This video has made the rounds on nearly every social media platform—and like others in its genre, it's led people to reduce fashion production to overly simplistic narratives.

So let’s take a look at why this bag might not be quite the same as the one you’d find at Hermès. 🧵

So let’s take a look at why this bag might not be quite the same as the one you’d find at Hermès. 🧵

Most people have a very functional relationship with their wardrobe. They choose garments for their utility—warmth, comfort, protection from the elements. In this context, quality is measured by durability and function: how long a piece lasts and how well it does its job.

Others dress with social aims in mind, such as climbing the corporate ladder, attracting a partner, gaining entry into certain circles. In these cases, luxury goods convey status, wealth, or cultural fluency. It’s still about utility—just of a more symbolic kind.

But there’s another way to appreciate fashion—through craft. It’s not about how well something performs or what it communicates. Instead, it’s about valuing the skill, time, and intention embedded in the object itself, even if no one else cares or recognizes those qualities.

In the original TikTok video, the maker claims his bags are just like Hermès because they use the same materials. That’s like me saying my spaghetti is on par with a Michelin-starred chef’s just because we both use tomatoes and flour. In fact, skill matters more than materials.

So what sets Hermès bags apart? A key element lies in how it’s sewn. Hermès employs a technique called the saddle stitch. The maker first pierces the leather with an awl, then threads two needles through each hole from opposite sides, arms stretching wide like a bird's wings.

This time-intensive method originates in harness making. When Thierry Hermès founded his company in 1837, it was one of many Parisian workshops producing bridles, saddles, and reins for the horse-drawn carriages. Hence why the company's logo still looks like this:

In this context, a saddle stitch about function. Unlike a machine-sewn lockstitch, which can unravel if a single thread breaks, a hand-sewn saddle stitch remains intact. Each pass of the needle locks the thread in place independently. When riding horses, this is about safety.

The arrival of automobiles in the late 19th century gradually swept horse-drawn carriages off the streets. As the need for harnesses and saddles declined, the leatherworkers who once supported that industry adapted by turning their skills toward other leather goods, such as bags.

In fact, Hermès is hardly the only maker using this technique. There are dozens of independent French artisans making similar things: Victor Dast, Serge Amoruso, Peter Charles, & Louis Chelli. My friend @RJdeMans, author of the brilliant book Swan Songs, uses Bertrand Montillet.

That said, not all saddle-stitched goods are equal. A few years ago, this video went viral thanks to a clickbait title: “We Made a $5,000 Hermès Wallet for $70!” But IMO, the edge finishing looked gloopy, and the final product lacked the refinement you’d expect from Hermès.

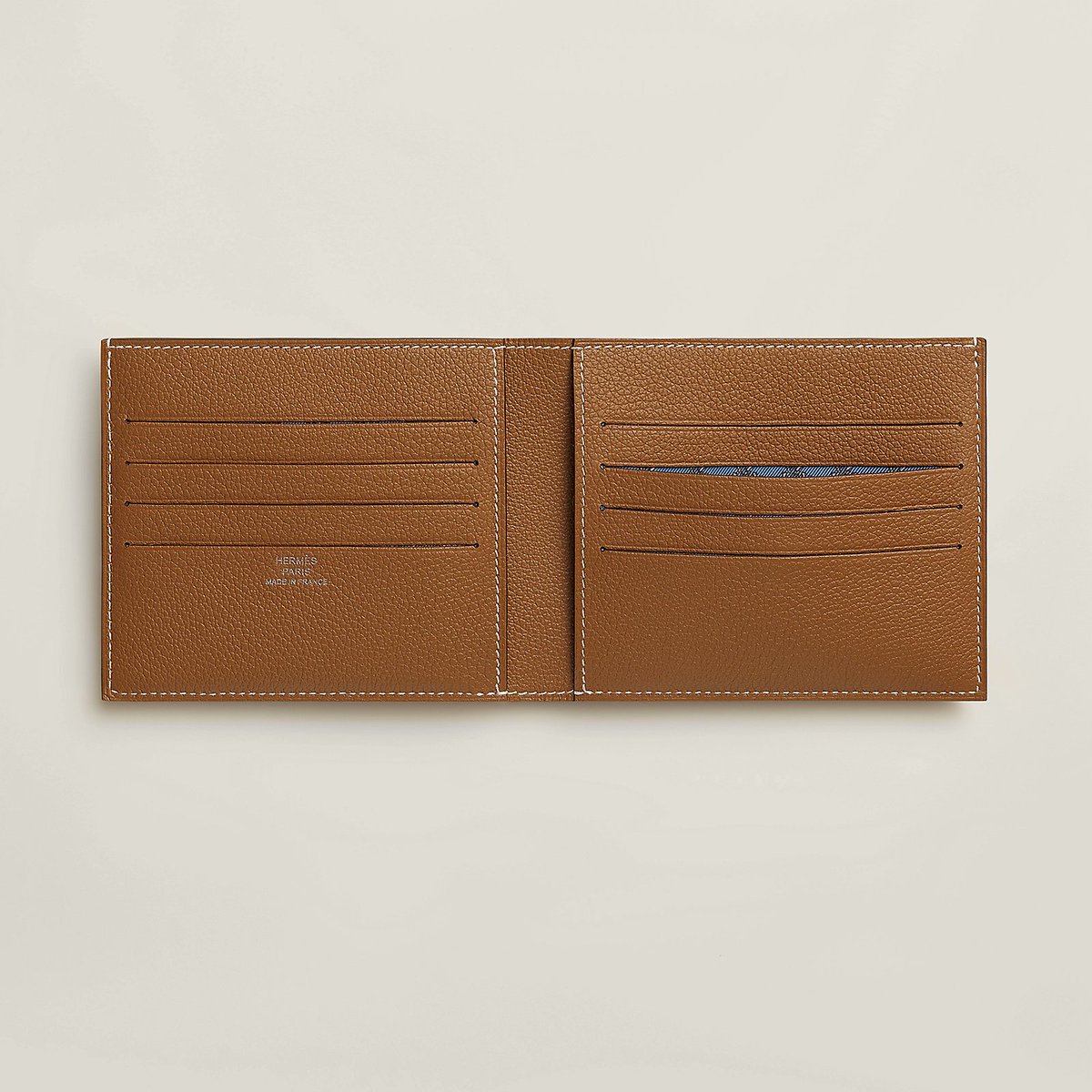

For comparison, here are Hermès wallets. IMO, stitching is neater and more precise. The wallet also folds more cleanly, likely bc Hermès selected a more appropriate leather. To be clear, Corter makes solid products. I just don’t think their wallet is on the same level as Hermès.

Beyond added durability, a saddle stitch also offers a visual appeal. When executed properly, there are no gaps between the stitches, creating a cleaner finish. Compare the handsewn Hermès bag and machine-sewn Symthson wallet examples below.

There's also the finishing. The dark brown bag is from Hermès; the tan one from Glenroyal. The Hermès edge finishing makes separate layers of leather appear seamlessly fused into a single whole. In contrast, the Glenroyal’s edges are rougher with clearly visible layers.

When everything is done well, you get beautiful bags like these. When you learn about the different dimensions of craftsmanship, it's easy to tick off things like checkboxes (e.g. "is it saddle sewn?"). But I encourage you to train your eyes to look at things as a whole.

For instance, the careful pattern drafting, pad stitching, and ironwork in Atelier Willow's suits translate to this beautiful shaping: curved chest, conical sleeves, and lapels that bloom out of the garment's buttoning point. It's about the total silhouette, not just each part.

J. Crew uses pretty nice materials (sometimes from Loro Piana!). But the difference in craftsmanship means that their garments don't have the same shaping. (Reasonable as they don't cost as much!).

I saw some people here say that I'm elitist and racist bc I don't think a random dude on TikTok is making bags at the same level at Hermes. But notice that the TikTok guy isn't actually showing you the craft that goes into his bags (nor are there many customer reviews).

There are plenty of Asian makers who do incredible work: Hosoi (France), Saic Firenze (Italy), Ortus (Japan), Atelier Shiang (Taiwan), and Shiue Wen Jhuang (also Taiwan).

My favorite is a Vietnamese-American woman named Bellanie Salcedo, one half of Chester Mox in the US.

My favorite is a Vietnamese-American woman named Bellanie Salcedo, one half of Chester Mox in the US.

Bellanie trained under a former Hermès craftsperson and sources leather from Hermès-owned tanneries. She does fully bespoke work and makes everything from bags to wallets to belts. My favorite item, her "dogleg card cases," start at just $75—a fraction of what Hermes charges.

I think you should buy things because you'll love and use them. Ideally, they make you just as excited in year ten as day one. Hermès bags are made from full grain leathers that take on a patina, but that patina only develops if you actually love using the item!

I think the whole project of buying a dupe is failed from the start because the object will always live in the shadow of the thing you actually want. You should buy things on their own terms. Is the item well-made? Does it excite you? Do you appreciate the maker's story?

We are living in a time where product is increasingly separated from process. I have no doubt that AI could make physical copies of Japanese woodblock prints. But I don't love those just bc they decorate my walls—I love them for *how* they're made, even if others don't care.

This video says little about craft. The appeal hinges entirely on the idea that you can get a status symbol for less money. But will you truly value and cherish something for decades if your introduction to it starts with the same sound effect used to signal a male erection?

Certainly, Hermès charges a premium. I support getting something similar from independent artisans for less. But even they won't charge just $1,000 for such labor intensive work. You are paying not only for their time, but the years it took to develop those skills.

I should note: a saddle stitch can also be faked. If you buy something under the presumption that it was handsewn—a mark of time, skill, and craftsmanship—but it turned out the person just ran it under a machine, would you be upset? Can you tell the difference? These are the issues at play.

Real craftspeople take years to develop a reputation, sometimes on forums where discerning customers can tell the difference between small details. Encourage you to be a bit more discerning when someone seeks to capitalize off cheap cynicism.

Real craftspeople take years to develop a reputation, sometimes on forums where discerning customers can tell the difference between small details. Encourage you to be a bit more discerning when someone seeks to capitalize off cheap cynicism.

• • •

Missing some Tweet in this thread? You can try to

force a refresh