The most comprehensive study to date of #cultivatedmeat production was just published, led by scientists from @believermeats

Much of the data in this paper will likely make up their safety dossier for regulatory approval in the US

What did we learn? 👇

nature.com/articles/s4301…

Much of the data in this paper will likely make up their safety dossier for regulatory approval in the US

What did we learn? 👇

nature.com/articles/s4301…

For context, @believermeats is the 2nd most capitalized #cultivatedmeat company, having raised nearly $400M to date

They recently broke ground on a large production facility in N. Carolina

They recently broke ground on a large production facility in N. Carolina

https://twitter.com/elliotswartz/status/1600831332724023297?s=20&t=YK6S6X_7L_Qkvcvy5wFF2w

Cell lines: The company isolated fibroblasts from fertilized chicken embryos from 2 breeds (broiler Ross 308 and Israeli Baladi chickens).

Over time, the fibroblasts spontaneously immortalized, w/ stabilized doubling times of ~20 hrs.

Over time, the fibroblasts spontaneously immortalized, w/ stabilized doubling times of ~20 hrs.

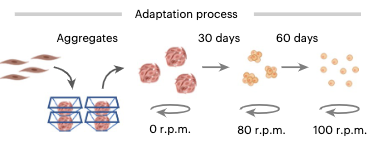

Cell lines: The cells were adapted to suspension culture thru a protocol that involves growing them in aggregates, shaking them to adapt to shear stress, dissociating them, and repeating until single cell suspension-adapted clones emerge.

Cell lines: Chickens have a lot of chromosomes. The cell lines displayed some karyotypic abnormalities & copy number variations throughout the genome.

Despite this, the cells retain a fibroblast identity.

Despite this, the cells retain a fibroblast identity.

Cell lines: They characterize the immortalization of adherent and suspension-adapted cell lines, finding that they occurred without telomerase upregulation but involved downregulation of p53, Myc, and EGFR.

Cell lines: The company answered whether immortalization = transformation by analyzing p53 SNVs, DNA repair, abundance of cancer-linked mutations, & tumorigenic potential.

They conclude the cell lines aren't transformed i.e. they are not like cancer cells.

They conclude the cell lines aren't transformed i.e. they are not like cancer cells.

Even if the cells were transformed, this is still not a food safety concern. From the FDA's pre-market consultation of UPSIDE Foods cultivated chicken:

https://twitter.com/elliotswartz/status/1597233030040809473?s=20&t=YK6S6X_7L_Qkvcvy5wFF2w

Cell lines: They also analyze prion protein & amyloidogenic protein levels, concluding these are normally expressed and pose no risk.

This level of detail goes above and beyond what was seen in UPSIDE Foods' pre-market FDA consultation based on what was shown.

This level of detail goes above and beyond what was seen in UPSIDE Foods' pre-market FDA consultation based on what was shown.

Cell lines: Finally, to ensure downstream food safety, the cells tested negative for a panel of chicken pathogens such as Influenza A and New Castle Disease Virus and other microbial contaminants

Cell culture: The cells grow in a serum-free media that's relatively simple & can definitely be sourced low-cost.

Generally speaking, fibroblasts are an easy cell type to grow (fewer growth factors needed). The company has previously stated this is an advantage to using them.

Generally speaking, fibroblasts are an easy cell type to grow (fewer growth factors needed). The company has previously stated this is an advantage to using them.

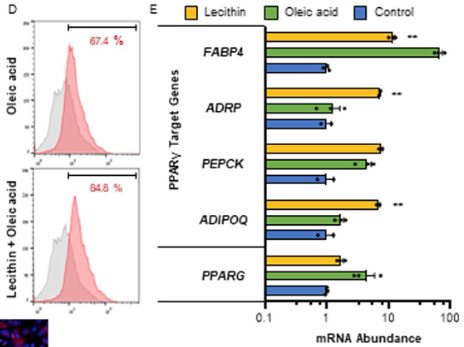

Cell culture: @believermeats turns fibroblasts into fat by adding food-grade molecules eg phosphatidyl choline & oleic acid (soy lecithin). These molecules induce PPARγ signaling, which regulates adipogenesis.

This avoids problems w/ standard fat differentiation protocols that use IBMX & Rosiglitazone, which may not be food-safe as seen in this paper by @mosa_meat

Between these 2 papers, food-safe serum-free fat production has kinda been open-sourced 👍

sciencedirect.com/science/articl…

Between these 2 papers, food-safe serum-free fat production has kinda been open-sourced 👍

sciencedirect.com/science/articl…

Cell culture: Impressive data is shown for perfusion growth in a 2L Sartorius bioreactor.

Over 15 days, the company reports cell densities of 108 million cells per mL, equivalent to 36% weight/volume or 360 grams biomass per liter. This is very high.

Over 15 days, the company reports cell densities of 108 million cells per mL, equivalent to 36% weight/volume or 360 grams biomass per liter. This is very high.

Notice that high amounts of lactate are also produced. If this were able to be captured, it could be a huge opportunity to offset costs and environmental impact.

https://twitter.com/elliotswartz/status/1564230635429847042?s=20&t=YK6S6X_7L_Qkvcvy5wFF2w

The Humbird analysis, which is the basis of The Counter article (thecounter.org/lab-grown-cult…), reports a maximum achievable perfusion culture density of 195 g/L.

So do @believermeats higher cell density data invalidate this study?

So do @believermeats higher cell density data invalidate this study?

Not quite. To achieve these very high densities, perfusion rate was nearly 20 vessel volumes/day (VVD).

This rate would become very costly as scale increases. Not only would media costs rise, but filter membrane fouling & replacement would become problematic.

This rate would become very costly as scale increases. Not only would media costs rise, but filter membrane fouling & replacement would become problematic.

According to the Humbird study, the largest ATF filters max out at 1000L/day, thus making realistic perfusion rates at scale more like 1-2 VVD rather than 20.

It's thus TBD if @believermeats will be able to maintain cost-effective high cell densities in scaled production.

It's thus TBD if @believermeats will be able to maintain cost-effective high cell densities in scaled production.

Product: @believermeats blends cultivated fat with extruded soy protein to make cultivated chicken. The paper does not state what percentage of fat is used for the end product.

Nutrition: The cultivated chicken has less saturated fat and cholesterol compared to conventional chicken but higher sodium due to the soy protein.

Below, cultured chicken refers to the blended product.

Below, cultured chicken refers to the blended product.

Nutrition: Full amino acid and lipid profile compared to conventional chicken.

Images are hard to see (not my fault, that's how it's published)

Images are hard to see (not my fault, that's how it's published)

Check out nutritional data from another cultivated chicken product here:

https://twitter.com/elliotswartz/status/1597231334333681664?s=20&t=YK6S6X_7L_Qkvcvy5wFF2w

Consumers: In a blind taste test, 67% of potential consumers prefer cultivated chicken to a soy-based analog, suggesting the added animal fat makes a noticeable difference.

Consumers: A large proportion of potential consumers rated product attributes highly and said they would be likely to replace conventional meat with cultivated meat.

In summary, this is the most comprehensive study of #cultivatedmeat published to date.

It is a very positive signal of transparency that it was led by a prominent company in the industry.

Journalists should be all over this one, IMO.

It is a very positive signal of transparency that it was led by a prominent company in the industry.

Journalists should be all over this one, IMO.

Many cultivated meat companies, including @believermeats, were founded by leading academics.

In 2022, cultivated meat companies/suppliers led or participated in 12 publications/pre-prints.

Yet people still draw comparisons to Theranos... 😄

In 2022, cultivated meat companies/suppliers led or participated in 12 publications/pre-prints.

Yet people still draw comparisons to Theranos... 😄

In 2023, we are likely to see the completion of more FDA pre-market consultations, which means access to a lot more data like the stuff presented here.

For an overview of the first #cultivatedmeat product cleared by FDA, check my thread here:

For an overview of the first #cultivatedmeat product cleared by FDA, check my thread here:

https://twitter.com/elliotswartz/status/1597231272681566208?s=20&t=YK6S6X_7L_Qkvcvy5wFF2w

"We must ensure that we, as an industry, provide all the scientific data and information to the public. If we do not rise to this challenge, consumers will search and find disinformation from charlatans online. I want to lead this conversation." 👏

proteinreport.org/newswire/hebre…

proteinreport.org/newswire/hebre…

• • •

Missing some Tweet in this thread? You can try to

force a refresh