From the @ScarbsTech archives, Ferrari 126k 1981.

When #F1 cars were made mainly from aluminium!

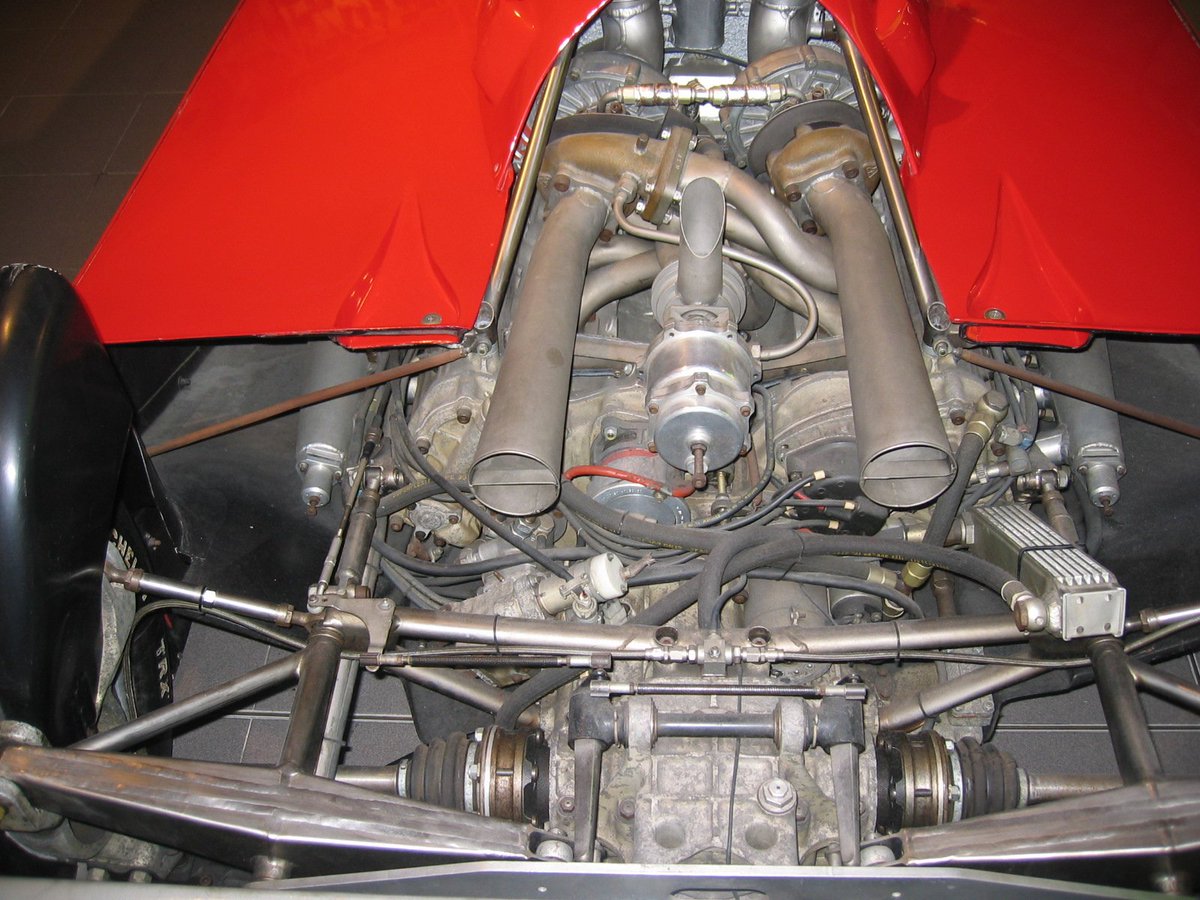

The chassis was steel tube clad in alu, just 20cm of front crash structure, rocker arm suspension front and rear.

Front wing off the ground to feed the underfloor tunnels

When #F1 cars were made mainly from aluminium!

The chassis was steel tube clad in alu, just 20cm of front crash structure, rocker arm suspension front and rear.

Front wing off the ground to feed the underfloor tunnels

Power came from a 1.5l 120° V6, with a hot 'V' nestling two turbochargers and a central wastegate.

Alu inlet plenums outside the V, just visible either side of the cylinder heads

Alu inlet plenums outside the V, just visible either side of the cylinder heads

Analogue Cockpit: Veglia dials, gear stick, steel roll hoop, extinguisher & medical air tanks, ARB adjuster, boost adjuster, in your face extinguisher outlet.

• • •

Missing some Tweet in this thread? You can try to

force a refresh