How are TRUSS BRIDGES similar to @LEVIS jeans?

A thread to appreciate 19th-century truss bridges,

practical and versatile like a good pair of jeans.

#TrussBridges

🧵👖

A thread to appreciate 19th-century truss bridges,

practical and versatile like a good pair of jeans.

#TrussBridges

🧵👖

A truss is a structural frame of straight members, connected by joints, forming triangles.

The members work in compression (red bars) or in tension (blue bars) with almost no bending.

It's the most common structure used in 19th-century railway bridges.

The members work in compression (red bars) or in tension (blue bars) with almost no bending.

It's the most common structure used in 19th-century railway bridges.

In many cases, the thrill of the crossing can be enjoyed from the window seat.

The train runs inside the truss, through the triangulated structural tube.

The train runs inside the truss, through the triangulated structural tube.

In the middle of the 19th-century, the American railway construction was in full swing.

At this time, Levi Strauss moves to San Francisco to open his wholesale business selling work clothing and cotton trousers.

At this time, Levi Strauss moves to San Francisco to open his wholesale business selling work clothing and cotton trousers.

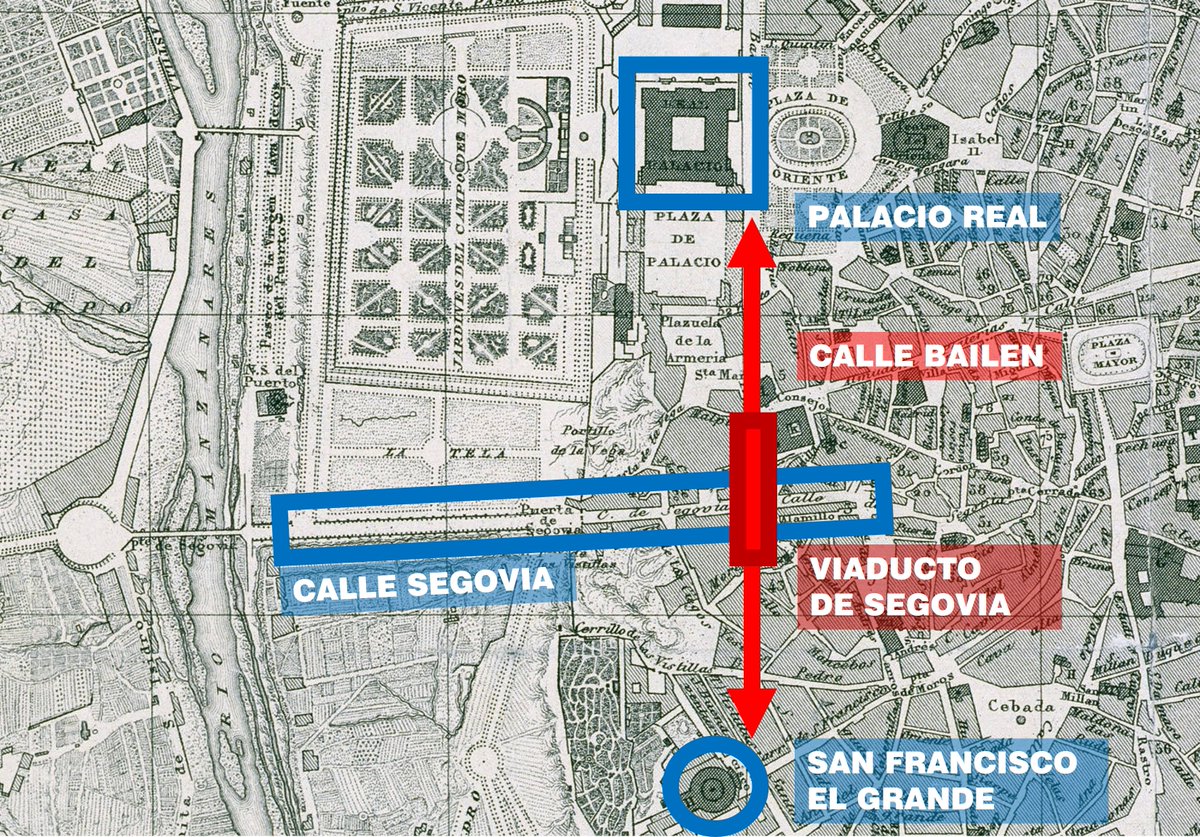

But the history of truss bridges begins earlier.

Wood is plentiful in the USA. At the beginning of the 19th century, pioneering "carpenter engineers" built large bridges with triangulated stiffened arches.

The Colossus Bridge over the Schuylkill River reaches a span of 102m.

Wood is plentiful in the USA. At the beginning of the 19th century, pioneering "carpenter engineers" built large bridges with triangulated stiffened arches.

The Colossus Bridge over the Schuylkill River reaches a span of 102m.

In 1817 Theodore BURR patented his truss consisting of a load-bearing arch and a triangulated truss that gives rigidity to the arch.

The patent was used in countless road bridges for decades.

The patent was used in countless road bridges for decades.

These are the famous American covered bridges, timber-truss bridges with roof and siding to protect the wooden structural members from the weather.

Ithiel TOWN patented the first modern truss design without arch. A lattice truss with many closely spaced diagonal elements.

Ithiel TOWN patented the first modern truss design without arch. A lattice truss with many closely spaced diagonal elements.

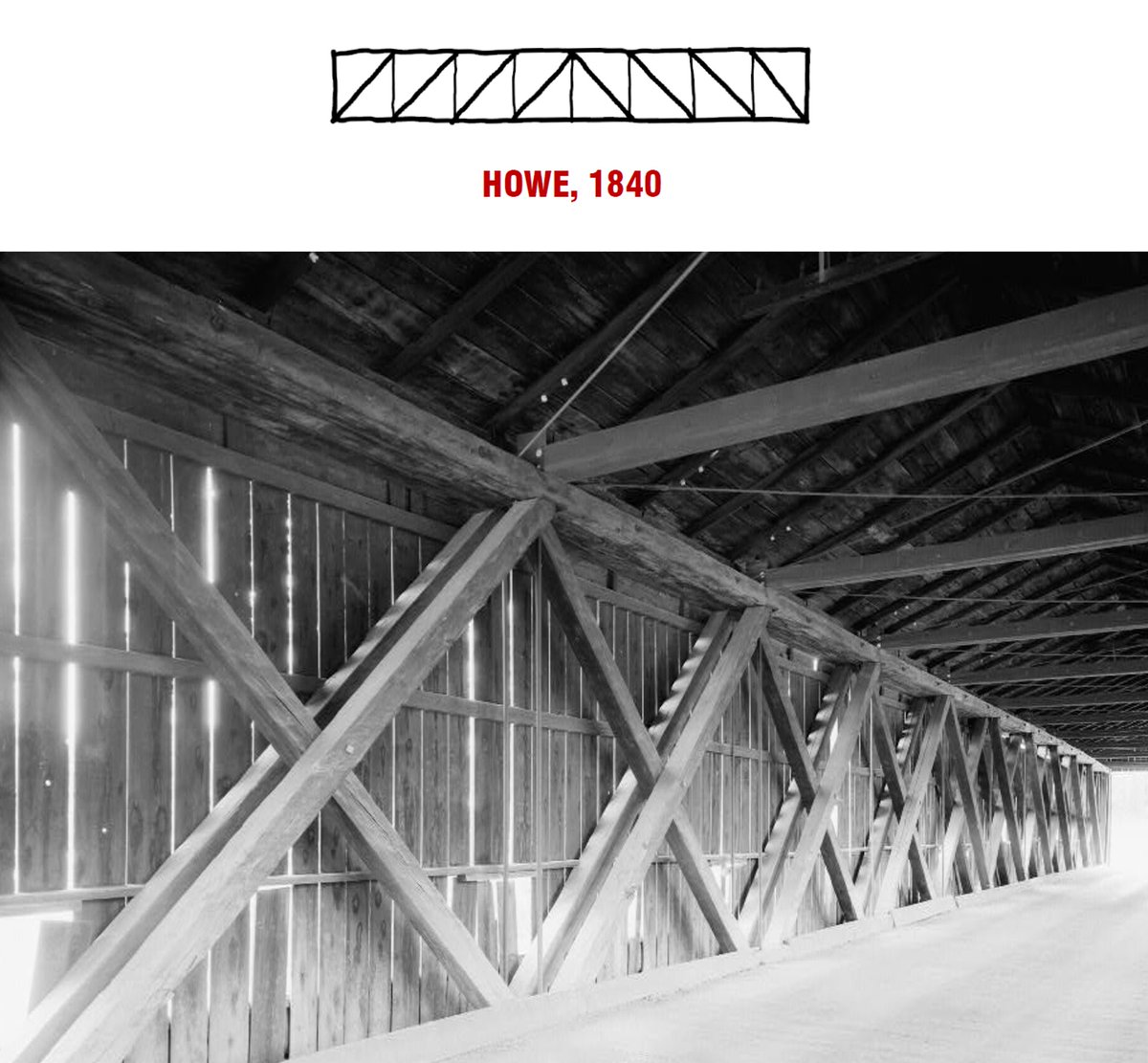

HOWE's 1940 Patent is similar to LONG’s but incorporates for the first-time iron bars working in tension in the verticals.

The diagonals inclined towards the center are in compression.

Gradually, wood gives way to iron.

The diagonals inclined towards the center are in compression.

Gradually, wood gives way to iron.

In the well-known 1944 PRATT brothers' patent, the tensioned iron bars are arranged in diagonals.

Verticals in compression are shorter in length and have a lower risk of buckling.

This type of truss, simple and efficient, is still standard today.

Verticals in compression are shorter in length and have a lower risk of buckling.

This type of truss, simple and efficient, is still standard today.

The PRATT truss derives in many variants:

PARKER or "camelback", with a polygonal top chord.

BALTIMORE with additional bracing in the lower section.

K truss, with K-shaped vertical and diagonals.

PENNSYLVANIA, a mixture of PARKER and BALTIMORE.

PARKER or "camelback", with a polygonal top chord.

BALTIMORE with additional bracing in the lower section.

K truss, with K-shaped vertical and diagonals.

PENNSYLVANIA, a mixture of PARKER and BALTIMORE.

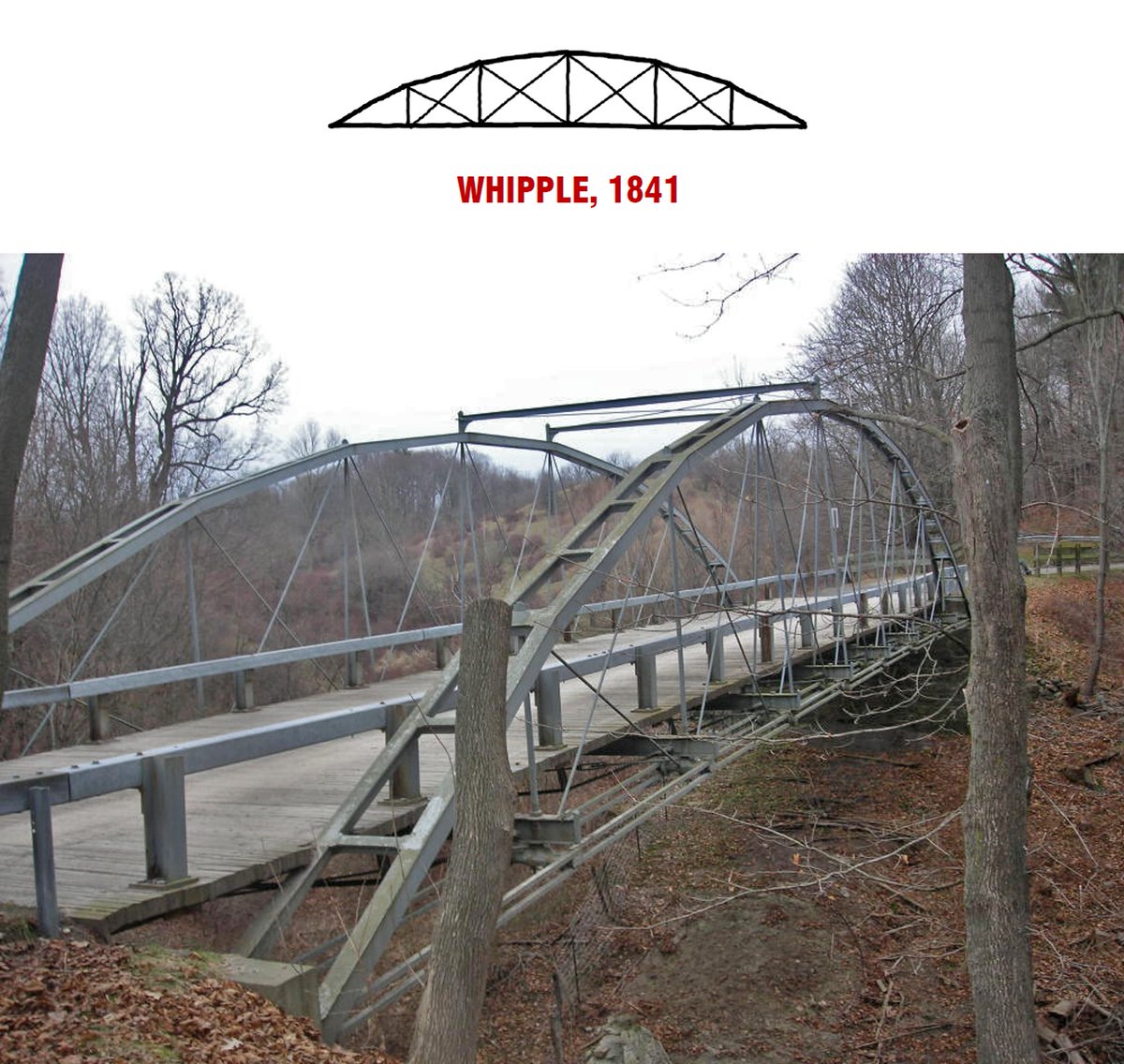

Civil engineer Squire WHIPPLE holds two patents:

The Bowstring arch, a tied-arch bridge with diagonal load-bearing members, the lower chord serves as a tension brace.

The Bowstring arch, a tied-arch bridge with diagonal load-bearing members, the lower chord serves as a tension brace.

In 1847 the patent known as the WHIPPLE truss.

The two parallel chords, with vertical cast iron compression members, and crisscrossed tensile iron diagonals.

The two parallel chords, with vertical cast iron compression members, and crisscrossed tensile iron diagonals.

Wendel BOLLMAN's truss of 1852 is also made entirely of iron.

It multiplies the tensioned braces, forming a bundle of tensioned bars that are anchored to the vertical members of the piles.

It multiplies the tensioned braces, forming a bundle of tensioned bars that are anchored to the vertical members of the piles.

Albert FINK's 1854 patent is fascinating:

no bottom chord.

The diagonal braces are tensioned bars which form a lower tie net for the compressed verticals.

Very attractive but not very effective and too flexible for large spans.

no bottom chord.

The diagonal braces are tensioned bars which form a lower tie net for the compressed verticals.

Very attractive but not very effective and too flexible for large spans.

John H. LINVILLE's truss, patented in 1868, overlaps two PRATT trusses and, to increase the rigidity of the deck, it has crossed diagonals at mid-span.

On the Cincinnati Bridge over the Ohio River, it set the world record with a span of 157m.

On the Cincinnati Bridge over the Ohio River, it set the world record with a span of 157m.

Meanwhile in Europe...

NO patents are made.

But they DO have efficient triangular bridges.

The distinguished English engineer Isambard K. Brunel designs a collection of wooden viaducts and a bowstring iron arch that have no reason to envy to the American patents.

NO patents are made.

But they DO have efficient triangular bridges.

The distinguished English engineer Isambard K. Brunel designs a collection of wooden viaducts and a bowstring iron arch that have no reason to envy to the American patents.

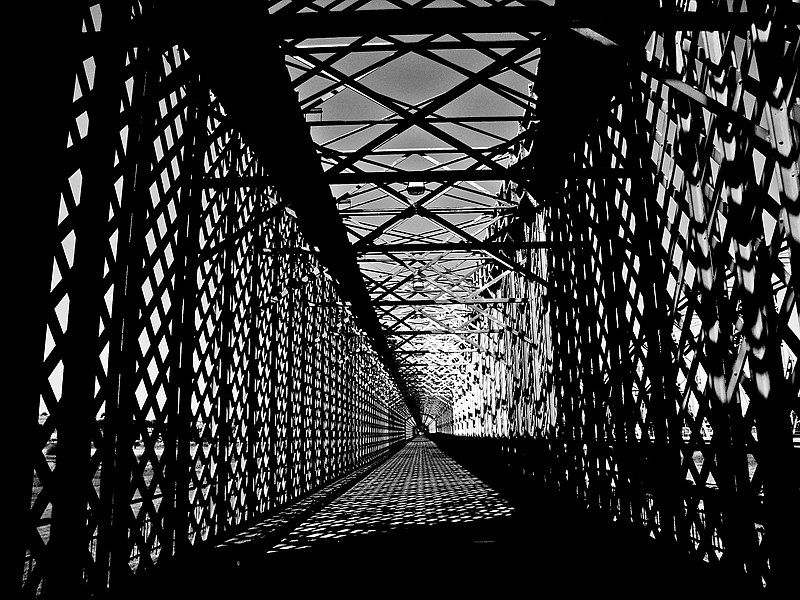

Europe closely followed the development of trusses in the United States.

It did not take long to incorporate them in the bridges of the new railway network.

In particular, the TOWN lattice truss, replacing wood with iron.

It did not take long to incorporate them in the bridges of the new railway network.

In particular, the TOWN lattice truss, replacing wood with iron.

The only European patent of the time is British, the famous WARREN.

A simple symmetrical truss with identical V-shaped diagonals, alternating tension and compression.

The Crumlin Viaduct in Wales is the first major WARREN bridge.

Today WARREN it is the most widely used truss.

A simple symmetrical truss with identical V-shaped diagonals, alternating tension and compression.

The Crumlin Viaduct in Wales is the first major WARREN bridge.

Today WARREN it is the most widely used truss.

Europe also defined new construction processes.

The TOWN lattice truss allowed a pioneering system: pushing.

The deck is built on one of the abutments and is pushed, sliding onto the piles with the help of rollers, until it reaches its final position.

The TOWN lattice truss allowed a pioneering system: pushing.

The deck is built on one of the abutments and is pushed, sliding onto the piles with the help of rollers, until it reaches its final position.

Wilhelm Nördling perfects the pushing process by constructing the piles from the front end.

The pile elements are suspended from the cantilevered deck supported by means of a temporary tie.

The deck remains the TOWN lattice truss.

The pile elements are suspended from the cantilevered deck supported by means of a temporary tie.

The deck remains the TOWN lattice truss.

One last European patent: the Belgian system of Jules A. VIERENDEEL.

Architects tend to like it, although it is not a real truss. Members are not triangulated but form a rectangular frame.

It is less efficient and more flexible. It requires fixed joints for bending moments.

Architects tend to like it, although it is not a real truss. Members are not triangulated but form a rectangular frame.

It is less efficient and more flexible. It requires fixed joints for bending moments.

And to top it all off, a summary poster (can be kept, printed or put on T-shirts).

Truss bridge patents of the 19th century are as American as @LEVIS

Well, most of them.

Note US patents are marked in red.

But there are even more similarities with jeans.

⤵️

Truss bridge patents of the 19th century are as American as @LEVIS

Well, most of them.

Note US patents are marked in red.

But there are even more similarities with jeans.

⤵️

We have already seen that Levi Strauss & Co was founded in the mid-19th century.

In 1872, one of his customers, the tailor Jacob W. Davis, noticed a problem with his trousers: the pockets were easily ripped.

Together they came up with a solution, which they patented in 1873...

In 1872, one of his customers, the tailor Jacob W. Davis, noticed a problem with his trousers: the pockets were easily ripped.

Together they came up with a solution, which they patented in 1873...

The RIVET.

Levi Strauss and Jacob W. Davis' patent reinforces the pocket corners with copper rivets.

Thus was born the first riveted jeans @LEVIS, which are still in use today.

There is also a crucial detail in truss bridges...

Levi Strauss and Jacob W. Davis' patent reinforces the pocket corners with copper rivets.

Thus was born the first riveted jeans @LEVIS, which are still in use today.

There is also a crucial detail in truss bridges...

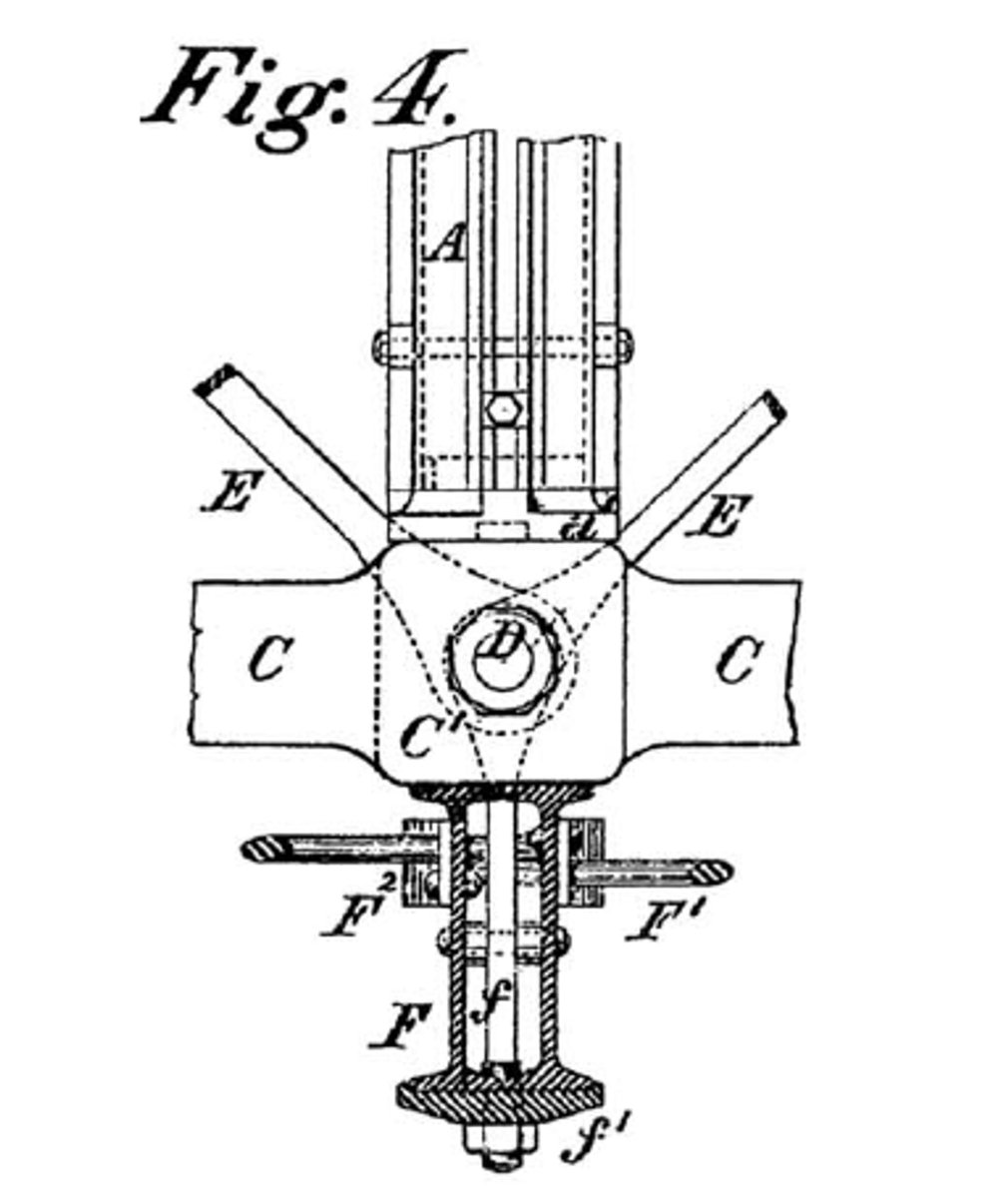

The JOINT.

Joints in trusses define the ease of construction, resistance, and formal connection of members.

Always look at the joints. Their detail says a lot about the technique of the bridge.

Observe the planes in which members are arranged, whether they cut or cross.

Joints in trusses define the ease of construction, resistance, and formal connection of members.

Always look at the joints. Their detail says a lot about the technique of the bridge.

Observe the planes in which members are arranged, whether they cut or cross.

All the patents we have seen define the joints precisely.

This is where the economy of the solution, ease of construction, durability and aesthetics lie.

Like the @LEVIS rivet

But there is something more important.

⤵️

This is where the economy of the solution, ease of construction, durability and aesthetics lie.

Like the @LEVIS rivet

But there is something more important.

⤵️

THE HERITAGE VALUE OF BRIDGES.

@LEVIS are not thrown away.

Their latest campaigns emphasize that they are designed to be worn for generations.

Historic bridges must also endure.

They should be known and cared for.

They are our heritage.

@LEVIS are not thrown away.

Their latest campaigns emphasize that they are designed to be worn for generations.

Historic bridges must also endure.

They should be known and cared for.

They are our heritage.

https://twitter.com/AKQA/status/1580835181400915968?t=bX-GKu29Qun-CeQnIL7Zzg&s=08

Thanks for getting hooked on 19th-century engineering.

Now you know, defend the bridges, and don't throw away your 👖.

If you want to promote the heritage value of bridges, please ♥️ like and 🔄retweet the first tweet of the thread (find the link below).

Now you know, defend the bridges, and don't throw away your 👖.

If you want to promote the heritage value of bridges, please ♥️ like and 🔄retweet the first tweet of the thread (find the link below).

https://twitter.com/Jorge_Bernabeu/status/1656703511722090496?s=20

Credits:

All jeans’ photos are @LEVIS second-hand.

All truss schemes are my own.

Bridge images are credited in the description of the first photo of each tweet.

All jeans’ photos are @LEVIS second-hand.

All truss schemes are my own.

Bridge images are credited in the description of the first photo of each tweet.

CC licenses of the images:

CC BY: creativecommons.org/licenses/by/2.…

CC BY-SA: creativecommons.org/licenses/by-sa…

CC BY-ND: creativecommons.org/licenses/by-nd…

CC BY-NC-SA: creativecommons.org/licenses/by-nc…

CC BY-NC: creativecommons.org/licenses/by-nc…

CC BY-NC-ND: creativecommons.org/licenses/by-nc…

CC BY: creativecommons.org/licenses/by/2.…

CC BY-SA: creativecommons.org/licenses/by-sa…

CC BY-ND: creativecommons.org/licenses/by-nd…

CC BY-NC-SA: creativecommons.org/licenses/by-nc…

CC BY-NC: creativecommons.org/licenses/by-nc…

CC BY-NC-ND: creativecommons.org/licenses/by-nc…

Spanish version.

Enamórate de los puentes en celosía.

Enamórate de los puentes en celosía.

https://twitter.com/Jorge_Bernabeu/status/1656340809887744002?s=20

• • •

Missing some Tweet in this thread? You can try to

force a refresh

Read on Twitter

Read on Twitter