How much would it cost to ensure electrolytic #hydrogen production is truly low-carbon?

Debates about how to implement rich new clean H2 subsidies in the 🇺🇸🇪🇺🇨🇦🇦🇺, etc. may hinge on the answer.

A new ZERO Lab report compiles the best available evidence: doi.org/10.5281/zenodo…

Debates about how to implement rich new clean H2 subsidies in the 🇺🇸🇪🇺🇨🇦🇦🇺, etc. may hinge on the answer.

A new ZERO Lab report compiles the best available evidence: doi.org/10.5281/zenodo…

Earlier this year, ZERO Lab published a peer-reviewed paper showing that three requirements for clean electricity procurement - new supply, deliverability, & hourly matching - are necessary to ensure H2 production meets legal emissions thresholds in IRA iopscience.iop.org/article/10.108…

Although these 'Three Pillars' are the only viable way to enable H2 production at the effective emissions rates required by the Inflation Reduction Act, some industry players have argued that compliance would be too costly and would kill the nascent H2 industry in the cradle...

This perceived conflict between the priorities of a) legally required decarbonization, and b) successful scale-up of what we anticipate will be a critical clean industry has led some to call for a delayed implementation of robust emissions standards, particularly hourly matching.

While there are certain areas of climate policy where such trade-offs are real & necessary, the best available evidence suggests this is not one of them: with clean hydrogen, America can eat its cake and have it, too, meeting our technology policy AND climate goals at same time.

For this new meta-analysis, we built an open-source levelized cost of hydrogen (LCOH) tool, which you can download here zenodo.org/record/7869238… and compiled assumptions from 10 different studies from a range of academic, consulting, & hydrogen & renewable energy industry sources.

This tool captures to three central factors that determine hydrogen production costs: the average cost of input electricity, the utilization rate of electrolysers, and the fixed costs of electrolysis (capital & fixed O&M). Go ahead and play with it yourself!

Even assuming electrolysis projects cost $1750/kW, which is DOE's current estimate for 2 MW pilot-scale projects, we find 8 of 10 studies conclude Three Pillars compliant H2 will cost <$2/kg post-subsidy, w/7 finding post-subsidy costs <$1/kg, easily competitive w/fossil-based H2

The key to making clean H2 pencil even w/expensive electrolyzers & with hourly matching is to *over-size* clean electricity supply vs electrolyzer capacity. ALL studies that optimized sizing of wind/solar & electrolysis capacity result in LCOH <$1.25/kg target price of fossil H2

In contrast, 2 studies (from @rhodium_group & @EFIfortheFuture) that assume 1:1 solar/wind to electrolysis capacity resulted in low utilization rates & VERY expensive H2. This doesnt mean hourly matching is prohibitively expensive. It means these project designs are suboptimal!

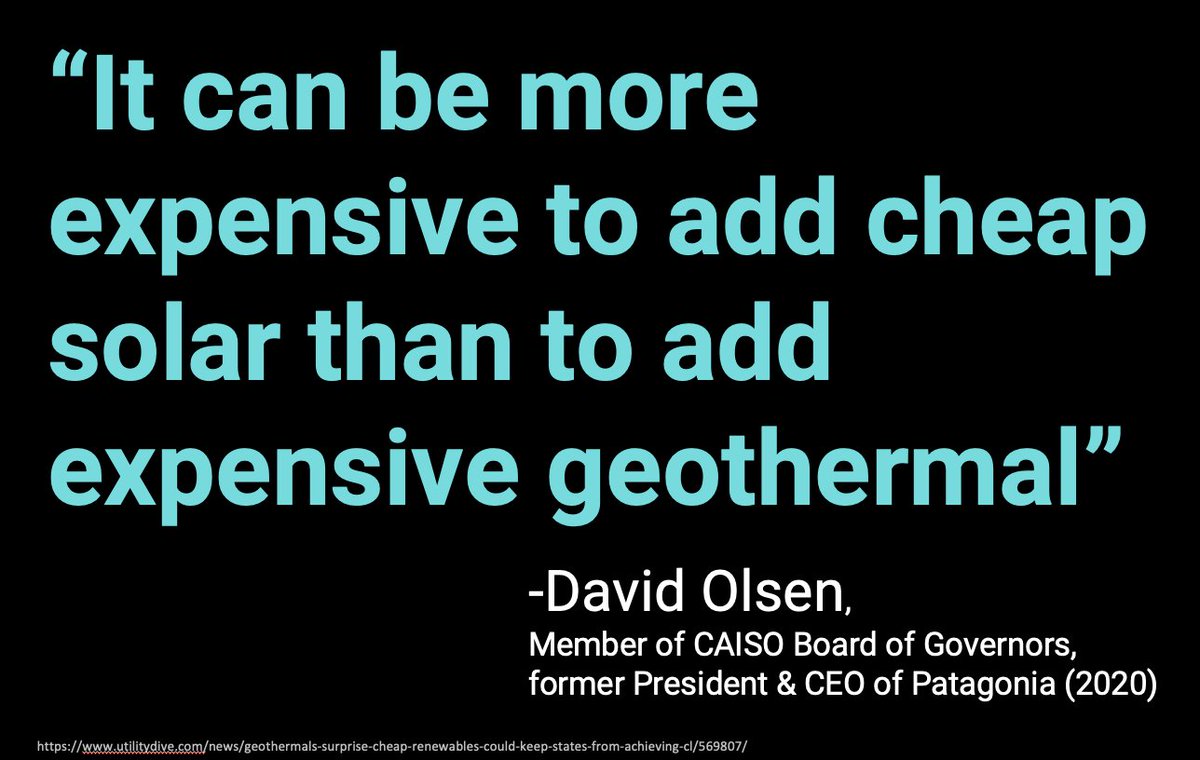

If electrolyzers are expensive but wind & solar cheap, you are much better off buying more wind/solar to increase electrolyzer utilization rates to 70+% than skimp on clean electricity supply & run electrolyzers at 25-40% utilization. Do that, and your projects are good to go!

In short, even with TODAY'S estimates for small, pilot-scale electrolysis project costs ($1750/kW installed), clean hydrogen producers & good sites w/optimized procurement can pencil FROM DAY ONE while meeting hourly matching & IRA's strict emissions limits (<0.45 kg CO2-e/kg H2)

Remember: electrolyzers today are built in factories at bespoke scale (10s of MW/yr) & DOE's $1750/kW estimate is for a tiny, 2-MW project. The days of gigafactory electrolysis production are near

https://twitter.com/JesseJenkins/status/1659170035221315587& clean H2 projects planned now are 100s of MW to GW scale

Just scaling up to 'gigascale' manufacturing & 'gigascale' electrolysis projects will capture big economies of scale that will drop electrolyzer costs significantly. Projects coming online 3-4 years out will be MUCH cheaper. See @IEA for a bullish view: iea.blob.core.windows.net/assets/c5bc75b…

If project costs fall to ~$1150/kW (likely just due to economies of scale alone), even cases that neglect excess sales & use only a single renewable resource are in the money, and those competitive @ $1750/kW are now generally being produced at negative cost. Free hydrogen y'all!

At $550/kW electrolyzer project costs, fixed costs become a smaller component of LCOH compared to input electricity costs. In this case, every study’s electricity cost lead to near-zero or negative cost hydrogen production, even at low utilization rates.

Recall, @IEA thinks that installed electrolyzer project costs could fall to the neighborhood of $500/kW by 2030 (and $600-700/kW even as early as 2025). iea.blob.core.windows.net/assets/c5bc75b…

What does this all mean for how to design rules to ensure 'clean' H2 subsidies actually go to clean producers?

It means industry attempts to scare govts into enacting weak environmental rules, claiming it's necessary to get industry liftoff are, to use a technical term, bullshit

It means industry attempts to scare govts into enacting weak environmental rules, claiming it's necessary to get industry liftoff are, to use a technical term, bullshit

There's broad agreement in studies we surveyed & using conservative estimates of 2022 project costs from agencies like DOE, IEA, that early projects built in good locations w/optimized procurement of wind &/or solar to get 70+% utilization rates will pencil under 45V subsidy NOW.

For a sector scaling from ~0, these are exactly the kind of projects we WANT to start the sector off. Not every project under the sun should be economic from day one. We want H2 projects siting where there's ample, good renewables & access to H2 demand to start the industry off.

So think of a project in Texas near existing refineries sourcing good wind & solar or projects in Kansas or Iowa near ammonia production with strong wind resources as the "Tesla Roadster" of the early clean H2 sector. Early deployment niche that the sector can use for liftoff.

Then, as projects @ gigawatt scale start securing electrolyzers from gigafactories coming online c. 2024-2026, costs fall, maybe to the $1150/kW range. All of a sudden, LOTS of locations with decent renewable resource access are economic -- the Model S's of H2 industry scale-up.

Before we know it, c. 2030, we've hit "the Model 3 moment" for electrolysis, with economies of scale & learning by doing in manufacturing and project installations cutting costs to c. $550/kW. Now you can build clean H2 pretty much wherever you want. Industry liftoff is complete!

We can do ALL of that while ensuring H2 projects meet Three Pillars standards for electricity sourcing -- use electricity from NEW clean supply, deliverable to their location, matched w/use on hour by hour basis. No need for weaker rules pushed by NextEra, Constellation or others

The Three Pillars are the only way to credibly allow grid-connected electrolyzers to claim the clean hydrogen tax credit at $3/kg, which requires demonstrating near-zero emissions & thus near-100% clean electricity consumption. Fortunately, doing that won't break the bank either!

In closing: Requiring the Three Pillars to demonstrate clean H2 production is necessary, feasible to implement, and economically viable from day one.

Do NOT believe industry players telling you otherwise. (Dont believe me? Play w/the LCOH tool yourself zenodo.org/record/7869238…)

Do NOT believe industry players telling you otherwise. (Dont believe me? Play w/the LCOH tool yourself zenodo.org/record/7869238…)

We can meet the statutory near-zero emissions requirements in the Inflation Reduction Act's 45V subsidy AND launch a critical new clean industry at the same time. Near- and long-term climate goals are not in conflict here. @treasury needs to do the right thing here.

In contrast, permitting weak annual matching or allowing existing clean electricity to supply electrolyzers, as big industry players (NextEra, Constellation, etc.) are lobbying the Administration hard for now, would make 45V the biggest policy disaster since US biofuels policy!

Here's 3 reasons why caving to industry pressure would be a massive fail (cc @johnpodesta):

1. It would be a self-inflicted scandal: $10s of billions of taxpayer $ going to projects demonstrably INCREASING CO2 by 10s of Mt/yr. Could forever ruin reputation of "clean" hydrogen!

1. It would be a self-inflicted scandal: $10s of billions of taxpayer $ going to projects demonstrably INCREASING CO2 by 10s of Mt/yr. Could forever ruin reputation of "clean" hydrogen!

2. It would create zombie industry dependent on 45V subsidies, with projects that arent actually clean crowding out those that are, stiffling growth of real business models, project designs, and operational strategies we need the hydrogen industry to perfect to be viable post-45V

3. It would cut US 'clean' hydrogen production (and resulting fuel products) off from the global export market, including the EU, which is requiring the Three Pillars for all imported clean hydrogen and ammonia.

The path to scale a truly clean hydrogen sector in America is clear. The stakes are high. And the alleged tradeoffs of 'clean' 45V rules following the Three Pillars are nowhere near what big industry players claim. Do the right thing @USTreasury @johnpodesta @alizaidi46 /end

@threadreaderapp unroll please!

• • •

Missing some Tweet in this thread? You can try to

force a refresh

Read on Twitter

Read on Twitter