1/ As we wait for full mirror deployment, here are some cool-to-know facts about #Webb 's mirrors.

📷 Northrop Grumman, NASA/Chris Gunn

📷 Northrop Grumman, NASA/Chris Gunn

2/ #Webb has a primary mirror 6.5m across as this is what was needed to measure the light from very young galaxies 🌀 over 13 billion light years away.

3/ A mirror this large had never before been launched into space! If the @HUBBLE_space 2.4 m glass mirror were scaled to be large enough for #Webb, it would be too heavy to launch into orbit.

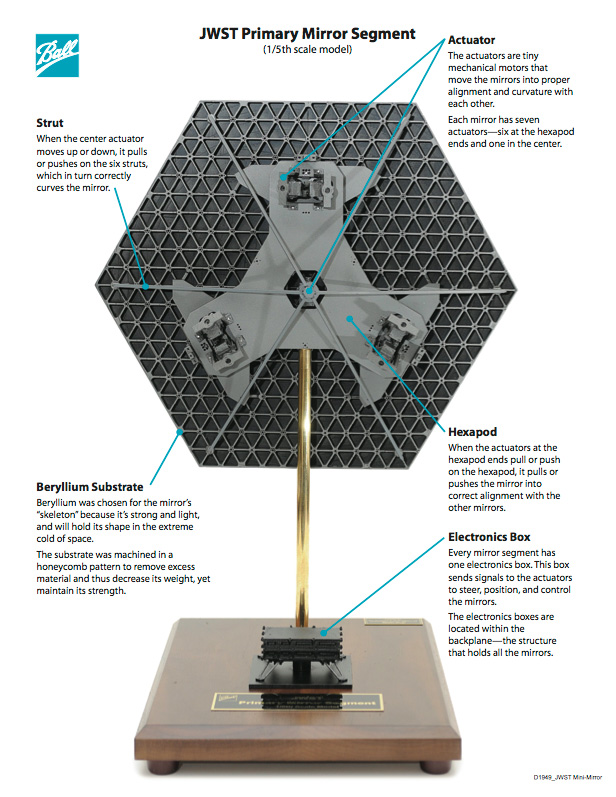

4/ The #Webb Telescope team decided to make the mirror segments from beryllium, which is both strong & light. Each mirror segment weighs approx. 20 kg. Beryllium is also a good conductor of electricity and heat, and is not magnetic.

5/ The #Webb Telescope team also decided to build the mirror in segments on a structure which folds up so that it could fit into the Ariane 5 rocket 🚀 which was also adapted for Webb

📷 NASA/Chris Gunn

📷 NASA/Chris Gunn

6/ The hexagonal shape allows for a roughly circular, segmented mirror with high filling factor which means the segments fit together without gaps. A roughly circular overall mirror shape also focuses the light into the most compact region on the detectors.

7/ To get these mirrors to focus correctly on faraway galaxies, actuators, or tiny mechanical motors, help achieve a single perfect focus. The primary mirror segments & secondary mirror are moved by 6 actuators that are attached to the back of each mirror piece.

8/ The primary mirror segments also have an additional actuator at its centre that adjusts its curvature. The telescope's tertiary mirror remains stationary.

📷 ASU/NASA (thread to be continued, stay tuned)

📷 ASU/NASA (thread to be continued, stay tuned)

9/ #Webb is a 3-mirror anastigmat telescope. The primary mirror is concave, the secondary is convex, and it works slightly off-axis. The tertiary removes the resulting astigmatism & also flattens the focal plane.

10/ How were the mirrors built? A fine beryllium powder was placed into a stainless steel canister & pressed into a flat shape. The resulting chunk of beryllium was cut in half to make 2 mirror blanks about 1.3 m across. Each mirror blank was used to make 1 mirror segment

11/ Then, most of the back side of the beryllium mirror blank was cut away, leaving just a thin "rib" structure. Although most of the metal was gone, the ribs are enough to keep the segment's shape steady. This makes each segment very light.

📷 Axsys Technologies

📷 Axsys Technologies

12/ Once a mirror segment's final shape was corrected for any imaging effects due to cold temperatures, and polishing was complete, a thin coating of gold was applied, as gold improves the mirror's reflection of infrared light.

13/ How was the gold 🪙 applied? The mirrors were put inside a vacuum chamber and a small quantity of gold was vaporised and it deposited on the mirror. Other areas were masked-off.

14/ A thin layer of amorphous SiO2 (glass) was deposited on top of the gold to protect it from scratches in case of handling or if particles get on the surface and move around since the gold is pure and very soft

15/ To protect the mirrors during assembly, they were fitted with lightweight, black covers, which were removed once the mirror was fully assembled.

📷 NASA/Chris Gunn

📷 NASA/Chris Gunn

16. Once the mirrors were completed, the science instruments were integrated into the telescope. Curious to know even more? Go here: webb.nasa.gov/content/observ…

📷 NASA/Chris Gunn

📷 NASA/Chris Gunn

• • •

Missing some Tweet in this thread? You can try to

force a refresh