I respectfully disagree. To me, this represents a poor financial decision. Let me show you why. 🧵

https://twitter.com/BasedSatori/status/1928219853246050555

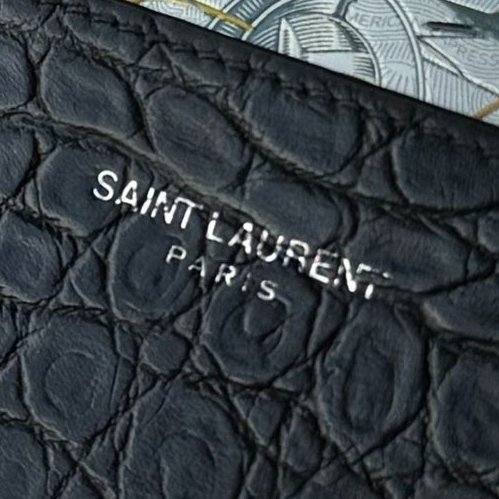

When we zoom in on the wallet, we see the label "Saint Laurent Paris," a French luxury fashion house that became popular about ten years ago when Kanye started wearing the label. This was also when Hedi Slimane was at the company's creative helm.

For many young men at the time, Saint Laurent was their entry into designer fashion, partly because the designs were conceptually approachable (LA rocker, Hot Topic), while the Kanye co-sign made them cool and the prices signaled status (and for the uninformed, suggested quality)

Indeed, we see this card case retails for $350. On Saint Laurent's website, they describe it as "crocodile embossed" calfskin. Calfskin is the most basic type of material for leather goods. But this was put through a machine stamp to imitate the look of a pricier exotic leather.

IMO, the stamp is not particularly attractive. On the left, we see genuine Nile crocodile from the Hermes-owned tannery HCP. Note how the scales are very clean. Saint Laurent choose a stamp to imitate the look of a lower-grade exotic of a bad part of the hide (e.g. tail, sides).

When we zoom in closer, we see something peculiar: there are small holes between each stitch. This indicates this item was machine-sewn.

There are two main ways to make leather goods: machine sewing vs a hand sewing technique known as saddle stitching.

There are two main ways to make leather goods: machine sewing vs a hand sewing technique known as saddle stitching.

In saddle stitching, a worker gently marks the leather by punching it about halfway through with an awl, then passing two needles from both sides, stretching their arms wide like a bird stretching its wings. The thread is commonly waxed to give it strength.

This creates a more durable seam. Whereas a machine-sewn lock stitch can unravel if only one stitch breaks, a hand-sewn saddle stitched seam has to be picked apart with a special tool. This is why it was traditionally used to make horse riding equipment — it's failsafe.

To the untrained eye, it can be hard to spot a machine vs hand sewn seam, esp since many companies try to imitate the look of the second. But you can sometimes tell when there are no holes between the stitches. See the tight, neat stitching on this Dast briefcase

IG victordast

IG victordast

The most famous purveyor of saddle-stitched goods is Hermes, but even they don't do everything by hand nowadays. Instead, if you want this sort of quality, you typically have to go to small, independent workshops run by craftspeople. Serge Amoruso tours Japan:

IG serge_amoruso

IG serge_amoruso

There's just a handful of these artisans nowadays, most of them based in or around Paris: Victor Dast, Serge Amoruso, Peter Charles, Bertrand Montillet and Louis Chelli.

My favorite is Chester Mox, co-founded by Bellanie Salcado, who trained under a former Hermes artisan.

My favorite is Chester Mox, co-founded by Bellanie Salcado, who trained under a former Hermes artisan.

Everything here is done by hand, which means no machines are involved. Since everything is made-to-order, you can choose your own leathers and thread, as well as ask for a monogram. The leathers are often from Hermes-owned tanneries.

IG chestermox

IG chestermox

To me, this represents better value. The machine-made stamped calfskin Saint Laurent wallet on the left is $350. The fully handmade Chester Mox wallet on the right is $260 for calfskin. Exotics start at $330, depending on the configuration.

To be sure, there's nothing wrong with buying designer goods or getting something because of a celebrity (although many celebs now are paid to wear things). IMO, the purest fashion experience is being a teen and trying to dress like your favorite musician.

Nas in Polo Sport:

Nas in Polo Sport:

But I think you should be clear-eyed about it. Brands often use flagship items — a $50k coat or haute couture dress — to create a halo. Profits then depend on a sprawling array of perfumes, sunglasses, and leather goods. These are more accessible and have bigger profit margins.

Personally, I think it's more interesting to shop from skilled, independent artisans who make things the old way. Many represent a dying breed of craftspeople who have turned their back on machines. Not only are their products more affordable, they're higher quality.

When you pull out that bag or wallet, you're reminded not of celebrities or designers, but the skill, patience, and time it took for someone to keep a craft alive. IMO, this is more satisfying. And as a matter of price-to-quality ratio, represents a better financial decision.

Don't know why Twitter has messed up the ordering of my thread, but if you've arrived here through a retweet or something, you can read the rest of the thread here.

https://x.com/dieworkwear/status/1928920214667931850

• • •

Missing some Tweet in this thread? You can try to

force a refresh