Let me show you the difference between a $40 hoodie and a ~$100 hoodie. 🧵

https://twitter.com/twiflgab/status/1988312978647904727

Within the part of the menswear industry that I operate in, Roopa Knitting Mills is widely regarded as one of the best hoodie manufacturers. Founded in 1991 by an Indian immigrant named Nat Thakkar, they do every production step after yarn spinning in Ontario, Canada.

That means knitting, dyeing, cutting, sewing, embellishing, and finishing. They knit fabrics on high-end German machines at 22 revolutions per minute, whereas fast fashion brands may use materials knitted at 30 revolutions per minute (or more).

The slower pace means each machine only makes 23 to 28 meters of hoodie fabric per hour, but this also ensures quality (e.g., no holes or runs in the material). When hoodies are cheap, companies have to maximize output, but this can also mean they have lower quality control.

Once the fabric has been knitted and dyed, it's brushed on the underside for softness (turning terry fabric into fuzzy fleece). The fabric is then washed and dried to reduce shrinkage, stacked into piles so it can be cut by hand-operated saws, and sewn into hoodies.

Roopa typically uses a heavier material: 400 grams per square meter, which translates to 14oz (remember this number). Using a heavier fabric adds cost to every production stage — more fiber material, more dyeing and drying time, more shipping cost, etc.

On the upside, a thicker, fluffier fabric means a warmer hoodie. It also allows the hood to stand up on your shoulders, rather than falling limp across your back. This is not necessarily better or worse, just an aesthetic detail to consider.

These hoodies are sewn using a double needle coverstitch for durability, but the underarm and side seams are sewn using a flatlock stitch. This produces a smoother, flatter seam, removing the bump that rub against the body.

Paul at IG toofbush explains the flatlock stitch below.

Paul at IG toofbush explains the flatlock stitch below.

Roopa Knitting Mills is a manufacturer, which means they work with brands. But they also sell directly to consumers through their in-house label House of Blanks. Their hoodies cost $110 partly because they use USA grown cotton and produce everything else in Canada.

Notably, Canada's 1970s immigration policy allowed Nat Thakkar to set up a factory in Ontario, which is now run by his son. The factory has created jobs for Canadians. Unfortunately, Trump's tariffs have hurt their business, which also harms US farmers since Roops uses US cotton.

Anyway, let us now move to the cheaper option.

There's a good chance you have this hoodie in your closet. It's one of Gildan's many stock blanks, which you can buy online for about $20. Although, it's more likely that you paid $40.

There's a good chance you have this hoodie in your closet. It's one of Gildan's many stock blanks, which you can buy online for about $20. Although, it's more likely that you paid $40.

You likely paid $40 because online influencers, music bands, and non-clothing related shops often use Gildan for their merch. Of course, they don't actually produce merch — they partner with on-demand printing houses.

Here's an example from Donald Trump Jr.

Here's an example from Donald Trump Jr.

Like House of Blanks, these hoodies are also double-needle sewn, but they lack the more refined flatlock stitch along the underarm and side seams. They also use lighter fabric (8oz vs 14oz), which saves cost across the entire production process.

Loosely knit, lightweight fabrics like this are more prone to stretching out. Such companies also use lower quality cotton, which can look great on day one, but will easily pill over time, especially in high-friction areas. Just look at the little fuzzy balls along the edge:

Whereas House of Blanks uses a brushed 100% cotton fleece, Gildan uses a 50/50 cotton-polyester blend. This is partly lower cost and strengthen inherently low-quality cotton fibers, but also to meet government regulations around the world.

A pure cotton, brushed fleece is more flammable, which limits which counties you can export to. When you run a massive operation such as Gildan, you may want to add polyester to meet flammability regulations, allowing you entry into more markets.

However, the result is a garment that doesn't fade as well. If you, like me, love the look of vintage hoodies — the beautiful fades, thick fabric, and stout feel — then you'll want a heavier pure cotton garment.

All of these are pure cotton (check out the fades on the last pic!)

All of these are pure cotton (check out the fades on the last pic!)

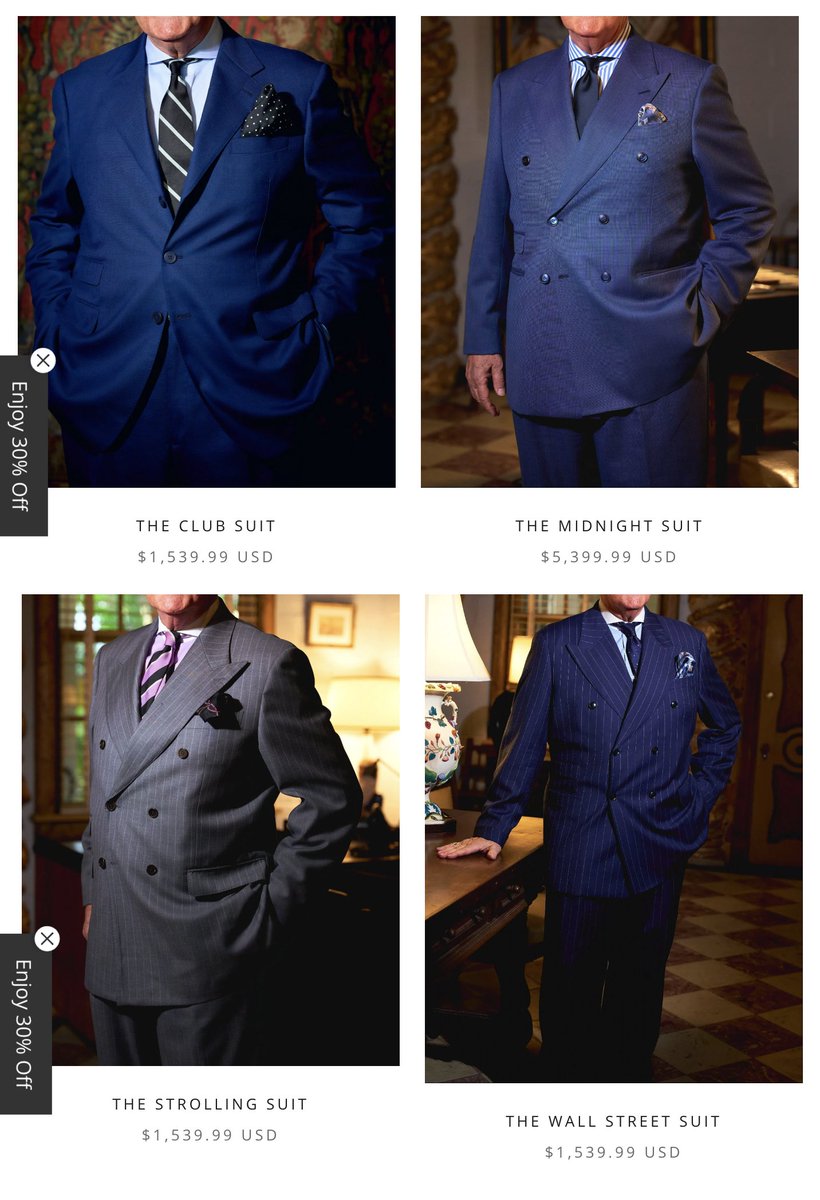

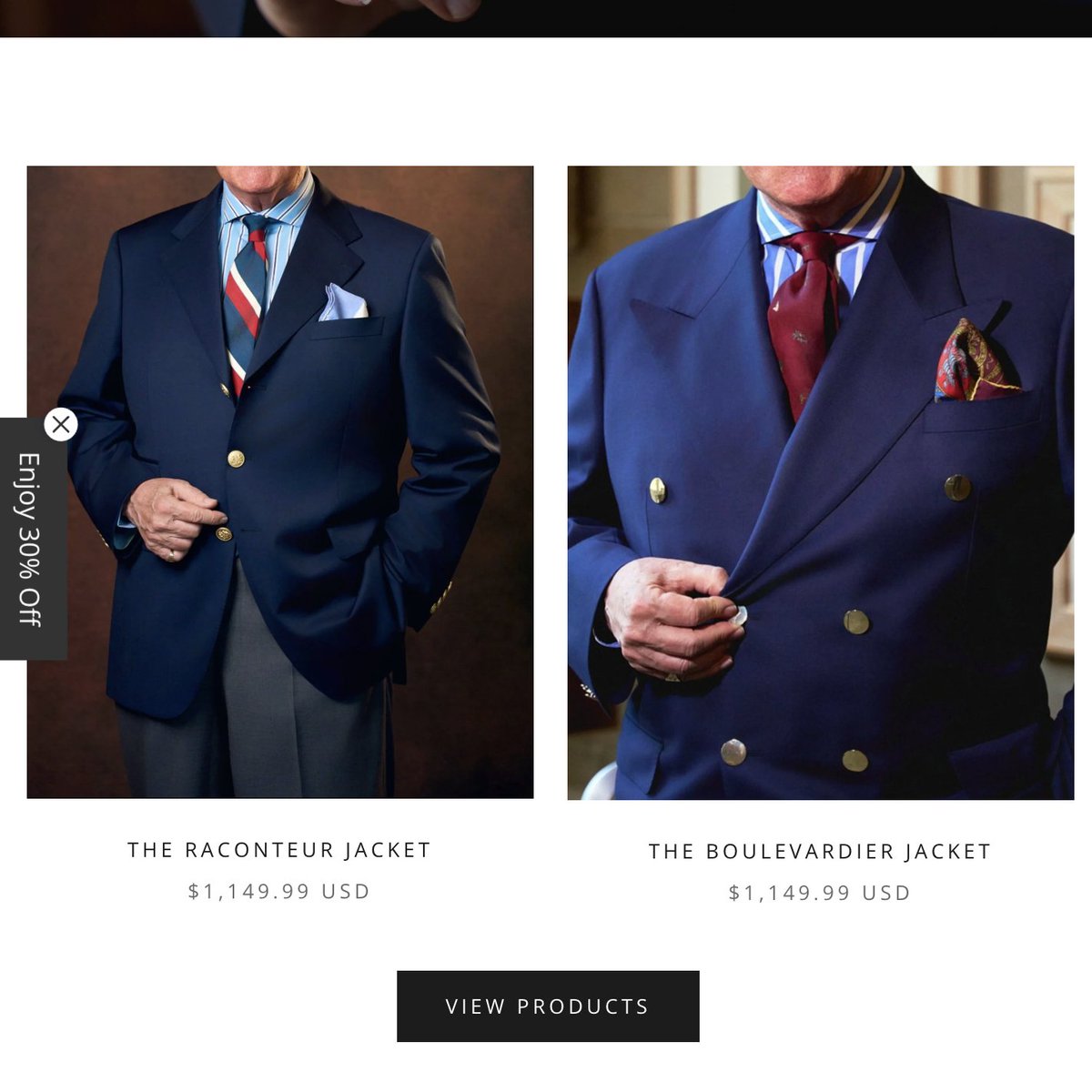

Worst of all, Gildan has a history of working with sweatshops. A lot of MAGA merch nowadays will say it's "designed and printed in the USA," but if you dig a little deeper, the blanks are often from Gildan, typically produced in Bangladesh or Latin America.

Some of their factories have been associated with human rights abuses, such as putting workers in hazardous work conditions, stealing their wages, and sometimes even murdering them for trying to organize. When garments are produced through misery, no joy can be derived from them.

I'm not against buying things made abroad. My favorite hoodie is from Brut Paris ($220), which was produced in China. It's a misconception that everything made in China is low quality or even cheap.

Some of the most beautiful clothing is made in China. For example, I love this Amur coat by @the_rosenrot 😮💨. Such work requires skilled labor, quality materials, and time — all of which comes at a price.

At the same time, there are low-quality garments made in US sweatshops

At the same time, there are low-quality garments made in US sweatshops

The difference between a $40 and $100 hoodie will be about a few things:

— Location of production

— Time it took to produce the garment

— Quality of the materials

All of this can add up to how much you love wearing the garment over the long run.

— Location of production

— Time it took to produce the garment

— Quality of the materials

All of this can add up to how much you love wearing the garment over the long run.

If a $40 hoodie ends up stretching out, pilling badly, and looking like crap in a year, it will still cover your torso, but won't bring you any joy. Conversely, if it holds its shape and ages in a charming way, you'll want to *repair* and not *replace.* This is sustainability.

The point of this thread is not to give you a checklist for "quality metrics," but rather help you develop an understanding for clothes. There are lots of quality hoodie companies in the world. Each makes a design according to their taste, much like how a chef creates a dish.

Don't just think about the price. Consider how much you'll love wearing the garment in the long run, which will be about finding a manufacturer that produces things to your taste. A $100 hoodie worn for a decade is cheaper than a $40 hoodie you replace in a year.

• • •

Missing some Tweet in this thread? You can try to

force a refresh