Having looked at the T-64's engine cooling system, now we move just a little over to its engine air intake and cleaning system...

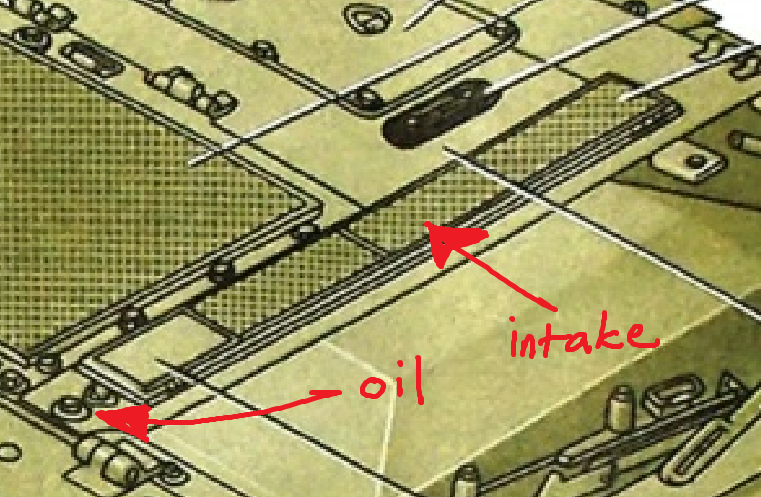

Now, of course, like any internal combustion engine, the 5TDF needs air. And it doesn't like dusty air either, so it needs an air cleaning system too.

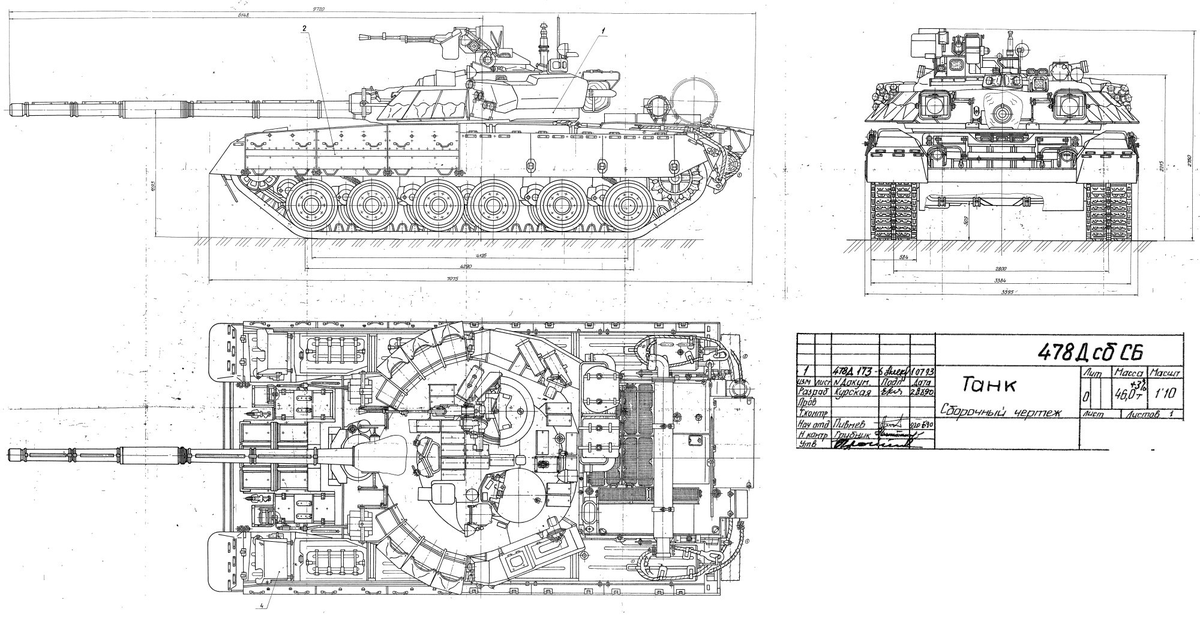

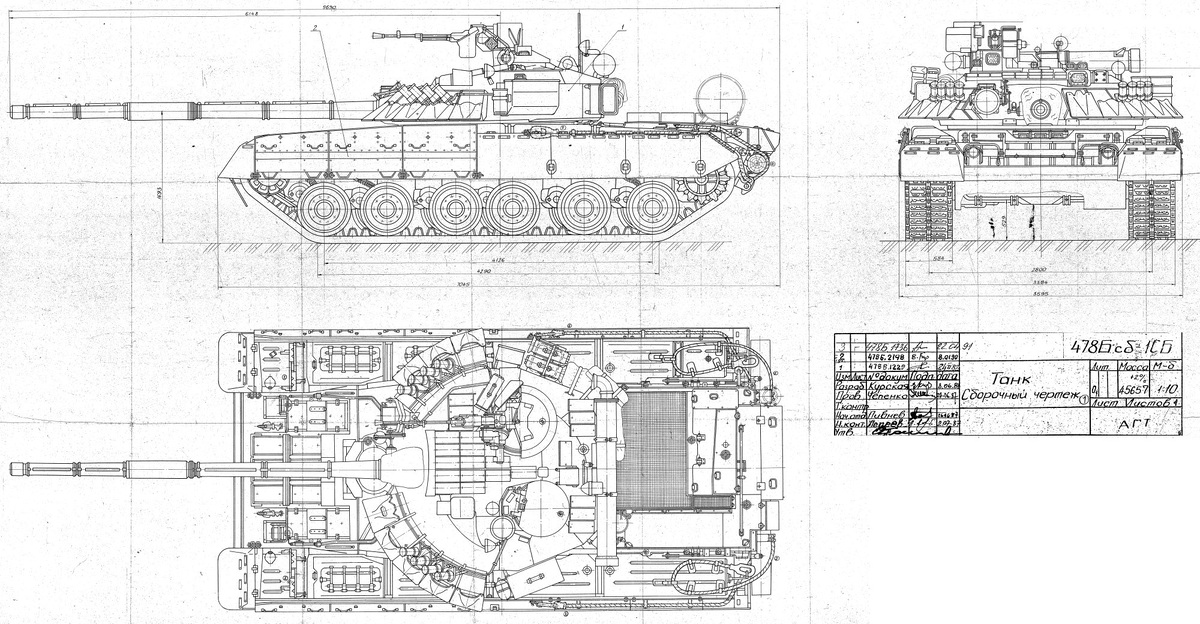

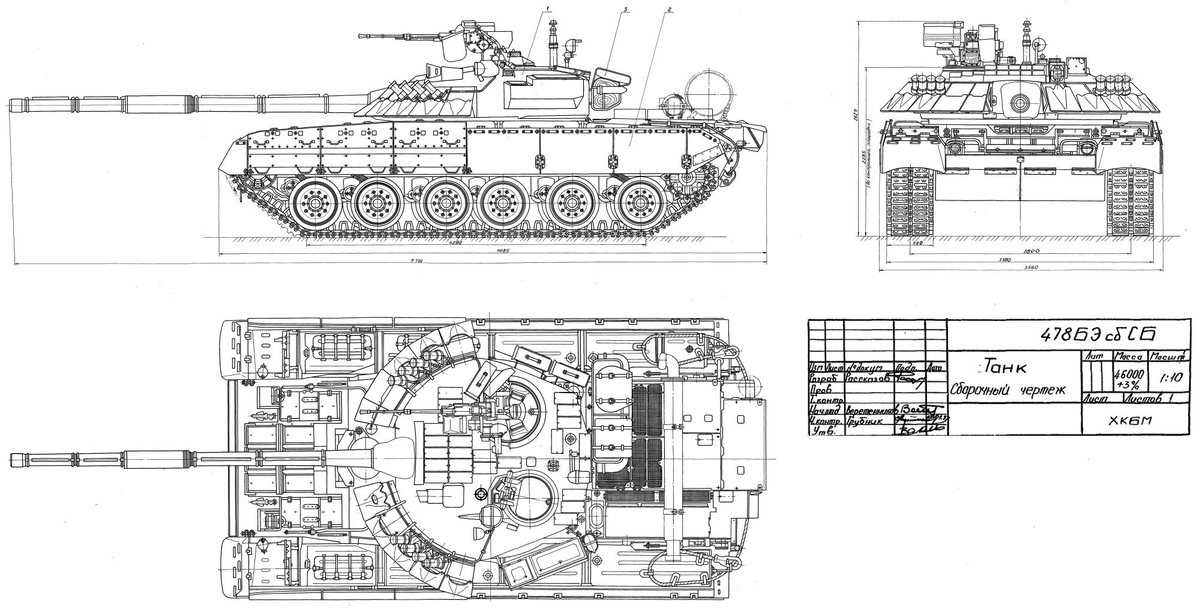

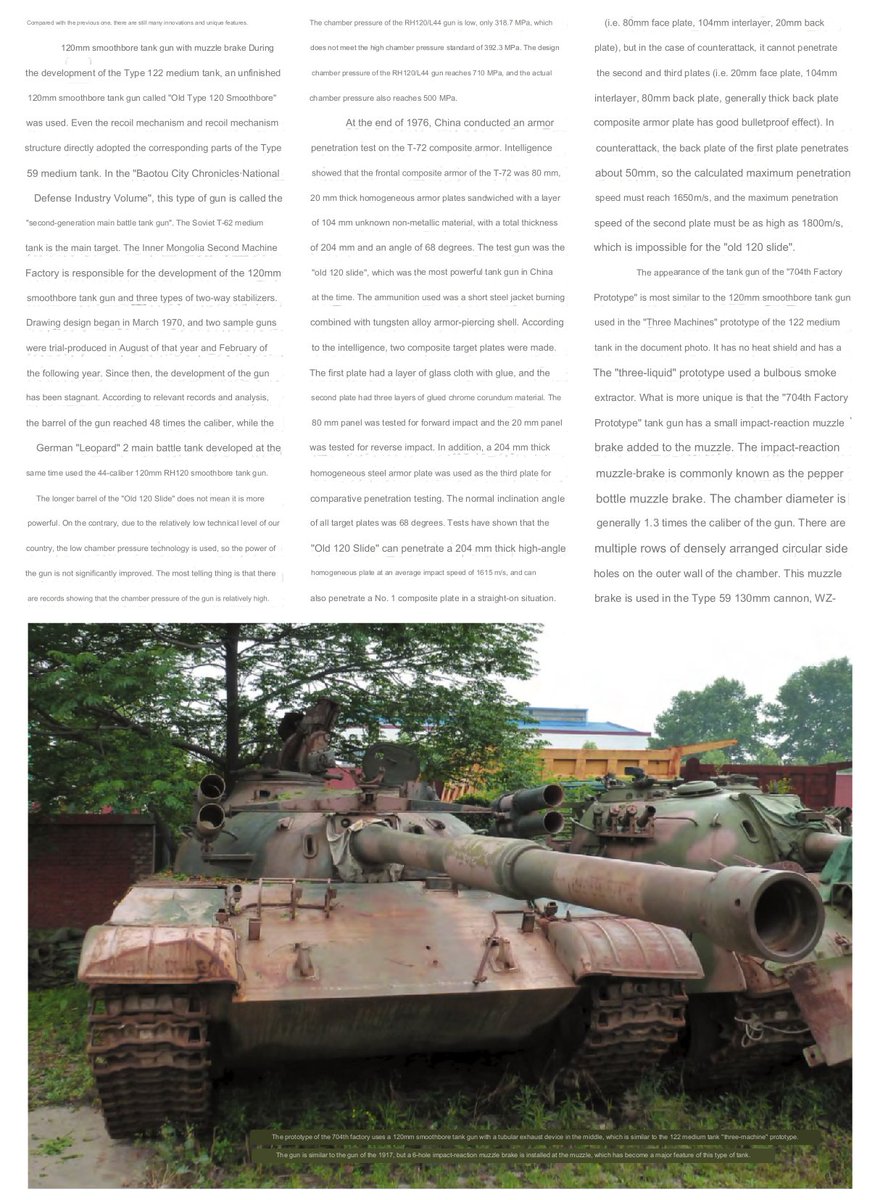

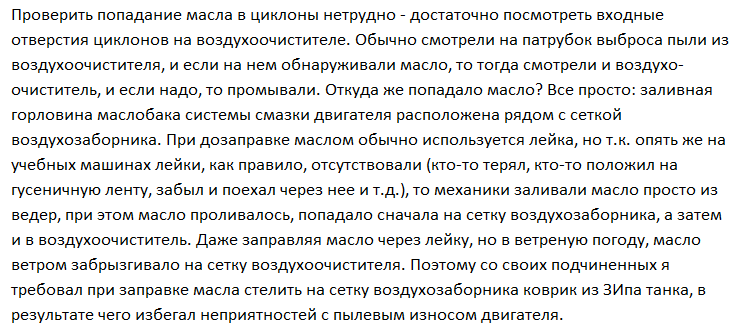

The first thing you'll notice are the flaps next to the intake. These are to deflect dust kicked up by the tracks next to the intake. They're unique to tanks with the 5TDF and 6TD engines due to the intake location, like the T-64, T-80UD, and T-84 (right).

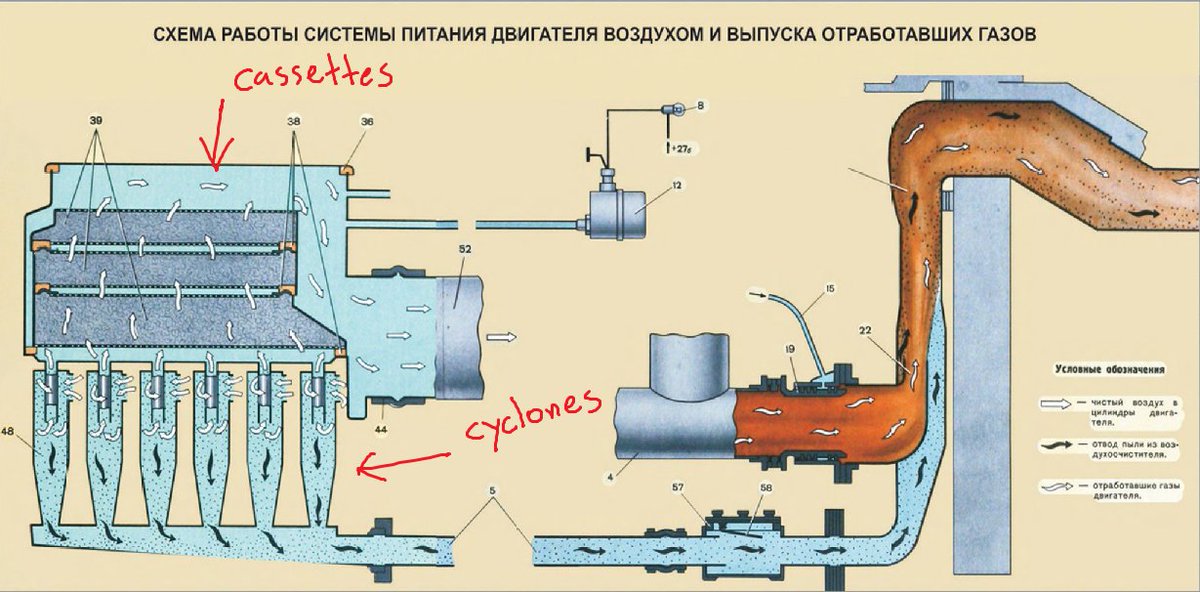

On most tanks, the air cleaning system would usually involve some sort of cassette filter, probably augmented by a cyclone air cleaners, like on the T-72. These cassettes will trap dust, which you'd have to open and clean every so often (500 km in the summer for the T-72).

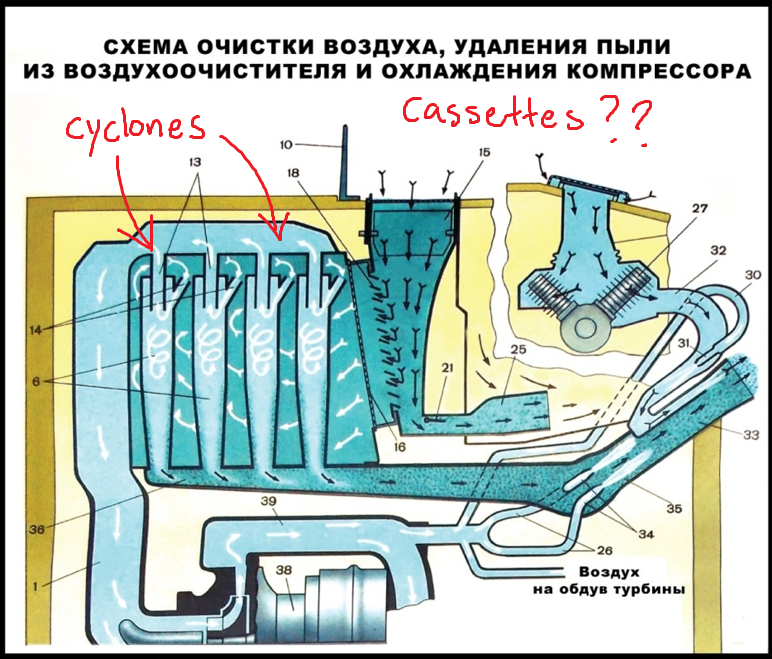

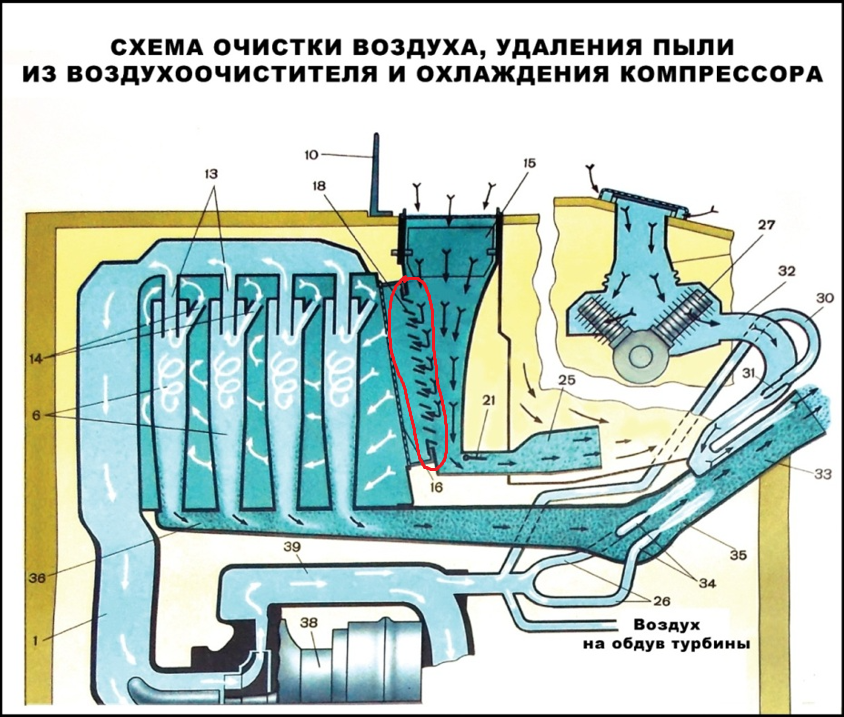

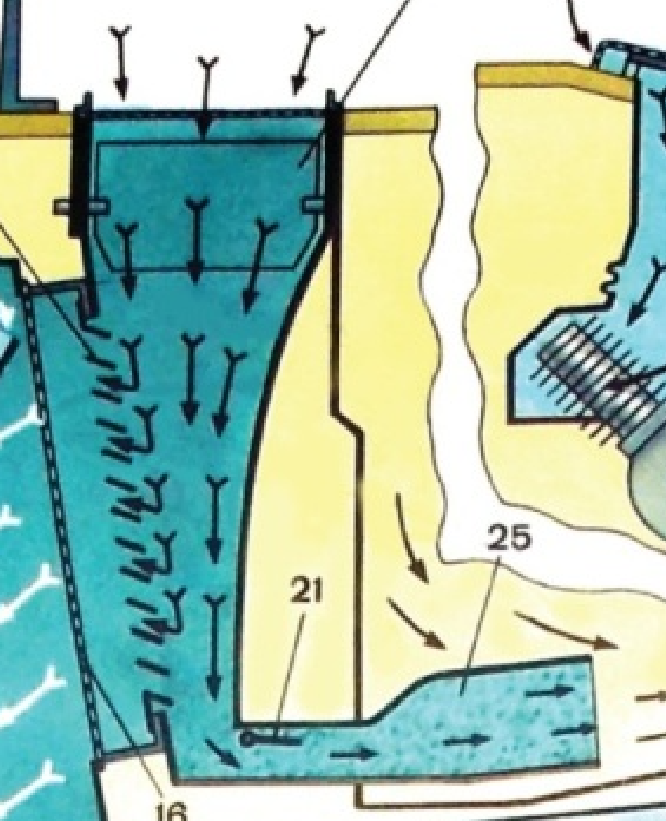

The inertial grating relies on the greater inertia of heavier dust particles or other contaminants to keep them falling towards the bottom of the intake hopper, when the air suddenly changes direction as it is sucked into the grating.

The dust collecting at the bottom of the hopper is then ejected along with the exhaust as a part of the ejection cooling system.

Meanwhile, the cyclone cleaners will further purify the air via cyclonic action. This dust also has to be ejected, but it goes a different way.

Meanwhile, the cyclone cleaners will further purify the air via cyclonic action. This dust also has to be ejected, but it goes a different way.

Bleed air from the 5TDF's supercharger is used to suck out the dust from the cyclones, and it's also used to draw in cooling air for the AK-150SV compressor (it compresses air for the compressed air engine starter bottles).

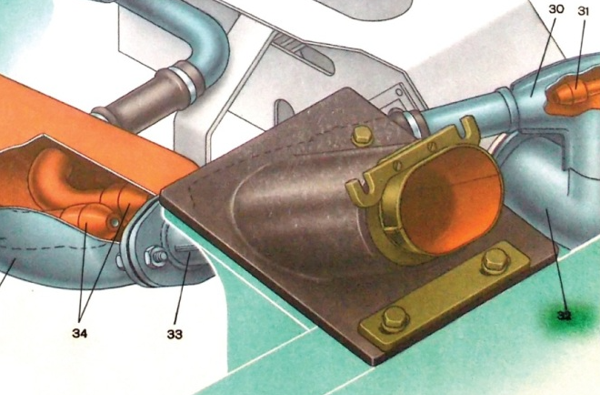

The dust from the cyclones is ejected through this port, separate from the exhaust/ejection cooling system.

So, why does the T-64 use this unique system? Well, again, #1 is that it saves space and thus weight. Anytime you look at the T-64 and wonder 'why does it have that?', the first thing you should think of is 'does it save space and/or weight?'.

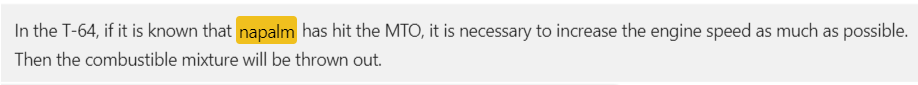

But there are also other reasons. #2 is that it helps protect the tank against napalm and other incendiary mixtures. The T-64's original specifications demanded the ability to survive napalm strikes.

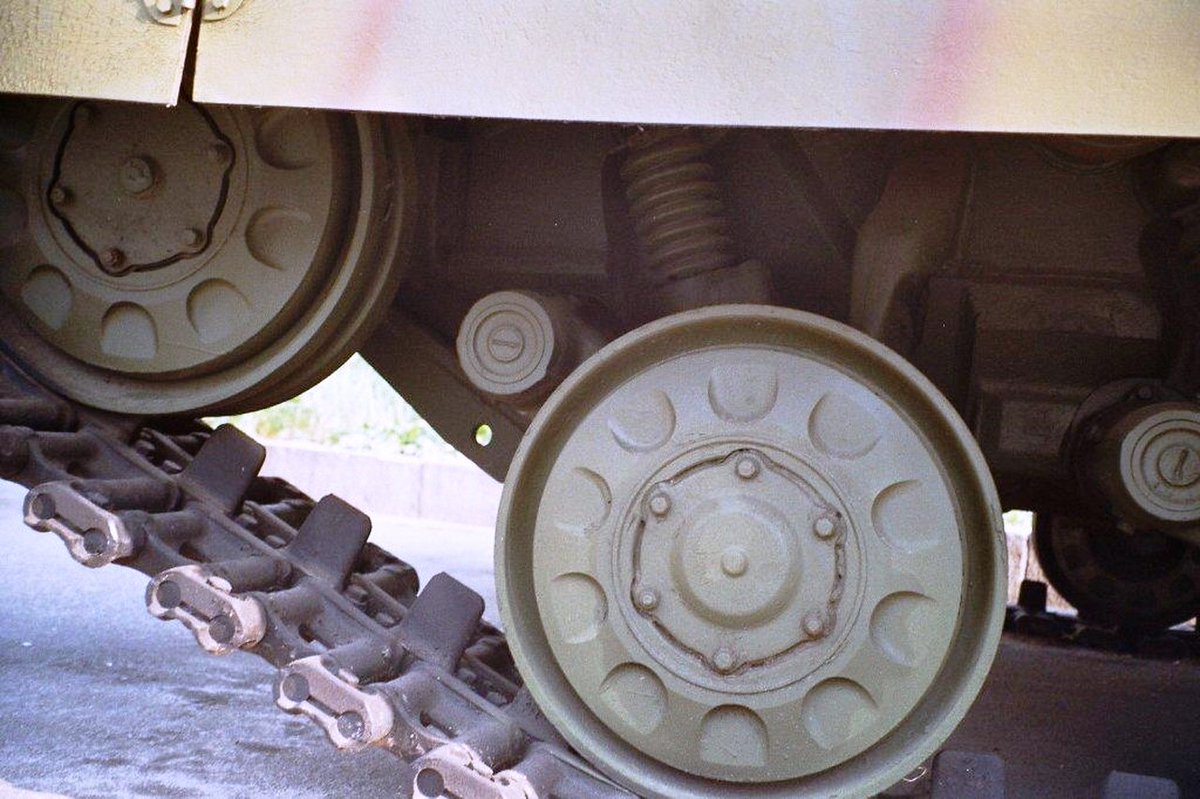

This is also one of the reasons why it uses those unique small steel road wheels with internal rubber shock absorbers, but that's a story for another time.

Returning to the air cleaning system, cassette filters would basically trap any incendiary mixtures that got into the intake and catch fire in the engine compartment, a sub-optimal situation.

According to Vasiliy Chobitok, who probably knows the T-64 better than anyone alive, if an incendiary mixture (be it napalm or a Molotov cocktail) gets onto the T-64's engine deck...

The inertial grating and increased suction from the engine's supercharger would ensure the heavier incendiary mixture particles would get thrown out, protecting the engine compartment. The same applied to the ejection cooling system.

#3, a cassette filter would have disrupted the inlet airflow of the two-stroke 5TDF, which would have greatly reduced its efficiency.

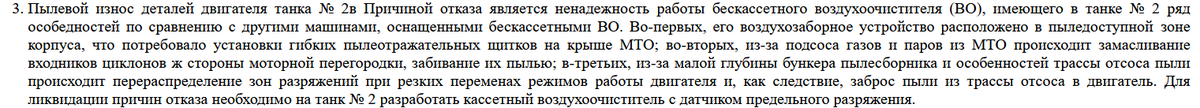

Now, the system isn't perfect. A report from 1986 in the Soviet 'Bulletin of AFV Technology' listed its flaws and recommended developing a cassette filter. But this would have been at the cost of the 3 reasons it was used in the first place.

btvt.info/5library/vot_1…

btvt.info/5library/vot_1…

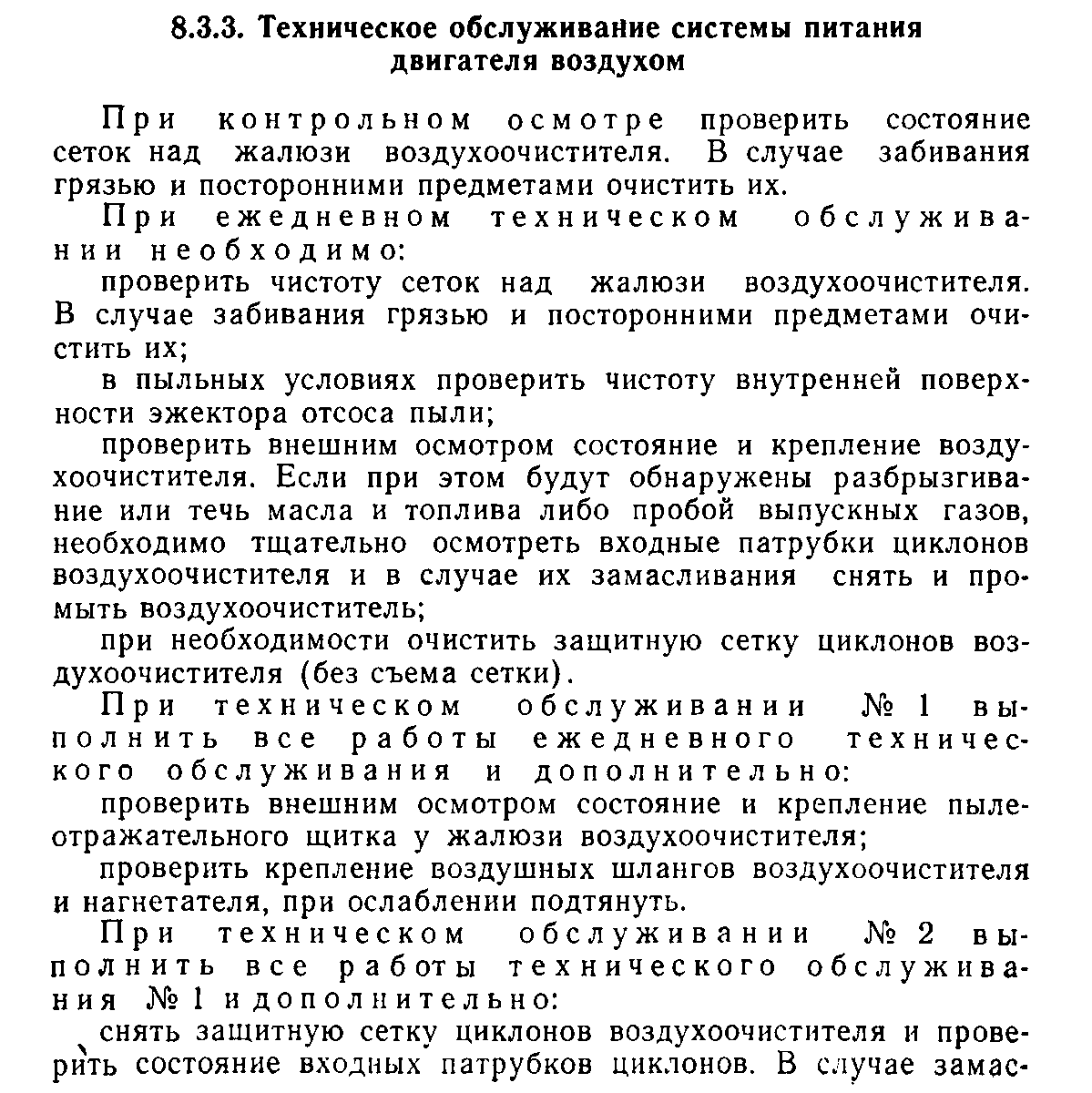

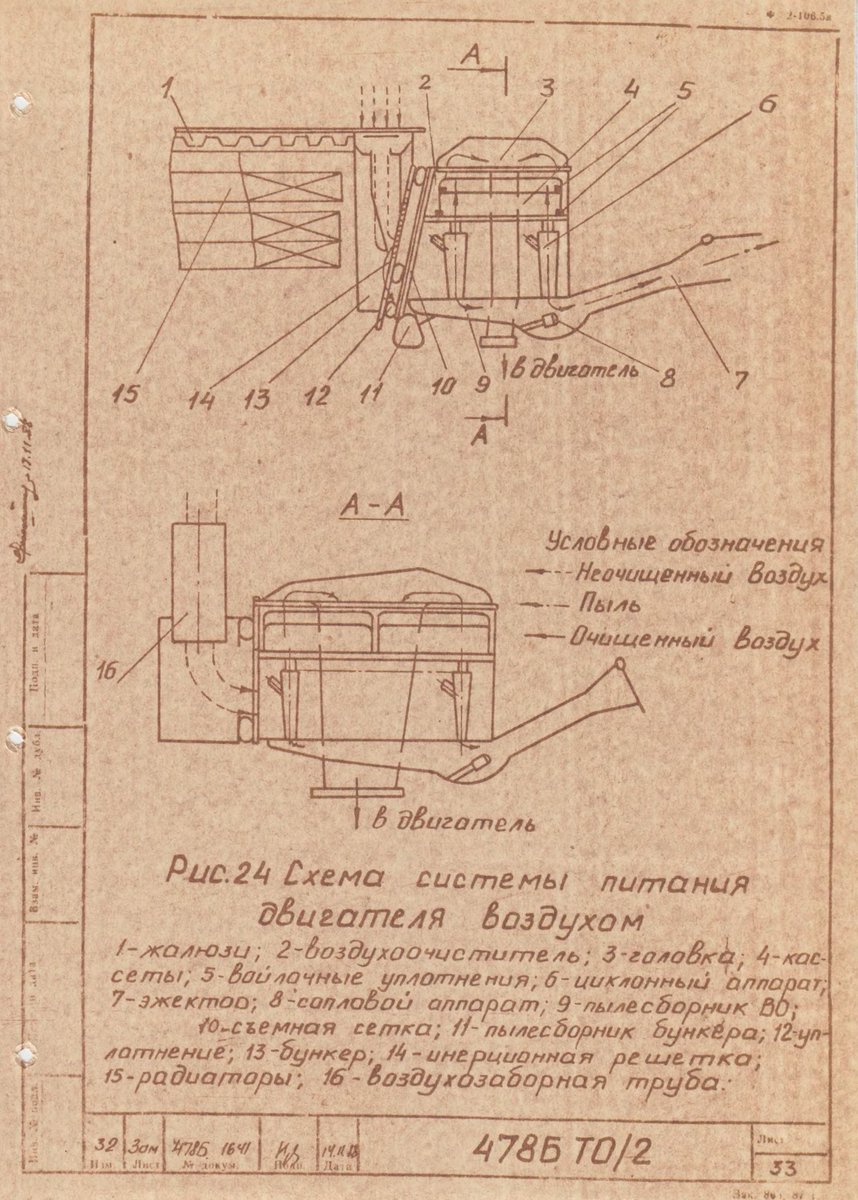

The most common problem was oil getting into the system. Suvorov notes that this was often due to neglect. The T-64's manual doesn't specify 'clean every X km', which predictably turns into 'no need to clean at all' for some people.

One has to check for oil contamination and clean it if necessary. Not spilling oil into the intake also helps.

The T-80UD (Object 478B), which is in many ways the spiritual descendant of the T-64, also uses a similar system, which the manual claims can purge 99.85% of contaminants. Presumably, so do the T-84 and BM Oplot.

• • •

Missing some Tweet in this thread? You can try to

force a refresh