Day 7 - June 21

#OttawaLRT Inquiry Live Tweet Mega Thread!

Today's Guests:

Lowell Goudge (Alstom) – Morning

Jacques Bergeron (OLRT) – Afternoon

ottawalrtpublicinquiry.ca/public-hearing…

#OttawaLRT Inquiry Live Tweet Mega Thread!

Today's Guests:

Lowell Goudge (Alstom) – Morning

Jacques Bergeron (OLRT) – Afternoon

ottawalrtpublicinquiry.ca/public-hearing…

Slow start... looking for the witness.

Irony isn't lost on me.

Irony isn't lost on me.

Witness now found. Computer issues. Swearing in and now we start.

The Lowell Goudge is the senior safety engineer and integration for Alstom and the bridge to the city to ensure safety compliance. In this role till 2021.

Talking now about the problems with the customization/new approaches with the train wanted in Ottawa.

The single most troubling part was noted to be the mechanical and getting the same crash standards as the original.

The single most troubling part was noted to be the mechanical and getting the same crash standards as the original.

Speaking of trouble on a train. Doors are #1 and brakes are #2 in his 40 year experience.

Talked about salt water contamination causing faults in 2019 due to bridge droppings, carbon dust, salt spray from roads. Train roof was apparently shaped to pour water in 😊

Talked about salt water contamination causing faults in 2019 due to bridge droppings, carbon dust, salt spray from roads. Train roof was apparently shaped to pour water in 😊

Talking now about manual train control failures. In a few instances operators thought the train would do a better job parking, so they would drift into stations and have automatic control take over.

The automatic control was too slow, and it panicked.

The automatic control was too slow, and it panicked.

As the system delayed in kicking in, it often thought the train would over shoot the station.

This was corrected by more communication.

More talk about supply changes, imports, made in Canada - and how our country jammed back of pro-train builders, who could build custom stuff

This was corrected by more communication.

More talk about supply changes, imports, made in Canada - and how our country jammed back of pro-train builders, who could build custom stuff

Talk about the testing and how they were still retrofitting the train with updates due to found faults, while trying to go under testing/validation tests.

Compounded the testing was done quite late in the project and the testing found even more issues.

Compounded the testing was done quite late in the project and the testing found even more issues.

Most of the issues were software post 2018, but needing to retrofit, fix and test, and then having to test the tests, compounded that they could only get a few trains out.

Looks like Counsel is trying to paint that this compression could have led to corner cutting.

Looks like Counsel is trying to paint that this compression could have led to corner cutting.

Statistically most electro mechanical system have a curve that you can plot that starts high, then curves down to a constant baseline.

Meaning if things are going to break it will be at the start, then in a semi predictable manner afterwards.

Known as bath tub curve.

Meaning if things are going to break it will be at the start, then in a semi predictable manner afterwards.

Known as bath tub curve.

The infant morality plagues any system. Alstom is pointing out that because they are bringing out the trains and pushing them out the door so late.

Getting out the kinks if you will was more error then trial. They of course tried to predict and mitigate them.

Getting out the kinks if you will was more error then trial. They of course tried to predict and mitigate them.

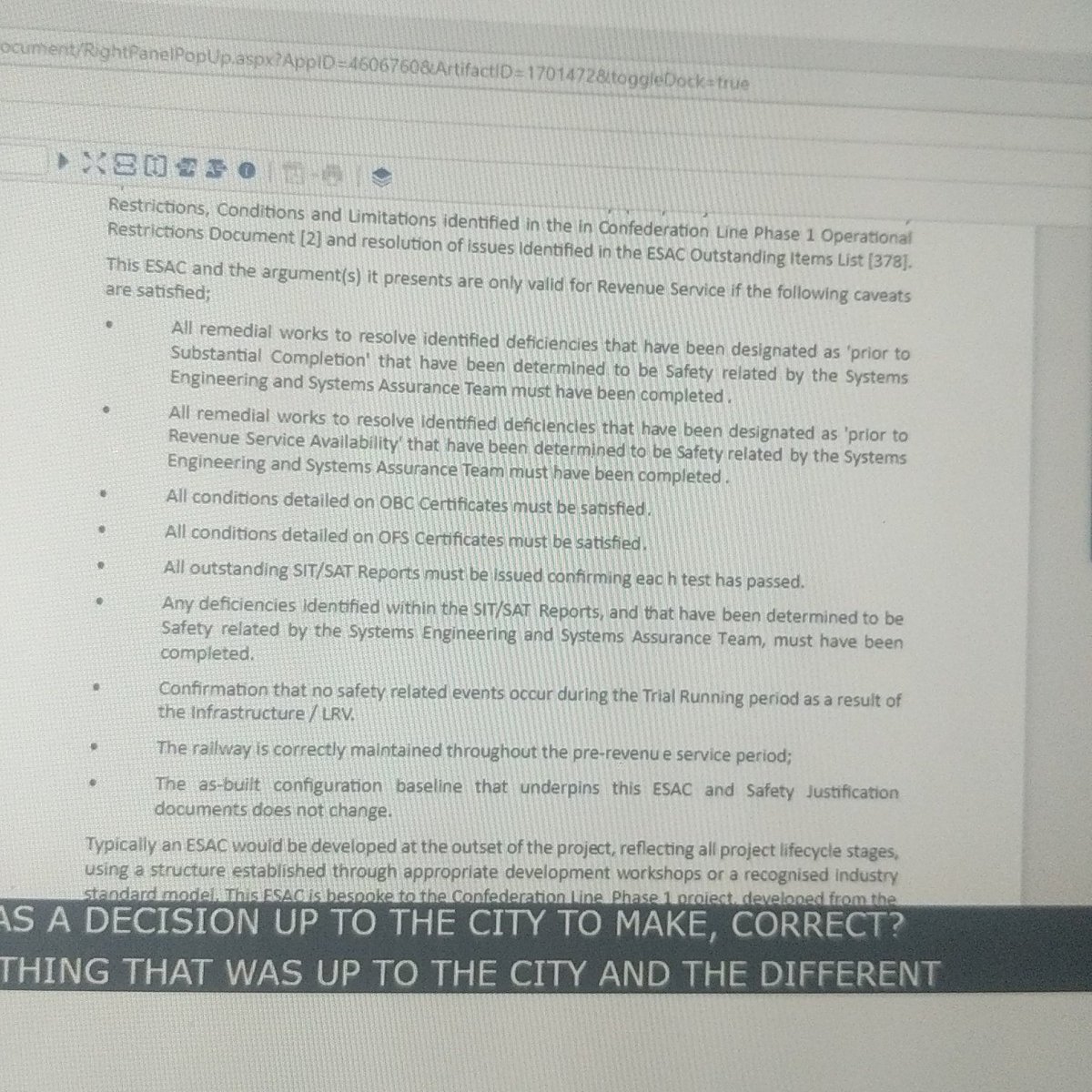

The City was given 9 wavers they signed off on allowing for the Trains to go forth to revenue production - nothing about real safety was deferred.

A sample of the wavers:

- Cab light dimmer couldn't turn off the cab light.

- Cab door was using an common lock. Drivers worried about being attacked.

- Cab door could crack

- Cab light dimmer couldn't turn off the cab light.

- Cab door was using an common lock. Drivers worried about being attacked.

- Cab door could crack

The doors on a train requires up to 3 months of safety testing before being deployed.

So in some cases, they would get a software update, but couldn't deploy it because it wasn't signed off for safety.

They talk about a train that doesn't move is safe.

So in some cases, they would get a software update, but couldn't deploy it because it wasn't signed off for safety.

They talk about a train that doesn't move is safe.

Alstom talks about the issues with the Aux Power Unit, but as a sub part, they couldn't get speedy vendor support to try to figure out the abnormally high failure rate.

None of this affected safety. It just lowers train availability, quality of service and public image - as you have to restart and reboot trains or send them back to the shop.

Asking about derailments. How common are they?

In rapid transit, uncommon. The most common cause is switch movement while a train is on the switch.

In freight, metro and passenger the number is more common.

In rapid transit, uncommon. The most common cause is switch movement while a train is on the switch.

In freight, metro and passenger the number is more common.

Now talking about the derailment in Aug 8 2021. He signed off on it. Talking about the Alstom report that just surfaced digging into the root cause of the failures.

The derailment was caused in short, that a wheel fell off the train 😂

Counsel now asking about heat detectors. Alstom points out heat detectors on track need to see the bearings. In this style they wouldn't be visible in the style/design of train.

Alstom believes any heat detector that gives you a 5 minute warning before you inevitably derail - isn't of much value. The development to get a heat sensor tuned to give you enough forewarning to avoid a breakdown isn't there.

Odd flex 😂

Odd flex 😂

Looking at the tech document of the root cause of failure. It was causes by vibrations that caused microscopic wear and vibrations - and track corrugation.

They blame the slipping and sliding of wheels. Because trains are fixed axels, if the train isn't profiled properly in curves, one wheel travels faster then the other - causes slippage and then the rail becomes corrugated.

When the train rail was inspected. it was found that the rail was surface/top grinded that caused unnatural damage that couldn't be caused by the train.

Alstom doesn't know who did what. However it was not in a health shape in parts.

Alstom doesn't know who did what. However it was not in a health shape in parts.

Now we are getting to the gold. Alstom states that the train rail doesn't meet spec.

After the a yard derailment. They looked at the rail, and it looked flat. So they measured some rail laying around, and Blair track (at the buffer)

After the a yard derailment. They looked at the rail, and it looked flat. So they measured some rail laying around, and Blair track (at the buffer)

The rail it self was found to be fundamentally flatter and a narrower gauge then spec. Alstom witness couldn't state what the outcome would be.

They just know that the train, curve and the system was taking excessive loads in curves - which is the likely cause the train to break

They just know that the train, curve and the system was taking excessive loads in curves - which is the likely cause the train to break

Counsel asks about the hard rails being an issue.

Alstom points out, that he thinks they were too soft, if anything problems might be better if the rails were much harder.

Alstom points out, that he thinks they were too soft, if anything problems might be better if the rails were much harder.

Alstom knew the gauge was off from day one, and the train wasn't able to run.

Someone took remedial action to allow the safe running of trains, but it needed a longer term solution (not their problem)

and obviously such solution never came in time it seems.

Someone took remedial action to allow the safe running of trains, but it needed a longer term solution (not their problem)

and obviously such solution never came in time it seems.

This was the suggestion from the Alstom report.

Grease the rail and wheel to adjust the slip and slide, check for profile defects, drop speed before curves and or fix the wheels to adapt to the garbage conditions 🤣

Grease the rail and wheel to adjust the slip and slide, check for profile defects, drop speed before curves and or fix the wheels to adapt to the garbage conditions 🤣

4.5km of the 13km of the Confederation line is curves.

Right now its all a big shit pile. On last check we are waiting on the tracks to be ground, before we can send the grease automaton down.

They are ready to adjust the wheels, but the profile needs to be agreed upon and frozen.

They are ready to adjust the wheels, but the profile needs to be agreed upon and frozen.

Alstom points out that all of this isn't ideal, but something has to be done now to keep safety - the best way to handle that is to drop speed and take the train into the shop more often.

Then once we figure this out, then we can go for a long term solutions.

Then once we figure this out, then we can go for a long term solutions.

Worse case, Alstom is going to beef up the axel and redesign it to make it work.

Sounds like they aren't waiting around to much for whomever to unscrew themselves.

I applaud the seemingly aggressive commitment to #Ottawa - my guess is they are contracted to care 😂

Sounds like they aren't waiting around to much for whomever to unscrew themselves.

I applaud the seemingly aggressive commitment to #Ottawa - my guess is they are contracted to care 😂

Counsel points out that the SEMP report points out very much the same thing as Alstom.

Alstom witness, says it's not surprising, it overlaps with what they found, but wasn't on the track daily to really know what's going on with RTM.

Alstom witness, says it's not surprising, it overlaps with what they found, but wasn't on the track daily to really know what's going on with RTM.

I'll have to do a deep drive on this document. With all these engineers with certifications and safety over watch it's hard to believe that this kind of bungle was allowed to make it all the way to the track level.

I guess this will be one of the major findings of the commission

I guess this will be one of the major findings of the commission

We were on a 15-minute break which is now after 22m has resolved itself.

And we are back, with original counsel going on about root causes.

And we are back, with original counsel going on about root causes.

Now talking about replacing the axels because the independent hubs were having issues with torque causing a undue wear.

However it's not really an issue because it's an immediate issue wouldn't cause the bearing issue, and once it wears in it's good to go.

However it's not really an issue because it's an immediate issue wouldn't cause the bearing issue, and once it wears in it's good to go.

But the reason for the wanting to change them. Is that now they know it exists they don't want to leave it for future design (as a train company). It lowers the quality of the design needlessly and removes lowers safety and life margins needlessly.

As it stands Alstom continues to point out that the Alstom axel issue is a secondary issue.

They know the corrugation is causing brackets and other things to fatigue way too early - can't tie it directly, but confidence, the vibrations are at fault.

They know the corrugation is causing brackets and other things to fatigue way too early - can't tie it directly, but confidence, the vibrations are at fault.

He still thinks that the risk of reoccurring is very low as mitigation measures are now in place. He believes they can manage away the risk.

He States his view of the failure in France that was similar was due to a manufacturing issue. They were improperly attaching objects and setting them in place.

It's was fixed, and developed away from rehappening. No risk/hazard to Ottawa.

It's was fixed, and developed away from rehappening. No risk/hazard to Ottawa.

Now talking about the second derailment the blame was solely on maintenance.

They were doing their 7,000 km checks, and they were in the part of replacing the hub and due to a shift changeover the work was not completed properly.

They were doing their 7,000 km checks, and they were in the part of replacing the hub and due to a shift changeover the work was not completed properly.

It was related in that the hubs are expiring quickly, forcing more work and more cycles (more possibilities for human error)

But unrelated as in vibrations and stress did not cause this failure directly.

But unrelated as in vibrations and stress did not cause this failure directly.

And this correlates to all the background stuff that the city is done and all the people they've hired to ensure processes.

Why the city couldn't be open and honest with us, is beyond me.

So my guess is they're probably just about as much in the dark as us.

Why the city couldn't be open and honest with us, is beyond me.

So my guess is they're probably just about as much in the dark as us.

Lol what a shit show. So at one point the signaling system wasn't detecting faults properly and then basically what the train was saying and the signalling was seeing - got so large and to the point the the system just shut down 😂

Counsel points out in 97-page document of a minor deficiencies that were still rolling around in 2019 😂

Only nine of those were safety related but they all got resolved or waivered

Only nine of those were safety related but they all got resolved or waivered

This was the list of conditions.

Alstrom points out to the public that the trains are safe to ride and the design is safe.

Alstrom points out to the public that the trains are safe to ride and the design is safe.

The low floor is guessed that it was because the city likely wanted to run these trains down city streets at some point.

Alstom has winterization and the city targeted -40 and has provided winterizing to other very cold climates

Alstom has winterization and the city targeted -40 and has provided winterizing to other very cold climates

The City wants to make the point that they didn't buy trains that weren't made for Ottawa's weather and that they were tested.

Alstom pushes back that the testing was static and only part of a train set.

Alstom pushes back that the testing was static and only part of a train set.

And we also know most of our failures are coming from cross interactions, less to do with the train being an inherent lemon.

Which is why individual safety systems are all being signed off, but when it comes together as a complex system things overlooked are now failure points

Which is why individual safety systems are all being signed off, but when it comes together as a complex system things overlooked are now failure points

We also know the heaters, the expansion and contraction of the rail all caused issues, I believe there was signaling failures, switch issues - on top of over wear 😜

The train might be ready for -40 but obviously where your train driving is looking less than desirable.

The train might be ready for -40 but obviously where your train driving is looking less than desirable.

Nothing too important but now Alstrom is now asking Alstom about the "wheel flats task force".

Which JVA, RTG and involved Alstom.

Which JVA, RTG and involved Alstom.

The findings concluded that wheel flats are principally caused by emergency brake events. Which is caused by a host of things:

- Guideway intrusion defaults to emergency break

- Software issues detecting overspreeding due to sudden speed restrictions

- Manual auto cont conflict

- Guideway intrusion defaults to emergency break

- Software issues detecting overspreeding due to sudden speed restrictions

- Manual auto cont conflict

We also found snow and rain caused a greater frequency of locked wheels alongside cold temperatures - as operators did not drive for the temperature and slip and slide warnings can trigger an emergency braking event.

The fix was mostly software. they lowered the performance of the vehicles in different weather conditions. Got sensor the systems which were being buried under the snow, and sounds like integrated in the train fixed.

And we're now on lunch break till 2:00 p.m.

And we're now on lunch break till 2:00 p.m.

Talking about train voltage. Most NA LRT's run on 750 volts, where Ottawa chose 1500v which is extremely common in Europe.

This caused trouble in the aux crane(?), and supply chain in North America. Requiring in-depth sourcing.

This caused trouble in the aux crane(?), and supply chain in North America. Requiring in-depth sourcing.

We're back with the system integrator for SNC Lav.

I also fixed the threading here. So you'll see all the posts that were hidden now.

I also fixed the threading here. So you'll see all the posts that were hidden now.

So this is the guy who is responsible for when the train fires off a signal all the other parts interact with that signal as expected.

So far he's saying the right things, but he's the guy that would have gatekeeped half these issues.

So far he's saying the right things, but he's the guy that would have gatekeeped half these issues.

Systems and civil engineering was split.

One was the sensors and the interactions, the other station and rails and the like.

And there was also RTG-EJV which was everything but the train and signals.

But he oversees it. Not to design, but to ensure they fit.

One was the sensors and the interactions, the other station and rails and the like.

And there was also RTG-EJV which was everything but the train and signals.

But he oversees it. Not to design, but to ensure they fit.

And there is also lots of other off the shelf components. It seems like a lot was reading documents and trusting them - for the most part - with some verification they perform as expected.

RTG-EJV produced over 55000 documents as per this witness.

Holy crap. Talk about killing people through documentation.

Holy crap. Talk about killing people through documentation.

In document it is pointed to the moveable block system - a system that allows for the "unsafe area/no go for a train"

Hasn't never been applied to a train of the Citdias* system.

A fixed block system might be 5-7 headway to allow blocks to clear.

In this system your seconds.

Hasn't never been applied to a train of the Citdias* system.

A fixed block system might be 5-7 headway to allow blocks to clear.

In this system your seconds.

We had a brief disconnect and we're back.

We're asking the questions about low floor and all the other new first time customizations on the train.

Counsel is trying to paint a picture.

Witness disconnected again.

We're asking the questions about low floor and all the other new first time customizations on the train.

Counsel is trying to paint a picture.

Witness disconnected again.

Counsel smartly asks why was this technical document that helps bridge the integration show up 3 years late - June 2016?

This was shortly after he was hired and he noticed it was missing and he was just plugging the gaps.

As this is good practice.

This was shortly after he was hired and he noticed it was missing and he was just plugging the gaps.

As this is good practice.

Witness points out that these documents are more likely to appear when there's differences of opinion. He's noting that it wasn't really necessary.

He mentions that documentation was lacking in how each person conducted themselves - so more work was needed to plug holes.

He mentions that documentation was lacking in how each person conducted themselves - so more work was needed to plug holes.

Essentially it sounds like because everything was "going okay" so they relaxed how much documentation they needed.

But once they found out that people are a little too relaxed, and key things weren't being documented, the pendulum swung the other direction.

But once they found out that people are a little too relaxed, and key things weren't being documented, the pendulum swung the other direction.

So the counsel points out that the design group and the product creation group are all in their own silos and that OLRT holds contracts with each of them but they don't hold contracts amongst themselves.

Decent point.

Which of course causes issues.

Decent point.

Which of course causes issues.

There's about 175 unique messages sent between Thales/Alstom and the control system

Witness states that the first revenue miss was a compounding problem but mostly driven by the fact that there was no track to run tests on - which blame lands on OLRT-C.

The witness notes that the standard in North America is [a certain rail gauge] and Alstom states it will operate within -1 to +3mm of that gauge.

So in good OLRT-C fashion. When they went and measured the gauge was off by +6mm in some places.

That's 100% over tolerance 🤣

So in good OLRT-C fashion. When they went and measured the gauge was off by +6mm in some places.

That's 100% over tolerance 🤣

Also in 2018, there was also an issue with stuttered breaking because the braking was not as precise as it needed to be so it would brake then coast, brake then coast, then brake.

So they're talking about some of the problems that he noticed. On the idea of rail corrugation is that when you break you push the material forwards causing a bit of a wave to form and a divot where you push the material from.

Neat

Neat

Also the next biggest one is if you're taking corners too fast or too sharply then you also get rolling contact wear.

The curves are the problem. However we have train systems to help manage it. However that's not able to handle this mess 😂

The curves are the problem. However we have train systems to help manage it. However that's not able to handle this mess 😂

So what I'm learning right now is that because the city didn't want to bulldoze and draw straight lines, we're basically increasing our maintenance cost to a great degree.

Because underlying systems are broken, we're breaking down in quick time.

Because underlying systems are broken, we're breaking down in quick time.

The witness says that there's nothing that crosses his mind that gives him reason for concern that we should be monitoring our rails for corrugation.

The real issue is just noise and comfort, or if you ignore it for a long period wheel issues.

The real issue is just noise and comfort, or if you ignore it for a long period wheel issues.

Of course it should be monitored like all things as over a long period of time it can cause problems.

This is in contrast to Alstom's statements where the wildly out of spec rail and odd quality of rail surface is causing excessive forces on their train - leading to damage

This is in contrast to Alstom's statements where the wildly out of spec rail and odd quality of rail surface is causing excessive forces on their train - leading to damage

Now the damage is mitigated though manual labor of checking the "wheels" more often trying to catch faults before they are failures

It's akin to knowing your car wrecks tires, so you check tire wear and alignment every few long trips trips vs twice a year.

It's akin to knowing your car wrecks tires, so you check tire wear and alignment every few long trips trips vs twice a year.

So at least our tires aren't going to explode and we're not going to fly off the road - but we either got to fix the road or get better tires. However there's nothing wrong with our tires, they're just not made for such horrible conditions.

Starting to make sense now.

Starting to make sense now.

Nothing too important from the city. Alstom is now lightly grilling the witness (OLRT-C integration manager)

He asked him that since you though the rail profile was such a big issue.

[Why didn't you take more steps]?

Well we looked into it, but nothing happened before I left.

He asked him that since you though the rail profile was such a big issue.

[Why didn't you take more steps]?

Well we looked into it, but nothing happened before I left.

Witness notes that it isn't uncommon to start without a integrator - and one shows up 6 to 9 months later.

Or in an #OttawaLRT timeframe 3 ish years later and still having latent issues 5+ years later 🤣

Or in an #OttawaLRT timeframe 3 ish years later and still having latent issues 5+ years later 🤣

And that's it.

Another day done and dusted. Nothing too new and damning aside from the 6mm quote.

@threadreaderapp unroll

Another day done and dusted. Nothing too new and damning aside from the 6mm quote.

@threadreaderapp unroll

• • •

Missing some Tweet in this thread? You can try to

force a refresh