We can absolutely dig into the fire of the No. 4 at Darlington and explain some of the possibilities and contributing factors. Thread incoming.

https://twitter.com/MilestonesMotor/status/1566999602519330817

To understand what contributes to these fires we have to go back to one of the driver cooling fixes that were done to lower the temperature of the footwell/pedal box which is directly beside the rocker box and where the exhaust comes off the car.

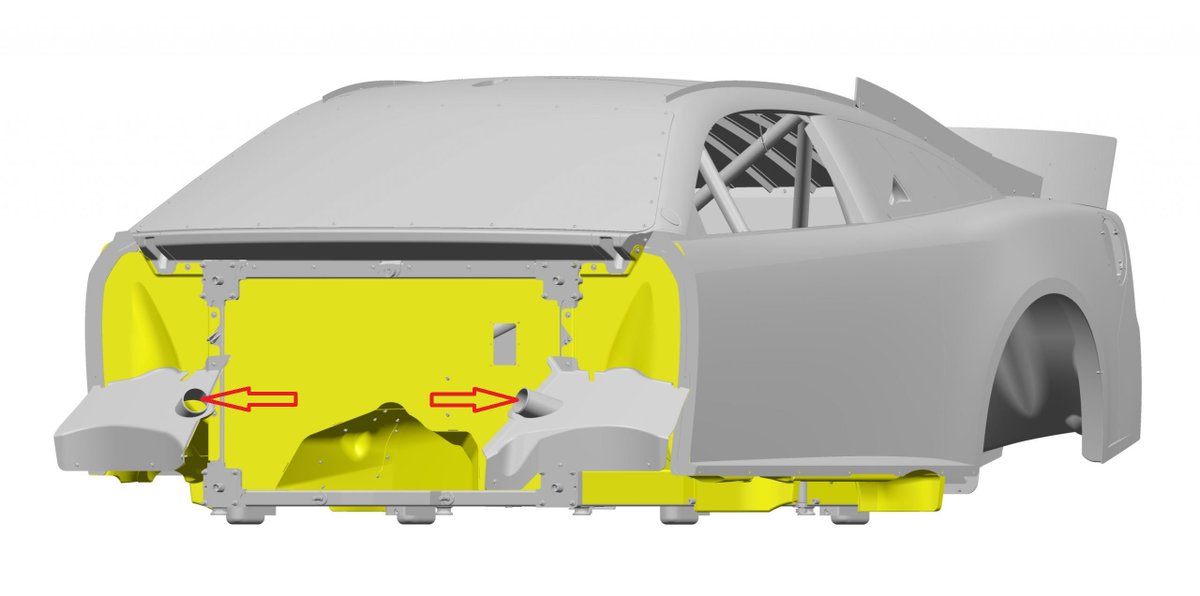

One of these fixes involved blowing air into the rocker box using the inlets shown below. These inlets are connected to hoses that are routed to the front of the car so that they can pull in air and blow it inside of the rocker box.

The source of this air comes from the openings in the grille that are marked here in red. These openings must be used for rockers box cooling and they must remain 75% open so fine mesh screens cannot be used nor can they be taped.

The rules also require one functional fan to be used per duct and to be configured to move air from the rocker cooling duct to the rocker box only.

This means that not only is there air passively moving from that front opening in the grille but it is also actively being blown.

This means that not only is there air passively moving from that front opening in the grille but it is also actively being blown.

Now let's think about a track with a surface like Darlington which is highly abrasive and that means that tires are basically getting ground down by the track surface which results in a lot of fine rubber being put down on the track.

Now take hours of racing and dozens of cars being on that surface with fresh tires being installed every so often and you get a lot of that rubber that's put down but also kicked up where it hits the front of cars.

Now imagine that fine rubber hitting the front bumper and that rocker box grille which has a grille screen that is 75% open allowing that fine rubber to enter the duct which contains a fan that ends up blasting that rubber into the rocker box.

In this view of the bottom of the car, we can see the inlet for that hose coming from that inlet at the front (red arrow) and how compact the space is where the headers go to the exhaust along with where the visible exhaust outlet ends up (blue arrow).

In addition to the air and possible debris that is coming in from the front of the car, there is also another opening on the bottom of that rocker box assembly that allows air to enter for cooling but can also be a source of debris. This opening cannot be closed off.

Teams that have been caught attempting to close off that opening in any manner have been penalized as we saw in July.

https://twitter.com/BoziTatarevic/status/1551218151169425410

So now that we know the potential of fine rubber to be deposited in this area we have to consider that there is not a lot of space and eventually that rubber will pile up and start touching the blazing hot exhaust which can result in it lighting up on fire.

Once the rubber is on fire all of the systems that are intended for cooling end up acting as accelerants because you end up feeding the fire with air moving from those fans that are connected to the ducts in the front bumper.

Once that are is on fire it is incredibly easy for it to spread as we saw with the No. 4 on Sunday night because the insulation that is used for the rocker box (yellow) will eventually combust itself once the temperature gets high enough and then spread to stuff like brake lines.

Once the fire gets to something like the brake lines then we see it spread to the other side of the car and even inside of the car behind the dash because of where the brake cylinders are located.

The best way to imagine the situation is to think about placing a hot coal inside of a vacuum cleaner canister and then trying to vacuum up tire chunks and other debris that ends up falling on top of it. Eventually it will start burning.

NASCAR has been looking at this for a while and have proposed some solutions for how the rocker box is designed. They have tested at least one change but there doesn't appear to have been a good solution yet because they have to strike a balance between cooling and debris issues.

These issues also appear to happen more commonly on the Fords and that is could possibly be due to the header design because that is the one item that OEMs are allowed to customizes and their might be located in such a way to allow the rubber/debris to build up faster.

While the headers are something to look at in detail, the design of the rocker box and the cooling ducts is shared across all of the cars and should be looked at first since fires have happenned in other types of cars in testing and in races.

My perspective is that there are multiple steps here to resolve these issues but the easy ones to start are attempting to find insulation that is a little more fire resistant since the teams have control over that.

On the side of NASCAR, I believe that a look at how the cooling inlets for the rocker box are designed will probably be helpful and finding a way to not have possible rubber and debris enter would help greatly.

Even reducing the amount of rubber and debris that enters could likely prevent many of these scenarios but that would require at least to allow teams to close off the grille inlets a bit more or to possibly modify what and how fans are used in the hoses.

I was only able to view the No. 4 car from a distance when I saw it burned at Darlington so this is all of course my perspective of seeing things from the outside and chatting with people in the garage but I hope it sheds a bit more light on how such a situation can happen.

Here is part of the reason why I think that it should be looked at as a Next Gen issue and not a Ford header design issue.

Smaller mesh could be a solution and could reduce the amount of build-up in the rocker box but also reduces cooling and changes the aero profile of the car so there are multiple things to balance hence why it's not an easy fix.

https://twitter.com/apawlows/status/1567182406624616455?s=20&t=mpO_Td3cDVWs6nfRaJ9nQg

NASCAR is already issuing an update to help mitigate fire risk as a notice went out to teams this evening that a piece will need to be added to the rocker boxes for this weekend. The piece will be available from the supplier in the morning so that teams can install tommorow.

Teams also have received a file of the design for the piece if they choose to fabricate it themselves. It will be a busy day in the shops tommorow as trucks are set to leave Thursday morning so cars need to be loaded in the trailers by tommorow evening.

Getting into the rocker box to make the modification requires removing bodywork on the sides of the car so teams will have to reset all of that and make sure that they can pass an OSS scan after everything is re-assembled and that will be a lot to do in a single day.

Some details on the changes here.

https://twitter.com/Brian_Murphy_/status/1567305149848190977

NASCAR comms acknowledged the change this morning and sent out a document with details matching what was shared with me from multiple team sources yesterday.

The first part of the document allows intumescent coatings to be sprayed in certain areas. These are coatings that acts as fire extinguishing barriers that can help to prevent fire from spreading.

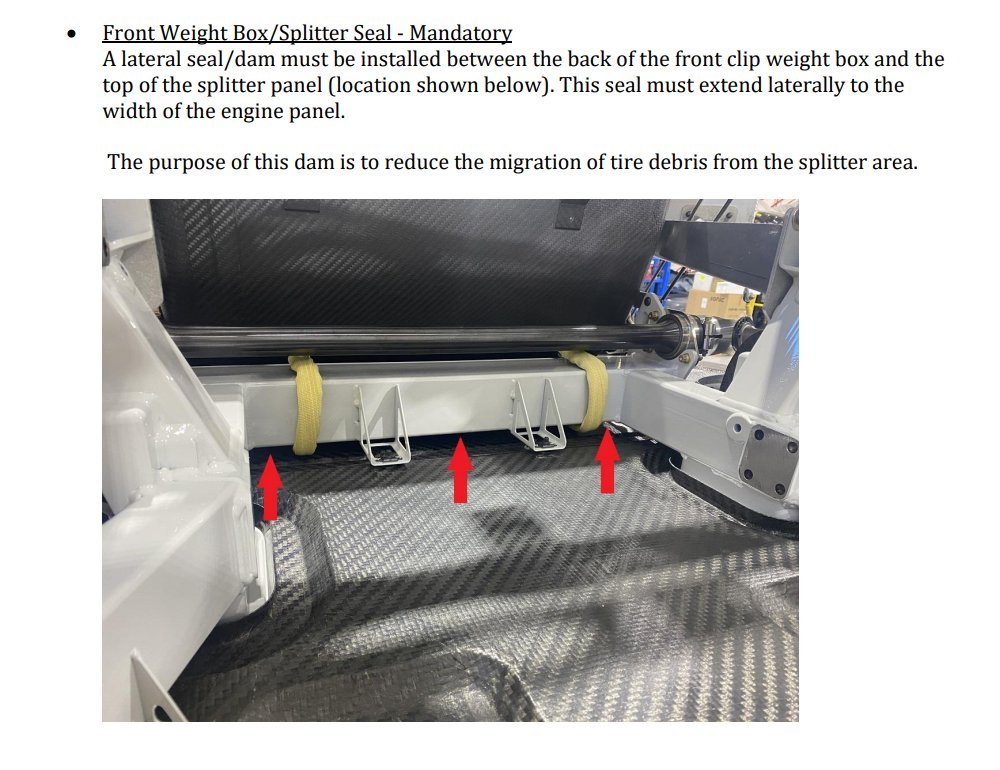

The next part of the document details a seal that must be installed between the bottom of the front clip and the top of the splitter to prevent tire debris from coming through that gap.

A portion of the right front stop panel is to be replaced with stainless steel. This is to slow the spread of fire if it happens in that right front rocker box area.

Lastly, there is recommendation to teams to space the exhaust from the bottom of the rocker box as much as possible. This is presumably to lower potential for fire risk in case rubber start piling up below the exhaust.

My impression of these proposed changes is that they are mostly focused on preventing the spread of fire if it happens with the allowed coatings and stop panel changes versus making bigger changes to prevent it.

• • •

Missing some Tweet in this thread? You can try to

force a refresh