Given the popularity of the topic around the AJAX problems, a brief summary of whole-body vibration (WBV) and why it's a problem. In short and to the surprise of no one, shaking a human rapidly and for a long time is bad, but can also be really bad.

Perhaps moreso than usual a disclaimer - this is Twitter, I dont have much space and some things are simplified or omitted for simplicity. I'm not a Dr or human factors specialist and this is a hugely complex science, I’m just giving a flavour of the topic. That out of the way...

So, what is WBV? UK Health & Safety Executive are rather interested in it, and define as shown. In essence, something vibrating your whole body, obviously.

As an occupant of any vehicle you are subject to WBV, the frequency and severity of vibrations are v important

As an occupant of any vehicle you are subject to WBV, the frequency and severity of vibrations are v important

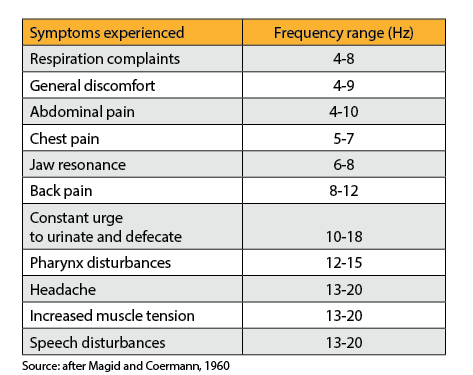

The human body is essentially a mass of bags of fluids and cavities with various membranes and other dividing structures, and different vibration frequencies and forces affect different areas in different ways.

Exactly like a powerplate at the gym, your muscles struggle to operate properly when being relentlessly shaken. Lungs and diaphragm find it harder to breathe under very low frequency, or your brain struggles to carry out normal functions while being buzzed by high frequencies.

A few common issues and frequency bands they are found in are shown. Clearly, there are some that you REALLY don't want to see your vehicle vibrating within, and self evidently the longer you are subject to those frequencies, the worse it is for you as the body tires fighting it

It's not just frequency but also the peak acceleration being imparted onto the body. Everything is subjective, but for sure a >1 m/s² acceleration is going to be very uncomfortable on the spine and neck.

Outside of generally breaking you, vibration also has physio and psychological impacts manifesting from the vibration of the brain and other organs and interfering with their normal operation

Visual acuity & manual tracking is a significant area. When vibration is transmitted to the eye the result is usually a blurred image. Errors in completing tasks using your hands to operate controllers, like a weapon system or turret, increase in line with vibration magnitude

Hearing is affected distinctly from noise levels, though research is hard - places where you have awful vibration tend to be very noisy too, so isolating each element is very hard. It is believed vibration exacerbates low-frequency hearing loss

Generally, this impact from vibration is a temporary hearing loss (or temporary threshold shift (TTS)) rather than a permanent change. Studies have also shown that prolonged vibration makes clear speech as well as speech recognition worse, which again are undesirable symptoms

Cognitive performance is the third big one. Testing has shown that increased vibration and increased

amount of time spent inside the AFV significantly impairs performance. Interestingly, noise is less impactful than vibration or time in the vehicle for cognitive tasks over time

amount of time spent inside the AFV significantly impairs performance. Interestingly, noise is less impactful than vibration or time in the vehicle for cognitive tasks over time

The reason this is such a big problem in AFV is they are a perfect storm of factors to produce awful vibrations, designed with absolute primacy on combat function - protection/firepower/mobility, plusd other factors. There is very little room for human factors engineering.

The primacy of combat-oriented considerations renders common mitigations or solutions invalid. For example, construction equipment commonly uses large air-sprung seats with tight seat belts

To avoid injuries from mine and IED blasts, all AFV now use suspended seating optimised for mitigating violent vertical impulses, not constant vibration

Certain roles like commander or loader sit or stand without restraints regularly, and lack of restraint allows the upper body to move out of sync with the vehicle and develop distinct aggravating movements in reaction to vibration/jolts

Vehicle commanders commonly stand in the hatch, passing vibration through the feet and through any contact with the hatch into the pelvis and lower back with common injuries or short to medium term medical complaints in these areas.

Fumes, heat, noise and lack of a clear external view for most occupants also rapidly accelerate the effects of disorientation, fatigue, nausea and general body fatigue allowing further symptoms to develop. Some of this is mitigated by experience and acclimatisation, but never all

The usage profile is also poor from a vibration perspective. As with most AFV engineering, it is aggressive and mechanically violent. Unlike agriculture or industrial applications where constant low-speed moves can be mitigated, the movements in an AFV are fast and unpredictable

VIbration is always a bigger challenge in tracked than wheeled AFV, with track patter and the general mechanical robustness of the track going around the running gear generating a lot of vibration and noise, a proverbial string of hammers constantly smashing everything they touch

Another factor is that, in general, AFVs demand extreme power levels from their engines, and so are more likely to have substantial vibration coming from the engine into the hull and thus the occupants than an industrial or agricultural vehicle running at more steady-state revs

There is also Hand Arm VIbration (HAV), discussed in recent @CommonsDefence AJAX sessions, where vibrations are passed specifically through the hand and arm into the body during operation of vibrating machinery - driving and gunnery controls for example, or construction kit

Manifesting as tingling and numbness through to manual dexterity loss and dreaded Vibration White Finger (VWF) / Hand-Arm Vibration Syndrome (HAVS), both secondary forms of Raynaud's syndrome, where vibration-induced spasming of small arteries restricts blood flow

Finally, a note on mitigation: HAV more readily dealt with than WBV via vibration mitigating mountings and other dampening elements in the hand controllers, as well as anti-vibration gloves. Engineering solutions can mitigate both, including dampeners and suspension mounting...

...of components interfacing with humans, as well as mountings attaching things like the engine to the hull. @DefenseSoucy's Composite Rubber Track (CRT), which I have an old thread on (new version w/updates soon) here

https://twitter.com/JonHawkes275/status/1263783182513721344?s=20can knock out up to 70% of vibration

There is a lot more to the science, and I may have described some of it slightly seductively, but a meandering summary of some core concepts. Welcome additional insight from the pros out there on Twitter!

Have assembled some good contacts for some experts in the vibration and noise industry, might put a piece together on it for Janes at some point soon. /end #tanktwitter #miltwitter #AJAXInquiry #badvibrations #engineering

P.S. There will be a Part 2 on vibrations looking at mechanical consequences, where this thread looked at the human body. Mechanical reliability, stabilisation, ammunition damage/fatigue, navigation issues and more.

• • •

Missing some Tweet in this thread? You can try to

force a refresh