At the moment, we don't know how much prices will go up as a result of tariffs. There are a lot of conditionals. But if the goal is raise the cost of imports so that people are encouraged to buy American-made goods, I want to tell you a story. 🧵

https://twitter.com/JamesRLandrum/status/1856871949135126904

Some of you may remember American Apparel. They were huge with young, urban consumers (often called hipsters) in the early 2000s. The company was popular for their US-made basics, such as t-shirts and sweats, which they marketed through sexualized advertisements.

The company's fonder, Dov Charney, turned out to be a real creep. But during those early 2000s years, when US manufacturing was still a selling point in fashion, he promised a new way forward. You could make clothes in the US if you just made cool clothes, he argued.

The business model worked until it didn't. In September 2015, the company filed for Chapter 11 bankruptcy because they had a ~$15M debt repayment due the following month (about $20M in today's dollars). They didn't have enough money to even sustain operations for the next year

In the wake, new investors came in. About two years later, Canadian sportswear manufacturer Gildan purchased American Apparel for $88M.

Many of you may know Gildan bc you prob have their t-shirts and socks in your closet. They're a huge operation with overseas facilities.

Many of you may know Gildan bc you prob have their t-shirts and socks in your closet. They're a huge operation with overseas facilities.

When Gildan came in, they faced a problem: were they going to continue with American Apparel's original premise of making clothes in the US? Or would they use their network of manufacturing facilities in places such as Honduras and the Caribbean?

Gildan CEO Glenn Chamandy wanted to keep the same brand and presentation alive, just without the expensive American manufacturing costs. But he also didn't want to lose diehard American Apparel fans. So he gave consumers a choice.

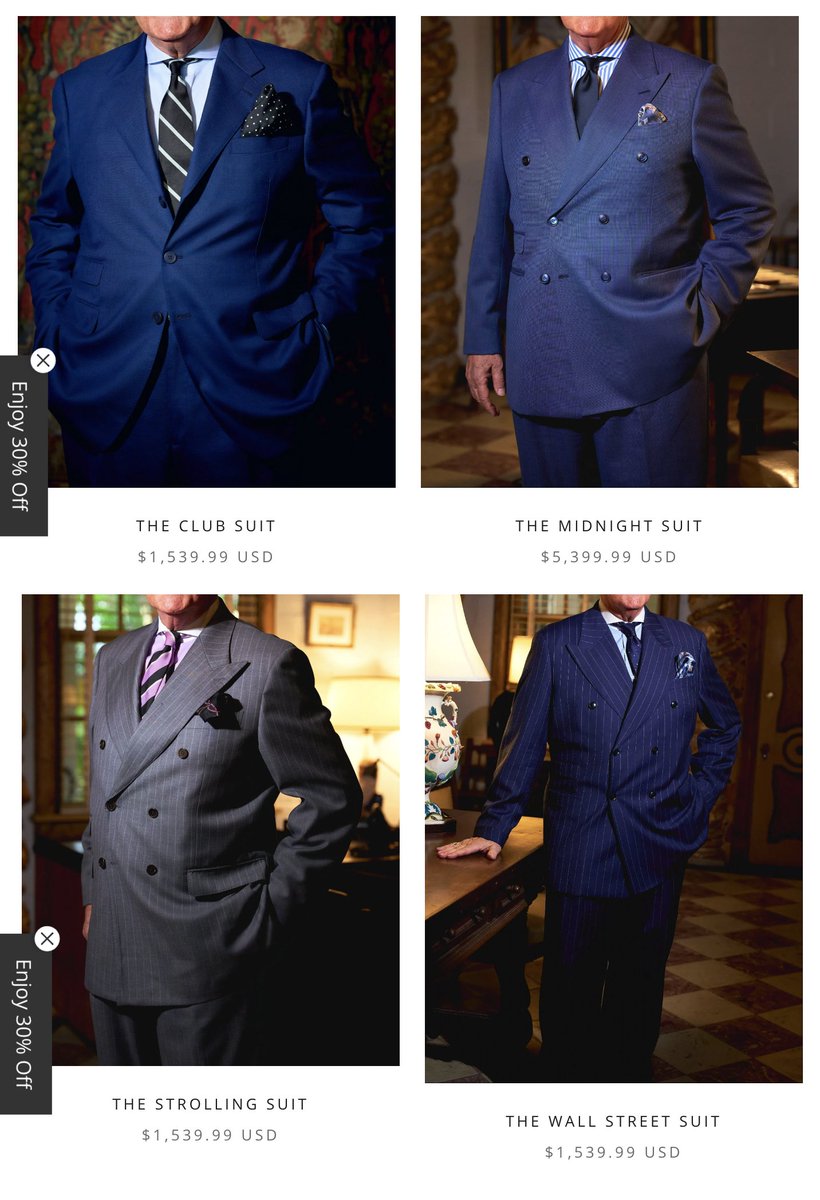

In August of 2017, shortly after the acquisition, American Apparel rolled out a new presentation on their website. For their best-selling designs, there was a twin companion: one made in the US; another made abroad.

The company promised that the products were identical in every way—fit, quality, and ethical production (no sweatshop labor). The difference is that the globally sourced version would cost about 20% less.

Basic tees were $22 vs. $18. Sweatshirts $24 vs. $20. Hoodies $48 vs $38

Basic tees were $22 vs. $18. Sweatshirts $24 vs. $20. Hoodies $48 vs $38

Gildan promised to follow the market. If consumers wanted US-made goods and were willing to pay an extra $4 for a t-shirt, they would keep selling it.

If you go to American Apparel's website today, you will know how the story turned out.

If you go to American Apparel's website today, you will know how the story turned out.

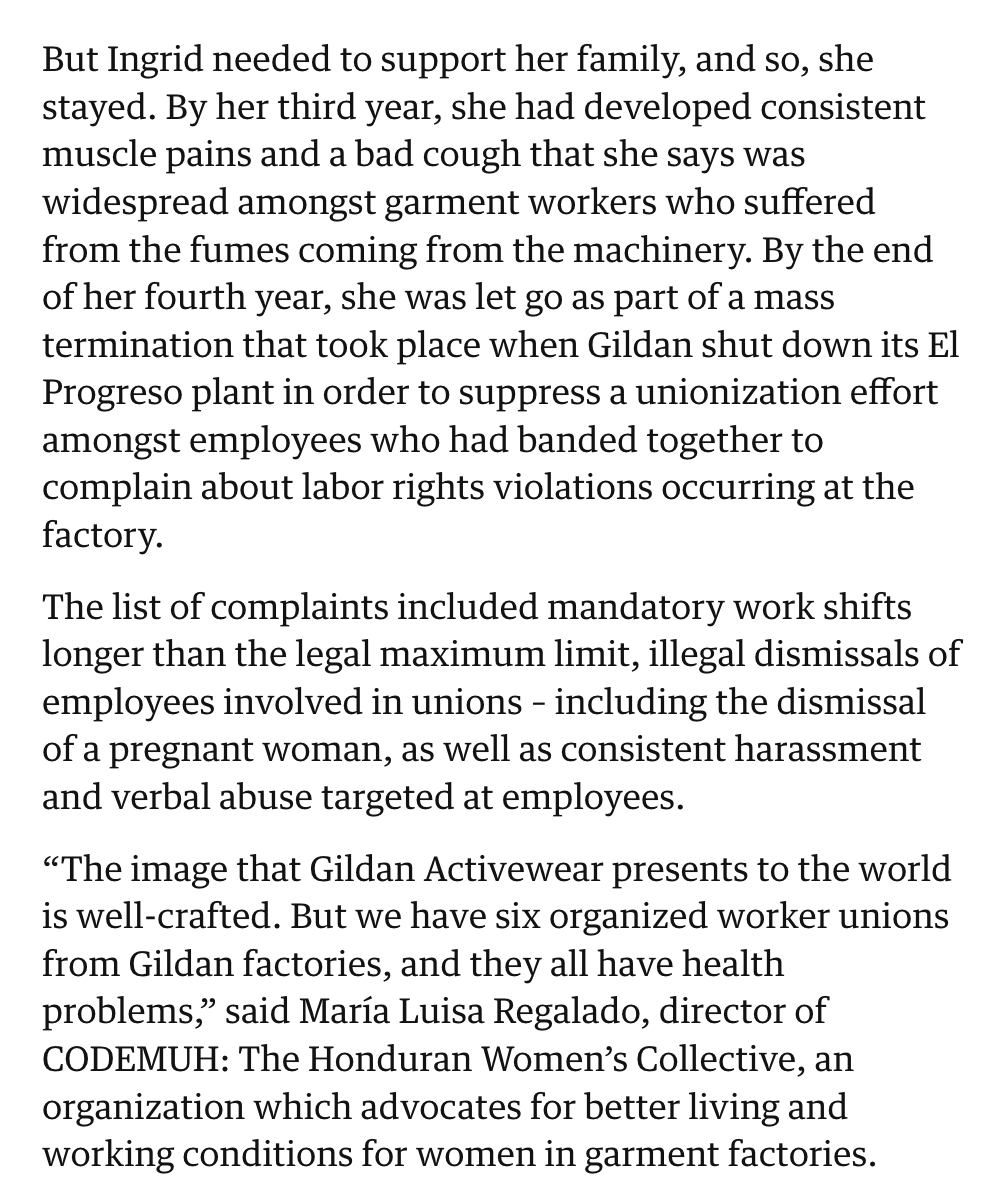

During that first year of operation, the company had a page on their website called “Sweatshop Free Stories," which featured their Latin American workers sharing stories about their hardscrabble life and how a Gildan job saved them. Turns out, that wasn't totally true, either.

Workers commonly suffered health problems as a result of the long hours, physical labor, and poor work environments. When workers at one factory tried to unionize, the company shut down the facility. (Such labor suppression tactics are also common in the US). From The Guardian:

IMO, consumers often just want their cake and eat it too. They want cheap clothes without the yucky suspicion that someone was exploited on the other end. Many make up totally fantastical ideas about automated manufacturing to justify cheap t-shirt, but reality is often yucky.

Either way, the 2017 experiment proved one thing: even with the promise of sweatshop fee production and identical garment quality, US consumers were not willing to pay an extra $4 for a US-made garment. You would have to raise tariffs so high that the US item is *cheaper.*

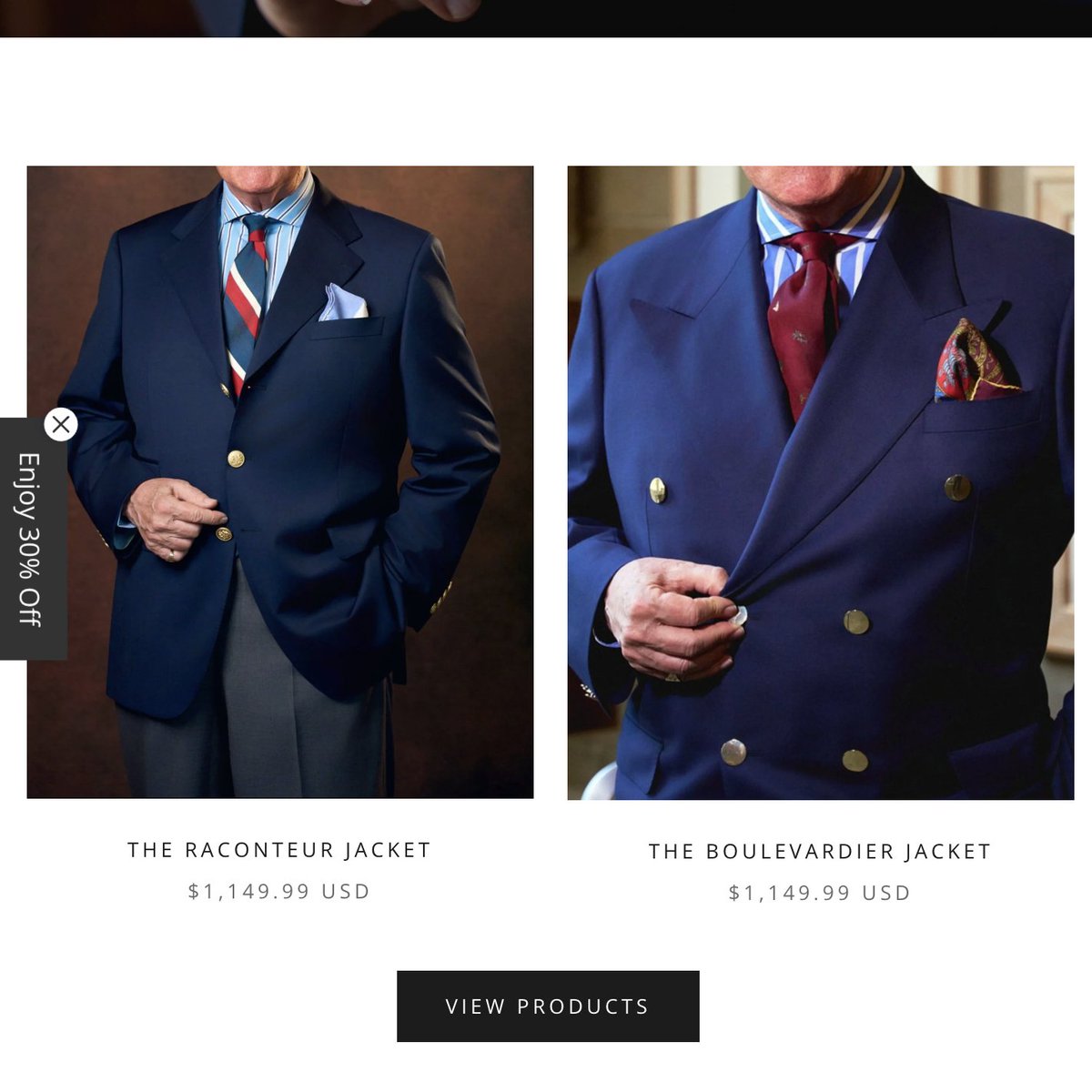

IMO, the hope for US garment manufacturing isn't in raising tariffs. This would only raise the cost of inputs, making US exports less competitive on the global market. The hope is to move US garment manufacturing upstream: higher end garments, custom garments, quick turnarounds

When Brooks Brothers filed for bankruptcy in 2020, I did a series of interviews, including with people who used their manufacturing facilities. One person ran a custom shirt business with the shirts made in Brooks Brotherse' Garland, North Carolina factory.

He expressed frustration over how his customers would always wait for deep discounts, require a lot of customer service, and return most things. Meanwhile, his shirts were coming off the same manufacturing line that produced Thom Browne's shirts.

The people who say they want to see a revival of US manufacturing often don't actually support it. They're the ones who will buy the cheaper t-shirt every time, which means the one made abroad. Meanwhile, the luxury consumer doesn't care where something is made but will pay $$$.

If there's any hope for US garment manufacturing, it's moving upstream towards those higher-end goods. Especially if we're talking about fair wages for workers (not sweatshops). Such luxury companies benefit from low tariffs because they need to import luxury materials.

• • •

Missing some Tweet in this thread? You can try to

force a refresh