This month marks the final, definitive closure of the Garland Shirt Factory. If you're interested in American manufacturing, I want tell you its story. 🧵

There's a teeny, tiny town in North Carolina called Garland, which for the last 100 years or so, has had a population hovering around 500. In the 1950s, a development company erected an industrial building here with the intention of creating manufacturing jobs.

The first tenant was Fleetline Indusries, later known as the Garland Shirt Factory. As the name implies, they made button-up shirts. With time, the small workforce here became so good at making shirts that Brooks Brothers acquired the factory in 1982.

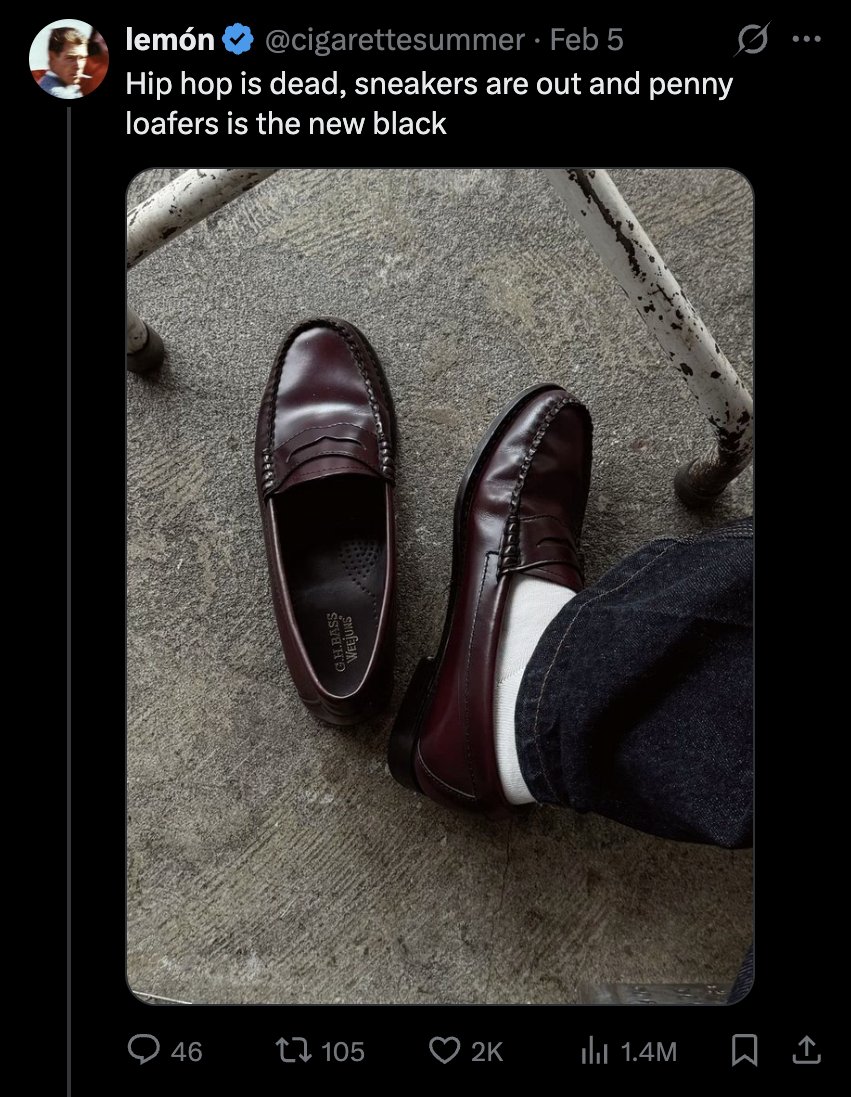

It was here where Brooks Brothers made its famous button-down shirts, which debuted at the turn of the century. Inspired by the secured collars worn by British polo players, this style was an overnight hit and became an American icon, up there with five-pocket jeans and t-shirts.

Since Brooks Brothers dressed that upwardly mobile class of Americans that saw their fortunes rise with industrial capitalism, their button-down collar was popular among their sons and daughters, including those who went to private schools that fed into the Ivy League system.

For much of the 20th century, the button-down collar was a symbol of all that is good: casualness, youth, education, trustworthiness, dependability, sport, and professionalism. Mary Mccarthy’s 1942 short story “The Man in the Brooks Brothers Shirt” is partly about its allure.

Up until about the 1990s, Brooks Brothers' button-down shirts were hardly ever discounted. They didn't need to—they were a popular perennial. Plus, their customers wore their oxford shirts until the collars frayed. Ppl paid full price for clothes they knew they'd wear forever.

If the shirts went on sale, it was just once a year—and only after Christmas.

But over time, Brooks Brothers fell into a common problem: the burden of expansion. In 1971, they had just 11 locations; in 2001, there were 155 stores and outlets in the US and Japan

But over time, Brooks Brothers fell into a common problem: the burden of expansion. In 1971, they had just 11 locations; in 2001, there were 155 stores and outlets in the US and Japan

During this expansion, their real estate costs grew and they became locked into long-term lease agreements. To turn a profit, they offshored more of its production, introduced trendier items, and started to hold more promotions to draw in deal-hungry customers.

By 2010 or so, it was pretty easy to get Brooks Brothers' shirts at a discount. They held mid-season sales, end-of-season sales, Christmas sales, "wardrobe event" sales, "4 for $249" sales, "3 for $109" sales, "select shirts for just $39" sales, etc.

During the time that Retail Brand Alliance owned Brooks Brothers (2001-2020), CEO Claudio del Vecchio was under a lot of pressure to offshore more of the company's manufacturing. However, he felt that styles key to Brooks Brothers' identity should be made in the US

That meant that Brooks Brothers' natural shouldered suits were made at the company's Southwick plant in Haverhill, Massachusetts; the rep striped silk ties were made at their tie-making facility in Long Island City, New York; and the button-down shirts at Garland, North Carolina

The Garland shirt factory was not without its problems. Along with making Brooks Brothers' shirts, they also made for some other clients. One told me that his orders were often riddled with quality control problems. Brooks brought consultants from TAL to help solve these issues.

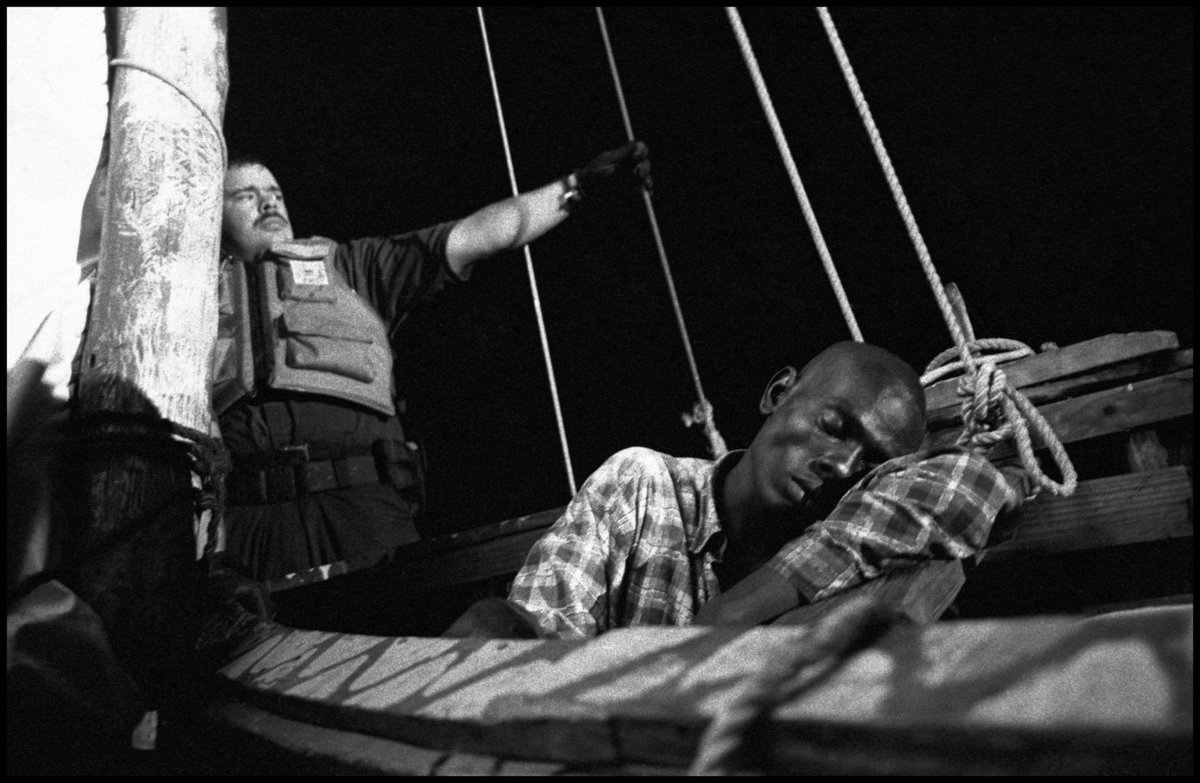

When Brooks Brothers filed for Chapter 11 bankruptcy in 2020, it shuttered its US factories, unable to commit to continuing to producing in the US. For a time, it seemed like 150 in a town of 600 would now be without work. But a year later, a bit of hope emerged.

The Garland Apparel Group acquired the company in 2021 and brought back about 100 of its former 150 workers. Garland's mayor said: "After the pandemic and the many gloomy challenges that the town has faced, we finally feel a ray of sunshine and see a beautiful rainbow."

The Garland Shirt Factory plugged along for a few years, making again for Brooks Brothers, Raleigh Denim, and customers in Korea and Japan. They even made hall-of-fame coats for Ultimate Fighting Championships and opened a new facility to produce uniforms for US Navy

But after not getting enough orders to even sustain daily operations, the company put the whole factory on furlough. There was a lot of speculation on what would happen next.

Kenneth Ragland, the managing partner for Garland Apparel Group, told a newspaper bluntly: “Lots of people talk about Made in the USA as being so necessary, but when the rubber meets the road, most Americans want cheap goods, which do not make it easy for US firms to survive.”

This month marks the finale: the Garland Shirt Factory went up for auction. I'm told the building and all of its contents have been sold: machinery, buttons, trims, and an estimated 450,000 yards of fabric, including high-end Thomas Mason oxford originally used for button-downs

When Brooks Brothers filed for Chapter 11 bankruptcy, I interviewed a number of their executives. One told me that there were discussions within the company about how to compete with labels such as UNTUCKit and J. Crew.

I asked: "How is it possible that the company that invented the oxford cloth button-down, one of the most iconic American designs, is not be able to charge a premium over stuff found on Amazon?"

The person agreed and said "that's the million dollar question."

The person agreed and said "that's the million dollar question."

The final chapter of the Garland Shirt Factory proved one thing: even without the Brooks Brothers behind it (a company that had its own problems), it could not find enough orders to sustain operations. The simple reason is because at $10-14/ hour wages, a shirt is expensive.

At such prices, a company might buy a shirt from Garland at $40, sell it to a store for $80, and then the store sells it you for about $150. This distribution model is necessary for scale (and scale is important for jobs). But people don't want to pay $150 for a shirt.

Ultimately, consumers want cheap clothes.

I'm sad to see yet another American clothing factory shutter. The Garland Shirt Factory lasted for about 70 years, much of that time producing one of America's most iconic styles.

I'm sad to see yet another American clothing factory shutter. The Garland Shirt Factory lasted for about 70 years, much of that time producing one of America's most iconic styles.

• • •

Missing some Tweet in this thread? You can try to

force a refresh