$mko.v Happy New Year to all Mako shareholders.

We end 2019 with our infill drilling at San Albino complete, and the plant approximately 40% done.

The crusher has been delivered (top right of the photo).

Mill has been purchased and both mill & lab equip are en route

We end 2019 with our infill drilling at San Albino complete, and the plant approximately 40% done.

The crusher has been delivered (top right of the photo).

Mill has been purchased and both mill & lab equip are en route

$mko.v you can see that construction and civil works are rapidly advancing at our San Albino mine. This picture from yesterday.

$mko.v from an hour ago. Laboratory is well on pace to be finished by early Feb. The final delivery for our crusher was made over the weekend.

$mko.v This morning’s update. concrete pour is complete for the CIL tank foundations. Laboratory is making good progress. Even if lab equipment is not installed early next month, we’ll send 6 weeks of production drilling to outside lab to ensure mining begins late Feb.

$mko.v crusher assembly well underway. CIL tanks getting erected. laboratory walls now complete. Lab will be fully air conditioned as we learned our lesson 6 years ago shorting out an atomic absorption machine in Mexico when our A/C broke.

$mko.v you can see the advancement of the secondary crusher and CIL tank installation. A lot of electrical work has been done inside the lab building this past week as well.

$mko.v More pics with labels. I’ll be headed down to site next week. I wonder if we’ll see some mining? I said we would start in February. Thank goodness it’s a leap year! #Feb29Counts

$mko.v In Nicaragua, but I’m stuck in a boring meeting at our El Jicaro office, so I’m sending a security camera update photo. Real pics later today.

$mko.v structure for the admin building going up. Finishing weld on 4th ring of CIL tanks. Expanding ROM “ore” stockpile area. We’ll provide detailed updates on mining when we get production assays back from external lab. Our lab should start working shortly thereafter.

$mko.v structure continues to advance on Admin building, and now for the lab loading area (and a section for our geology department). Thickener tank foundations nearing completion. Initial 10 days of mining is starting to change the landscape of San Albino hill.

$mko.v CIL tanks completed to full height. Reagent tanks being fabricated, plus cyanide storage building.

Mining progressing, changing the landscape. We should probably move that core shack directly on top of our vein though. Geologists never thought about mining this!! 😆

Mining progressing, changing the landscape. We should probably move that core shack directly on top of our vein though. Geologists never thought about mining this!! 😆

$mko.v admin building and loading area for lab/geology nearly complete. Reagent tanks getting erected. Mill arrived in Honduras last week. Awaiting clearance in Nicaragua. Still waiting for offsite production assays. Plan is to have our lab up and running by early May.

$mko.v lab complete. Admin exterior complete. MCC building for mill starting. Mill at border in Honduras. Trying to figure out how to get original customs documents to border control personnel working from home! Mining suspended until we train local grade control personnel.

$mko.v excavation for mill footings nearly done. Motor control center erection ongoing. crane arrived from Managua to install mill. Now where the f my mill(s) at??

Borders are a mess, but after a “polite” conversation with customs, we should get it next week.

Borders are a mess, but after a “polite” conversation with customs, we should get it next week.

$mko.v most of the work this week was focused on concrete and rebar work for mill footings.

We have our expats starting to come back for supervisory roles on 60 day rotations (14 day quarantine on either side). At site later this week. #mininginthetimeofcorona

We have our expats starting to come back for supervisory roles on 60 day rotations (14 day quarantine on either side). At site later this week. #mininginthetimeofcorona

$mko.v 1 mill shell and the 9 ancillary loads at site.

What happened to the second shell?

Find out next week on the next episode of ...

“Who Wants to Be a Mill-ionaire”

What happened to the second shell?

Find out next week on the next episode of ...

“Who Wants to Be a Mill-ionaire”

$mko.v 2nd mill shell now at site. This did take a few truck engine repairs and some dented speed bumps and broken paving stones along the way. Luckily we didn’t have to use our two hardest workers to make it across the finish line.

$mko.v concrete cured (and passed QA/QC) for the mill footings. MCC building erection ongoing. Excavation for tailings nearly complete. Our tailings liner was being manufactured in Italy (eek), but should be shipped with only minor delays. Mill motors to Managua for refurb.

$mko.v getting forms ready for mill pedestal pour for next week. Walls for motor control center. Platform pour for chemical storage tanks.

$mko.v My bad. That pour in the back is the platform for the refinery.

$mko.v could it be? We actually got something across the Honduras border without a problem? Our second reclaim tunnel for the crusher delivered to site without a hitch.

$mko.v forms for the mill pedestals still going up (5 day “measure twice cut once” delay for the pour).

Excavation at the TSF. we found a small high grade pocket near there. I am assured we have otherwise condemned the area. Mo’ Gold, Mo’ Problems.

Mining has recommenced.

Excavation at the TSF. we found a small high grade pocket near there. I am assured we have otherwise condemned the area. Mo’ Gold, Mo’ Problems.

Mining has recommenced.

$mko.v my mother-in-law really wanted a second reclaim tunnel installed for #HappyMothersDay. Started to power up our lab too.

As my in-laws are probably the 19th largest shareholders of $mko.v, a well deserved gift.

As my in-laws are probably the 19th largest shareholders of $mko.v, a well deserved gift.

$mko.v

🎶

Installation of the catwalk

The catwalk, yeah

Installation on the tanks of the catwalk

🎶

2nd Reclaim tunnel in the ground. Pedestal pour this week.

Also, after a 5 week vacation, our production drill is back!

🎶

Installation of the catwalk

The catwalk, yeah

Installation on the tanks of the catwalk

🎶

2nd Reclaim tunnel in the ground. Pedestal pour this week.

Also, after a 5 week vacation, our production drill is back!

$mko.v both mill pedestals poured. 6-7 day curing period. Final touches on lab. Ability to sample prep will be ready late this week, and fire assays with our atomic absorption machines late next week. It certainly would be nice to mine with a functional lab!

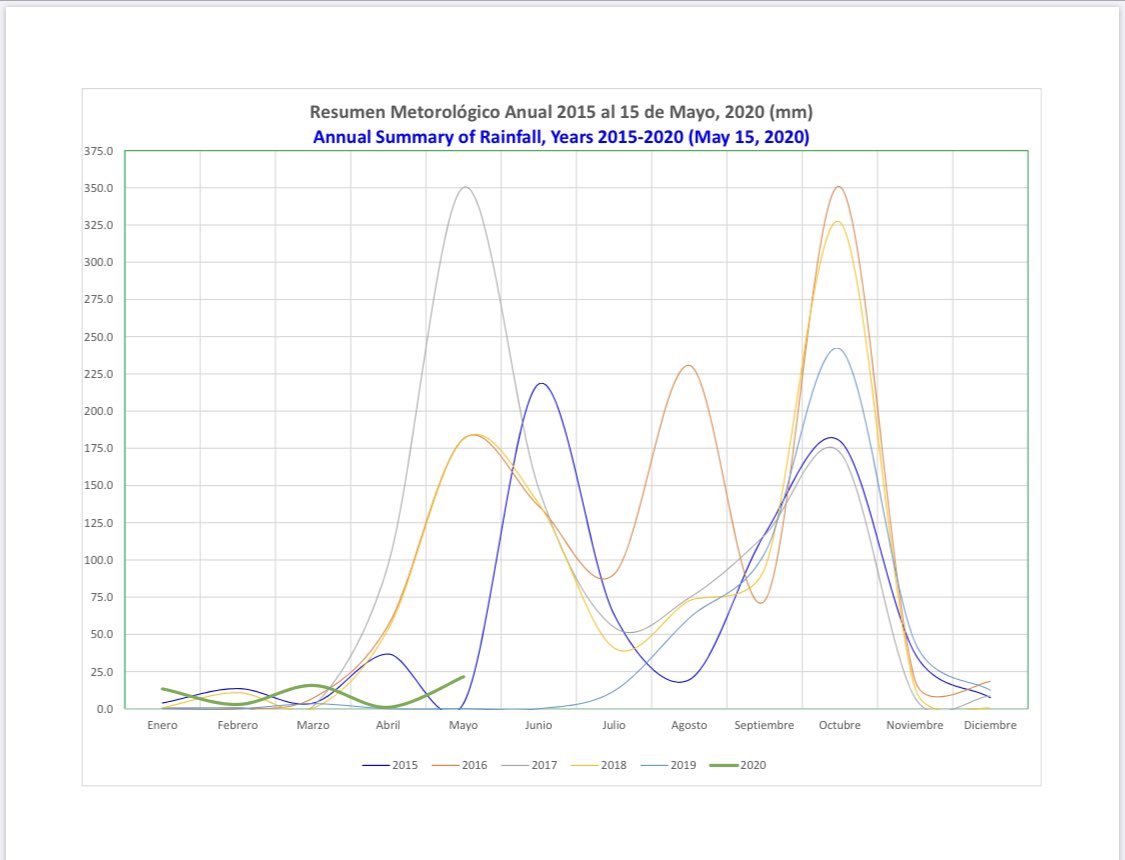

$mko.v BREAKING NEWS. It rains during rainy season. Actually May is generally one of the worst months over the past few years.

Pedestals ready. Getting ready for mill settings once we get our big-boy 90-tonne crane delivered.

Pedestals ready. Getting ready for mill settings once we get our big-boy 90-tonne crane delivered.

$mko.v moderate rain at the mine from the southern end of TS Amanda and the “Central American Gyre”.

Mill bearings placed on one pedestal, all snug in a mill bearing raincoat.

Mill bearings placed on one pedestal, all snug in a mill bearing raincoat.

$mko.v

BIG BOY 🏗 driving to the mine to set those mills!

BIG BOY 🏗 driving to the mine to set those mills!

$mko.v

Mills set.

Drainage for the dry-stack TSF.

I did get the question as to why we need drainage on a dry-stack tailings facility. It rains in Nicaragua!

Mills set.

Drainage for the dry-stack TSF.

I did get the question as to why we need drainage on a dry-stack tailings facility. It rains in Nicaragua!

$mko.v bull gears for mills sitting on site. TSF drainage construction ongoing. TSF buttress construction ongoing (its where most of our mined waste is headed).

We also got our first explosives delivered.

Who wants to blow sh!t up in the next couple of weeks?

We also got our first explosives delivered.

Who wants to blow sh!t up in the next couple of weeks?

$mko.v beautiful example of visual separation between vein/HW/FW/country. We use blast holes to open up bench, channel samples to determine grade. Onsite lab only starting to process assays. we should get these Ch smpls from external lab in next 7-10 days. Then we can mine.

$mko.v Some people asked us, now that we have US$20 million, what’s the first thing we are going to do with the money?

The same thing any red-blooded American, Mexican or Nicaraguan would do.

Blow. Shit. Up.

First blast at San Albino

The same thing any red-blooded American, Mexican or Nicaraguan would do.

Blow. Shit. Up.

First blast at San Albino

$mko.v Blast from another angle (from above).

This was a well executed blast. Judging by the rock size, we’ll be able to lower the powder factor going forward as our crusher can handle coarser material than “bug dust”

This was a well executed blast. Judging by the rock size, we’ll be able to lower the powder factor going forward as our crusher can handle coarser material than “bug dust”

$mko.v

🎶

Oh, oh big ol' plastic liner

Don't carry me too far away

Oh, oh big ol' plastic liner

'Cause it's here with a 2 month delay

🎶

Thick gauge HDPE for our TSF. Suppier was in Italy delayed by COVID-19. Now in Nicaragua with FULL visibility on our updated schedule.

🎶

Oh, oh big ol' plastic liner

Don't carry me too far away

Oh, oh big ol' plastic liner

'Cause it's here with a 2 month delay

🎶

Thick gauge HDPE for our TSF. Suppier was in Italy delayed by COVID-19. Now in Nicaragua with FULL visibility on our updated schedule.

$mko.v

I don’t know about you, but the new Live-Action @TheSimpsons Movie looks like it slaps!

San Albino Lab nearly ready to process production assays. We’ll be mining the high-grade continuously later this month.

I don’t know about you, but the new Live-Action @TheSimpsons Movie looks like it slaps!

San Albino Lab nearly ready to process production assays. We’ll be mining the high-grade continuously later this month.

$mko.v First rule of being a mining contractor: When mining starts, buy more equipment.

Our local contractors have been amazing. With borders closed, we’ve operated the project via remote control since March. Our local employees and contractors have stepped up — Big Time!

Our local contractors have been amazing. With borders closed, we’ve operated the project via remote control since March. Our local employees and contractors have stepped up — Big Time!

$mko.v Vault Door

”1, 2, 3, 4, 5? That's the stupidest combination I've ever heard in my life! That's the kinda thing an idiot would have on his luggage!”

-DH

”1, 2, 3, 4, 5? That's the stupidest combination I've ever heard in my life! That's the kinda thing an idiot would have on his luggage!”

-DH

$mko.v

Finishing off the sewage in the back left (we have to 💩 too). Berm for TSF continuing.

Half bench 610-613 nearly complete. Luckily, there’s fantastic visual separation even after blasting because we are still using an outside lab for our channel samples.

Finishing off the sewage in the back left (we have to 💩 too). Berm for TSF continuing.

Half bench 610-613 nearly complete. Luckily, there’s fantastic visual separation even after blasting because we are still using an outside lab for our channel samples.

$mko.v HOLY SCHIST!

One risk is geotech — hosted by metamorphic sedimentary rocks (not unusual for orogenic systems). Ground bad up top w/ weathering — gets better at depth.

Noticed few mm movement of ground below our water tank, so moved it.

No risk to people/mine/plant.

One risk is geotech — hosted by metamorphic sedimentary rocks (not unusual for orogenic systems). Ground bad up top w/ weathering — gets better at depth.

Noticed few mm movement of ground below our water tank, so moved it.

No risk to people/mine/plant.

$mko.v One upshot to COVID is that Managua is flush with mining equipment.

Our contractor was able to get an extra excavator to help us ramp up production 48 hours after we requested it.

Also, CAT had a spare fuel tank lying around. We’ll take that, thank you.

Our contractor was able to get an extra excavator to help us ramp up production 48 hours after we requested it.

Also, CAT had a spare fuel tank lying around. We’ll take that, thank you.

$mko.v

Let’s see if this helps with the overhang in the stock.

Second blast at San Albino.

Let’s see if this helps with the overhang in the stock.

Second blast at San Albino.

$mko.v

Looks like we got a bit of rain. In rainy season? Who-da-thunk?

Refinery construction ongoing.

TSF buttress coming along (organics removed).

Finished mining first full bench of high grade (I’ll report reconciliation numbers in a few weeks).

Looks like we got a bit of rain. In rainy season? Who-da-thunk?

Refinery construction ongoing.

TSF buttress coming along (organics removed).

Finished mining first full bench of high grade (I’ll report reconciliation numbers in a few weeks).

$mko.v

Something tells me I have to wait until the afternoon for a plant and TSF update.

“The Fog of Ore”

Something tells me I have to wait until the afternoon for a plant and TSF update.

“The Fog of Ore”

$mko.v

Induction furnace and tank screens delivered. Refinery construction speeding up.

LOTS of progress on the TSF buttress.

Oh my goodness. That almost looks like a real mine.

Induction furnace and tank screens delivered. Refinery construction speeding up.

LOTS of progress on the TSF buttress.

Oh my goodness. That almost looks like a real mine.

$mko.v

That’s either a Knelson Concentrator, or we’re going to be making the biggest milkshakes in all of Central America.

About 35% of gold is expected to be recovered through gravity, so a key piece of equipment.

That’s either a Knelson Concentrator, or we’re going to be making the biggest milkshakes in all of Central America.

About 35% of gold is expected to be recovered through gravity, so a key piece of equipment.

$mko.v

Is that a stockpile I see over the reclaim tunnel? Why yes, I think it is.

Nice concrete pour at the refinery.

TSF coming along.

Full bench 610-616 is mined. We sent assays for super-rush to get reconciliation data back. Getting ready for 3rd blast.

Is that a stockpile I see over the reclaim tunnel? Why yes, I think it is.

Nice concrete pour at the refinery.

TSF coming along.

Full bench 610-616 is mined. We sent assays for super-rush to get reconciliation data back. Getting ready for 3rd blast.

$mko.v

Good Morning!

(3rd blast at San Albino)

Good Morning!

(3rd blast at San Albino)

$mko.v

Electrowinning Cells from our former Mexican operations installed in our refinery.

Shaking Table from our former Arizona project installed as well

Electrowinning Cells from our former Mexican operations installed in our refinery.

Shaking Table from our former Arizona project installed as well

$mko.v

Refinery walls going up now that big equipment is in. Looks like we put a fresh coat of paint on the tanks. Bull gears still sitting on the ground — hope to install them shortly to get the mills moving.

TSF buttress is 50% complete (so more like a butt).

Refinery walls going up now that big equipment is in. Looks like we put a fresh coat of paint on the tanks. Bull gears still sitting on the ground — hope to install them shortly to get the mills moving.

TSF buttress is 50% complete (so more like a butt).

$mko.v

Leach tank agitators arrived.

This a big deal, because the last time we tried to have an agitator delivered to site, he was sent back to Peru.

Leach tank agitators arrived.

This a big deal, because the last time we tried to have an agitator delivered to site, he was sent back to Peru.

$mko.v

I like big buttresses and I can not lie ...

Dry stack TSF buttress nearly complete. Should start laying HDPE plastic week after next.

I like big buttresses and I can not lie ...

Dry stack TSF buttress nearly complete. Should start laying HDPE plastic week after next.

$mko.v

Refinery nearly complete. Mill gears ready for installation

TSF buttress complete. 1 week delay in getting plastic installation crew into country.

Not our intent (had to do w/ timing on assays) but 1st time mining 2 faces at once. need >= 3 to get to 500tpd.

Refinery nearly complete. Mill gears ready for installation

TSF buttress complete. 1 week delay in getting plastic installation crew into country.

Not our intent (had to do w/ timing on assays) but 1st time mining 2 faces at once. need >= 3 to get to 500tpd.

$mko.v

Anyone want to start seeing the mills turn?

Gear and clutch assembly commenced.

I don’t know about you, but it looks like this F-ing mine is on schedule for January first gold pour.

Anyone want to start seeing the mills turn?

Gear and clutch assembly commenced.

I don’t know about you, but it looks like this F-ing mine is on schedule for January first gold pour.

$mko.v

Bull gear for mill #1 installed. Additional generators en route.

Able to sneak in a concrete pour last week for the mill building floor in between a break in rains (October is usually the worst month in Nica).

Should start turning soon.

Bull gear for mill #1 installed. Additional generators en route.

Able to sneak in a concrete pour last week for the mill building floor in between a break in rains (October is usually the worst month in Nica).

Should start turning soon.

https://twitter.com/akibaleisman/status/1314759191685402624?s=21https://t.co/e9CVCZlG3Q

$mko.v

This mining multiple faces business is giving me a lot of comfort in being able to ramp up to 500tpd.

This is on 2nd half bench 604-07. Should finish this bench tomorrow. So outside lab results won’t be back until 2nd week of Nov.

Already blasted part of bench 598.

This mining multiple faces business is giving me a lot of comfort in being able to ramp up to 500tpd.

This is on 2nd half bench 604-07. Should finish this bench tomorrow. So outside lab results won’t be back until 2nd week of Nov.

Already blasted part of bench 598.

$mko.v

Wow! You can see how tight we are controlling dilution. The resource we’ll put out is expecting a 0.5m mining tolerance to calculate fully-diluted grades. You can CLEARLY see we are mining tighter than that.

Plus the vein over here is only 1.25 Arnold’s thick!

Wow! You can see how tight we are controlling dilution. The resource we’ll put out is expecting a 0.5m mining tolerance to calculate fully-diluted grades. You can CLEARLY see we are mining tighter than that.

Plus the vein over here is only 1.25 Arnold’s thick!

$mko.v

For those wondering, we normally won’t have a crane turning our mill.

This was to check alignment. Looks pretty good!

For those wondering, we normally won’t have a crane turning our mill.

This was to check alignment. Looks pretty good!

$mko.v

Yup. Pretty good.

Yup. Pretty good.

$mko.v

Unless we’re installing the biggest Slip N’ Slide in all of Nicaragua, I think our TSF liner is getting installed!

Lot’s of progress on the mill drive installation as well this weekend.

Unless we’re installing the biggest Slip N’ Slide in all of Nicaragua, I think our TSF liner is getting installed!

Lot’s of progress on the mill drive installation as well this weekend.

$mko.v

Big Boy Motor

Big Boy Motor

$mko.v

Refinery ceiling ready for pour.

TSF liner getting unfurled.

Mining 3rd HG bench (we’re FINALLY using our onsite lab blast hole assays to open this up). 2nd bench reconciliation (with offsite assays) I’m hoping will be out 1st week of Nov (possibly 2nd).

Refinery ceiling ready for pour.

TSF liner getting unfurled.

Mining 3rd HG bench (we’re FINALLY using our onsite lab blast hole assays to open this up). 2nd bench reconciliation (with offsite assays) I’m hoping will be out 1st week of Nov (possibly 2nd).

$mko.v

“Our mill looks pretty good”

“Well, that’s just your ‘pinion”

“You’re right”

Pinion gear installed

“Our mill looks pretty good”

“Well, that’s just your ‘pinion”

“You’re right”

Pinion gear installed

$mko.v

COO inspecting mill from the inside.

The mills were 1983/4 vintage purchased from a Southeast US power plant. Only thing they saw was lime, so in EXTREMELY good shape.

COO inspecting mill from the inside.

The mills were 1983/4 vintage purchased from a Southeast US power plant. Only thing they saw was lime, so in EXTREMELY good shape.

$mko.v

Mill conveyor attached to the reclaim tunnel.

Lots of progress this weekend.

Mill conveyor attached to the reclaim tunnel.

Lots of progress this weekend.

$mko.v

Refinery roof poured. Rains have been pretty heavy this month, but we managed to sneak in critical path pours to more than keep to our schedule.

Equipment now installed in the refinery.

Refinery roof poured. Rains have been pretty heavy this month, but we managed to sneak in critical path pours to more than keep to our schedule.

Equipment now installed in the refinery.

$mko.v

Looks like the hurricane didn’t vote for San Albino. So far, only minor rain. We’re still not out of the woods, but looks great so far.

Looks like the hurricane didn’t vote for San Albino. So far, only minor rain. We’re still not out of the woods, but looks great so far.

$mko.v

Adios, ETA!

Other than cleaning some mud, we’re in great shape.

The arroyo flows will need to calm down before our main crew gets to site (early this weekend at the latest).

Our skeleton crew for the storm finishing inspections.

Let’s finish this F-ing mine now!

Adios, ETA!

Other than cleaning some mud, we’re in great shape.

The arroyo flows will need to calm down before our main crew gets to site (early this weekend at the latest).

Our skeleton crew for the storm finishing inspections.

Let’s finish this F-ing mine now!

$mko.v

My biggest concern was the TSF — specifically erosion under the liner.

It looks perfect!

☀️ too.

My biggest concern was the TSF — specifically erosion under the liner.

It looks perfect!

☀️ too.

$mko.v

We started to fill the leach tanks.

Mill building going up fast.

TSF liner getting rapidly unfurled.

🤫 don’t tell anybody, but the last major long lead piece of equipment is now at the border.

We started to fill the leach tanks.

Mill building going up fast.

TSF liner getting rapidly unfurled.

🤫 don’t tell anybody, but the last major long lead piece of equipment is now at the border.

$mko.v

Mill clutch and discharge trommel.

Cyclones for the grinding circuit.

Propane tank for stripping circuit and refinery (and enough spare capacity for a quick fire barbecue as well).

Mill clutch and discharge trommel.

Cyclones for the grinding circuit.

Propane tank for stripping circuit and refinery (and enough spare capacity for a quick fire barbecue as well).

$mko.v

Looks pretty good so far. We’ll know for sure early this evening.

Oh, and F-ck hurricanes #Iota

Looks pretty good so far. We’ll know for sure early this evening.

Oh, and F-ck hurricanes #Iota

$mko.v

“Knock knock”

“Who’s there?”

#iota

#iota who?

#iota get back to finishing the project because we’re still going to pour gold in January.

“Knock knock”

“Who’s there?”

#iota

#iota who?

#iota get back to finishing the project because we’re still going to pour gold in January.

$mko.v

Looks like the loads of heavy equipment held at the Honduras border before the storm made it to site (with a little help).

Pretty amazing considering what some of the roads looked like to the south.

Looks like the loads of heavy equipment held at the Honduras border before the storm made it to site (with a little help).

Pretty amazing considering what some of the roads looked like to the south.

$mko.v

Main power to the mills sitting at Caterpillar’s facilities in Managua.

They’re giving it the blue ribbon treatment, then sending it to site.

Once we have these and our transformer at the mine, we can start operations.

Tick. Tock.

Main power to the mills sitting at Caterpillar’s facilities in Managua.

They’re giving it the blue ribbon treatment, then sending it to site.

Once we have these and our transformer at the mine, we can start operations.

Tick. Tock.

$mko.v

Back to business.

Carbon Regen circuit, Grinding Circuit.

That’s either a tailings thickener or a New SpaceX launch site.

Back to business.

Carbon Regen circuit, Grinding Circuit.

That’s either a tailings thickener or a New SpaceX launch site.

$mko.v

I’m not sure if it was written as such on the bill of lading, but our COO says we had a “Big Ass Hydrolic Piston for the Tailings Press” get delivered today.

The main press for the tailings was delivered between storms.

Tick. Tock.

I’m not sure if it was written as such on the bill of lading, but our COO says we had a “Big Ass Hydrolic Piston for the Tailings Press” get delivered today.

The main press for the tailings was delivered between storms.

Tick. Tock.

$mko.v

Mill feed conveyors installed.

Propane tank now hooked up.

Looks like our Knelson Concentrator recovered its first napsack!

Mill generators are in town (hidden from the Super Artisanals). Should be onsite tomorrow.

Mill feed conveyors installed.

Propane tank now hooked up.

Looks like our Knelson Concentrator recovered its first napsack!

Mill generators are in town (hidden from the Super Artisanals). Should be onsite tomorrow.

$mko.v

So far December has been better weather than November

So far December has been better weather than November

$mko.v

Now that the generators arrived, we might as well have some diesel tanks to run them.

Tick. Tock.

Now that the generators arrived, we might as well have some diesel tanks to run them.

Tick. Tock.

$mko.v

I prefer my cyclones to be these rather than the tropical variety.

Cyclones in place. Ready for action.

Tick. Tock.

I prefer my cyclones to be these rather than the tropical variety.

Cyclones in place. Ready for action.

Tick. Tock.

$mko.v

Our Cirque du SoLiner crew is back at the TSF in full force after the storms.

Patience. Grasshopper assembly for the TSF commenced.

Making great progress.

Tick. Tock.

Our Cirque du SoLiner crew is back at the TSF in full force after the storms.

Patience. Grasshopper assembly for the TSF commenced.

Making great progress.

Tick. Tock.

$mko.v

Plant almost done. Looks like the footings for the tailings press is getting ready for pour - the storms impacted that component’s schedule.

Mining high grade half bench.

Liner nearly complete.

Tick. Tock.

Plant almost done. Looks like the footings for the tailings press is getting ready for pour - the storms impacted that component’s schedule.

Mining high grade half bench.

Liner nearly complete.

Tick. Tock.

$mko.v

It’s amazing how fast this TSF liner gets unfurled when not being hit by 100 year storms every two weeks.

Tick. Tock.

It’s amazing how fast this TSF liner gets unfurled when not being hit by 100 year storms every two weeks.

Tick. Tock.

$mko.v

I know that door!

I know that door!

https://twitter.com/akibaleisman/status/1280573646654910466?s=21https://t.co/DJyeXlhhkw

$mko.v

Is that a Transformer I see, or is there more than meets the eye?

Not many days left until break, but let’s see if we can get the mills turning.

Is that a Transformer I see, or is there more than meets the eye?

Not many days left until break, but let’s see if we can get the mills turning.

$mko.v

Tailings press footings coming along.

Nice tents for the crew!

CIL tanks full. We’ll start turning the agitators over the next few days.

Dry run on the mill when we get back from Christmas. January we start for real.

Tick. Tock.

Tailings press footings coming along.

Nice tents for the crew!

CIL tanks full. We’ll start turning the agitators over the next few days.

Dry run on the mill when we get back from Christmas. January we start for real.

Tick. Tock.

$mko.v

Apparently we turned on the agitators right after I took the pic!

I haven’t seen an agitator this turned on since Mark Turner paid someone to read his blog to him!

Apparently we turned on the agitators right after I took the pic!

I haven’t seen an agitator this turned on since Mark Turner paid someone to read his blog to him!

$mko.v

Down to our skeleton crew until first week of Jan.

As soon as everyone is back, we’ll start commissioning the mills.

Down to our skeleton crew until first week of Jan.

As soon as everyone is back, we’ll start commissioning the mills.

$mko.v

OK Sharkheads!

As we close out the year, our plant is ready to be turned on, our TSF is complete, and our mine has produced a substantial HG stockpile generated from a real resource model.

Exploration was a huge success, with lots of room for growth.

Take that 2020!

OK Sharkheads!

As we close out the year, our plant is ready to be turned on, our TSF is complete, and our mine has produced a substantial HG stockpile generated from a real resource model.

Exploration was a huge success, with lots of room for growth.

Take that 2020!

@threadreaderapp unroll

• • •

Missing some Tweet in this thread? You can try to

force a refresh