#Balaji amines

#Balaji amines - clientele

@threader_app compile

#Balaji amines at new high , excellent returns 397 to 3200 , if you are a investor then first understand the business then only invest, read my thread to get knowledge about Balaji amines .

#Balaji amines - new capacity addition of 16500 TPA for Acetonitrile ( existing capacity of 9000 TPA )

@threader_app compile

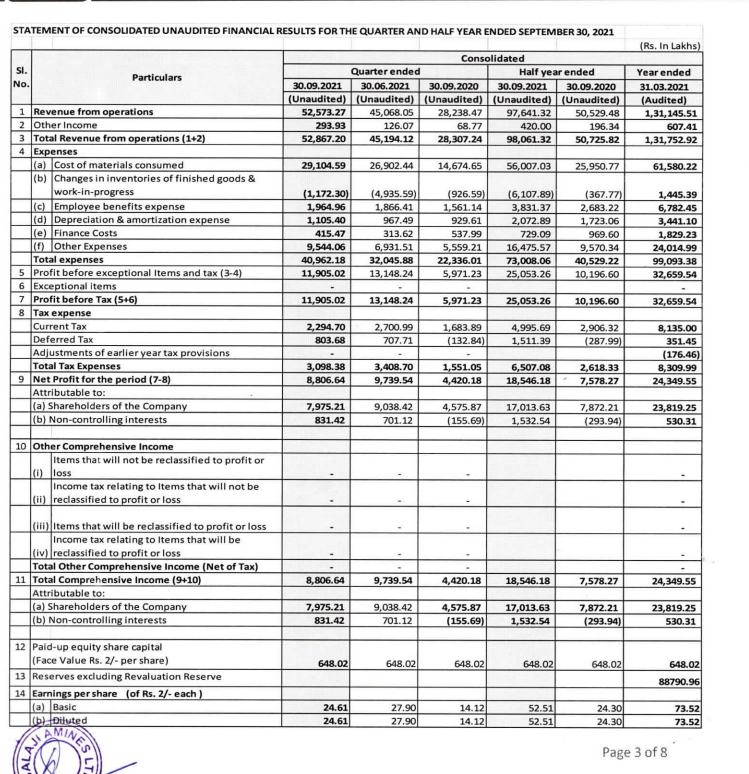

Balaji amines - top line growing- bottom line impacted due to increase in RM price,CFO negative in H1

- The prices of some of the key raw material prices witnessed significant increase

which impacted the operating margins of the business in the current quarter.

-However, the transition period of 3-4 weeks is now over, and they have started passing on the increase in cost

which impacted the operating margins of the business in the current quarter.

-However, the transition period of 3-4 weeks is now over, and they have started passing on the increase in cost

prices to end customers.

-expect operating margins to inch upwards in the H2FY22, from the current levels.

- Acetonitrile plant- plant capacity has now increased from 9 TPD (tons per day) to 18

TPD and now expect gradual ramp-up in capacity utilization in H2FY22.

-expect operating margins to inch upwards in the H2FY22, from the current levels.

- Acetonitrile plant- plant capacity has now increased from 9 TPD (tons per day) to 18

TPD and now expect gradual ramp-up in capacity utilization in H2FY22.

Balaji had to shut down our DMF plant in the first week of October 2021 due to a small incident

which had led to minor leakages and they took this opportunity to also undertake debottlenecking

exercise which will enhance the operating capacity of the plant from present

which had led to minor leakages and they took this opportunity to also undertake debottlenecking

exercise which will enhance the operating capacity of the plant from present

50 TPD to 75 TPD.

Management expect the DMF plant to re-commence operations within first week of November 2021. The

capacity utilization of DMF plant was about 53% in Q2FY22 and 37% in H1FY22 (versus 35% in

FY21)

Management expect the DMF plant to re-commence operations within first week of November 2021. The

capacity utilization of DMF plant was about 53% in Q2FY22 and 37% in H1FY22 (versus 35% in

FY21)

Balaji Specialty Chemicals – continues to witness robust demand and higher price realization for its products. The capacity utilization increased from

42% in Q1FY22 to 67% in Q2FY22 with average production of 1,675 tons per month in the

second quarter.

42% in Q1FY22 to 67% in Q2FY22 with average production of 1,675 tons per month in the

second quarter.

The subsidiary company has been facing shortage of raw materials which is imported. Upon smoother accessibility to the raw materials in coming quarters, company expect rapid increase in capacity utilization in H2FY22 and over the next fiscal year.

company also aim to increase

the share of exports from subsidiary plant to about 25-30% going forward from about 15%

in H1FY22.

the share of exports from subsidiary plant to about 25-30% going forward from about 15%

in H1FY22.

• • •

Missing some Tweet in this thread? You can try to

force a refresh