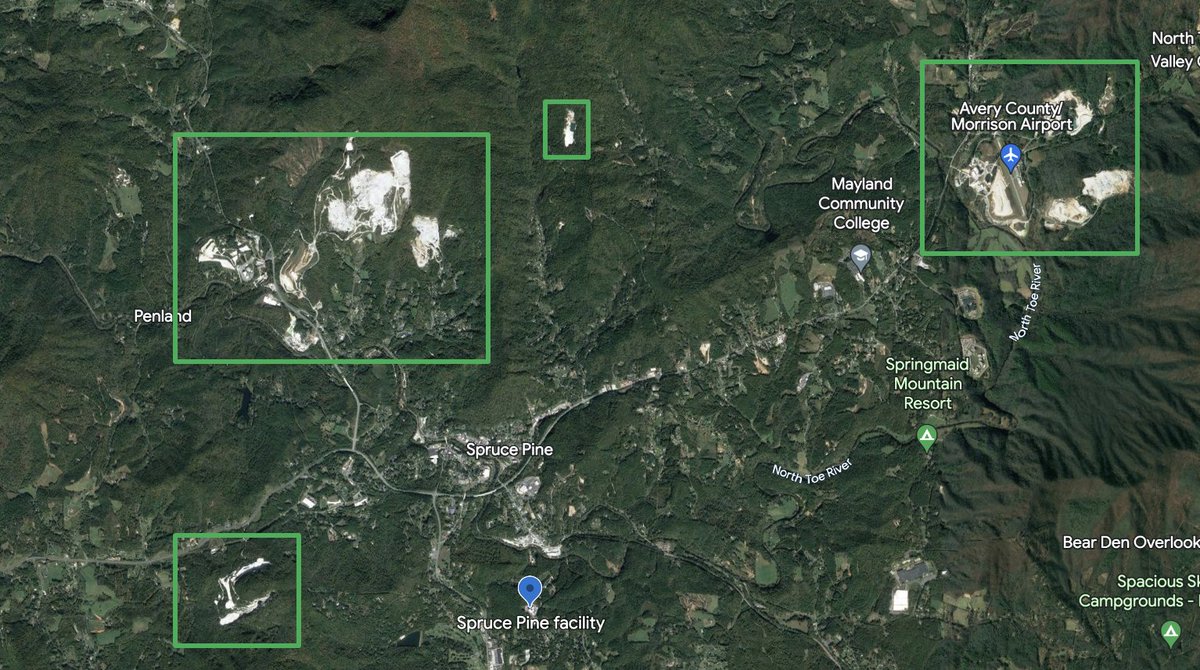

Finally found time yesterday evening to take an unofficial satellite's-eye-view tour of the quasi-legendary Spruce Pine ultra-high-purity quartz mine in North Carolina.

It'd be an understatement to say this mine is currently key to the semiconductor + solar PV industries. 🧵

It'd be an understatement to say this mine is currently key to the semiconductor + solar PV industries. 🧵

IIRC, there's no other ultra-high-purity quartz mine of this scale, creating quite the potential bottleneck. A fire at a Spruce Pine facility may have contributed to the 2008 spike in polysilicon prices that arguably set off the last decade's solar boom.

https://twitter.com/DustinMulvaney/status/1264965421809061888?s=20

Ultra-high-purity quartz is used for chip factory tools + crucibles used to contain molten silicon during manufacturing of ultrapure monocrystalline silicon ingots for chips + solar PV wafers via the Czochralski process. Pure quartz reduces impurities in the resulting product.

Sibelco's processing facility pictured in the screenshot shown in the first tweet of this thread is fairly easy to find by simply zooming in towards the town of Spruce Pine (35.90, -82.06).

The surrounding area shows many signs of mining activity, and it is unclear which of these sites are the source of this extremely valuable material.

This region has a long history of minerals production for other high-quality sand materials like mica and feldspar.

This region has a long history of minerals production for other high-quality sand materials like mica and feldspar.

This is a fascinating related book excerpt (h/t to @DustinMulvaney) from a few years back that describes the high secrecy (and aggressive legal strategies) that Sibelco subsidiary Unimin uses to protect its operations.

wired.com/story/book-exc…

wired.com/story/book-exc…

A neat tidbit from the article that I wasn’t aware of: after WWII it was actually public sector Tennessee Valley Authority scientists in nearby Asheville who adapted froth flotation to separate out high-purity quartz from mined rock, with TVA electricity.

tva.com/Newsroom/TVA-H…

tva.com/Newsroom/TVA-H…

Exact production from these mines is a guarded secret, but experts interviewed in this late 2021 SCMP article suggest that Spruce Pine mines then produced 180,000-200,000 tons/yr, 80-90% of the global supply. Local mine expansion efforts are ongoing.

scmp.com/news/china/art…

scmp.com/news/china/art…

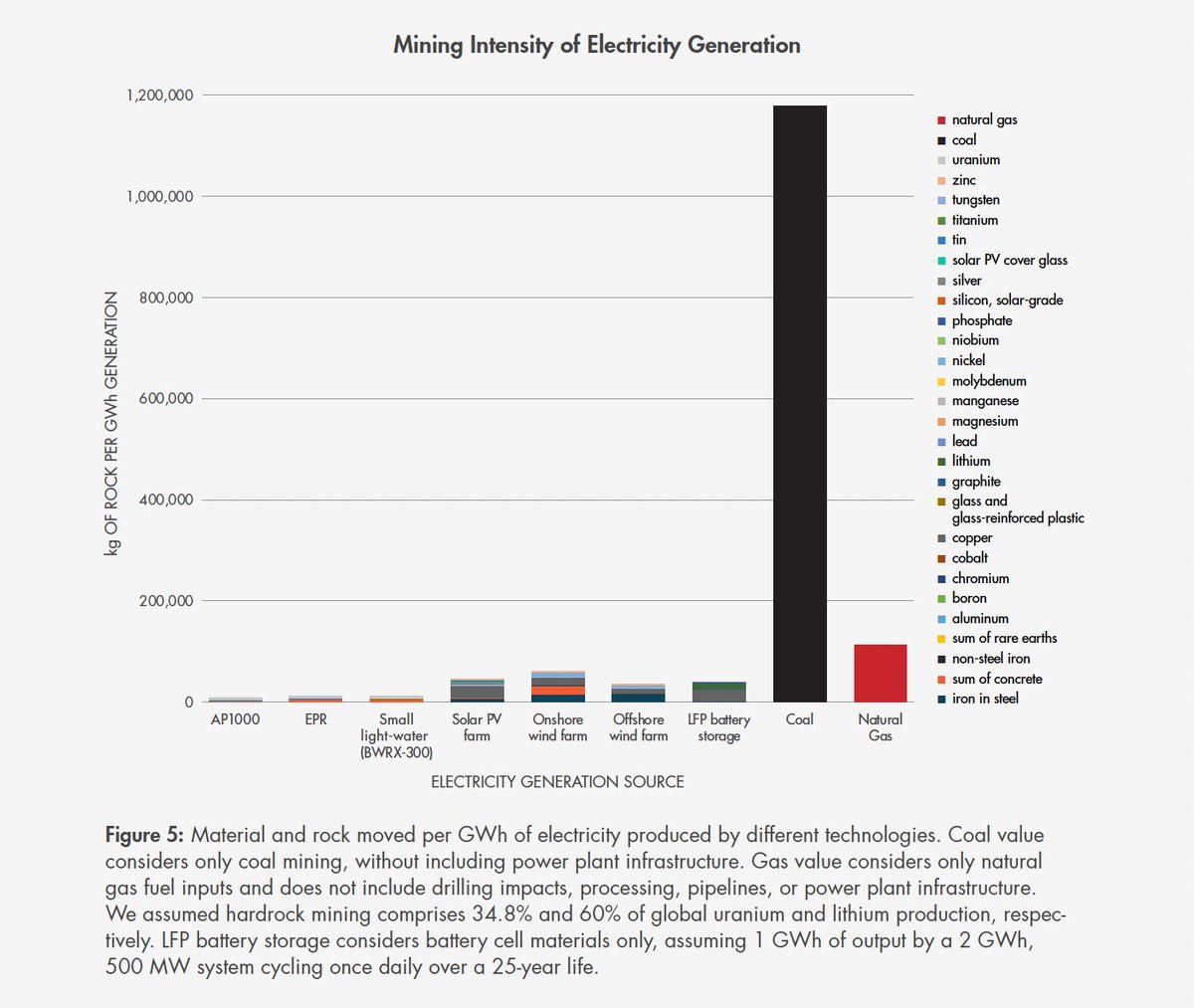

In nearly all cases, the absolute quantity of minerals on Earth is more than sufficient to meet raw material needs for the transition to low-carbon energy.

The much more relevant question is if the rate of mineral production may slow the transition.

The much more relevant question is if the rate of mineral production may slow the transition.

https://twitter.com/wang_seaver/status/1619043659927937024?s=20

It's worth noting that the ultra-high-purity quartz crucibles used to manufacture chips and solar PV wafers are expended during this process.

For now, Spruce Pine and other mines may suffice. But over the longer term, we could have to get creative.

For now, Spruce Pine and other mines may suffice. But over the longer term, we could have to get creative.

https://twitter.com/lifewinning/status/1265044506522648576?s=20

The transition to low-carbon energy tech can be protected from unexpected shocks by making sure not too many eggs depend on single/narrow supply chain links.

Upstream investments (and maintaining a porfolio of diverse low-CO2 technologies) could save much headache down the road.

Upstream investments (and maintaining a porfolio of diverse low-CO2 technologies) could save much headache down the road.

• • •

Missing some Tweet in this thread? You can try to

force a refresh