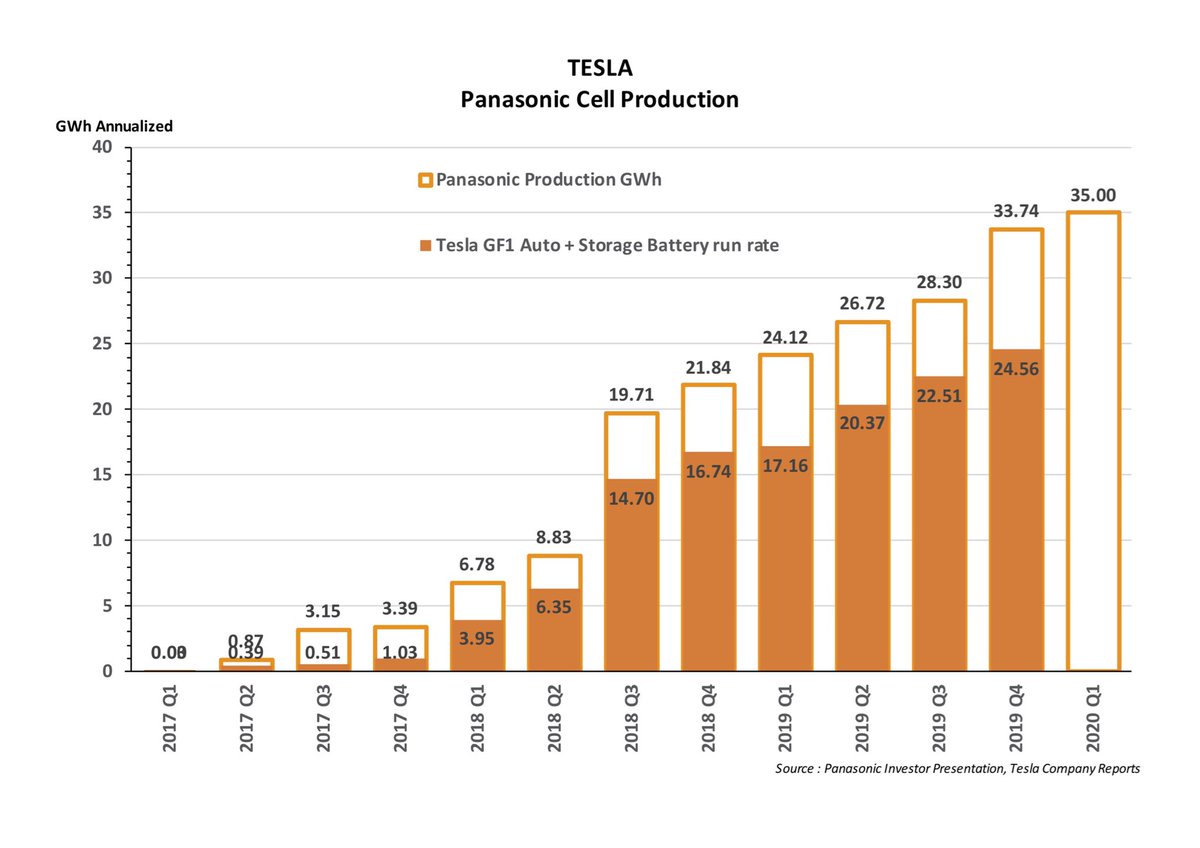

BATTERY MANUFACTURING 1.0 - PANASONIC AND OTHERS

But this ignores real-life yield loss due to line stoppages, downtime, bad output, and quality and performance issues

The actual yield against nameplate capacity appears to be only about 75%

But this ignores real-life yield loss due to line stoppages, downtime, bad output, and quality and performance issues

The actual yield against nameplate capacity appears to be only about 75%

This is based on Panasonic’s claimed capacity at GF1 compared with Tesla’s actual output of vehicles and storage batteries

So the claimed capacity of 35 GWh on 13 lines at GF1 seems to be yielding real output of only around 26.25 GWh

This is for both Auto and Storage Batteries

So the claimed capacity of 35 GWh on 13 lines at GF1 seems to be yielding real output of only around 26.25 GWh

This is for both Auto and Storage Batteries

BATTERY MANUFACTURING 2.0 - TESLA

Now let us assume that Tesla can build its Battery Manufacturing lines for the same nominal output of 400,000 cells per day

But it only takes 500 cells of 5590 format to make a Battery Pack instead of 4,416 cells of 2170 format

Now let us assume that Tesla can build its Battery Manufacturing lines for the same nominal output of 400,000 cells per day

But it only takes 500 cells of 5590 format to make a Battery Pack instead of 4,416 cells of 2170 format

And Tesla’s simpler and more streamlined process can be naturally expected to have lower yield loss

So let’s compare the effects of all of that

So let’s compare the effects of all of that

PANASONIC 2170 LINE :

400,000 / 4,416 cells = 90.58 packs per day

75% Yield —> 67.9 packs per day

13 lines = 883.15 packs per day @ 76 kWh each = 67.12 MWh per day x 350 days = 23.49 GWh per year

400,000 / 4,416 cells = 90.58 packs per day

75% Yield —> 67.9 packs per day

13 lines = 883.15 packs per day @ 76 kWh each = 67.12 MWh per day x 350 days = 23.49 GWh per year

TESLA 5590 LINE :

400,000 / 500 cells* = 800 packs per day

90% Yield* —> 720 packs per day

1 line = 720 packs per day @ 80 kWh* each = 58.32 MWh per day x 350 days = 20.41 GWh per year

NOTE : Using * to highlight three changed parameters

400,000 / 500 cells* = 800 packs per day

90% Yield* —> 720 packs per day

1 line = 720 packs per day @ 80 kWh* each = 58.32 MWh per day x 350 days = 20.41 GWh per year

NOTE : Using * to highlight three changed parameters

OBSERVATIONS

1. This suggests Tesla’s 1-line Kato Road operation may eventually achieve 87% of Panasonic’s 13-line GF1 finished output

1. This suggests Tesla’s 1-line Kato Road operation may eventually achieve 87% of Panasonic’s 13-line GF1 finished output

ON-LINE LABOR COST

2. It will only need on-line manning for 1 line instead of 13 lines

- on-line manning is the labor actually involved in running the line

- other labor is required to handle incoming materials and outgoing finished product

2. It will only need on-line manning for 1 line instead of 13 lines

- on-line manning is the labor actually involved in running the line

- other labor is required to handle incoming materials and outgoing finished product

3. Let’s say Panasonic’s on-line labor cost is 100 units per GWh for 13 lines

- then Tesla’s on-line labor cost would be 100 x 1 / 13 x 23.49 / 20.41 = 8.85 units per GWh

4. So Tesla’s on-line labour cost per GWh may be CUT by -91.15% just from scale effects

- then Tesla’s on-line labor cost would be 100 x 1 / 13 x 23.49 / 20.41 = 8.85 units per GWh

4. So Tesla’s on-line labour cost per GWh may be CUT by -91.15% just from scale effects

5. But the manning required for on-line labor may be lower because of a simpler production process that uses Maxwell Dry Coating and other improvements

- let’s say the labor is reduced to 80% or -20% lower than on a Panasonic line

- let’s say the labor is reduced to 80% or -20% lower than on a Panasonic line

6. So the on-line labour cost goes down to 8.85 x 80% = 7.08 units per GWh

- or 93% lower than for Panasonic 2170 cells

- just because of physical size of the cells and Dry Coating

- or 93% lower than for Panasonic 2170 cells

- just because of physical size of the cells and Dry Coating

YIELD LOSS AND WASTE

7. We assumed 25% lost production time for Panasonic and perhaps this resulted in 25% x 30% = 7.5% Waste

8. And we assumed 10% lost production time for Tesla and perhaps this resulted in 10% x 30% = 3.0% Waste

7. We assumed 25% lost production time for Panasonic and perhaps this resulted in 25% x 30% = 7.5% Waste

8. And we assumed 10% lost production time for Tesla and perhaps this resulted in 10% x 30% = 3.0% Waste

CAPITAL COSTS

8. If you only need 1 production line to produce 87% of the output of 13 production lines then the capital cost per GWh is massively reduced even if the lines have to be stronger and larger to build bigger and heavier jelly rolls

- 90% capital cost saving per GWh?

8. If you only need 1 production line to produce 87% of the output of 13 production lines then the capital cost per GWh is massively reduced even if the lines have to be stronger and larger to build bigger and heavier jelly rolls

- 90% capital cost saving per GWh?

PHYSICAL FOOTPRINT

9. And the physical footprint of the production facility is smaller

- again perhaps -90% production floor area saving

9. And the physical footprint of the production facility is smaller

- again perhaps -90% production floor area saving

10. NO WONDER TESLA HAS NOT CHOSEN TO EXPAND GF1 YET

- the new paradigm should be confirmed in practice before spending too much money on physical expansions that may be paced out over a longer period

- the new paradigm should be confirmed in practice before spending too much money on physical expansions that may be paced out over a longer period

• • •

Missing some Tweet in this thread? You can try to

force a refresh