Semiconductors - Follow me to learn all about microchips & how we print them. My web scraper is a live dashboard for the freshest tech news & press releases.

How to get URL link on X (Twitter) App

[2/16] The List

[2/16] The List

Link to report:

Link to report:

One of the more important slides in their EUV talk discusses the history and roadmap for the source power. Unlike prior generations of projection lithography, EUV consumes huge amounts of energy to generate the source photons, yet only 2% of this ever reaches the wafer. For this reason, this is the top metric that determines how many tools a fab needs to purchase and what the ROI will be on that fleet. Another important thing to understand is that as the chip geometry is scalled down, the required dose to pattern a chip goes up exponentially. So the timing for which the source power increases has many consequences.

One of the more important slides in their EUV talk discusses the history and roadmap for the source power. Unlike prior generations of projection lithography, EUV consumes huge amounts of energy to generate the source photons, yet only 2% of this ever reaches the wafer. For this reason, this is the top metric that determines how many tools a fab needs to purchase and what the ROI will be on that fleet. Another important thing to understand is that as the chip geometry is scalled down, the required dose to pattern a chip goes up exponentially. So the timing for which the source power increases has many consequences.

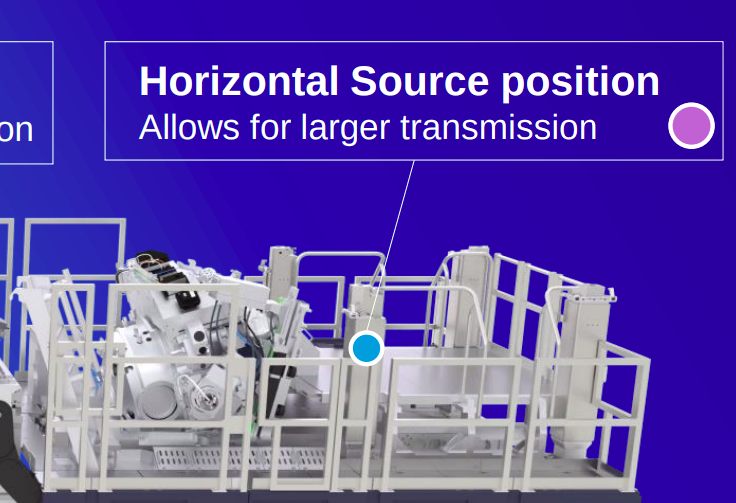

Horizontal Source Position.

Horizontal Source Position.