HOW TO BUY BETTER SHOES WITHOUT SPENDING MORE MONEY

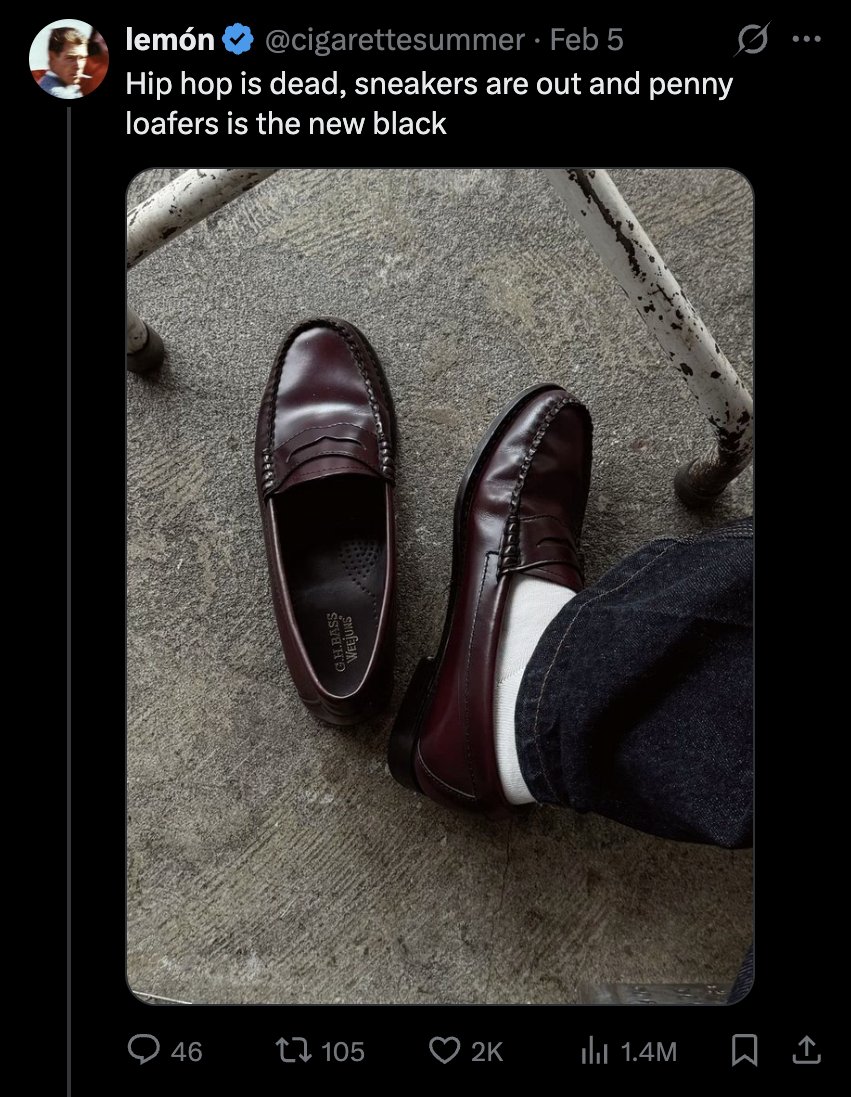

Let's talk about how you can buy better shoes without spending more money. This thread is aimed at people who spend less than $200 and people who buy designer shoes. 🧵

Let's talk about how you can buy better shoes without spending more money. This thread is aimed at people who spend less than $200 and people who buy designer shoes. 🧵

We should first talk about how shoes are made.

Shoes are made from leather, which comes from animals. And when leather arrives at a tannery, it can be marred with scars and imperfections (e.g., insect bites).

Shoes are made from leather, which comes from animals. And when leather arrives at a tannery, it can be marred with scars and imperfections (e.g., insect bites).

The best shoe producers use the best materials, but lower-end companies and designer brands (which are often making mediocre shoes) try to cut costs where they can. That means they are using lower-quality materials.

What does lower-quality material mean?

What does lower-quality material mean?

If a tannery is buying lower-quality hides with a lot of scars and imperfections, they will sand off the top layer to create a more uniform appearance and then coat the surface with a chemical. The result is something called "corrected grain leather."

"Corrected grain" is distinct from "full grain," which retains the full grain of the natural hide. When you see corrected grain leather shoes, they will often look a little shiny and plasticky, like this:

The problem with corrected grain is that it doesn't age very well. In the second photo, you can see how scuffs look like the marring you get on plastic packages. It doesn't dig into the leather because the leather is coated. This is bad.

In extreme cases, corrected grain leather can start to flake (pic 1). Compare this to full-grain leather (pic 2), which develops a rich patina. Corrected grain leather shoes can look OK on day one but only get worse from there. Full-grain leather gets better with age.

Cheaper producers don't just buy lower-quality hides—they try to save costs by maximizing their yield.

In a bespoke workshop, a shoemaker might only get a pair of shoes from each hide. But in a factory, a company will try to get many more in order to save costs.

In a bespoke workshop, a shoemaker might only get a pair of shoes from each hide. But in a factory, a company will try to get many more in order to save costs.

That means laying the patterns onto the hide in such a way that it almost looks like a Tetris game. You are trying to maximize yield by minimizing the amount of space between each of the pieces.

In a factory, this work is typically done by someone called a boot and shoe clicker, who uses a giant machine like this. They lay out metal pieces on the hide, and the machine presses down to cut. It almost looks like a baker with cookie-cutter pieces.

The problem is that not every part of the hide is the same. The best part is located near the animal's spine. This is where the grain is the tightest, which will result in minimal wrinkling. As you move toward the shoulders and belly, the leather is prone to heavy wrinkling.

Here is a pair of shoes that were made from leather cut from the center of the hide. They are technically corrected grain because the surface has been embossed with a grain pattern, but they don't have a chemical coating. Notice that wrinkles are very fine.

As you get closer to the belly and shoulder, the more likely the shoes will develop "loose grain wrinkling," where the top layer separates from the bottom. This is especially pronounced in some leathers, like Chromexcel. Not a big deal on work boots, but bad in finer footwear

OK, so now we know that lower-quality companies:

1. Buy lower-quality hides, which are then sanded down and given a chemical coating to make the surface look more uniform.

2. Use as much of the leather as possible, even the bad parts of the hide.

1. Buy lower-quality hides, which are then sanded down and given a chemical coating to make the surface look more uniform.

2. Use as much of the leather as possible, even the bad parts of the hide.

Such practices are not limited to lower-end lines. It's also common in designer shoes. These Raf derbies are $1,800, but made from corrected grain. I've seen the same from Dries Van Noten, Margiela, etc. Designer shoes are often more about design than quality construction.

So, if you're trying to get the best quality you can without spending more money, what can you do?

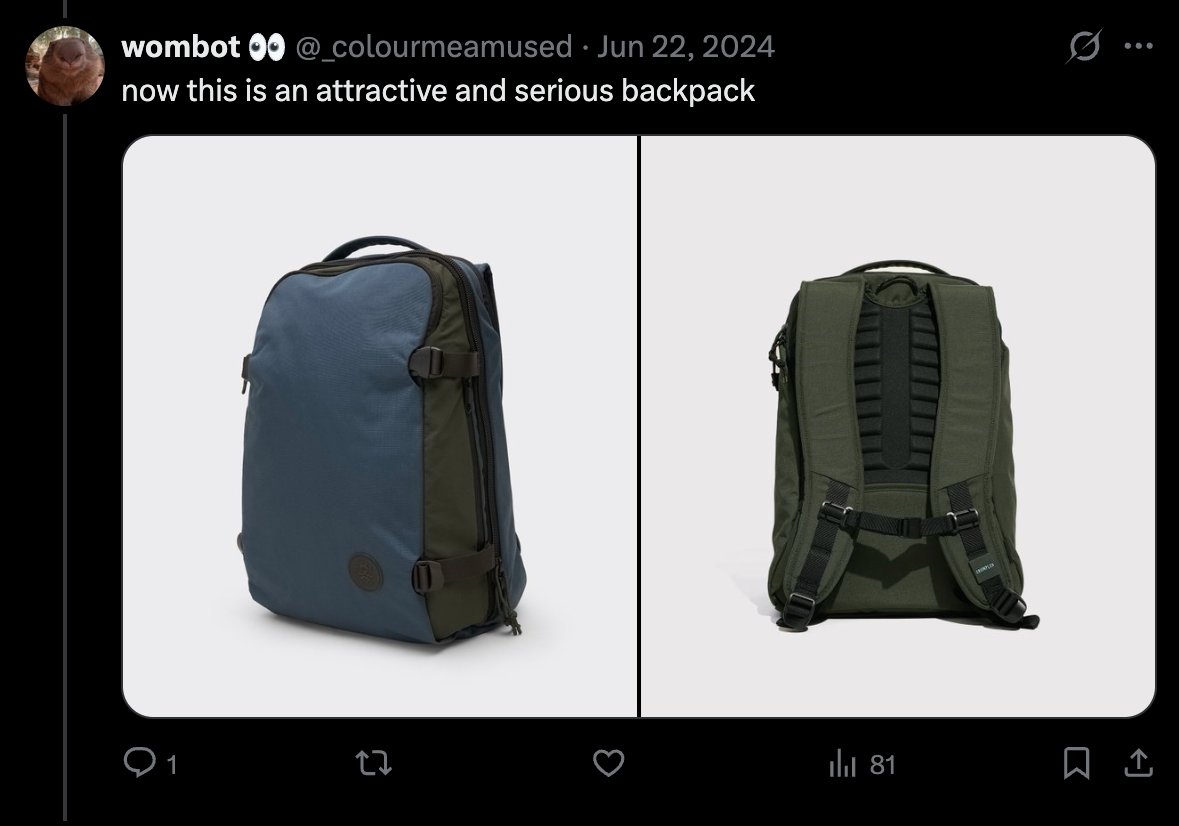

Buy suede.

There are two types of suede: reverse suede is full-grain leather but made with the flesh side out rather than the grain side out. This is the most durable suede.

Buy suede.

There are two types of suede: reverse suede is full-grain leather but made with the flesh side out rather than the grain side out. This is the most durable suede.

The other type is split suede, where a tannery will buy a lower-quality, blemished hide and then "split off" the top-grain, leaving the velvety, uniform suede portion below. Split-suede is not as durable as reverse suede but also not as expensive.

As a consumer, the best way to know whether something was made from reverse or split suede is to ask the sales rep. Price and brand reputation are generally the tells. If you're buying $700 Aldens, that's prob reverse suede. $150 Clarks? Split suede.

But here's the thing: even lower-quality suede will not have the problems discussed above. Since there's no chemical coating, it will not flake. For whatever reason, suede will also not develop loose grain wrinkling.

Suede does age in a particular way. The nap can get compressed; the material picks up oils. Over time, suede shoes can look kind of patchy, but this is part of the charm. IMO, bad suede looks better than bad calfskin over time.

So when shopping, consider suede over calfskin.

So when shopping, consider suede over calfskin.

• • •

Missing some Tweet in this thread? You can try to

force a refresh