In the mid-1970s, the Type 74 was put into active service in Japan, but at the same time the Soviet Union was operating T-64 and T-72 tanks that had been put into service years earlier, Japan at the time did not have any vehicles of its stature at the time.

Given the need for a new MBT that was capable of dealing with the T-64 and T-72 After the formalization of the type 74, studies began for the creation of a new MBT, With the development name of "TK-X"

The TK-X was a development of the Technical Research Headquarters, The Type 74 was adopted in 1975, the development of the "TK-X" began in the same year, after two years of study partial prototyping of the engine, main gun, ammunition and FCS has begun.

The vehicle components were tested until 1982, When the TK-X got its first prototype, A very different vehicle from the second prototype that shows a lot of similarity with the final product.

The first prototype was tested until 1984, The second prototype was born in 1986 and as mentioned it was a vehicle very similar to the final version of the type 90, this vehicle was tested until 1988.

The type 90 had 6 prototypes which were tested until 1989, prototype number 6 served as the basis for the TTB that would give rise to the type 10.

In December 1989 at an equipment review meeting it was decided that the TK-X would be acquired by the JSDF, In August 1990 the TK-X was named type 90 "Kyū-maru" (from what I researched this means "90")

The Type 90 was delivered in small batches from 1990 to 2009, totaling 341 vehicles delivered to the JSDF, production ceased in 2009 due to the emergence of the type 10. All vehicles were manufactured by Mitsubishi Heavy Industries.

The Japanese government had a lot of help from national companies in the development of the TK-X, Mitsubishi Heavy Industries for example developed the vehicle's turret and hull.

Part 2

Protection

Protection

Like the type 10, the type 90 also has frontal armor based on blocks, one on the hull (UFP) and two on the turret cheeks. It appears to be composed of ceramic and composite materials, the blocks were made by Kyocera korp.

However, unlike the type 10, the turret cheek armor blocks cover part of the crew compartment as well, providing better coverage.

Although some sources claim that the Type 90 supports the JM33 at just over 200 meters, this idea seems erroneous. Therefore, to this day the real efficiency of this armor has never been truly revealed.

The side protection of the hull and turret was in the hands of Mitsubishi Heavy Industries as they developed It, The side of the turret have spaced armor made of high-hardness steel, the side of the hull has steel side skirt + main Hull side armor.

The turret's spaced armor add up to approximately 80mm RHA, the hull has 5mm of side skirt and 35mm of hull armor.

Turret: capable of withstanding 35mm APDS at 1km.

Hull: 14.5mm shots at an indeterminate distance

Both protect against shrapnel from 155mm rounds at 10 meters.

Turret: capable of withstanding 35mm APDS at 1km.

Hull: 14.5mm shots at an indeterminate distance

Both protect against shrapnel from 155mm rounds at 10 meters.

It was the first MBT in the world equipped with a LWS, the Type 90's LWS covers 180 degrees in front of the turret and alerts the crew in case the vehicle is being illuminated by a laser, And it can automatically launch smoke grenades to protect the vehicle.

Part 3

Main Cannon

Main Cannon

In 1982, were ready the national 120mm cannon that would be used in the TK-X together with the APFSDS ammunition also national, The cannon was made by Japan Steel Works and the ammunition was made by Daikin industries.

cannon and ammunition underwent comparative tests with the Rheinmetall 120mm L44 cannon and German ammunition, In the tests the Japanese 120mm cannon and Daikin ammunition achieved greater penetration capacity, but details of which type of ammunition was used are not given.

For several years, parties involved in the TK-X project defended different ideas, some defended the use of the national 120mm cannon in the TK-X and others defended the use of the L44 because it was cheaper to produce.

In the end the cheapest option was Chosen and the L44 would be produced under license at Japan Steel Works. The experience gained by the company ultimately helped in the development of the Type 10's main gun.

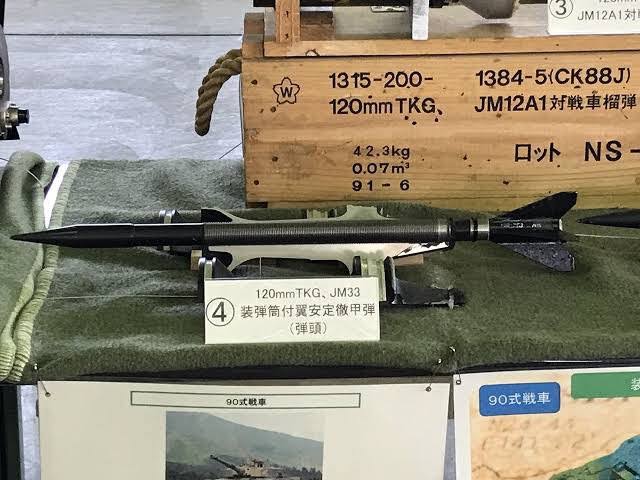

The domestic production license of the DM33 APFSDS and DM12A1 HEAT-MP accompanied the L44, in Japan the DM33 is called JM33 and the DM12 is called JM12. "DM" stands for "Deutsches Modell" And JM is "Japanisches Modell"

Part 4

The ammunition

The ammunition

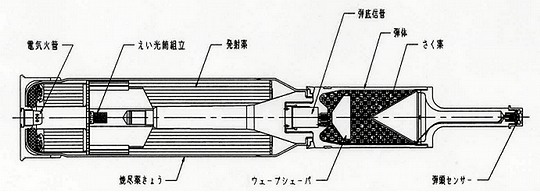

the JM33 when fired from the L44 is capable of penetrating up to 460mm RHA at 2km distance. Penetration increases to 500mm at 1km. The projectile's penetrator is made of tungsten and the initial velocity is 1.650 m/s. The projectile itself measures 643mm.

The JM12A1 is a HEAT MP projectile that reaches an initial velocity of 1140m/s when fired from the L44 cannon and can penetrate 600 to 700mm RHA at any range.

In addition to penetrating armor, the JM12 spreads shrapnel when it explodes, making it useful for use against infantry. It can also be used against structures, making it a multi-purpose projectile.

Part 5

Ammunition position, quantity and the autoloader.

Ammunition position, quantity and the autoloader.

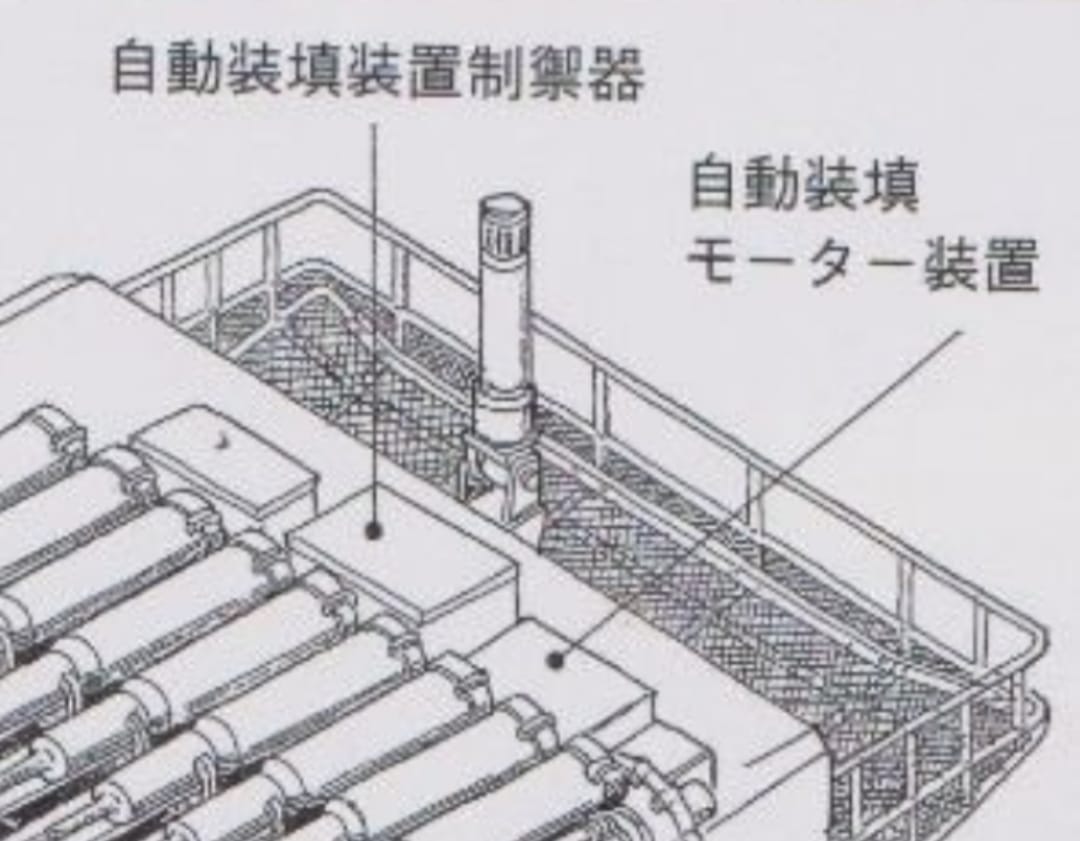

The Type 90 has a bustle autoloader which is made by Japan steel works, it is the first vehicle in Japan with this capability. The autoloader has two rows with 9 projectiles totaling 18, they are loaded in 3 seconds into the cannon.

Behind this autoloader are located the The system controller and mechanism motor. The autoloader is equipped with blast >doors< and blowout panels that protect the crew in case of a ammo cookoff.

Behind the gunner there are 4 ready rounds in case the autoloader is damaged or runs out of ammunition. Ammunition can be loaded into the autoloader through a door behind the gunner.

In the hull next to the driver and in front of the commander are located 18 rounds that are in a box fused to a fuel tank, there is no type of blowout panel or blast door in the hull ammunition or in the 4 behind the gunner. In total the type 90 carries 40 120mm rounds.

Part 6

FCS (simplified)

FCS (simplified)

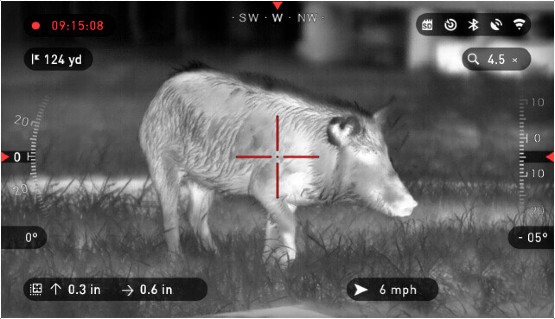

The gunner is equipped with a first generation thermal sight made by Fujitsu Ltd that operates in LWIR of 8-12 µm. (single system image)

The gunner's sight system is made by Nikon Instruments Inc and contains the thermal vision system, day vision sight with zoom of up to 12X, backup sight and laser rangefinger capable of measuring distances from 500 to 5000 meters.

Both the commander and gunner have access to the gunner's thermal sight system via CRT (cathode ray tube) monitors at their stations. You know this type of monitor as a "tube monitor".

The gunner uses autotracking to hit targets accurately, the fire control system relies on the target's thermal signature to track it even behind structures. (In case of a quick pass behind structures while moving).

The commander has access to a fully stabilized independent sight with daytime vision only, which can be accessed through a binocular system and as mentioned before a CRT monitor displays an gunner's thermal system extension. The commander can take over the turret if he locates.

Part 7

Engine and hybrid suspension.

Engine and hybrid suspension.

The Type 90's hybrid suspension consists of 4 wheels with hydropneumatic suspension and two in the middle with torsion bars, very different from the Type 10 with fully hydropneumatic suspension.

With this suspension the vehicle can increase its size by 170mm and decrease in 255mm, Being able to reach several different positions that favor the vehicle in different combat situations. The FCS can calculate shots in any position the vehicle is in.

The vehicle is equipped with a 10ZG32WT engine 1,500HP made by Mitsubishi heavy industries and is capable of taking the vehicle to a maximum speed of 70km/h. The vehicle's range is 340km driving on asphalt at 45km/h the fuel capacity is 1272L.

We have reached the end of the thread, if you want to help encourage future work, consider supporting the page below

paypal: spion083@gmail.com

読んでいただきありがとうございます!! buymeacoffee.com/2S7pion

paypal: spion083@gmail.com

読んでいただきありがとうございます!! buymeacoffee.com/2S7pion

@aGzP8TJIvR70KIO

@threadreaderapp please unroll

• • •

Missing some Tweet in this thread? You can try to

force a refresh