there's a joke on here that goes something like this:

"i asked him how much it would cost to make this today. i will never forget his answer. 'we can't, we don't know how to do it anymore.'"

I unironically think this is true of pants 🧵

"i asked him how much it would cost to make this today. i will never forget his answer. 'we can't, we don't know how to do it anymore.'"

I unironically think this is true of pants 🧵

even people who don't know much about bespoke tailoring can probably guess at least two of the major steps: 1) drafting and cutting the pattern, and 2) sewing the pieces together. but most people don't think about the ironing.

ironwork in tailoring is not the same as what you do at home. when you iron a shirt, your goal is to get out the wrinkles and press the garment flat. but in tailoring, ironwork is used to create shapes.

this means using water and a heavy iron to shrink and stretch the fabric, and create fullness where you need. a japanese tailor here demonstrates part of the process. the video is long (10 mins), but you can fast forward to see the transformation.

when making trousers, ironwork is important because human legs are not straight, like you'd see on a chair. instead, they bend and curve, forming something like a backwards S shape.

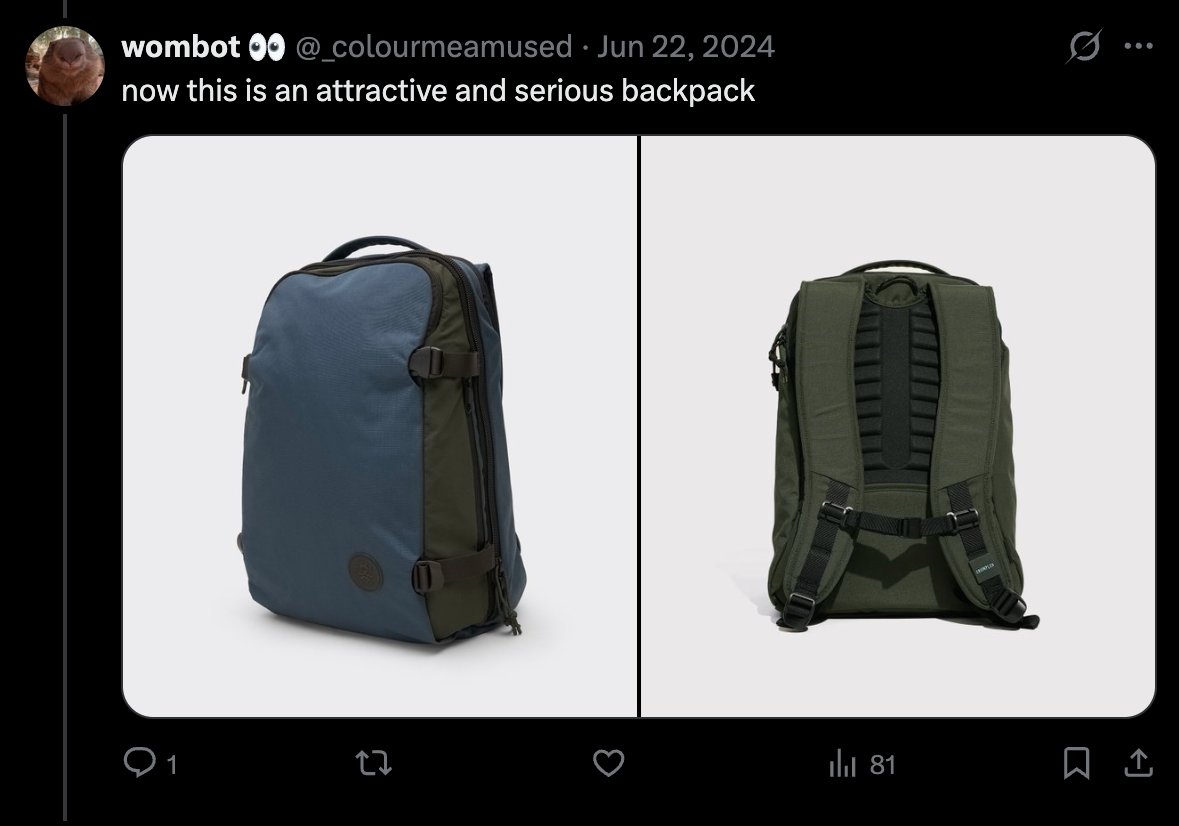

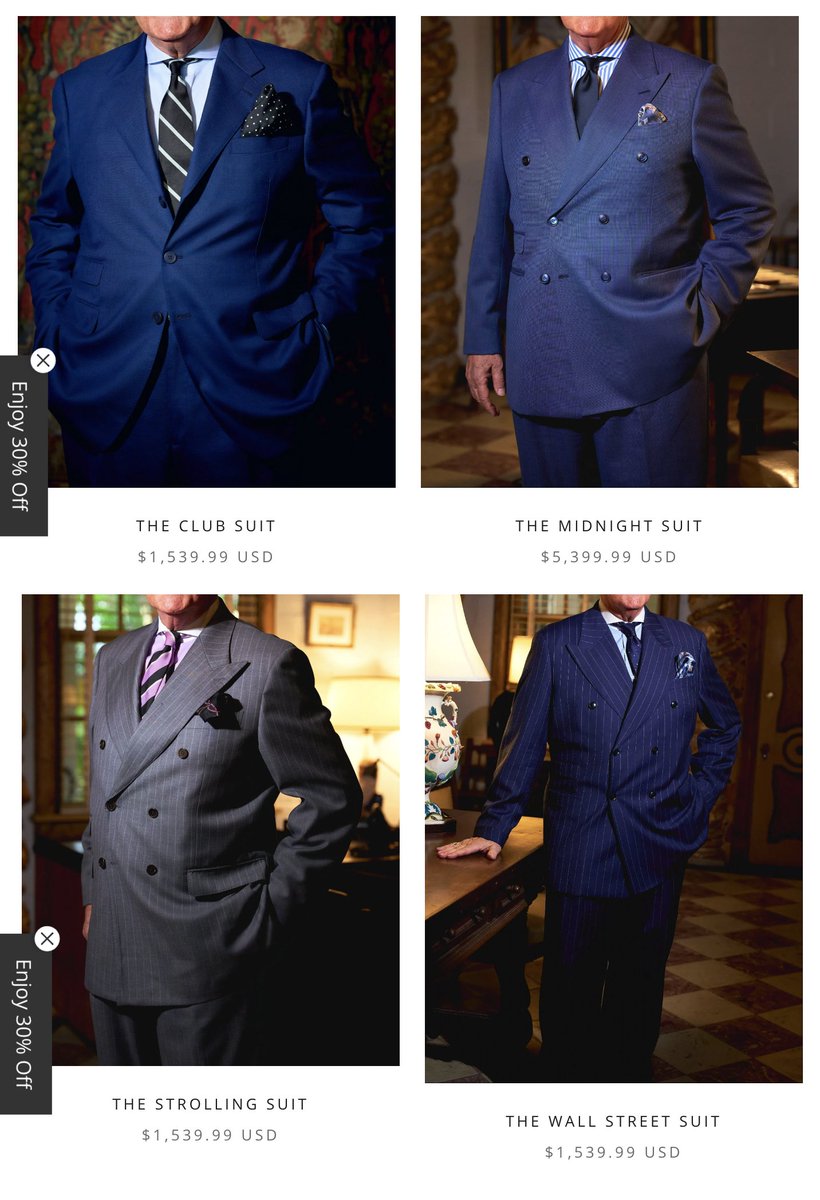

it's not difficult to accomodate those curves if you wear full trousers (pic 1), but what happens if you wear slim pants (pic 2)? well, all of a sudden, the trousers can catch at the front of your thigh and the back of your calves, causing messy wrinkles.

if you want to cut a proper pair of slim pants, you need to get the trousers to bend along the same path as your legs. this is where ironwork comes in. see how these flat pieces of fabric are shaped

(images from the blog tuttofattoamano)

(images from the blog tuttofattoamano)

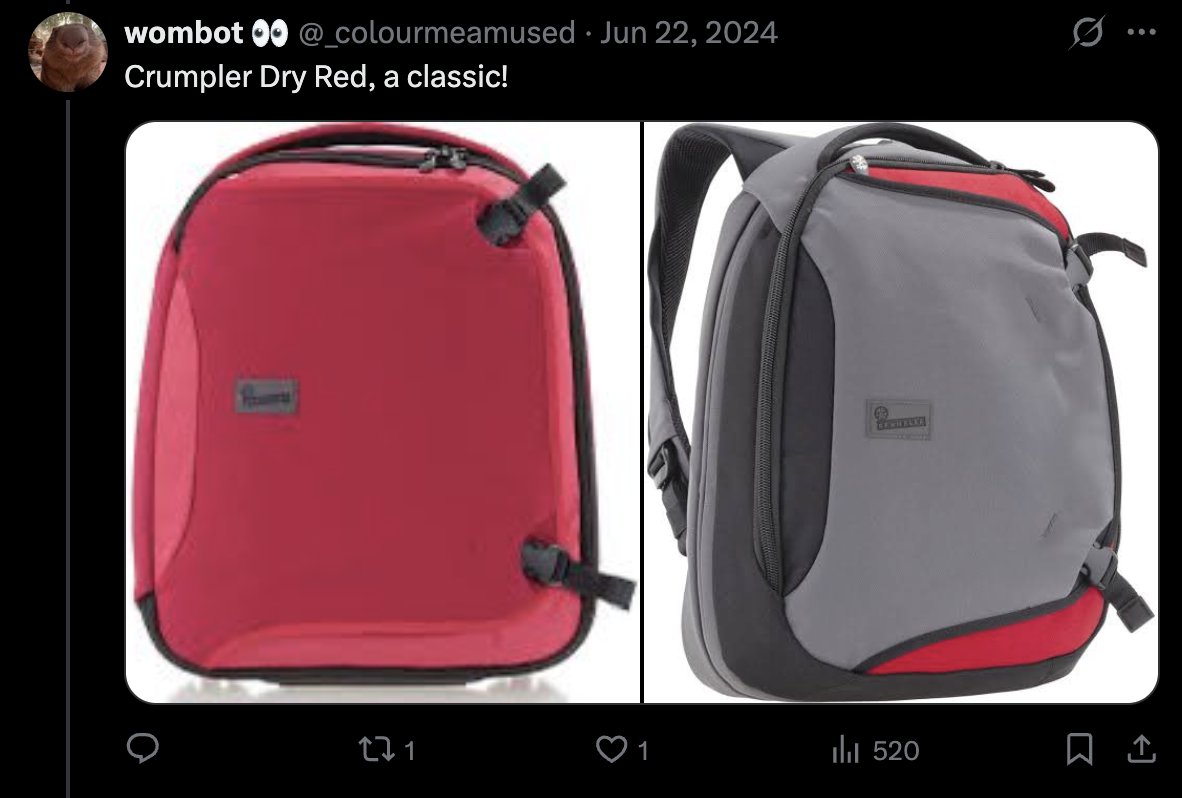

the results can be dramatic

in the first panel, these pants have been sewn straight with no manipulation, shrinking, or stretching

in the second & third panels, the pants were taken apart and each of the panels were manipulated with an iron. then they were sewn together again

in the first panel, these pants have been sewn straight with no manipulation, shrinking, or stretching

in the second & third panels, the pants were taken apart and each of the panels were manipulated with an iron. then they were sewn together again

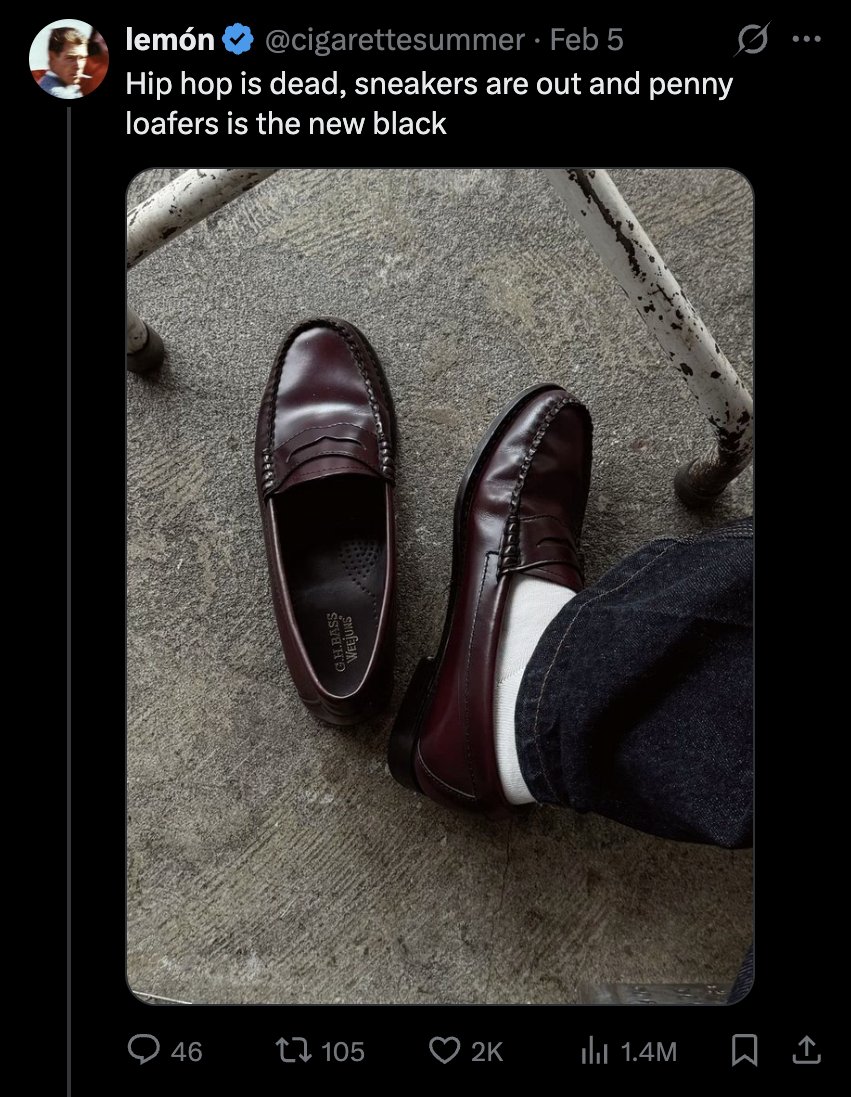

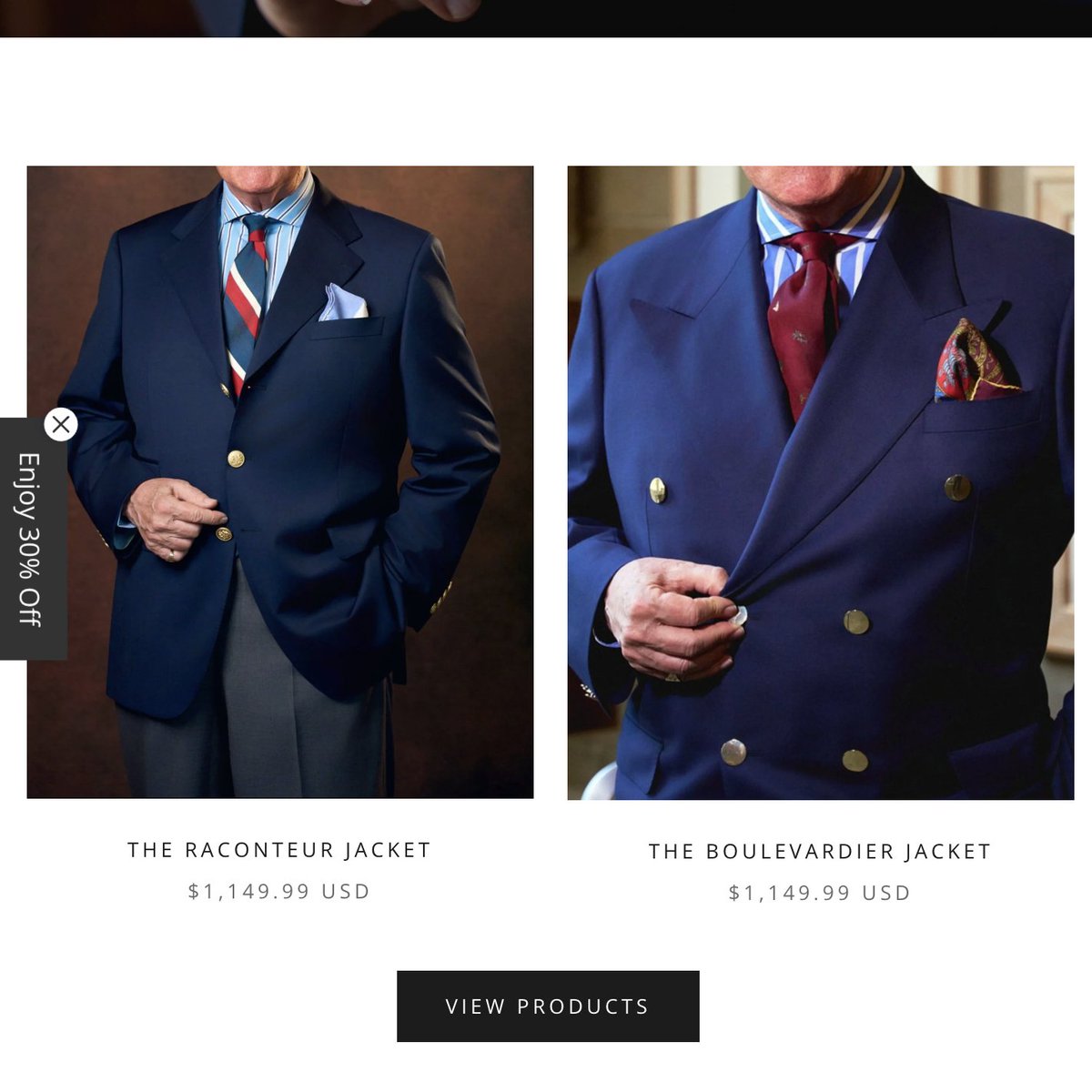

this is how a tailor is able to create trousers that seemingly defy physics. this is colin hammick, the late managing director of huntsman. check his left leg in the left photo. the trousers curve along the path of his leg, resulting in a smooth line.

the problem with ironwork is that it doesn't last. think of how a woman might put curls into her hair. the shape stays for a while, but the hair—especially if put in contact with heat or humidity—will eventually relax. then they have to use a curling iron again.

eventually, the shaping put into a tailored garment falls out, and you will have to bring it to a tailor (this sort of shaping is not something you can do). the problem: no one really offers this kind of service anymore. as the meme goes: "we don't know how"

most people don't wear suits with any regularity, so the industry around this has shrank. most towns don't have a good store for ready-to-wear suits, let alone custom suits, and let alone the support services necessary for regular maintenance (e.g., ironwork).

and so, most of us are stuck with subpar pants. this has been particularly bad in the last twenty years, as slim fit has dominated everything. the slimmer your pants, the more likely they will catch on your legs in awkward places. very obvious here when you lighten the photos.

• • •

Missing some Tweet in this thread? You can try to

force a refresh