Shortly before I posted my first detailed thread about my #SuperHeavy #B9 propellant simulation results, #SpaceX rolled B10 to the launch site, and some new weld marks were observed in the lower LOX tank. Like others, I also speculated this may indicate new slosh baffles. /1

It appears SpaceX determined the existing baffles within the LOX tank aren’t enough to mitigate slosh at staging. Using the weld marks, I devised a few designs and tested them with the same conditions as the previous thread to see how each design would change the liquid behavior. /2

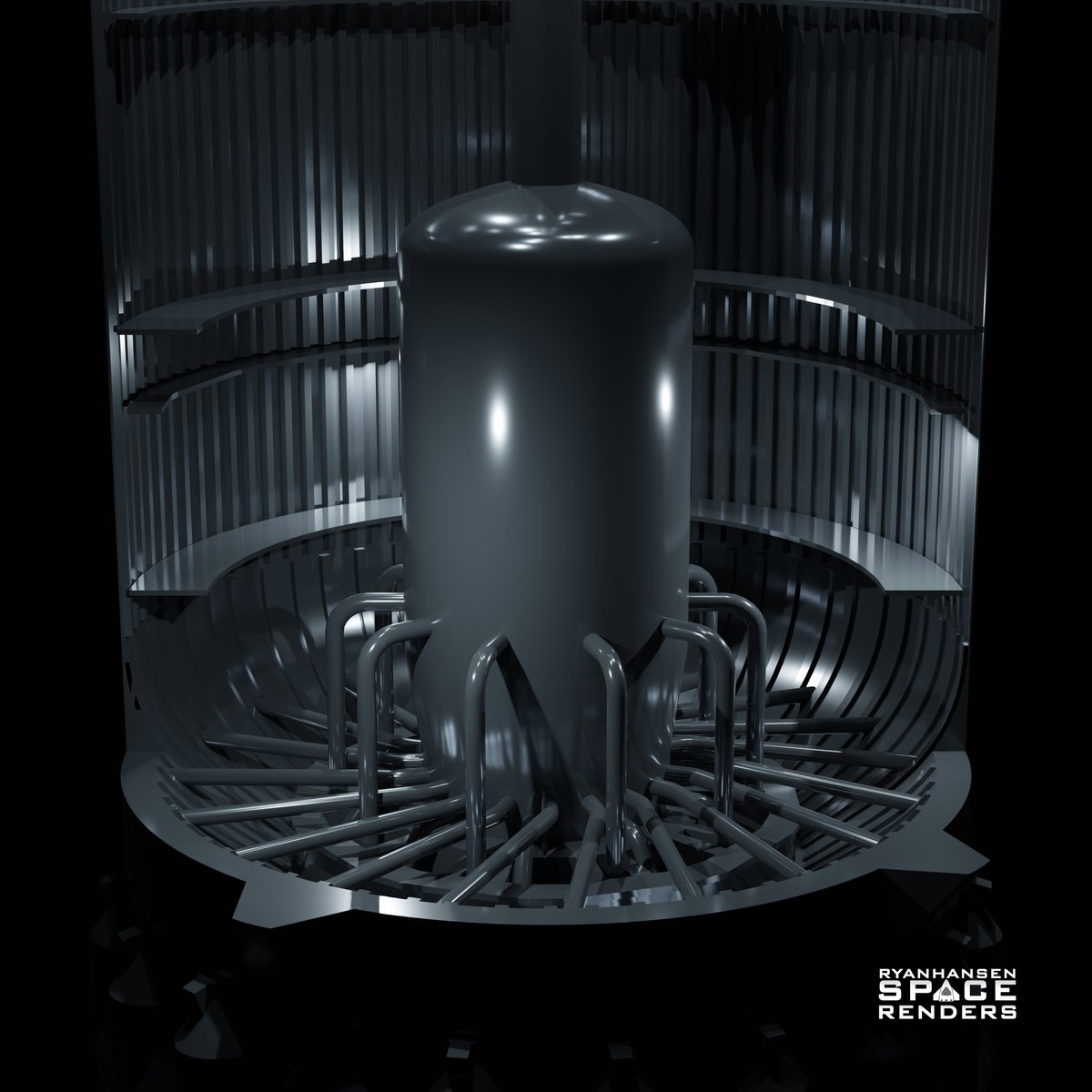

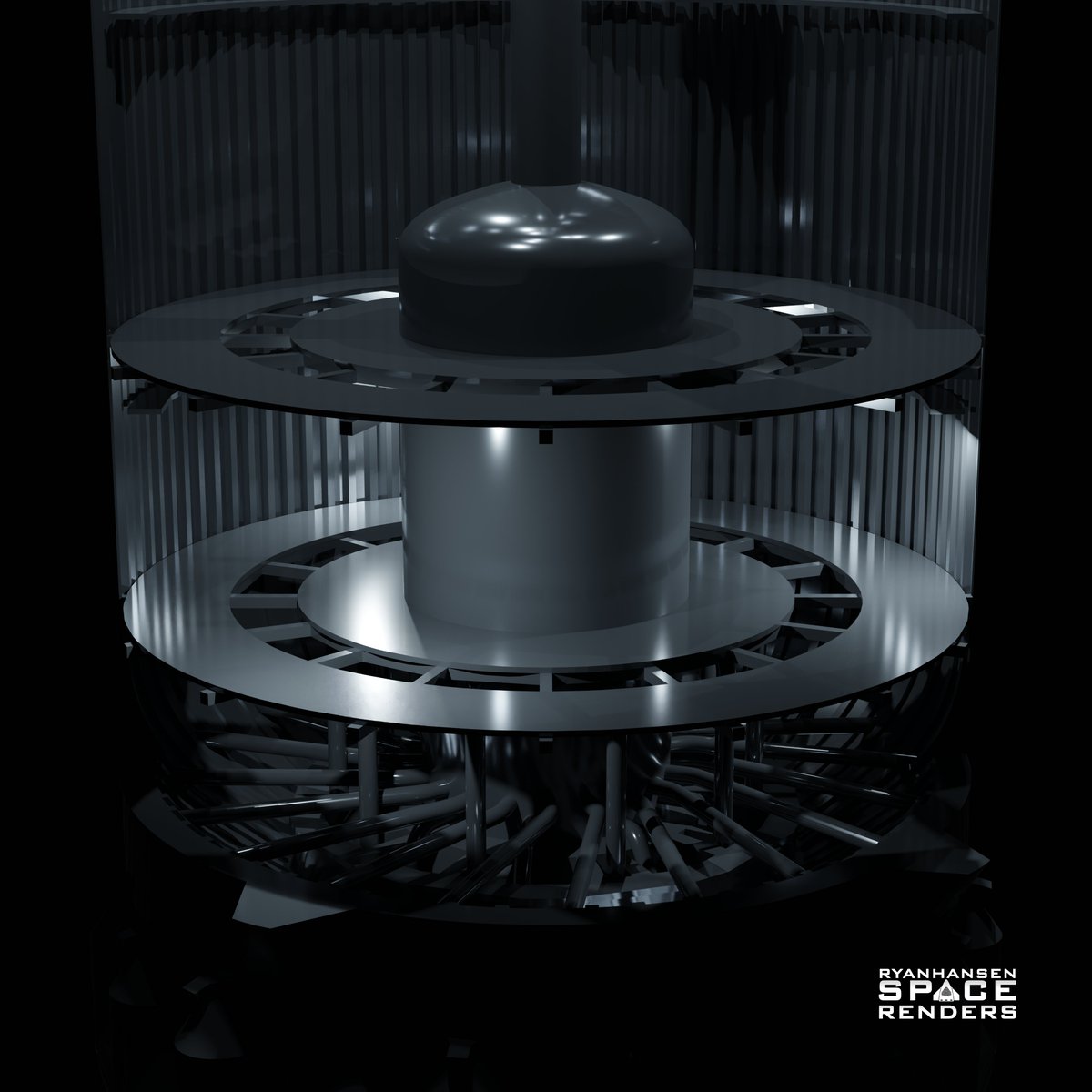

Before looking at any new simulations, let's look at the original side cutaway. I will be using this angle and animation throughout this thread to make comparisons. Also, keep in mind my disclaimer in the previous thread about these results and their theoretical accuracy. /3

The first design is two large ring baffles similar to the existing baffles but they extend further out from the tank walls. The thought is these baffles could catch more of the liquid as it is accelerated upwards and divert it inwards to choke additional upward liquid motion. /4

You can see from the results these baffles do very little to prevent the upward motion of the liquid. A pretty strong column of liquid in the middle is thrown upwards still. When that column of liquid crashes down it exerts unwanted forces and introduces trapped gas bubbles. /5

The second design is like the first but I’m including a larger ring baffle around the LOX landing tank. There is no proof this exists but it should provide some resistance to the liquid column that moves upwards in the center observed in the previous simulations. /6

Unfortunately, that doesn't help much. It seems that reducing the cross-sectional area while leaving a large opening just funnels the liquid into the gap producing a “finger over the hose” effect. This obviously will not help the situation of preventing slosh. /7

At this point, I considered taking the second design and increasing the baffle size again extending them further toward the middle of the tank. This comes with its challenges since the propellant mass will now exert more torque on the baffle the further it extends. /8

As the baffle size increases, supporting the baffle with only the exterior wall becomes more challenging or impossible. Cross-bracing would eventually be needed to span between the exterior walls and the landing tank so that larger surfaces could be properly supported. /9

While that design might work, I decided to skip ahead to a design that I felt had a better chance of showing improvement. Each simulation takes around a week to simulate and render so I didn't want to waste time on a design that might not yield any visual improvement. /10

The third design is intended to act like an industrial flow restrictor. These are essentially 9m wide plates with orifices that restrict fluid motion. The quantity and size of the orifices would be determined by the flow rate needed for all 33 engines on ascent. /11

As I hoped, this design has a noticeable improvement and keeps more liquid at the base of the tank where the engine inlets are. However, I’m not sure how realistic this design is as it would have mass penalties and possibly unwanted fluid dynamics in its depicted form. /12

In this comparison, you can see how much cleaner the liquid is without all the propellant crashing down causing gas bubbles to be trapped under the surface. This would ensure more laminar flow into the engine inlets as well. /13

From all my testing, the most effective solution involves a structure covering the complete cross-section of the tank while still letting enough propellant through passively to not restrict flow while all 33 Raptor engines are burning through the ascent portion of the flight. If SpaceX has implemented something like this inside B10 it likely looks a bit different. /14

SpaceX has implemented many changes to B10 and S28 to try and prevent the failures from the last flight. I believe the configuration for IFT-2 was possibly a worst-case scenario for data collection and IFT-3 will feature many changes based on that data. I’m guessing staging will be softer due to reconfiguring the engine parameters around hot staging. I don’t know what exactly, but they may play with the engine counts and ignition timing to reduce the deceleration on the booster. /15

With that in mind, I wanted to see what it would look like if SpaceX could reduce the deceleration on the booster during hot staging by half. I don’t know if this is realistic in practice, but changes in acceleration will have a large impact on the simulation. /16

As you can see, reducing the deceleration significantly changed the liquid behavior. This isn’t to say that they can reduce the declaration this much, but more to show a combination of changes can have a big impact on giving B10 the best chance at a powered landing in the gulf. /17

Another thing to note in the previous simulation is how the liquid sloshes to one side during the booster rotation. I'm wondering if this is the reason why the boostback burn is beginning 1 second earlier in the IFT-3 timeline. This could be intended to pull the liquid more evenly to the bottom of the tank before rotating the booster. /18

I think SpaceX learned a lot from IFT-2 data and the additional weld marks on B10 indicate some level of slosh they would like to mitigate. I’d like to think that they implemented something like my last design but we won’t know unless SpaceX tells us. /19

Taking into consideration the possible changes covered in this thread and assuming some other unforeseen issue doesn’t pop up on ascent, I think B10 has a good chance of making it through the boostback burn during IFT-3. Excitement guaranteed! /20

• • •

Missing some Tweet in this thread? You can try to

force a refresh