Alright, since the Bilge Pumps episode 52 is up, and I really didn't get a chance to go deep with US military 3D printing as is, versus what I see coming.

I'm going to drop a background thread here to do just that.

Note: long thread warning

1/

the-bilgepumps.simplecast.com/episodes/bilge…

I'm going to drop a background thread here to do just that.

Note: long thread warning

1/

the-bilgepumps.simplecast.com/episodes/bilge…

3D Printing/Additive Mfg has been around for a while.

The four “foundational” patents for 3D/AM processes were issued one each in 1984 and 1986 with the remaining two in 1989.

Two National Science Foundation impacted 3D/AM patents were issued in 1987 and 1995. (See photo)

2/

The four “foundational” patents for 3D/AM processes were issued one each in 1984 and 1986 with the remaining two in 1989.

Two National Science Foundation impacted 3D/AM patents were issued in 1987 and 1995. (See photo)

2/

U.S. Gov't 3D/AM Processes Senior Policy Maker Timeline

Jun 2011 - Pres. Obama launched the Advanced Manufacturing Partnership (AMP)

2012 -- National Network for Manufacturing Innovation (NNMI), $1 billion program

2013 Mil-STD-31000A for 3D Model tech data packages (TDP)

4/

Jun 2011 - Pres. Obama launched the Advanced Manufacturing Partnership (AMP)

2012 -- National Network for Manufacturing Innovation (NNMI), $1 billion program

2013 Mil-STD-31000A for 3D Model tech data packages (TDP)

4/

...was issued

2014 – US Military Service Chiefs include 3D/AM in strategic visions of their organizations

Sep 2016 - NNMI Rebranded “Manufacturing USA” by Commerce Dept.

2017 – DOD AM Roadmap with common requirements & objectives from DLA & Services AM roadmaps

5/

2014 – US Military Service Chiefs include 3D/AM in strategic visions of their organizations

Sep 2016 - NNMI Rebranded “Manufacturing USA” by Commerce Dept.

2017 – DOD AM Roadmap with common requirements & objectives from DLA & Services AM roadmaps

5/

2018 – “Legacy Tech Data Package Crisis” identified.

The attached painting of an autonomous ground resupply convoy with automated driving and 3D printing vans as provided in 2014 by Chief of Staff of the Army (CSA) Gen. Raymond T. Odierno as his service's 3D/AM vision.

6/

The attached painting of an autonomous ground resupply convoy with automated driving and 3D printing vans as provided in 2014 by Chief of Staff of the Army (CSA) Gen. Raymond T. Odierno as his service's 3D/AM vision.

6/

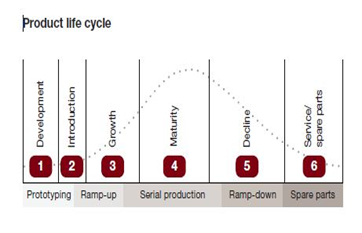

3D/AM excels in low volume production runs compared to traditional mass production.

This helps in prototyping and engineering development and spares production for legacy users after new sales no longer support a large production line.

7/

This helps in prototyping and engineering development and spares production for legacy users after new sales no longer support a large production line.

7/

3D/AM processes reduce the total cost of ownership of a product/weapons system by eliminating either or both the overhead of inefficient production lines & large stocks of spare parts with their cost of storage.

8/

8/

Military procurement and commercial life cycles both benefit from 3D/AM’s speed in prototyping and providing low volume production. Redesigning existing parts to use fewer components via AM often makes for lower weight and higher reliability in existing applications.

9/

9/

These are examples of two emerging 3D/AM products at the current state of the art.

o Aerojet Rocketdyne RL10 rocket engine (re-engineered w/lower part count)

o GE Printed Turboprop engine (New design w/fewer parts & has an economic low rate production)

10/

o Aerojet Rocketdyne RL10 rocket engine (re-engineered w/lower part count)

o GE Printed Turboprop engine (New design w/fewer parts & has an economic low rate production)

10/

Where 3D/AM beats mass production manufacturing methods are when existing parts weigh more and are less reliable in existing applications.

See:

The future of spare parts is 3D

© 2017 PwC

Dr. Reinhard Geissbauer, Dr. Jorge Lehr, Jens

strategyand.pwc.com/media/file/The…

11/

See:

The future of spare parts is 3D

© 2017 PwC

Dr. Reinhard Geissbauer, Dr. Jorge Lehr, Jens

strategyand.pwc.com/media/file/The…

11/

The 3D printed fuel nozzle for the GE Leap 1 turbofan engine uses 19 fuel nozzles per engine and a 3D part is 33% lighter, lasts 5-times longer and reduces fuel consumption due to optimized fuel paths.

If you have flown in a 737X or Airbus jet built since 2016.

12/

If you have flown in a 737X or Airbus jet built since 2016.

12/

Your GE Engine has been using a 3D Printed Fuel Injection Nozzle.

3D/AM processes can also scale per national tariffs, as small 3D/AM manufacturing cells can be established for local production. If geo-political market condition warrant.

13/

3D/AM processes can also scale per national tariffs, as small 3D/AM manufacturing cells can be established for local production. If geo-political market condition warrant.

13/

So, I've touched on the US gov't senior policy making & market penetration of 3D/AM. What has this to do with the day to day functioning of the US Military?

A great deal, as it turns out.

14/

A great deal, as it turns out.

14/

The US Army has developed three families of ISO container manufacturing facilities to meet mission readiness requirement since 9/11/2001 via spares production.

These started with CNC machines and has since added CMM, 3D/AM manufacturing, and CAD/CAM capabilities.

15/

These started with CNC machines and has since added CMM, 3D/AM manufacturing, and CAD/CAM capabilities.

15/

This is a Mobile Parts Hospital Ver. 1.0 (2003 – 2009) in Balad Iraq. 100,000 parts were built 24/7 at three MPH by 2009 via a computer-controlled Mazatral 640MT PRO lathe.

16/

16/

MPH Ver. 2.0 -- Mobile Technology Complex (2010)

This is a MPH developed for SOCOM with 3-D Printer

It can fix more complex and exotic gear as well as create new capabilities in the field

See:

Logistics: Smaller, Lighter, Faster, Cheaper, Unexpected

strategypage.com/htmw/htlog/201…

17/

This is a MPH developed for SOCOM with 3-D Printer

It can fix more complex and exotic gear as well as create new capabilities in the field

See:

Logistics: Smaller, Lighter, Faster, Cheaper, Unexpected

strategypage.com/htmw/htlog/201…

17/

MPH Ver. 3.0 -- Expeditionary Lab (2013)

* More compact and relies more on 3-D Printers

* Computer-aided design workstation

* Operators trained to help users come up with designs for components that don’t yet exist

18/

* More compact and relies more on 3-D Printers

* Computer-aided design workstation

* Operators trained to help users come up with designs for components that don’t yet exist

18/

All of this effort was noticed by DARPA and the USN.

Under DARPA’s Manufacturing Experimentation & Outreach Two (MENTOR2) program a fabrication laboratory, or Fab Lab, was located at the Mid-Atlantic Regional Maintenance Center (MARMC, pronounced “mar-mack”) in Norfolk, Va.

19/

Under DARPA’s Manufacturing Experimentation & Outreach Two (MENTOR2) program a fabrication laboratory, or Fab Lab, was located at the Mid-Atlantic Regional Maintenance Center (MARMC, pronounced “mar-mack”) in Norfolk, Va.

19/

The goal of MENTOR2 is to reduce logistics supply chain costs and boost defense readiness by improving training and tools for operating, maintaining and adapting complex military equipment in low-tech environments.

darpa.mil/program/manufa…

20/

darpa.mil/program/manufa…

20/

The US Navy has deployed 3D/AM devices and FAB LAB’s on combat deployment since 2014.

USS Essex (LHD-2) 2014 3D Printer (test)

USS Kearsarge (LHD 3) 2015 MARMC Mini-Fab Lab

USS Harry S. Truman (CVN 75) 2015 MARMC Mini-Fab Lab

USS Wasp (LHD 1) 2016 MARMC Mini-Fab Lab

21/

USS Essex (LHD-2) 2014 3D Printer (test)

USS Kearsarge (LHD 3) 2015 MARMC Mini-Fab Lab

USS Harry S. Truman (CVN 75) 2015 MARMC Mini-Fab Lab

USS Wasp (LHD 1) 2016 MARMC Mini-Fab Lab

21/

USMC Ex-MAN 3D/AM containerized spares production facility had exercised with prepositioned ships in recent years.

USNS Sacagawea (T-AKE 2) - Seen w/Aegis cruiser USS Mobile Bay

USNS Robert E Peary (T-AKE 5). – Seen top Left

22/

USNS Sacagawea (T-AKE 2) - Seen w/Aegis cruiser USS Mobile Bay

USNS Robert E Peary (T-AKE 5). – Seen top Left

22/

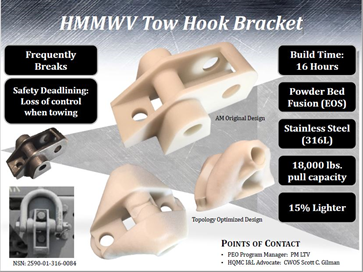

The lead US service in 3D/AM is the Marine Corps. USMC “MARSOC” Humvee heavy add-on armor kits had been causing their tow hook brackets break at high rates.

The USMC used it’s Fab Lab capability to redesign & print tow hooks to be 15% lighter and less likely to break.

23/

The USMC used it’s Fab Lab capability to redesign & print tow hooks to be 15% lighter and less likely to break.

23/

What was the hook for the USS Ford as USS Unicorn was what the USMC was doing with it's quad-copter drone.

The Nibbler was a 3D Printed/AM Drone

24/

The Nibbler was a 3D Printed/AM Drone

24/

The ability to build on the spot spares kept the Nibble drones flying at a far higher rate than traditionally procured drones.

This is a USMC example of where 3D/AM manufacturing technology will change the DoD supply base.

25/

This is a USMC example of where 3D/AM manufacturing technology will change the DoD supply base.

25/

The services want to be able to print very low production runs of legacy parts, or remanufactured for 3D/AM new TDP for legacy parts in order to keep legacy systems operational to meet mission requirements.

And there is a whole lotta "legacy."

26/

And there is a whole lotta "legacy."

26/

When production of the military airframes in these photos stopped.

1962 -- B-52

1968 - C-5

1970 - KC-135

1983 - A-10

The end of A-10 Warthog production is closer to WW2 than 2021.

27/

1962 -- B-52

1968 - C-5

1970 - KC-135

1983 - A-10

The end of A-10 Warthog production is closer to WW2 than 2021.

27/

The problem with this 3D/AM policy objective and USMC execution of same is the US Government does not own all of the intellectual property rights for the legacy weapon TDP's.

See:

US Air Force Is Waiting a Year for Parts That It Could 3D-Print

defenseone.com/business/2018/…

28/

See:

US Air Force Is Waiting a Year for Parts That It Could 3D-Print

defenseone.com/business/2018/…

28/

3D/AM simply works best with new/current production weapons for reasons of TDP rights.

A 3D/AM drone facility on USS Ford with a F-35B & V-22 VSTOL & Drone air group side steps the issues with the EMALS catapult & weapons lifts.

29/

A 3D/AM drone facility on USS Ford with a F-35B & V-22 VSTOL & Drone air group side steps the issues with the EMALS catapult & weapons lifts.

29/

That argument was what I sold to @ArmouredCarrier and got me on Episode 52 of the bilge Pumps podcast.

/End.

/End.

@threadreaderapp unroll

• • •

Missing some Tweet in this thread? You can try to

force a refresh