Let me make the case for why the NHL should abolish its dress code, which currently requires players to wear a suit and tie while heading to and from games. 🧵

https://twitter.com/BR_OpenIce/status/1938244691817889992

The arguments I've seen for the dress code fall into one of two categories: players look better in a coat-and-tie (some use descriptions such as "classy"). Others say that requiring players to dress in this way shows respect for the game. I will address each argument in turn.

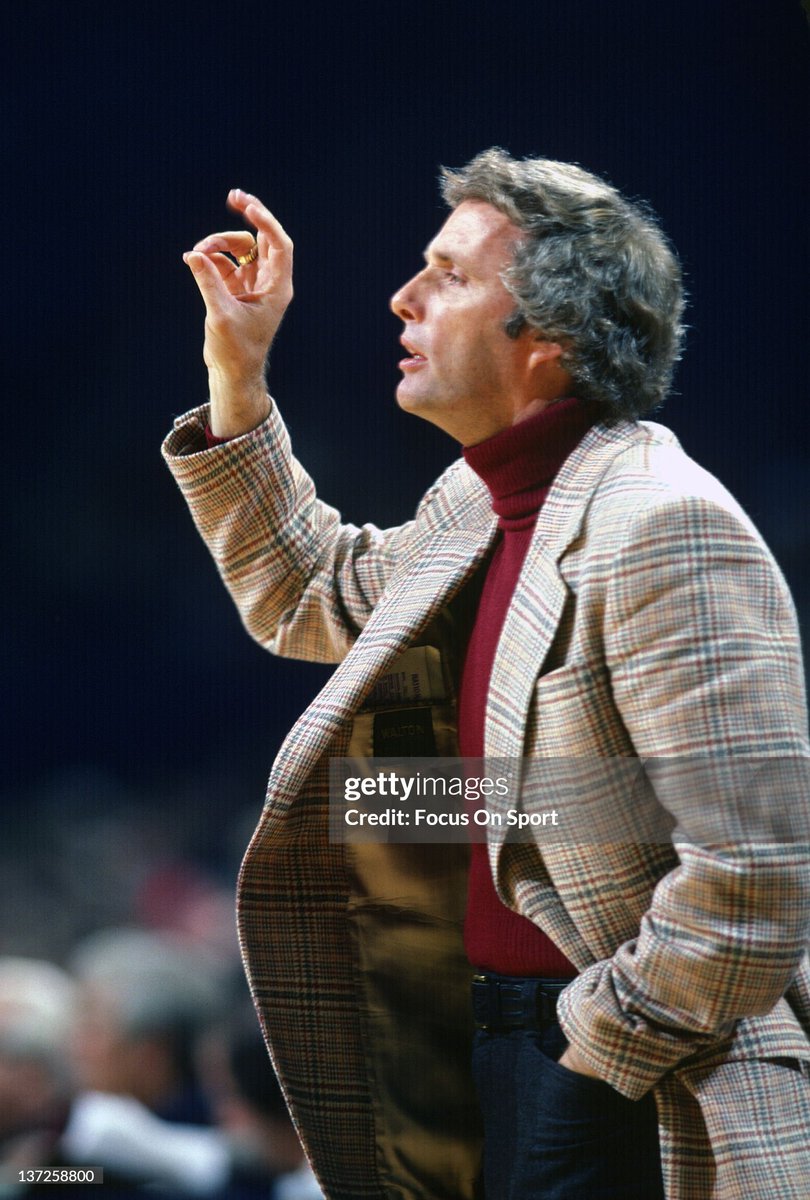

It's true that tailoring once played a larger role in sports. Basketball coaches, for instance, used to wear tailored jackets pretty regularly, even at games. Some even looked quite good in these outfits.

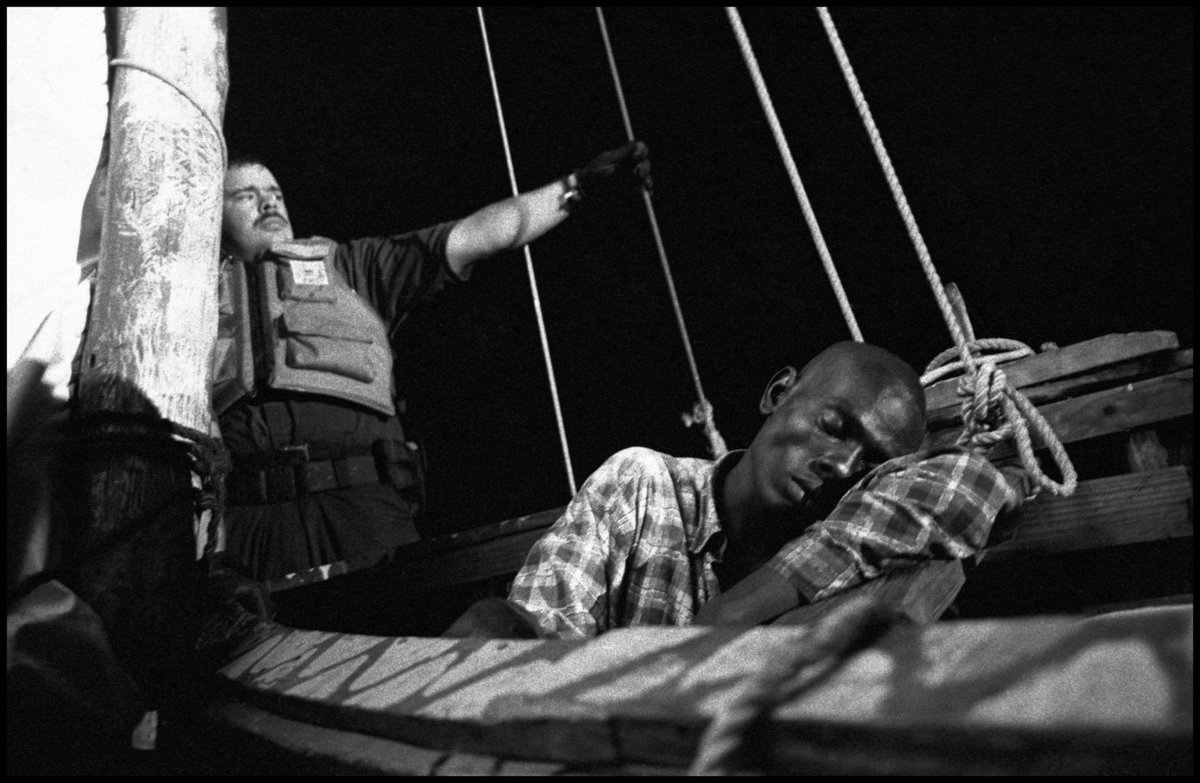

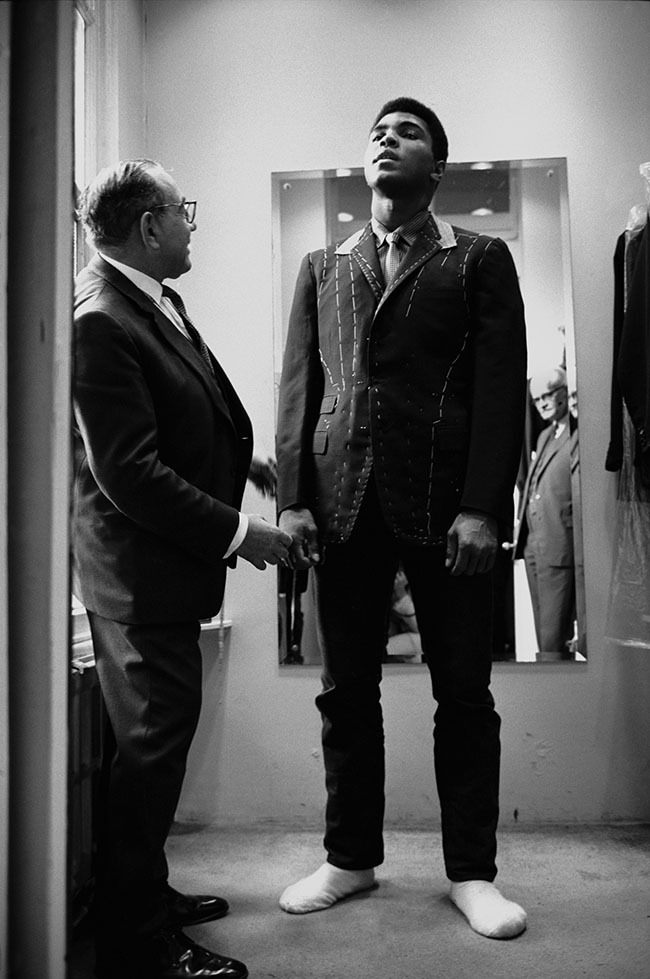

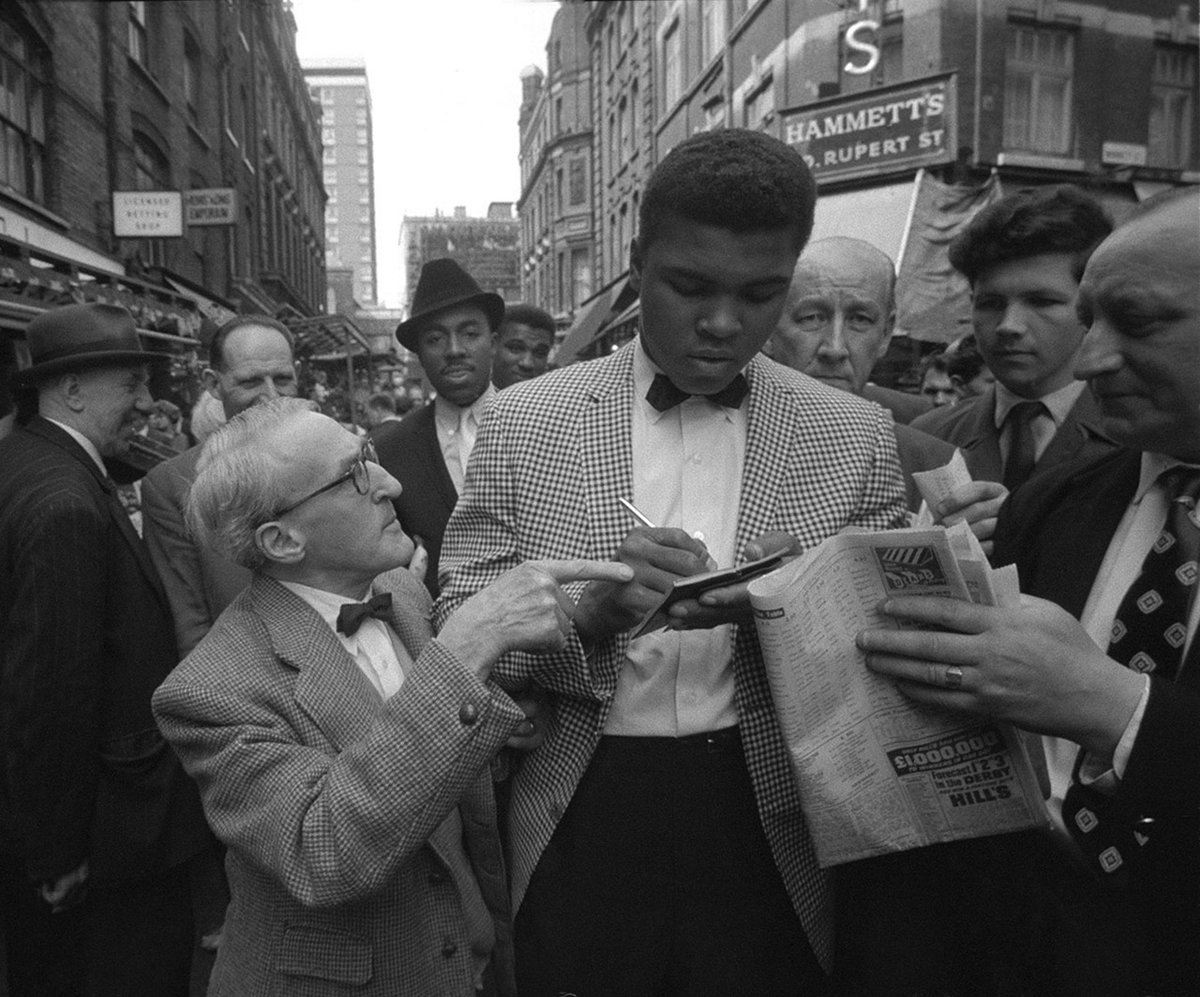

Even professional athletes occasionally wore tailoring, such as Muhammad Ali. Although this was not a requirement for going to or from games.

It's important to note this happened during the Golden Age of tailoring (1930s-80s), when bespoke tailors were more common.

It's important to note this happened during the Golden Age of tailoring (1930s-80s), when bespoke tailors were more common.

What's a bespoke tailor, you ask? A bespoke tailor is someone who makes you a garment from scratch. They take your measurements, draft a pattern from scratch, and then use that pattern to create a custom garment that's refined through an iterative series of three fittings.

This is important because professional athletes have atypical builds, which means they don't fit easily into ready-to-wear clothing. When Kareem Abdul-Jabbar bought custom clothes as a UCLA sophomore, he went to a bespoke tailor. (He had a 51" inseam!)

As ready-to-wear has taken over the market, and as fewer people today wear tailored clothing, the market for bespoke tailors has shrunk dramatically. A few are left in NYC, but most people rely on international tailors who visit select US cities three or four times per year.

Such cities include NYC, San Francisco, Los Angeles, and Washington DC. If you're located in another city, such as Chicago or Phoenix, your options are smaller. If you're not located in or near a city, your options are basically next to none.

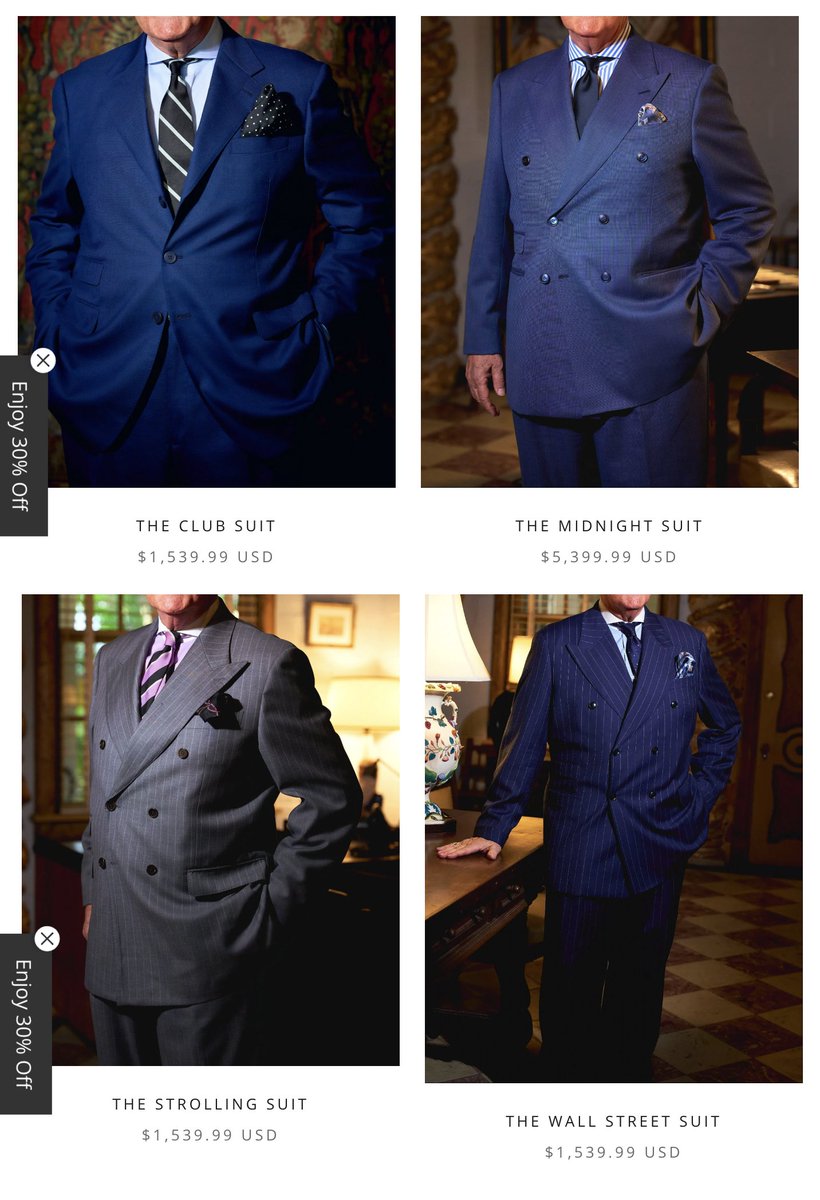

Most people who buy custom clothes don't actually use bespoke tailors. They use made-to-measure outfitters, where someone measures you. These measurements are then sent to a distant factory, where a block pattern is adjusted and a garment is made straight to finish.

It's important to note that the person measuring and fitting you is typically not a tailor. Meaning, they don't know how to draft a pattern or make clothes. They are business people, sales people, and fitters. This is sometimes fine if you're within distance of the block pattern.

But the further you are from the block pattern, the more problems you'll encounter. The MTM companies I've seen often suffer from a few problems:

— Prices are low (sub $1,000), which means they run on slim margins. This limits how much they can serve you. Have a problem? Too bad

— Prices are low (sub $1,000), which means they run on slim margins. This limits how much they can serve you. Have a problem? Too bad

— Since they run on small margins, they often have to sell a lot of units. Which means the block pattern is downmarket from early 2000 trends (short jacket, slim pants, low waisted)

— The person running the company is not really into clothing, they are into making money.

— The person running the company is not really into clothing, they are into making money.

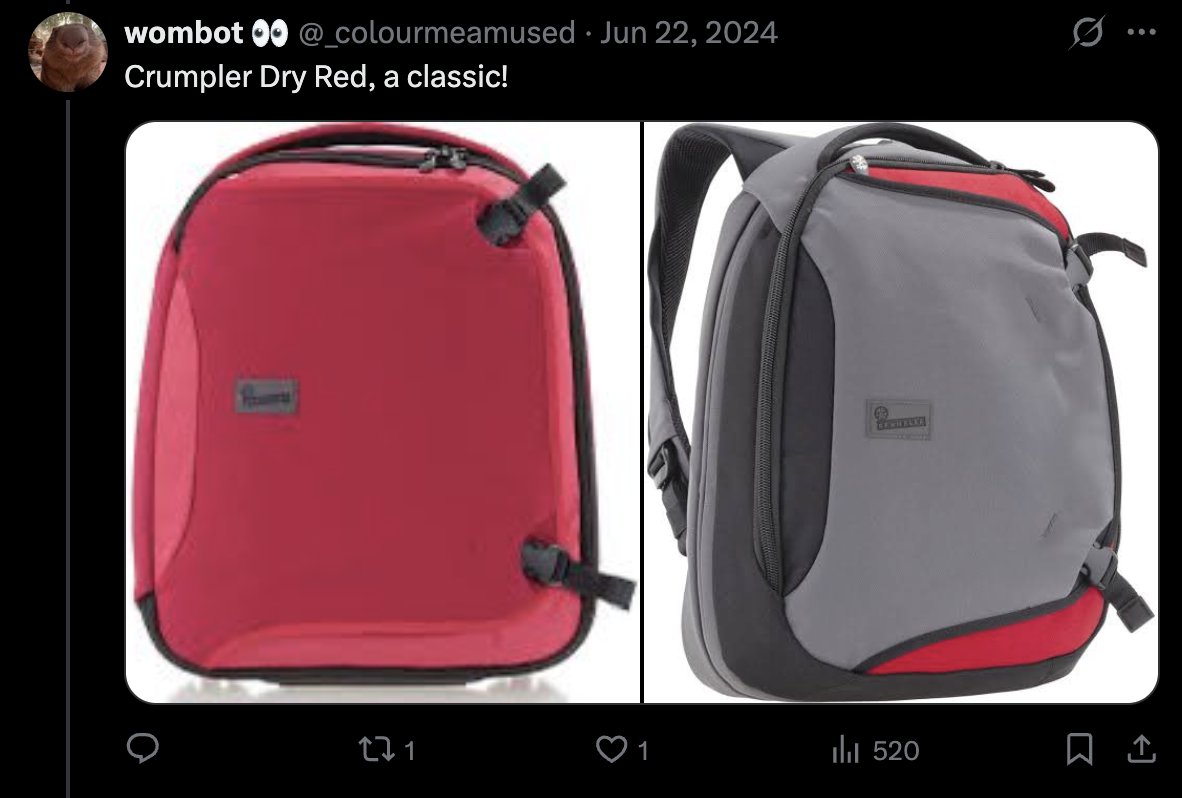

In such cases, you often have the blind leading the blind. Since the person is primarily interested in sales, not tailoring, they play up gimmicks like contrast buttonholes, wacky lining, contrast stitching. Anything to make the sale.

These are all cheap gimmicks:

These are all cheap gimmicks:

Compare, for instance, the fully machine-made coat in the first image. The client is likely new to tailoring, so they throw everything into the sauce. Contrast stitching! Exciting!!

But when a coat is genuinely well-made, the hand-felled stitching is invisible.

IG lawtonltd

But when a coat is genuinely well-made, the hand-felled stitching is invisible.

IG lawtonltd

These flash bang gimmicks blind the customer, preventing them from noticing that the garment doesn't fit very well. They may not have much experience with quality tailoring, so they have no reference point. But just compare the fit and silhouette of these two outfits:

This situation is exacerbated when the person has an athletic build. The salesperson (who, again, is not a tailor) has developed a trendy block pattern. They are then trying to squeeze these athletic figures into slim fit suits designed for thinner men. That's how you get this:

I should stress this is not to demean the men in these clothes. It's their clothier that failed them.

These clothiers try to solve every problem by taking in the seams. To prevent the seams from busting, they use stretch fabrics.

This looks ridiculous:

These clothiers try to solve every problem by taking in the seams. To prevent the seams from busting, they use stretch fabrics.

This looks ridiculous:

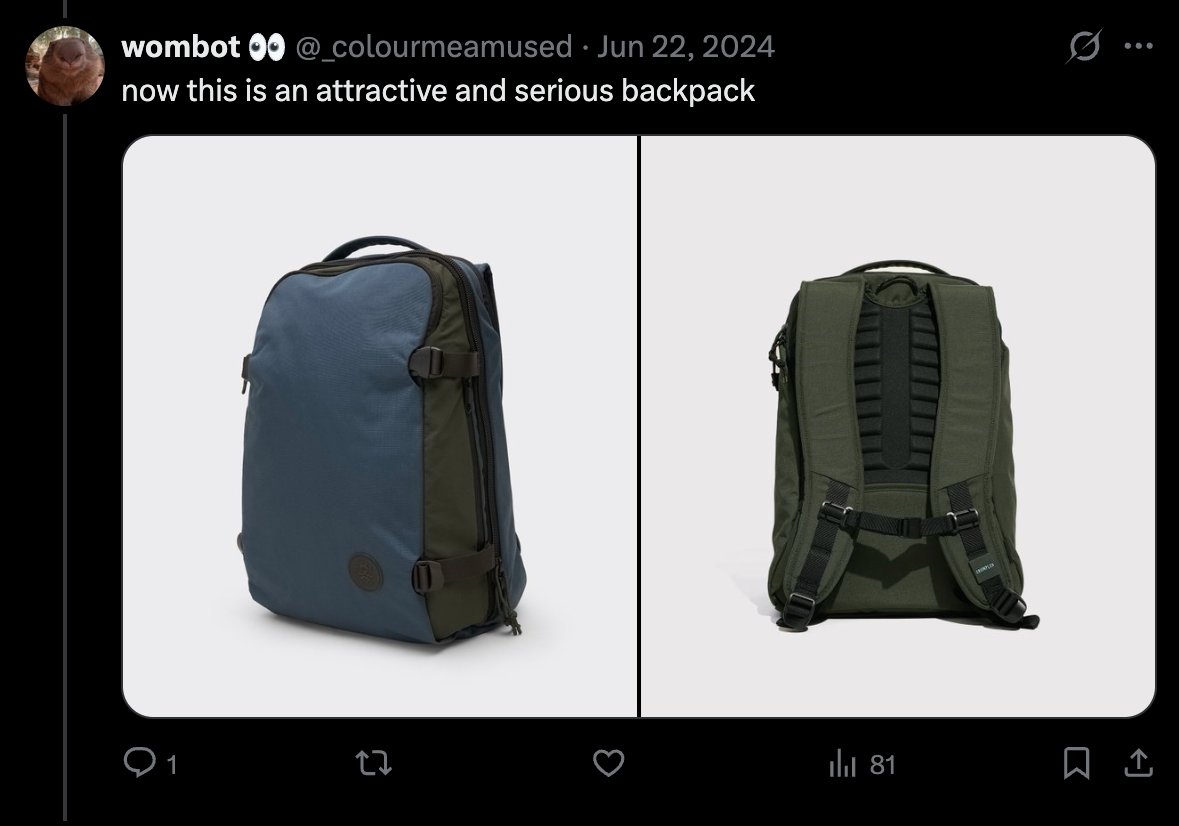

As a matter of aesthetics, I don't see anything special about bad tailoring. IMO, guys look better in hoodies, sweats, and casualwear than an ugly suit.

Why have a dress code that only serves to put money in the pockets of clothiers that make players look bad?

Why have a dress code that only serves to put money in the pockets of clothiers that make players look bad?

The dress code also places a weird expectation on players. This article from the hockey blog Offside News suggests players should be fashion icons. Unique doesn't necessarily mean good, and athletes aren't necessarily fashion icons. They are there to play sports.

The idea that a good outfit has to be unique and creative also negates the person underneath the clothes. Some guys are "crazy outfit guys;" other guys are "conservative outfit guys." Ignoring this treats the person as a mannequin, not as a human with a personality.

As I understand it, hockey players have been asked to adhere to a dress code since at least the 1990s. Part of this is so that the player's attire doesn't "embarrass the organization."

I think you can create a dress code that's a bit more flexible while meeting this standard.

I think you can create a dress code that's a bit more flexible while meeting this standard.

IMO, the current dress code isn't about "showing respect for the game," as some suggest. If you force everyone to wear a coat-and-tie, then many will do so simply because they wish to adhere to rules. They are meeting a requirement, not signaling what's in their heart.

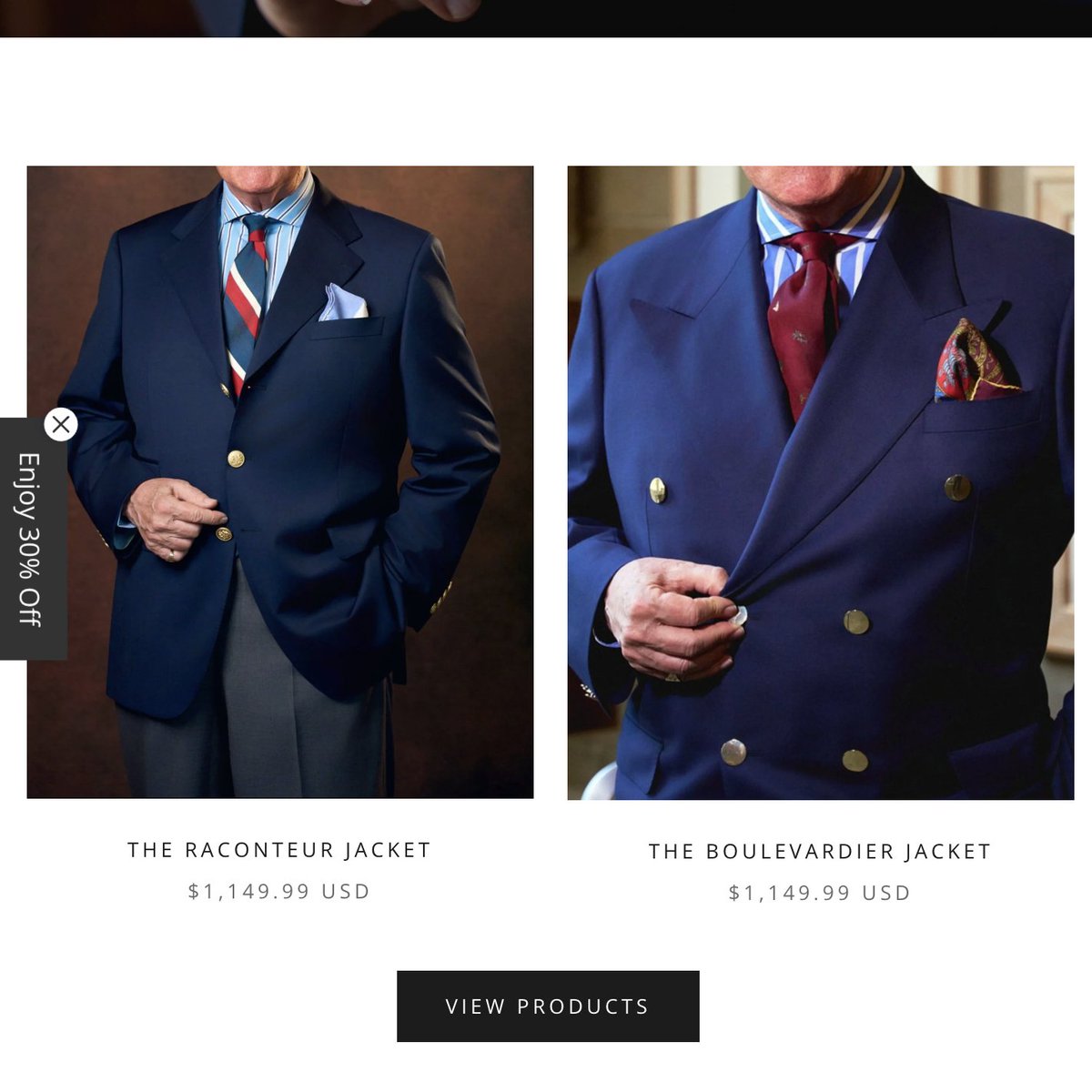

Tailoring is also ill-suited for traveling as an athlete, as these clothes need special storage and pressing. Since players have atypical builds, making them look good requires special construction techniques. This looks great, but it's bespoke and required multiple fittings:

Note everyone has time for that.

If you want a strict dress code, consider a team uniform, but in a more casual style that can be easily transported. Something like a tracksuit, which won't wrinkle or get crushed in transit. More importantly, it's more forgiving in terms of fit.

If you want a strict dress code, consider a team uniform, but in a more casual style that can be easily transported. Something like a tracksuit, which won't wrinkle or get crushed in transit. More importantly, it's more forgiving in terms of fit.

• • •

Missing some Tweet in this thread? You can try to

force a refresh