This is a thread addressing Chinese military technology innovation today, it's parallels with Imperial Japan in the Mid-1930's to early 1940's period, & the "Great Supply Chain Collapse."

They are related.

1/

thedrive.com/the-war-zone/4…

They are related.

1/

thedrive.com/the-war-zone/4…

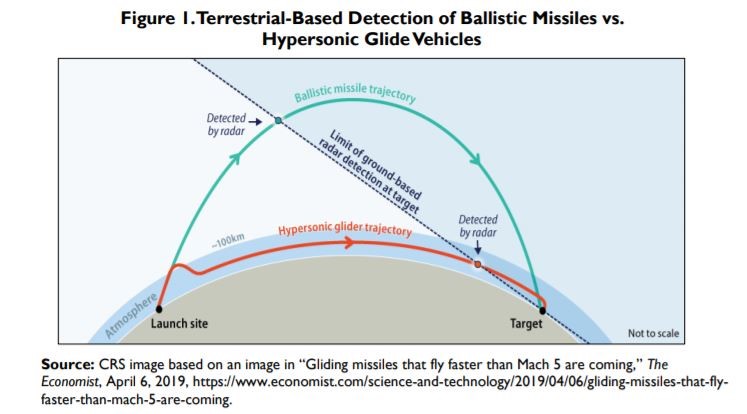

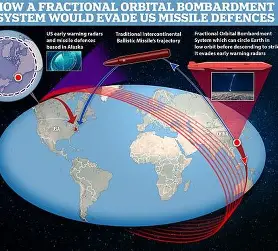

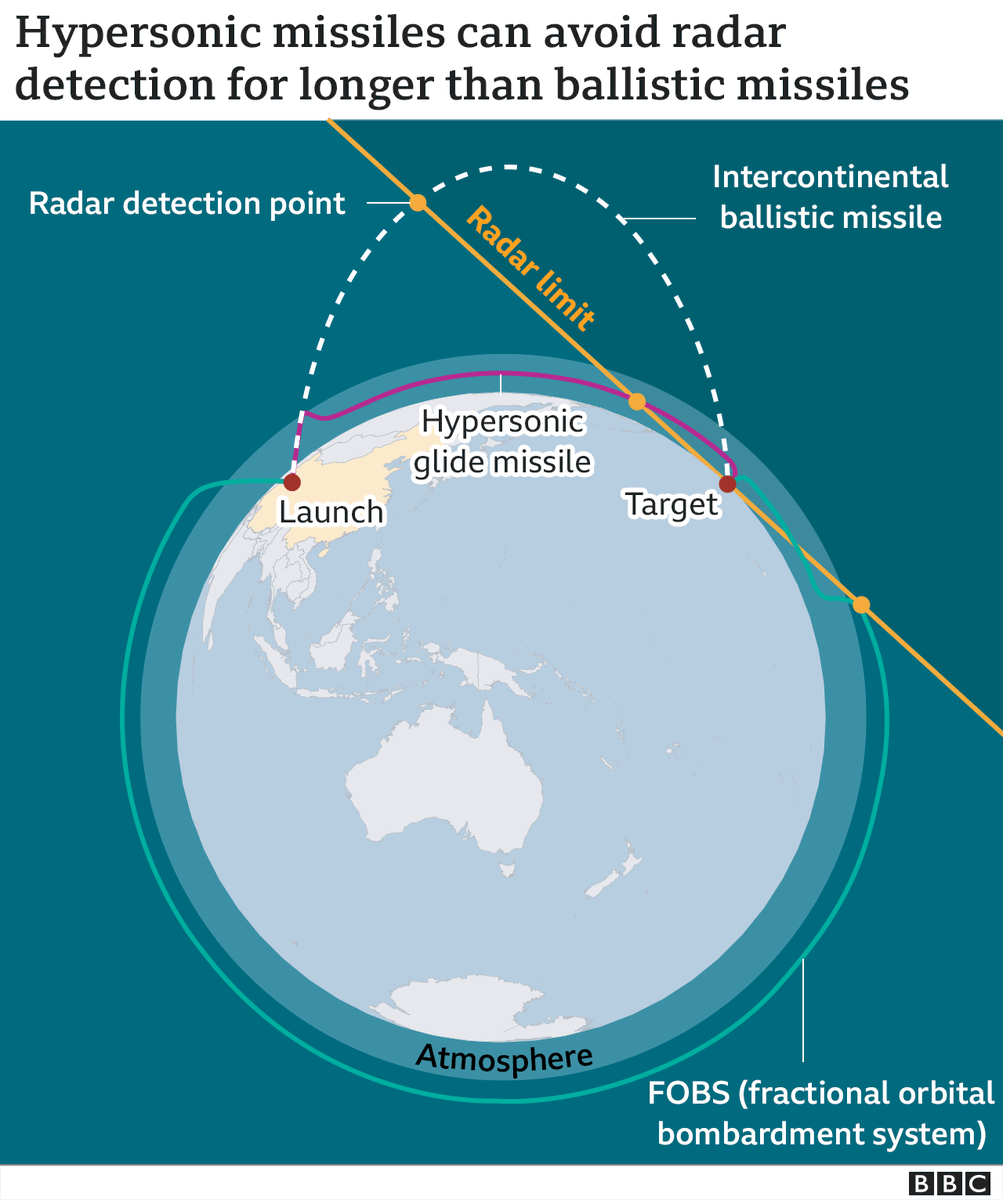

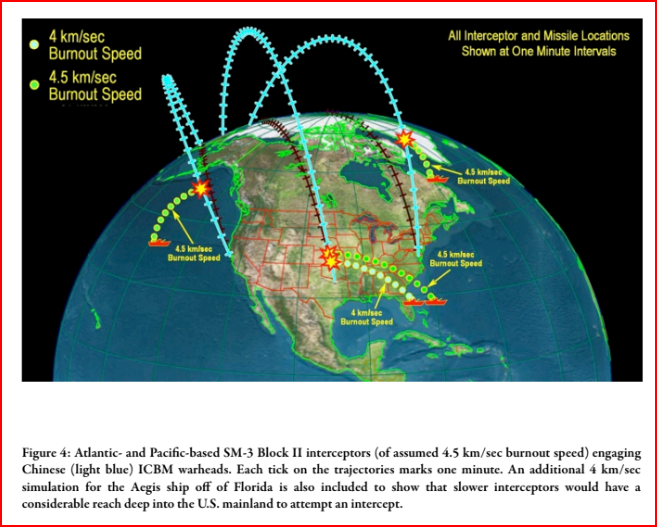

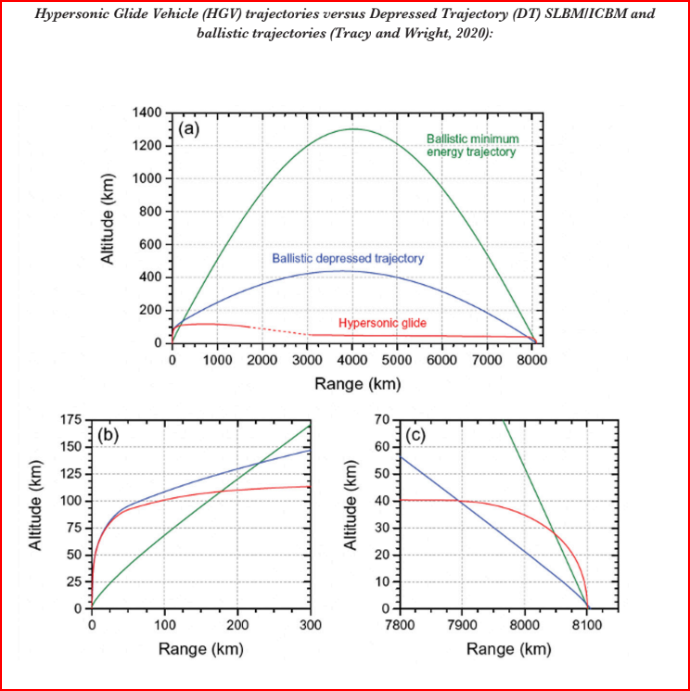

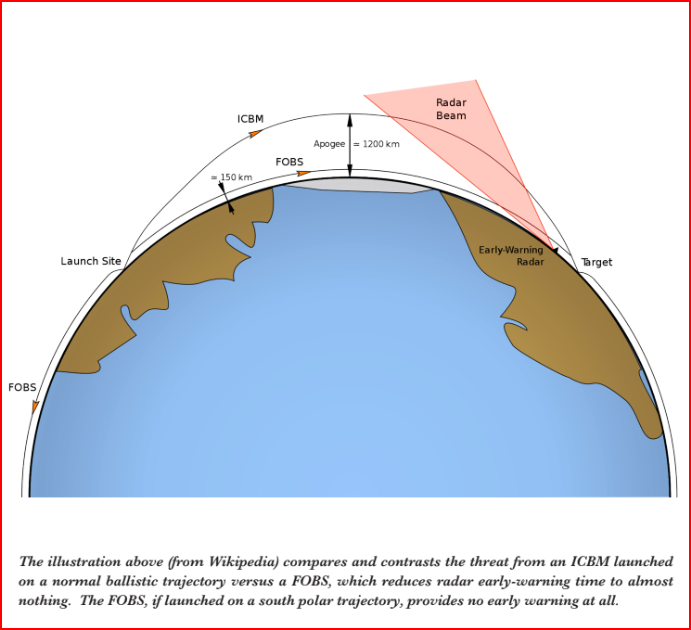

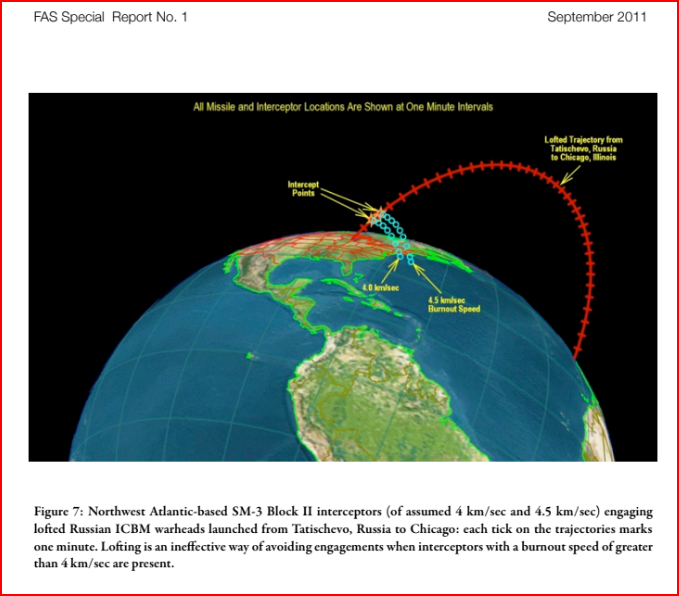

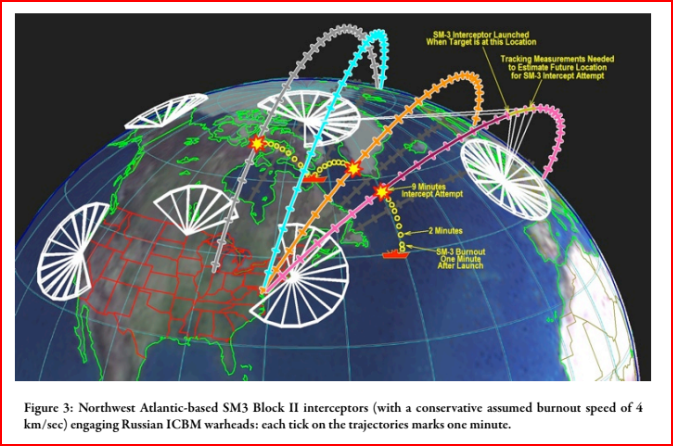

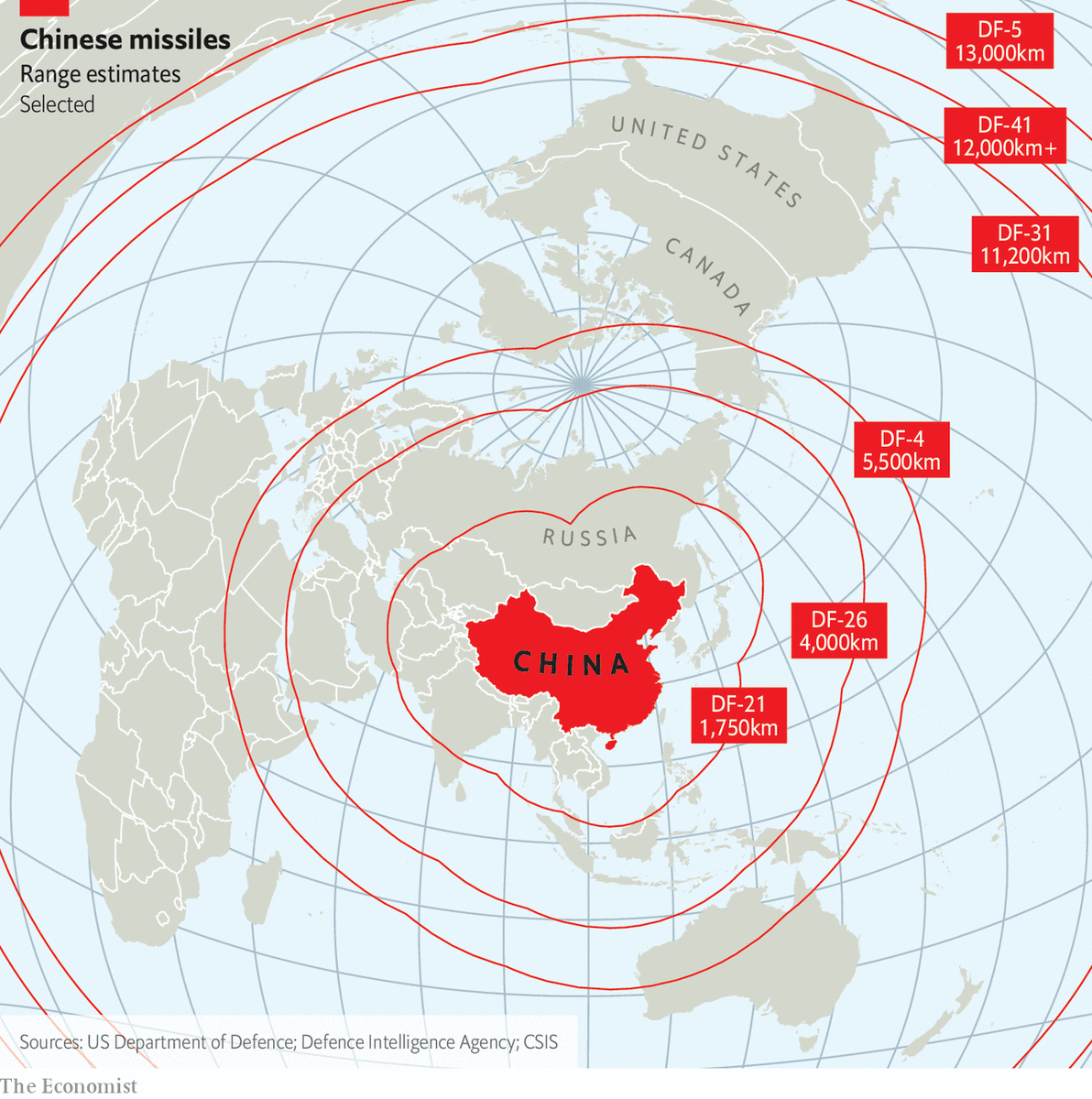

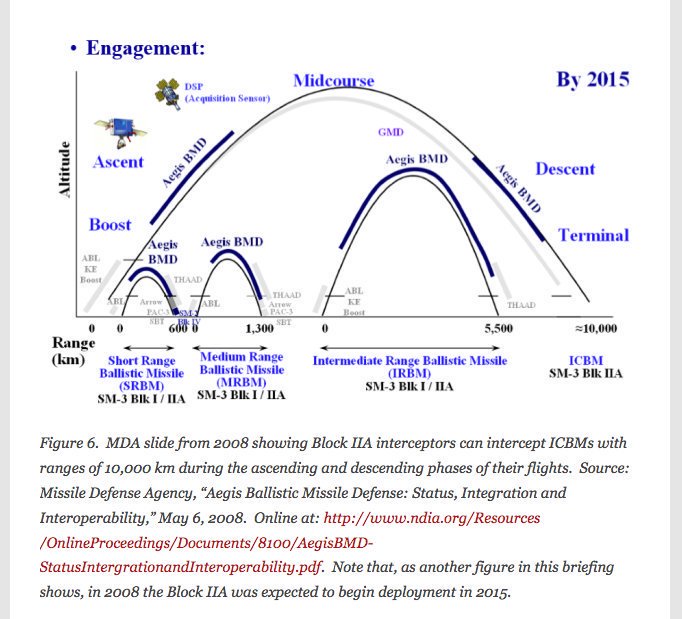

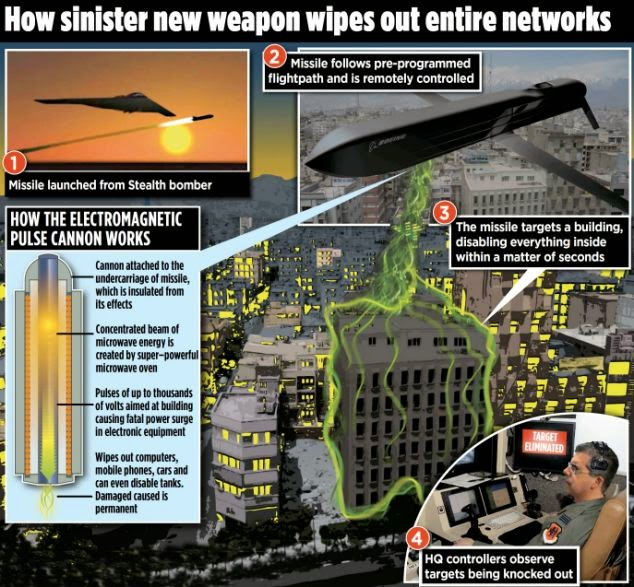

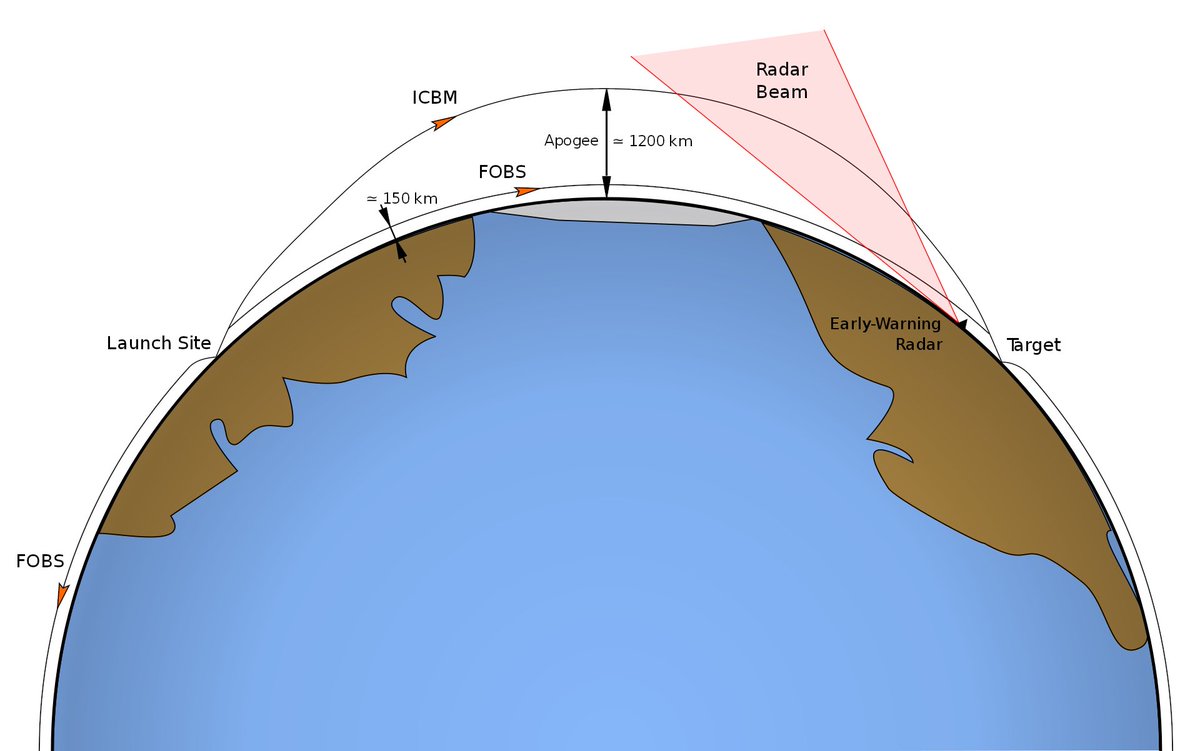

The Chinese took two existing technologies, the Fractional Orbital Bombardment System (FOBS) and the Hypersonic Glide Vehicle (HGV) & kit bashed them together into a 1st strike nuclear weapon that evades US ICBM trajectory early warning radar coverage.

2/

2/

One can argue about the usefulness of this kit bash.

The one thing you cannot ignore is that it's a highly innovative weapon system design aimed like a laser at a decades old weakness.

A weakness the Chinese have been aware of for its entire existence, via @TheDEWLine

3/

The one thing you cannot ignore is that it's a highly innovative weapon system design aimed like a laser at a decades old weakness.

A weakness the Chinese have been aware of for its entire existence, via @TheDEWLine

3/

A PLARF Long March 2C expendable launcher was used to launch the 3-4 ton FOBS payload with a HGV for reentry vehicle(RV). The DF-ZF from the DF-17 system is the likely candidate RV.

4/

4/

The Long March 2C is a proven legacy design from the 1980s, like the LGM-25C Titan II and Soviet R-36.

It is fueled with hypergolic N2O4 / UDMH propellants & capable of lifting almost 4 tons to LEO. It benefitted from the 1998 Loral missile scandal

5/

jonathanpollard.org/1998/040798b.h…

It is fueled with hypergolic N2O4 / UDMH propellants & capable of lifting almost 4 tons to LEO. It benefitted from the 1998 Loral missile scandal

5/

jonathanpollard.org/1998/040798b.h…

One of the benefits, if you can call it that, of being a retired tail end Boomer/early Gen X'er military procurement official means I know where the bodies are buried...because I helped to bury them.

Living Loral's "ITAR Gift" to DoD is a case in point

6/

federalregister.gov/documents/2020…

Living Loral's "ITAR Gift" to DoD is a case in point

6/

federalregister.gov/documents/2020…

Like most men of my generation, I have the WW2 history bug. Unlike most, I was interested in how the War & Navy Dept. bought weapons in lieu of war gear "Top Trumps," because day job.

Doing this while training other in the admin. of ITAR w/in DoD gave me unique perspectives.

7/

Doing this while training other in the admin. of ITAR w/in DoD gave me unique perspectives.

7/

I also looked at how other WW2 major powers, particularly the Japanese, developed their weapons.

I laid out Imperial Japan's national technological style in a July 2021 @WW2TV stream on MacArthur's Secret Radar Hunters, Section 22. See Photo & link

8/

I laid out Imperial Japan's national technological style in a July 2021 @WW2TV stream on MacArthur's Secret Radar Hunters, Section 22. See Photo & link

8/

The Japanese had a "challenger technological style" I've seen echoed in Soviet/Russian & now Chinese military development.

US, by contrast, always invested more thought into both usability and maintainability of its weapons, vice UK or Germany tech.

9/

US, by contrast, always invested more thought into both usability and maintainability of its weapons, vice UK or Germany tech.

9/

There are usually two prices for the "US Style of Design."

1. It takes longer to get out there.

2. It costs more & competitors quickly copy it with cheap knock off's.

10/

1. It takes longer to get out there.

2. It costs more & competitors quickly copy it with cheap knock off's.

10/

If you have a smart US management. You can win using that style via better service & by continually improving design -- See IPad & early IPhone

That smartness has been lacking the last couple of decades as marketing hype displaced good engineering via MBA "Off-shoring."

11/

That smartness has been lacking the last couple of decades as marketing hype displaced good engineering via MBA "Off-shoring."

11/

This is a highly dangerous place for the USA to be in as China has made in the late 20-teens the kind of innovative leap the Imperial Japanese 1935(+) did via a class of truly innovative world class engineers.

Yamato, A6M Zero & I-400 sub-carriers are historical examples.

12/

Yamato, A6M Zero & I-400 sub-carriers are historical examples.

12/

While the PLARF FOBS with HGV RV is the current events example of China "Post-Challenger/Peer Competitor" national technological style, arriving.

13/

wirewag.com/china-successf…

13/

wirewag.com/china-successf…

I've talked about this recent Chinese engineering leap recently on Twitter regards NORINCO's comprehensive family of unmanned ground vehicles.

14/

14/

https://twitter.com/TrentTelenko/status/1449467173190184961

I've also mentioned a few months ago "why" the US Defense industrial base lacks the ability to systems engineer their way out of a paper bag, let alone a ship design, namely the death by corruption of Mil-STD-499.

14/

See:

14/

See:

https://twitter.com/TrentTelenko/status/1362456225145782273

If you search Twitter with the term "Mil-STD-499" you'll find my previous rant threads.

This blog post is where you see why & how "Systems Engineering" by DoD contractors died.

The 737 MAX and the Death of MIL-STD-499A SYSTEM ENGINEERING MANAGEMENT

chicagoboyz.net/archives/59466…

15/

This blog post is where you see why & how "Systems Engineering" by DoD contractors died.

The 737 MAX and the Death of MIL-STD-499A SYSTEM ENGINEERING MANAGEMENT

chicagoboyz.net/archives/59466…

15/

Unlike 1941-1945, the now 'Innovative Peer Level' Chinese military industrial base is facing off against a decayed Western Military Industrial base that has had its system engineering hollowed out by political corruption and "Off-shoring."

16/

16/

This isn't to say Systems Engineering has completely disappeared from the West.

The Israeli Iron Dome anti-rocket system has some of the best systems engineering on the planet.

/17

The Israeli Iron Dome anti-rocket system has some of the best systems engineering on the planet.

/17

https://twitter.com/TrentTelenko/status/1396980231257403394

Systems engineering that is so elegant that it includes considerations of digital selectivity and the economic cost avoidance for Israeli policy makers in its architecture.

It beats Islamist suicide terrorism with superior economic cost accounting.

18/

It beats Islamist suicide terrorism with superior economic cost accounting.

18/

https://twitter.com/TrentTelenko/status/1396980598363799553

The reason that Israel has such a high level of systems engineering is their decades long industrial policy of "On-shoring" it defense industrial base to meet local existential threats, AKA the 2006 Lebanon War & 2008-2009 Operation Cast Lead rocket attacks.

19/

19/

Space X is another example of high levels of systems engineering via both "in-sourcing" & "On-shoring."

Roughly 70% of every Space X rocket or capsule is mfg by Space X internally.

20/

Roughly 70% of every Space X rocket or capsule is mfg by Space X internally.

20/

Short, internal, supply chains with 3D/AM make systems engineering with swift, iterative, innovation much easier.

It also avoids the worst effects of the "Great Supply Chain Collapse" now washing over the "off-shore supplier" world economy.

21/

It also avoids the worst effects of the "Great Supply Chain Collapse" now washing over the "off-shore supplier" world economy.

21/

The 21st Century Chinses challenge for US economic, national security & foreign policy calls for on-shoring, in-sourcing, & shortening supply chains with 3D/AM.

That is, returning to the traditional US technological style.

22/

That is, returning to the traditional US technological style.

22/

Making this reality will the politics of the post "Great Supply Chain Collapse" western world.

/End

/End

• • •

Missing some Tweet in this thread? You can try to

force a refresh