In 2000, Nokia ruled the world—selling 7 phones every second and owning 70% of the market.

But a decade later, it collapsed completely.

How did the king of mobile phones fall so fast—and could it have been saved?

The rise and fall of Nokia, explained: 🧵

But a decade later, it collapsed completely.

How did the king of mobile phones fall so fast—and could it have been saved?

The rise and fall of Nokia, explained: 🧵

Nokia’s was founded in 1865 as a paper mill.

By the mid-20th century, it diversified into cables, rubber, and electronics.

Its big break came in the 1980s when it entered the mobile communications market.

By the mid-20th century, it diversified into cables, rubber, and electronics.

Its big break came in the 1980s when it entered the mobile communications market.

Tasked by the Finnish government to research military radio technology during the Cold War, Nokia gained expertise in communication systems.

By introducing smaller, affordable, and feature-rich devices, Nokia tapped into an exploding global market.

By introducing smaller, affordable, and feature-rich devices, Nokia tapped into an exploding global market.

1992: Nokia launched the world’s first GSM phone, the 1011.

1994: The iconic Nokia 2110 introduced features like SMS and the Nokia ringtone.

1997: Nokia’s 6110 brought Snake, the game that cemented its place in culture.

1994: The iconic Nokia 2110 introduced features like SMS and the Nokia ringtone.

1997: Nokia’s 6110 brought Snake, the game that cemented its place in culture.

1998: Nokia became the world’s largest mobile phone maker, overtaking Motorola.

By the early 2000s, Nokia was synonymous with reliability, innovation, and affordability.

By the early 2000s, Nokia was synonymous with reliability, innovation, and affordability.

Nokia invested heavily in Symbian, an operating system used across many Nokia devices.

In 2000, The Nokia 3310 became a cultural icon, selling over 125 million units worldwide.

And in 2002, Nokia launched the first 3G phone, the Nokia 6650.

In 2000, The Nokia 3310 became a cultural icon, selling over 125 million units worldwide.

And in 2002, Nokia launched the first 3G phone, the Nokia 6650.

The turning point came in 2007, when Apple unveiled the iPhone, a sleek device with a full-touchscreen interface and a revolutionary operating system.

Nokia underestimated the threat.

Executives dismissed the iPhone as expensive, fragile, and unsuitable for emerging markets

Nokia underestimated the threat.

Executives dismissed the iPhone as expensive, fragile, and unsuitable for emerging markets

In 2008, Google launched Android, an open-source platform that quickly gained traction.

Meanwhile, Nokia's internal dysfunction exacerbated the situation:

Meanwhile, Nokia's internal dysfunction exacerbated the situation:

1. Competing teams worked on two separate operating systems—Symbian and MeeGo—without clear direction.

2. Bureaucracy slowed decision-making, causing delays in innovation.

3. Engineers focused on hardware durability while neglecting user experience.

2. Bureaucracy slowed decision-making, causing delays in innovation.

3. Engineers focused on hardware durability while neglecting user experience.

Prototypes like the Nokia N9 with the MeeGo OS showed promise but arrived too late.

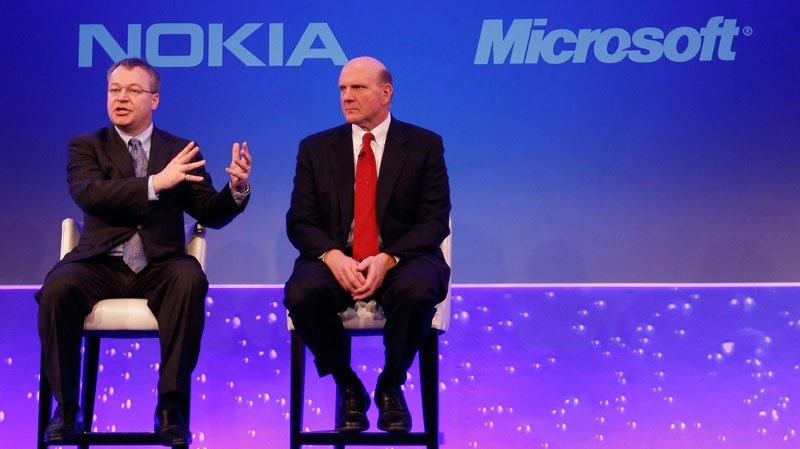

By 2011, Nokia partnered with Microsoft, ditching MeeGo for Windows Phone.

But the platform failed to attract developers, leaving Nokia without apps to compete.

By 2011, Nokia partnered with Microsoft, ditching MeeGo for Windows Phone.

But the platform failed to attract developers, leaving Nokia without apps to compete.

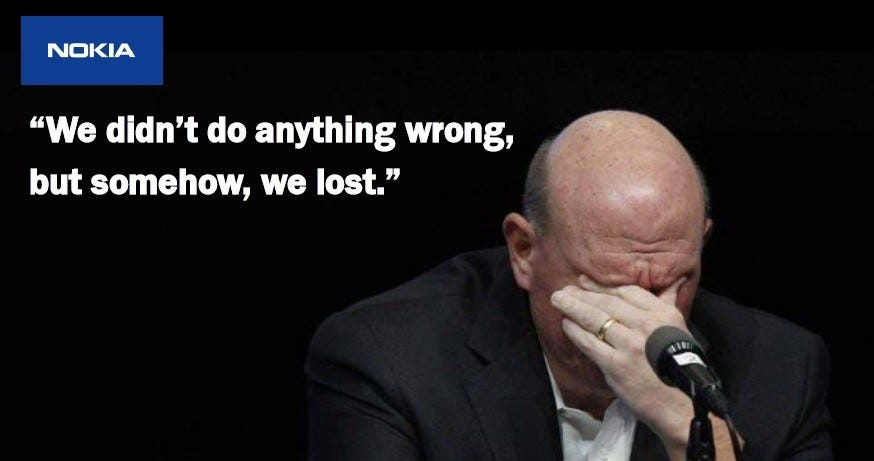

In 2013, Microsoft acquired Nokia’s mobile division for $7 billion.

Once the world’s mobile giant, Nokia had become irrelevant in the smartphone era.

Today, Nokia survives as a telecommunications company, but its fall remains a business case study:

Once the world’s mobile giant, Nokia had become irrelevant in the smartphone era.

Today, Nokia survives as a telecommunications company, but its fall remains a business case study:

1. Adapt or die. Nokia’s inability to embrace change destroyed it.

2. Internal unity matters. Divisions within the company slowed decision-making.

3. Innovation must be relentless. Resting on past success is a fatal mistake.

2. Internal unity matters. Divisions within the company slowed decision-making.

3. Innovation must be relentless. Resting on past success is a fatal mistake.

"The Digtal Gold Rush Is Upon Us."

Just like the internet in the 90s, or the iphone in 2007...

Personal Branding is the next BIG THING.

Just like the internet in the 90s, or the iphone in 2007...

Personal Branding is the next BIG THING.

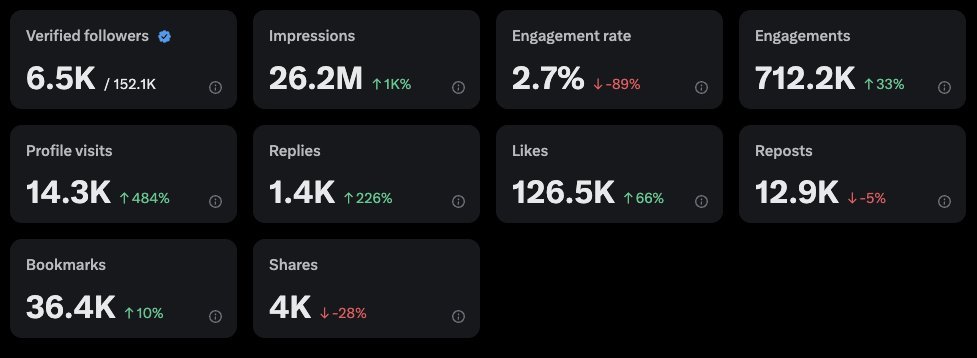

In the last 18 months, I have helped dozens of entrepreneurs generate over half a billion impressions and build a strong personal brand.

And built a network of 8 theme pages to over 800k+ followers.

And built a network of 8 theme pages to over 800k+ followers.

If you're an entrepreneur, who:

- has a content strategy but is unhappy with the results

- OR has no content strategy at all

And want to be part of this Digital Gold Rush.

DM me "I'm The Entrepreneur" and let's work together 🤝

- has a content strategy but is unhappy with the results

- OR has no content strategy at all

And want to be part of this Digital Gold Rush.

DM me "I'm The Entrepreneur" and let's work together 🤝

• • •

Missing some Tweet in this thread? You can try to

force a refresh