Machinist, software engineer, turned founder @ https://t.co/D5H1LTJYTb making brains for CNC machines | LAUNCH Accelerator 25. Opinions my own and most likely wrong.

How to get URL link on X (Twitter) App

1) Find your salesperson. (Nearly) every machine tool brand sells through dealers. One dealer per brand per territory, usually a few brands per dealer. You'll have one rep, this will be your primary point of contact through the whole process. Start just googling "haas [your city]", doosan [your city] okuma [your city]" etc and reach out to all the ones you want on your radar. Give them your cell #, and a salesperson will reach out, probably from their own cell

1) Find your salesperson. (Nearly) every machine tool brand sells through dealers. One dealer per brand per territory, usually a few brands per dealer. You'll have one rep, this will be your primary point of contact through the whole process. Start just googling "haas [your city]", doosan [your city] okuma [your city]" etc and reach out to all the ones you want on your radar. Give them your cell #, and a salesperson will reach out, probably from their own cell

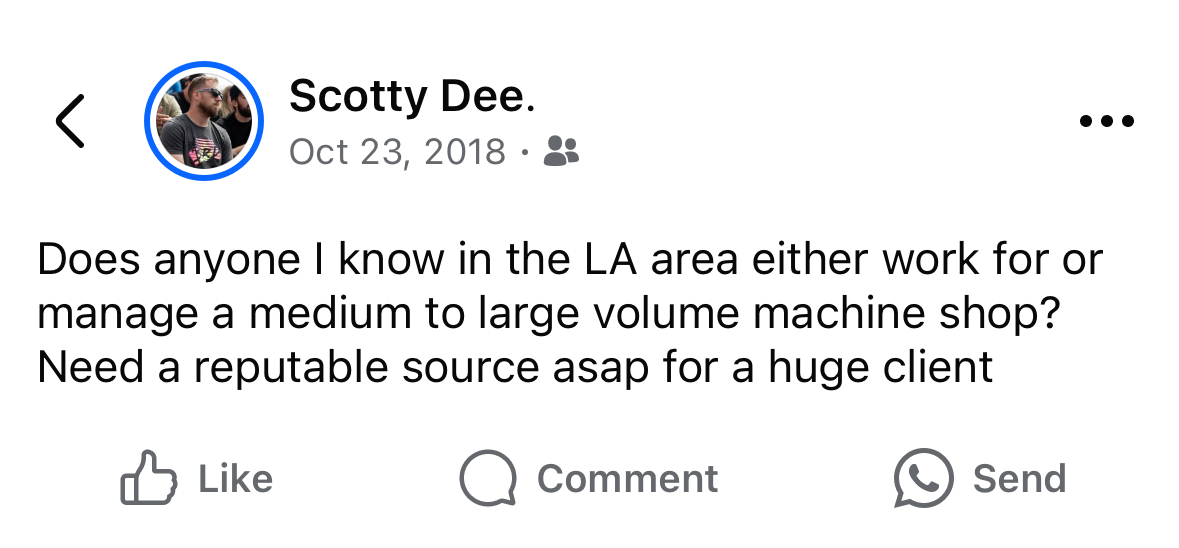

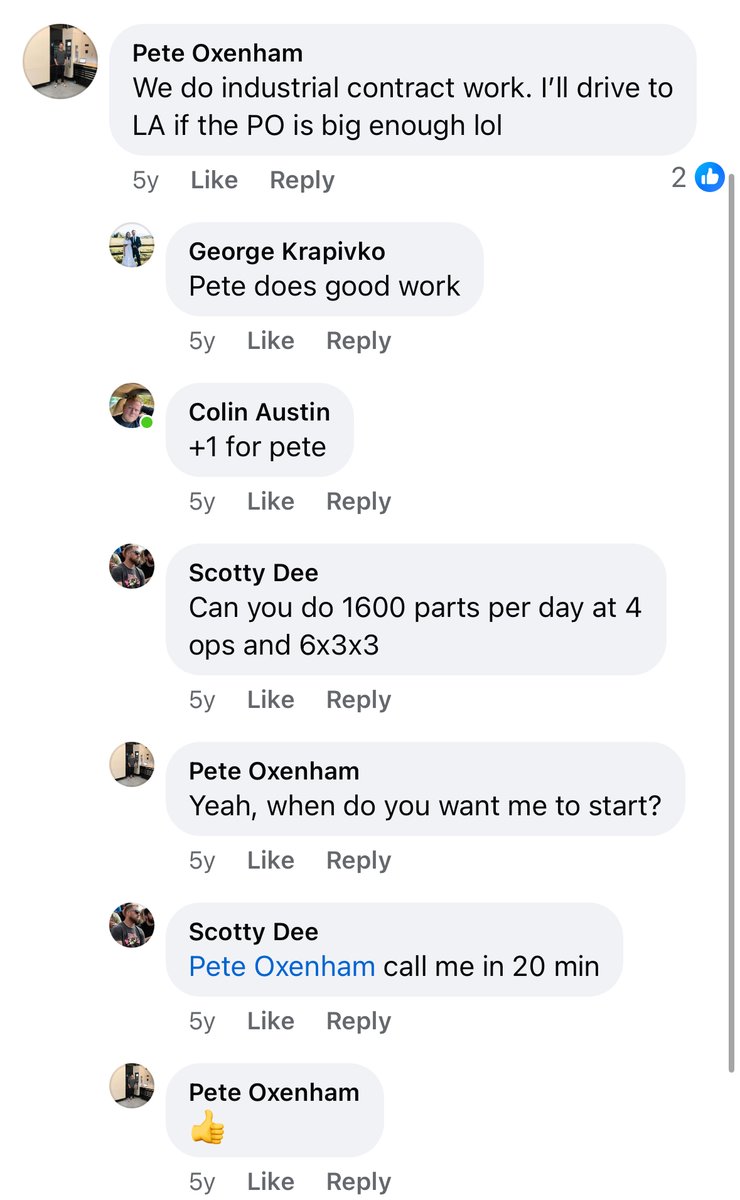

October 2018 - My friend Scott posted on FB that he was looking for a CNC shop. I said "me!" and he told me I couldn't handle the volume (he was right).

October 2018 - My friend Scott posted on FB that he was looking for a CNC shop. I said "me!" and he told me I couldn't handle the volume (he was right).

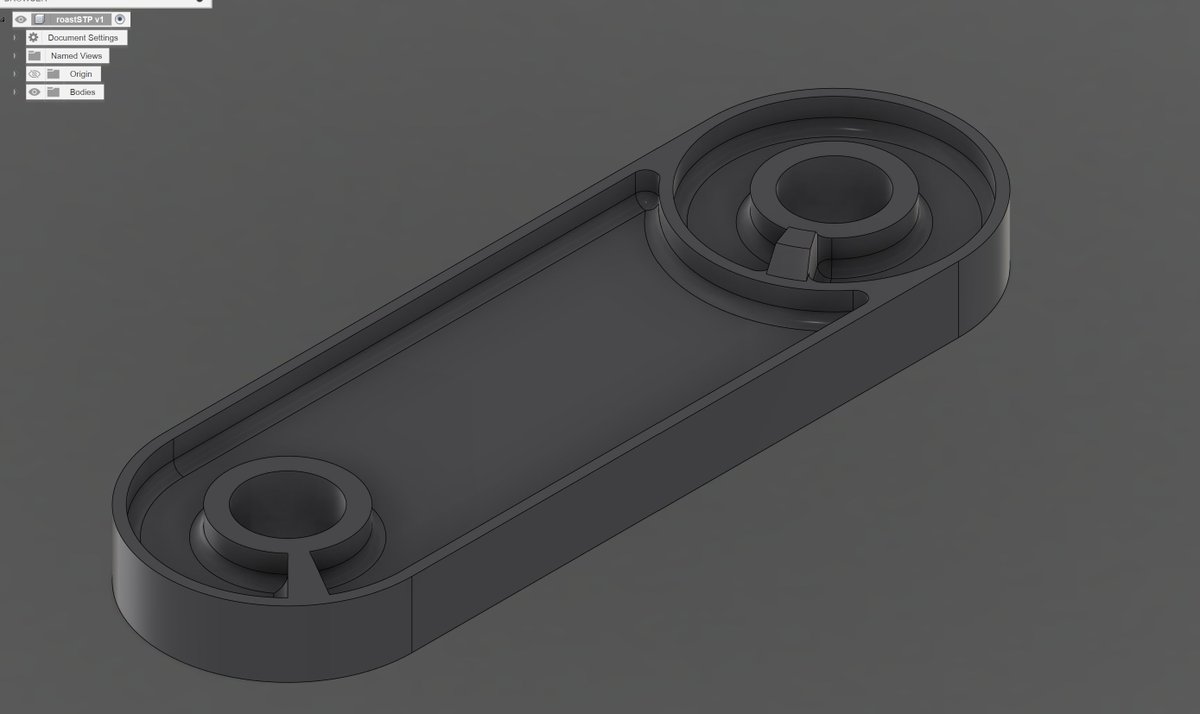

Off the bat, we have the cardinal sin of zero radius internal pocket corners. A round tool can't get into a corner. Some of the others are radiused so I'm just assuming it's a mistake and i'm going to note that I'm making this change for later

Off the bat, we have the cardinal sin of zero radius internal pocket corners. A round tool can't get into a corner. Some of the others are radiused so I'm just assuming it's a mistake and i'm going to note that I'm making this change for later